Sibit is a type of aerated concrete produced using autoclave hardening technology. It is produced in Novosibirsk using equipment from the German company Ytong. Hence the name of the material, made up of two words - SIBERIAN ITong. It was Ytong who became the discoverer and first manufacturer of autoclaved aerated concrete. The raw materials for production are cement, sand, lime, gas-forming and other special additives, and water. Aluminum powder is usually used as an additive to promote void formation.

The components are mixed in a certain ratio, in accordance with calculations. The resulting solution is distributed into molds and processed in autoclave ovens under high pressure. There, the source material swells and hardens, forming Sibit aerated concrete at the output, which has a porous, uniform structure. Molding occurs in large-sized arrays, which are subsequently cut into products of the required sizes. Due to this, high geometry accuracy is achieved.

What products are made from sibit

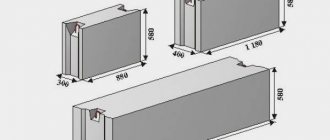

The entire Sibit range is in great demand among developers in Eastern and Western Siberia. The main place in the assortment is occupied by basic, partition, and additional blocks. In addition, the company produces reinforced lintels, floor slabs, and thermal insulation panels. The dimensions of aerated concrete products are indicated in the table:

When it is necessary to calculate the need for materials for building a house, a wall block with dimensions of 200*300*600 mm is usually taken as a basis. Its volume is 0.036 m³, that is, 1:0.036 = 27.78 pieces fit in one cubic meter of masonry. Calculations are performed in a similar way for other standard sizes of sibit gas blocks.

Shipment from the factory and delivery to consumers is carried out on special pallets and packed with protective film. How many pieces of sibit can fit in a pallet? It depends on the size of the site itself. Several types of pallets are available. Based on the traditional block size of 20*30*60 cm, they come in the following capacities:

- 25 pieces or 0.9 m³;

- 40 pieces or 1.44 m³;

- 50 pieces or 1.8 m³.

It is not recommended to transport and reload sibit products without pallets or in unpackaged form. Because due to its porous structure it has increased fragility.

General recommendations for facing an aerated concrete house with bricks

Here are some recommendations that should be taken into account when facing walls made of aerated concrete with bricks.

Laying the foundation

The width of the foundation is thought out in advance, even before construction begins. The width of aerated blocks, facing bricks and insulation is taken into account. Under no circumstances should cladding be allowed to hang over the edge of the foundation.

Brick selection

Aerated concrete should be faced with bricks laid across its width. That is, half a brick. Different types of bricks are used as materials: solid, hollow, silicate, clinker. In practice, hollow or clinker bricks are usually used. The latter option will cost more, but it also has many more advantages:

- Clinker looks more presentable. It can literally transform the walls of any building.

- Low water absorption of about 5%. For ordinary bricks this figure reaches 13%.

- High compressive strength.

- The frost resistance of clinker is three times higher than that of conventional facing bricks.

Brick laying

The brickwork is laid on a layer of rolled waterproofing. Thus, the foundation is protected from the effects of formed condensation. Each subsequent row of bricks is laid on the prepared mortar in such a way that the seams of the previous row overlap. For masonry, a metal rod with a diameter of 0.8–1 cm is used. It is laid on the outside of the row. The same rod, but short, is used to form a vertical seam.

Mortar is applied to the already laid row, and then the brick is laid. As the row progresses, the bar moves along it.

Every few rows of masonry must have reinforcement. For this purpose, you can use synthetic mesh, cutting it into strips about 8 cm wide.

Once the solution has hardened, it may be necessary to grout the joints. First, the joints are filled with mortar. After the solution has set, it is jointed with a special tool.

Brick facing a house built from gas silicate blocks is a labor-intensive and costly process. However, this finish is very reliable, beautiful and durable. It will pay for itself in the long term, since the house will not require any external repairs for a long time.

Advantages and properties of sibit products

All the advantages of this material are based on the technical characteristics of Sibit blocks. Their coordinated combination best meets the requirements for products for structural and structural-thermal insulation purposes. For clarity, let’s combine the main properties of sibit and compare them with traditional brick.

The vapor permeability of sibit blocks is 5-6 times higher than that of brick, and is equal to 0.17 g/m. This means that aerated concrete is able to get rid of moisture that has entered it in a short time and ensure normal air conditions in the room.

Today, the construction of houses from sibit in Siberia is very popular; the pros and cons of such construction are worth considering in more detail. First, about the advantages.

- The low thermal conductivity coefficient allows you to significantly save on heating your home. The thermophysical characteristics of sibit enable walls to retain heat indoors, and wall surfaces to be warm when touched.

