Taring of cement:

| Factory | PC-400 D20 | PC-400 D0 | PC-500 D20 | PC-500 D0 |

| Sengileevsky Cement Plant | — | — | — | Bags of 50 kg. Navalny |

| Mordovcement | 40 kg bags. Navalny | — | 40 kg bags. Bags of 50 kg. | Bags of 50 kg. BIG-RUN for 1 ton. |

| Ulyanovsk cement plant | Navalny | Navalny | Navalny |

Packaging options

- Packaging, 40 kg bags

- Packaging, 50 kg bags

- Packaging, Big Bag 1000 kg

- Bulk cement in a container

Cement m-500 Portland cement 40 kg

Cement m-500 Portland cement 40 kg is one of the best brands that is known in our market. Many professional builders value this particular brand of cement for its high physical and mechanical characteristics and reasonable price. The convenience of packaging into 40 kg bags is suitable for both small construction sites and large industrial facilities.

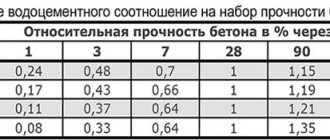

The fact is that M500 D20 cement is manufactured and packaged on the most modern automated equipment with precise control of the dosage of components. The release of each bag occurs under strict quality control, which guarantees not only compliance with GOST standards, but also in many ways exceeding the minimum parameters, which provides a significant margin of safety for this brand. Fully complying with GOST 31108-2003, Portland cement M500 D20 gains a compressive strength of 19 MPa already on the second day after preparing the solution.

The marking means that cement M500 D20 is a fast-hardening Portland cement with additives up to 20%, having a strength class of 42.5. The clinker content of Portland cement ranges from 80 to 95% by weight. The loss of dry matter mass during calcination does not exceed 1%. Sulfur oxide (VI) is contained in an amount of 2.5%. Chloride ions Cl-, which are part of cement, occupy about 0.02%.

The strength characteristics are such that after 28 days the cement material obtained on the basis of the M500 D20 grade increases to 46 MPa. This confirms the highest quality of the plant’s products, because according to GOST 31108-2003, cement has a strength of 42.5 MPa after 28 days. This margin of safety allows the material saving effect to be used on the construction site.

The beginning of setting of concrete mortar or cement-sand screed, which is prepared using M500 D 20, begins 120 minutes after diluting the dry mixture with the required amount of water. Final setting occurs after 180 minutes have passed since the start of preparing the mixture. At the same time, the high-quality cement brand M500 D20 is completely free from the negative effect of false setting, which is often found in various fakes or low-quality products. The time until complete setting allows installers to thoroughly prepare for construction and installation work and makes the process of pouring a foundation or screed as convenient as possible.

The specific surface area of this brand of Portland cement reaches 350 m2/kg, which indicates a high degree of grinding and indicates the absence of harmful impurities and foreign particles.

Application Cement M500 Portland cement 40 kg

Preparation of reinforced concrete for walls, as well as reinforced concrete products, panels, interfloor slabs, beams, armored belts.

Production of cement-sand screed.

Preparation of masonry and plaster mortar.

Pouring the foundation.

Reliable packaging containing 40 kg of ultra-pure cement brand M500D20 fully guarantees the preservation of factory quality throughout the entire shelf life indicated on the packaging.

Delivery by road and rail transport

Our company, having its own fleet of trucks, delivers products in the shortest possible time (1-3 days during the season). Each delivery is accompanied by a quality certificate, which allows customers to be confident in the quality of cement.

We deliver with our own vehicles not only to administrative centers, but also to regions and republics.

It is possible to remove cement from the plant by your vehicle, as well as deliver it by rail car or barge .

Cement loading rate from

| Factory | Cement brand | Download method | Delivery method | Packing | Delivery tonnage |

| Sengileevsky Cement Plant | PC-500 D0 | on pallets | Car | 50 kg (40 bags per pallet) | from 20 tons |

| Barge | from 200 tons | ||||

| Navalny | Cement tanker | from 20 tons | |||

| Mordovcement | PC-400 D20 PC-500 D20 | on pallets | Car | 40 kg (40 bags per pallet) | from 19.2 tons |

| Railway carriage | 64 tons | ||||

| Car | 1 