- The low physical weight of structures made of cellular concrete does not require a powerful foundation for a house made of sibit.

- In terms of strength, sibit products, especially reinforced ones, are quite comparable to ordinary and reinforced concrete.

- The extremely high frost resistance indicates that Sibit is an excellent material for construction in Siberia.

- The use of floor slabs made of Sibit porous concrete means a ready-made insulated attic, saving expensive wood and reducing the cost of one square meter of the house.

- Labor costs in the construction of buildings from sibit are almost one and a half times lower than when using brick. Experienced masons lay 15 m³ of light blocks during one work shift; bricks can make no more than 7 m³. This means that you can build a house from sibit in a shorter time.

It is difficult to find flaws in sibit products, except for its fragility. But this disadvantage can be easily overcome by careful handling of blocks and slabs during transportation, rigging and any movements.

Rules for facing a house made of aerated concrete with bricks

Aerated concrete is becoming increasingly popular in the construction of houses. It has a high degree of heat capacity, low weight, and does not require a powerful foundation. At the same time, aerated blocks are a porous material that can absorb moisture. To ensure their protection from external influences, the walls must be protected with facing material. The most reliable way for this is to cladding a house made of aerated concrete with bricks. Below we will look at how to properly clad a house made of aerated concrete with brick.

Laying sibit blocks

Working with sibit blocks is not much different from ordinary bricklaying or other block products. That is, precise placement of corners and special attention to the first row, constant control of verticality with a plumb line and horizontality with a spirit level. It’s good if you have the opportunity to use a laser level. But there are still some nuances.

- The blocks can be easily processed with the simplest tools. They can be sawed, cut, planed, that is, all the necessary additional elements can be prepared at the construction site.

- For masonry, it is recommended to use special sibit glue. It will ensure reliable adhesion of the blocks to each other. Although the first row of foundation waterproofing can also be laid on masonry cement-sand mortar.

- The external and internal surfaces of the walls of the building should be covered with finishing materials.

- To decorate door and window openings from above, it is advisable to use reinforced sibit lintels.

Products made from cellular concrete are lightweight, durable and reliable. However, wall cabinets do not hold up well on porous walls. When arranging furniture and decorating rooms, you must use fasteners specifically designed for porous surfaces.

When choosing a sibit

As the main material for the walls

of a house,

one should not forget that sibit, like any other material, has its

pros and cons

.

Sibit in construction

Let's first touch on its positive characteristics.

Firstly, sibit has excellent sound and heat insulation, the second is worth mentioning separately. The thermal conductivity of sibit is approximately four times lower than that of brick, that is, a house made of sibit retains heat 4 times better in winter, as well as comfortable coolness in hot weather, since the material “breathes” like wood. The material has these properties due to its porous structure; as a result of the excellent thermal insulation, sibit will allow you to significantly save on heating.

Sibit houses are environmentally friendly houses. No toxic substances are used in this production of this wonderful material. Sibit is created on the basis of only natural mineral substances, which are also insoluble in water. The material does not burn.

Sibit is a very convenient and pliable material: thanks to its lightness and ease of processing, installation and transportation of the material will cost less than when building with bricks for building a house from Sibit

no crane or similar equipment is needed. In addition, when designing foundations, a much smaller load is taken into account, and this also saves on the amount of concrete. Sibit is easy to saw and nails can be driven into it.

Main disadvantage

sibita lies in its low strength, in comparison with brick and concrete. It is not advisable to hang heavy metal brackets on sibit walls, massive cabinets, water heaters and hunting trophies; for this purpose, special reinforcing structures should be built from angle iron.

The remaining disadvantages are not so critical for private housing construction:

- You should not build houses from sibit without a frame of more than five floors.

- Sibit requires interior and exterior finishing.

- Some skeptics still argue that sibit absorbs moisture over time and cracks due to the presence of open pores. (Just use a moisture-proof finish in damp areas.)

- Again, some skeptics argue that the lime contained in the material is harmful. Well, even the resins contained in the most environmentally friendly wood are also harmful to some extent.

Methods for lining walls with bricks

There are two ways to cover an aerated block house with facing bricks:

The cladding is laid close to the wall

This option is less popular. It is used for unheated rooms. If we apply this method to a heated room, we get the following problem. Warm air from the room will tend to escape outside the house. Since it will not find a way out, moisture will accumulate in the outer part of the aerated concrete wall and its gradual destruction.

It is strictly unacceptable to rigidly connect the cladding to the main wall, since the materials have different coefficients of thermal expansion. In cold or hot weather, they will expand to varying degrees, which will lead to disruption of the masonry.

Facing aerated concrete with bricks with an air gap without ventilation

The thermal insulation properties of the wall are improved and its durability increases. But, since there is no ventilation with such finishing, the condensation formed between the gas blocks and the brick can drain and accumulate from below the wall, above the foundation. Therefore, the method is good for unheated rooms.

A layer of insulation can be laid in this gap.

Three-layer wall with ventilated space

Consists of aerated blocks, brickwork and ventilated space between them. This is the most profitable solution, although it is quite difficult to do everything correctly. An air gap of 6–15 cm is left between the wall and the cladding.

Characteristics and prices of Sibit

Due to the low density of aerated concrete (approximately 600 kg per cubic meter) and its porosity, the characteristics of sibit

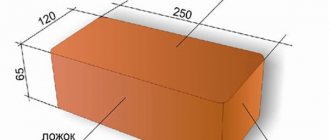

thermal insulation is 3-5 times higher than brick. A standard block of sibit 200*250*600 weighs about 18 kilograms, which is comparable in weight to twenty bricks. This is where the main difference comes from in labor costs.

If, according to the thermal technical requirements of SNiP, the thickness of a brick outer wall must be at least 1.8 meters (without insulation), then a sibit wall is about.5 (with a sibit density of 500 kg per cubic meter, which corresponds to the D500 grade). And also, due to its porosity, sibit “breathes” better than many other materials, making it easier for excess moisture to escape from rooms. For comparison: the vapor permeability of sibit is 0.17 grams per meter, and that of brick is 0.10.

Sibit is also used to produce reinforced floor slabs, which are not inferior in strength to reinforced concrete - they are designed for a load of about 800 kilograms per square meter. And the installation of structures made of sibit is much less labor-intensive, as mentioned above - one block of sibit is equivalent to twenty bricks, which reduces the final price of building a house.

As for the prices for sibit

, buying this very material will cost approximately the same as buying bricks. At the time of publication of the article, a pallet of M 150 bricks costs about 3,350 rubles, which is 480 bricks, which means 7 rubles per product. One sibit block 200*250*600 mm costs 140 rubles, and since up to 20 bricks can fit into a sibit block, we get the same 140 rubles. But do not forget, thanks to the lightness of foam concrete, the comparative cheapness of installation and transportation of this material, the final price of building a house from sibit will be much less. Savings on the foundation for sibit walls alone will amount to 15%.

Is it necessary to insulate aerated concrete 400 mm thick?

The issue of insulating aerated concrete, first of all, must be economically justified. That is, the money invested on insulation should be returned with subsequent savings on heating. It follows from this that the choice, first of all, depends on the cost of heating per year, and it can vary greatly in different climatic zones and energy tariffs.

It is also worth considering the density of aerated concrete itself, which can vary from D300 to D600. The higher the density, the worse the heat retention.

If you have a house made of autoclaved aerated concrete D400 with a thickness of 375 or 400 mm, then its thermal resistance is ideally 3.4 m2 °C/W. In reality, about 3 m2 °C/W.

If the house is made of aerated concrete D300 with a thickness of 400 mm, then the real thermal resistance is about 4 m2 °C/W. For the vast majority of Russian cities, such an aerated concrete house will not need to be insulated.

But if you heat with electricity, which is a very expensive pleasure, you definitely need to insulate. The economically justified insulation thickness is 100 mm.

It is worth remembering that heat escapes not only through walls, but also through windows, doors, floors and especially through the ceiling. For comprehensive insulation, all elements of the house must be well insulated.

Next, we will look at options for aerated concrete houses and different regions where you can do without wall insulation.

Prices for aerated blocks from the manufacturer Sibit

Sibit gas block 3250 rub/m3. Delivery as a gift!

Sibit aerated blocks are a popular building material in Yekaterinburg and the Ural region. Individual builders and large companies are attracted by the products of the Novosibirsk plant of the same name due to their consistently high quality, as well as the fact that the price of gas blocks from the manufacturer Sibit compares favorably with competitors.

The Siblock company is the official dealer of Sibit, and offers its customers to buy gas blocks in Yekaterinburg at the manufacturer’s price. Cellular concrete in the form of standardized blocks has long established itself in the construction market of the Ural capital and is widely used by private builders and in the construction of commercial and high-rise buildings.

Aerated concrete production plant Sibit

The Novosibirsk plant for the production of aerated concrete and molded products from this material is one of the oldest companies in Russia specializing in the production of similar products. The company, despite its leading position in its niche, does not cease to develop and improve, constantly increasing production volumes and offering the best prices for aerated blocks from the manufacturer.

Today the enterprise has a modern technological line for the production of aerated concrete blocks. All equipment used in production is developed by the German company Ytong.

Assortment and prices for aerated blocks from the manufacturer Sibit

The Sibit plant produces the entire line of aerated concrete blocks. Any element that you may need during construction can be found in the company’s catalog:

- Economy class blocks;

- Masonry tool;

- Partition blocks;

- Jumpers;

- Floor slabs;

- Wall blocks;

- Branded masonry mixtures.

All Sibit products are manufactured using patented technology, one of the mandatory stages of which is autoclave firing of the product. This gives the blocks special strength and gives them unique characteristics. At the same time, prices for gas blocks from the manufacturer Sibit remain at a competitive level.

What are the methods for facing aerated concrete blocks with bricks?

A gas block wall can be covered in several ways. This refers to the distance between the brick and the aerated concrete block, as well as the presence of insulation, if there is a gap between the wall and the cladding. Let's look at each of them in detail.

Dense masonry without gaps and ventilation

The danger of rapid destruction appears when it is planned to use a heated room. That is, the difference in temperatures inside and outside the house will significantly reduce the service life of such a building. When the room is heated from the inside, water vapor will begin to move out through the porous aerated concrete. If there is no gap or insulation, they will accumulate between the gas block and the brick, destroying both materials. In this case, condensate accumulates unevenly, which accelerates the process of decay and deformation of the structure of the gas block. The most cost-effective option would be to use external insulation in the form of mineral wool or wet plaster finishing. A similar finishing of aerated concrete with bricks (without a gap) is applied only to unheated buildings.

Buy aerated blocks in Yekaterinburg at manufacturer’s price

The Siblock company is the official dealer of the Sibit company, which has exclusive rights to supply and sell the plant’s products. From us you can buy aerated blocks in Yekaterinburg at the manufacturer’s price, without fear for quality and service. Prices for products stated on the website are final.

The Siblock company can be found in the list of official dealers on the Sibit website.

“SIBIT” is a trademark of autoclaved cellular aerated concrete produced by OJSC Glavnovosibirskstroy only in Novosibirsk at the plant of the same name. Main advantages of SIBIT:

- non-flammable

SIBIT aerated concrete does not burn and has a high fire resistance limit, which is confirmed by the “Fire Safety Certificate”, which allows the use of products in buildings of the 1st fire hazard category. - warm

SIBIT aerated concrete has exceptional thermal insulation, retains heat well in winter and cool in summer. Walls made of cellular concrete "SIBIT" are 3 ÷ 5 times warmer than brick. - environmentally friendly

SIBIT aerated concrete is made from natural minerals without the use of chemical additives. It breathes like wood thanks to its porous structure; cellular concrete accumulates heat, thereby equalizing temperature fluctuations and humidity, creating an optimal indoor climate.

Rights and obligations of the parties

6.1. The user has the right:

6.1.1. Make a free decision to provide your personal data necessary to use the BrickStone.su website and consent to their processing.

6.1.2. Update, supplement the provided information about personal data if this information changes.

6.1.3. The user has the right to receive from the Administration information regarding the processing of his personal data, unless such right is limited in accordance with federal laws. The user has the right to demand that the Administration clarify his personal data, block it or destroy it if the personal data is incomplete, outdated, inaccurate, illegally obtained or is not necessary for the stated purpose of processing, as well as take measures provided by law to protect his rights.

6.2. The administration is obliged:

6.2.1. Use the information received solely for the purposes specified in clause 4 of this Privacy Policy.

6.2.2. Ensure that confidential information is kept secret, not disclosed without the prior written permission of the User, and also not sell, exchange, publish, or disclose in other possible ways the transferred personal data of the User, with the exception of paragraphs. 5.2 and 5.3. of this Privacy Policy.

6.2.3. Take precautions to protect the confidentiality of the User's personal data in accordance with the procedure usually used to protect this type of information in existing business transactions.

6.2.4. Block personal data relating to the relevant User from the moment of application or request from the User, or his legal representative or the authorized body for the protection of the rights of personal data subjects for the period of verification, in the event of detection of unreliable personal data or unlawful actions.

Sibit house: pros and cons

SIBIT aerated concrete is “not afraid” of water, since it consists of a water-insoluble mineral; its structure ensures the rapid removal of moisture into the environment without changing the physical and technical characteristics of the material.

SIBIT aerated concrete is an almost eternal material. This is an artificial stone that does not burn or rot. With a frost resistance grade of 250 cycles, its service life can be predicted to be over 500 years.

SIBIT aerated concrete blocks can be used to build load-bearing walls of houses up to 5 floors, and when constructing enclosing structures of frame buildings, the number of storeys is not limited.

And one more quality of SIBIT aerated concrete, which is of great importance directly for builders - this material is well processed with the simplest tools, sawed, drilled, nailed, planed, chipped.

Main characteristics

Wall mass

The weight of a wall made of SIBIT aerated concrete (per 1 m2) is 4-5 times less than a brick wall (300 kg/m2 for SIBIT versus 1200 kg/m2 for brick). As a result, savings on the foundation during cottage construction reaches 10-15%.

A standard small SIBIT block measuring 20x25x60 cm, brand D600, weighs 18 kg and can replace 15-20 bricks weighing up to 80 kg in a boundary wall.

Wall thickness

According to the requirements of SNIIP, the thickness of a wall made of SIBIT must be at least 0.6 m, and of brick - 2.3 m.

In 1996, changes were adopted to energy saving standards, which came into force in stages, from January 1, 1997 and from January 1, 2000. As a result of tightening requirements, it became unprofitable to build houses from one brick. Most of the so-called new “brick” houses are built using effective insulation materials, which in practice are far from durable. From SIBIT we get a homogeneous wall.

VAPTOR PERMEABILITY

The vapor permeability of SIBIT is 4-6 times higher than that of brick. The vapor permeability of SIBIT cellular concrete (0.17 g/m) ensures the rapid removal of construction moisture from the material and the maintenance of normal indoor air conditions; aeropermeability contributes to the preservation of fresh air in the premises. For comparison, the vapor permeability of brick does not exceed 0.11 g/m, and that of a cross-section of pine – 0.06 g/m.

Thermal conductivity

The thermal conductivity of a SIBIT wall is 4 times lower than a brick one (thermal conductivity coefficient 0.16 W/mK for SIBIT versus 0.61 W/mK for brick), saving on heating the building is up to 20%.

Frost resistance

In terms of frost resistance, SIBIT cellular concrete is unique: according to GOST, the building material must withstand 35 “freezing” cycles, and SIBIT easily tolerates 200 cycles - this approximately corresponds to the 500-year service life of a house.

Floor slabs

Floor slabs in the roof - a ready-made warm attic! When constructing low-rise buildings, the use of cellular concrete floors can significantly reduce the use of wood, roofing steel, and hardware due to the installation of combined roll-free roofs and the efficient use of roof space, which significantly reduces the cost per square meter of the building.

Labor and material costs

During construction work, it is easily processed with tools available at any construction site. This also results in a reduction in the labor intensity of masonry, since instead of 15-20 bricks it is enough to lay one block of SIBIT. The speed of building a house from SIBIT is certainly higher - on average, 7 cubic meters can be laid per shift. meters of brickwork and 15 - SIBIT. Country house with an area of 250 sq.m. it is possible to “raise” it with five workers in 40 days.

Physical and technical indicators

| Name of products and designs | Concrete grade by compressive strength | Density (volumetric mass), kg/m3 | Release humidity, % | Sorption humidity, % | Thermal conductivity, W/mC | Frost resistance, cycles | Drying shrinkage, mm/m | Vapor permeability, mg/mchPa |

| Wall small blocks | M35 (B2.5) | 500 | 25 | 2.8 | 0.109 | 250 | 0.240 | 0.200 |

| 600 | 25 | 3.1 | 0.122 | 250 | 0.225 | 0.200 | ||

| M50 (B3.5) | 700 | 25 | 2.2 | 0.138 | 250 | 0.167 | 0.170 | |

| Reinforced structures (floor panels, lintels) | M50 (B3.5) | 700 | 25 | 2.2 | 0.138 | 250 | 0.167 | 0.170 |

| Thermal insulation boards | M15 (B1.0) | 400 | 25 | 3.8 | 0.092 | 75 | 0.290 | 0.239 |

The Siberian Meridian company offers SIBIT aerated concrete for sale.

SIBIT aerated concrete does not burn and has a high fire resistance limit, which is confirmed by the “Fire Safety Certificate”, which allows the use of products in buildings of the 1st degree of fire danger.

SIBIT aerated concrete has exceptional thermal insulation, retains heat well in winter and cool in summer. Walls made of cellular concrete “SIBIT” are 3-5 times warmer than brick.

SIBIT aerated concrete is made from natural minerals without the use of chemical additives. It breathes like wood thanks to its porous structure; cellular concrete accumulates heat, thereby equalizing temperature fluctuations and humidity, creating an optimal indoor climate.

SIBIT aerated concrete is “not afraid” of water, since it consists of a water-insoluble mineral; its structure ensures the rapid removal of moisture into the environment without changing the physical and technical characteristics of the material.

SIBIT aerated concrete is an almost eternal material. This is an artificial stone that does not burn or rot. Based on its frost resistance, its service life can be predicted to be over 500 years.

SIBIT aerated concrete blocks can be used to build load-bearing walls of houses up to 5 floors, and when constructing enclosing structures of frame buildings, the number of storeys is not limited.

And one more quality of SIBIT aerated concrete, which is of great importance directly for builders - this material is well processed with the simplest tools, sawed, drilled, nailed, planed, chipped.

1. WALL WEIGHT

The weight of a wall made of SIBIT aerated concrete (per 1 m2) is 4-5 times less than a brick wall. As a result, savings on the foundation during cottage construction reaches 10-15%.

A standard small SIBIT block measuring 200x250x600 mm, brand D600, weighs 18 kg and can replace 15-20 bricks weighing up to 80 kg in a boundary wall.

2. WALL THICKNESS

A brick wall during capital construction is 2 times thicker than an aerated concrete one.

According to SNiP requirements, the thickness of a SIBIT wall must be at least 0.6 m for aerated concrete density grade D600 and 0.5 m for a D500 grade, and for a brick wall - 2.3 m.

In 1996, changes were adopted to energy saving standards, which came into force in stages, from January 1, 1997 and from January 1, 2000. As a result of tightening requirements, it became unprofitable to build houses from one brick. Most of the so-called new “brick” houses are built using effective insulation materials, which in practice are far from durable. From SIBIT we get a homogeneous wall.

3. VAPTOR PERMEABILITY

The vapor permeability of SIBIT is 4-6 times higher than that of brick. The vapor permeability of SIBIT cellular concrete (0.17 g/m) ensures the rapid removal of construction moisture from the material and the maintenance of normal indoor air conditions; aeropermeability contributes to the preservation of fresh air in the premises. For comparison, the vapor permeability of brick does not exceed 0.11 g/m, and that of a cross-section of pine – 0.06 g/m.

4. THERMAL CONDUCTIVITY

The thermal conductivity of a SIBIT wall is 4 times lower than that of a brick wall, saving on heating the building is up to 20%.

Thermophysical properties allow houses made of cellular aerated concrete to retain heat well and make wall surfaces warm to the touch.

5. BULK INSULATION

Porous crushed stone from the SIBIT plant is half the volume and four times cheaper than expanded clay gravel.

In Siberia, the issue of insulation is especially acute - the Henkel company has calculated that while there is no insulation, the losses per square meter are the same as if a 60-watt light bulb were constantly turned on on each meter section of the wall.

6. FROST RESISTANCE

In terms of frost resistance, SIBIT cellular concrete is unique: according to GOST, the building material must withstand 35 “freezing” cycles, and SIBIT easily tolerates 250 cycles - this approximately corresponds to the 500-year service life of a house.

The frost resistance of cellular aerated concrete is explained by its reserve porosity - during freezing, expanding ice and water are displaced into these pores without destroying the material.

General characteristics of materials

Brick

SIBIT

Thermal conductivity coefficient (λ, W/(m K))

Vapor permeability coefficient (mg/m∙h∙Pa)

Deviation of geometric dimensions (mm)

Based on the level of thermal conductivity of materials, SIBIT wins significantly; a house made from it is 3 times warmer than a brick one. Through an external wall with a thickness of 2 bricks or 510 mm at an outside air temperature of -30 ° C, heat loss will be 60 W/h through 1 m2 of wall, and in a house made of SIBIT, with an external wall of 40 cm, under similar loss conditions heat will be only 20 W/h per 1 m2, that is, 3 times less. This will provide significant savings to the family budget on heating costs.

Brick is 2-4 times stronger than SIBIT, which makes it possible to build a house of 5 or more floors from it, without enclosing structures (usually a concrete frame). The only question is: why do you need a private house of 5 floors...

Vapor permeability, which affects dampness and durability of the structure, is 2 times better with SIBIT. The house “breathes”, allows moisture to pass through and does not mold.

The deviation of geometric dimensions in SIBIT is slightly better and the laying is carried out not on a thick mortar joint, but on a thin (2 + 1 mm) glue joint. This will affect the labor costs when plastering the walls and the cash costs for materials. The smoother the walls, the less money is required for materials and time for plastering work.

Aerated concrete Sibit - characteristics and main advantages

FLOOR PLATES

The strength of SIBIT cellular aerated concrete floors is comparable to reinforced concrete slabs - about 800 kg.

Floor slabs in the roof - a ready-made warm attic! When constructing low-rise buildings, the use of cellular concrete floors can significantly reduce the use of wood, roofing steel, and hardware, which significantly reduces the cost per square meter of the building.

LABOR AND MATERIAL COSTS

Labor costs when working with SIBIT are 1.4 times less compared to brick due to the friendliness of the material to builders.

During construction work, it is easily processed with tools available at any construction site. This also results in a reduction in the labor intensity of masonry, since instead of 15-20 bricks it is enough to lay one block of SIBIT.

The speed of building a house from SIBIT is certainly higher - on average, 7 cubic meters can be laid per shift. meters of brickwork and 15 - SIBIT. Country house with an area of 250 sq.m. it is possible to “raise” it with five workers in 40 days.

Specific capital investments in the construction of low-rise buildings from SIBIT are 1.8 times less than when using brick due to the ease of transportation and ease of installation.

9. TECHNOLOGY

The SIBIT plant uses autoclave technology for producing aerated concrete, which significantly increases the strength of the block, and reduces the shrinkage of the finished blocks to almost zero (the shrinkage of the block during operation for non-autoclaved aerated concrete is 2-3 mm, and for autoclaved aerated concrete - 0.3 mm). Only as a result of the autoclave process, a new, extremely durable mineral, tobermorite, a naturally occurring mineral, is obtained from the raw materials.

Sibit is a fairly new building material for masonry. The thing, I must say, is very practical, inexpensive, and with many useful properties. Speaking according to the rules of construction tone, autoclaved aerated concrete should be called sibit.

Sibit is made from cement, sand, lime and several special additives. First, a solution is made, then it is poured into special molds, after which the whole mass is sent to the oven, subjected to enormous pressure. After all these simple manipulations, a porous aerated concrete material is obtained.

What's good about this very sibit, and why not use classic brick instead? The thing is that sibit will give a head start in many respects not only to brick, but also to almost all masonry materials found on the construction market today. Firstly, it has incredible thermal insulation properties, while keeping you cool in the summer and warm in the winter. We can safely say that the owner of a house made from sibit will be able to save thirty percent on heating. With the freed up funds, you can stock your home bar to capacity, or buy your wife a new phone, for example, or even have a mistress. Secondly, the air in the house will always be clean, since sibit is a “breathing” material. Despite the fact that this material absorbs moisture, it evaporates very quickly from the surface of the sibit, which makes the residents feel good and, as they say, sing a trill.

Sibit is such a cool and irreplaceable material that it has almost no downsides, and therefore I propose to sing Sibit’s praises for a couple more paragraphs. I am pleased to note that sibit is a very light material, although fragile. Probably, the fragility of sibit is the only disadvantage of this material. In principle, there is nothing terrible about this, you just need to remember to use special drills when installing windows and doors. It is also interesting to note that firefighters themselves say that it is possible to build buildings from sibit that meet the first degree of fire safety.

Oh, sibitushka, sibit (this is from myself)! What cool stuff you are, huh! Even I, who likes to understand the details, could not find anything bad in your properties, well, except for fragility, perhaps. In general, I can confidently recommend it to people planning to build a house. By the way, according to experts, sibit is an almost eternal material with no established expiration dates. And there is no need to insulate buildings from sibit at all; moreover, sibit is generally used separately and as insulation. For people who are afraid of everything new and have doubts, we inform you that sibit is a material so durable that it copes with the function of load-bearing walls. In general, our sibit is good everywhere, although I don’t know what it tastes like. Perhaps you can eat it.

Knowing that among the population of our country there are people who like to work with a calculator, so to speak, at the stage of preparation for construction, we will give several examples in numbers. Sibit is 5 times lighter than brick, labor costs for its laying are 1.5 times less, compared to the same brick. And construction will go very quickly, because sibit replaces 20 standard bricks! Such are the things.

The modern trademark “Sibit” today produces products using the German “YTONG” technology. All products made from cellular concrete have the highest quality and meet all European standards. All Sibit products have the distinctive sign “100 Best Products of Russia”. All sizes of sibit blocks are very popular in Eastern and Western Siberia. The blocks are used not only for the construction of private houses, but also for the construction of industrial structures. The main thing is to choose the right size of the building unit.

Sibit blocks are made from cellular concrete, are of high quality and meet European and Russian standards.

To produce cellular building materials, lime, cement, sand, aluminum powder, and water are used. The main processes for the production of sibit:

- dry grinding;

- wet grinding;

- preparing the mixture;

- formation of large arrays;

- cutting to required sizes.

After going through all the processes, the products are subjected to specific processing in autoclaves at high pressure. As a result of a rather complex process, blocks with a very high percentage of strength are obtained.

Heat transfer resistance standards

For example, there is an aerated concrete house in Sochi, where it is very warm, the heating season there is short, and the winters are not cold. According to the standards for this region, the thermal resistance of the walls should be only 1.79 m2 °C/W.

To understand how thick an aerated concrete wall must be in order to meet thermal transfer standards, we will use the table. In the table you need to find values of thermal resistance that will be higher than 1.79 m2 °C/W, this is specific for Sochi.

Sochi is sorted out, the region is very warm, almost all options are suitable, except for the two highlighted in orange.

Now let's look at central Russia, in particular Moscow and the region. The required heat transfer resistance of the walls should be 3.28 m2 °C/W.

Options for aerated concrete walls that do not require insulation according to Moscow standards are highlighted in green in the table.

The coldest cities in Russia are: Yakutsk, Krasnoyarsk, Magadan, Irkutsk, Novosibirsk. The required heat transfer resistance in these regions ranges from 4 to 5.28 m2 °C/W.

For Irkutsk (4.05 m2 °C/W), the following options for aerated concrete walls, highlighted in green, without insulation, are suitable:

It is worth noting that in our tables we indicated the thermal resistance of individual aerated concrete blocks, and not the wall as a whole. The thermal resistance of the wall is slightly less than that of a separate gas block. This is due to the fact that in aerated concrete masonry there are adhesive seams between the blocks, which, although thin (2-3 mm), are still cold bridges.

Plus, aerated concrete can be wet, which also somewhat reduces the thermal resistance of the wall. To summarize, we note that it would be more fair to subtract 10% from our table values.

Now let's move on to the main table, in which we calculated the thermal resistance of different options for two-layer walls (aerated concrete + insulation). Choose the option that suits your region.

Conclusion. Is it necessary to insulate 400 mm thick aerated concrete? If the house is heated with electricity, then this is definitely necessary. Insulation is also recommended if aerated concrete walls do not meet the standards for thermal protection, which depend on the climate zone.

If you still have to insulate, it is better to use 100 mm thick mineral wool slabs. Although mineral wool is more expensive than polystyrene foam, it is vapor-permeable and removes excess moisture from the house and walls.

Main characteristics of Sibit aerated concrete

On average, the mass of a wall made of sibit blocks is 4.5 times less than a wall made of ceramic bricks.

Due to this, a lower load on the foundation is achieved, and, accordingly, savings occur during foundation work. For example, a small sibit block, the size of which is 200 * 250 * 600 mm, grade 600, weighs only 18 kg. In turn, such a block can easily replace about 15 bricks with a total weight of up to 80 kg.

Unlike other building materials, the walls must subsequently be heat and sound insulated. A sibit building does not require such additional finishing. The result is a solid wall that will last a long time, and there will be no need to repair or change insulating materials.

Sibit has a very high vapor permeability, which is 5 times more than that of ordinary brick. This allows you to remove excess moisture from the material much faster. Thus, a normal microclimate and air exchange are created in the room.

Due to its structure and high porosity, the material has very low thermal conductivity, which makes it possible to retain up to 20% of heat during the heating season.

Application of sibit in modern construction

Frost resistance of sibit is extremely high. This is achieved due to high porosity. As a result of moisture penetration into the material, it quickly evaporates, and during freezing and expansion, the ice does not destroy the structure of the material. On average, a sibit can last several centuries.

Construction with cellular blocks is very fast as different sizes can be selected. Light weight also contributes to faster work. It is worth noting the flexibility of the material for processing. It can be easily processed with various materials and given almost any architectural shape.

As a result of complex production technology, the shrinkage of the finished material is practically zero. This is due to autoclave processing.

Return to contents

Labor and financial costs

1 gas block = 15-20 bricks.

Working with aerated concrete of this brand is much simpler and easier than, for example, with brick. This is due to the lightness of the blocks. This material lends itself well to processing, which you can handle using ordinary construction tools available to any builder.

Laying 15 to 20 bricks is equal to installing one aerated concrete block, which significantly reduces labor intensity and construction time frames. After all, in the time it takes to build 7 cubic meters of brick, you can build 15 m3 of aerated concrete.

In addition, by choosing Sibit building material for building a house, you will save significantly. Indeed, in this case, there is no need for additional auxiliary materials, technical devices, or extra labor, because only five builders can handle the construction of a building with an approximate area of 250 m2, and this is only in a month.

Transportation of this material also does not create any difficulties and does not require significant financial investments.

Options for using sibit in modern construction

Cellular aerated concrete is so versatile that it can be used in various fields of construction. Most often it is used for:

- construction of private houses of various sizes;

- construction of outbuildings;

- construction of large industrial buildings;

- creating partitions between rooms;

- insulation of walls built with other building materials;

- design of door and window openings.

Return to contents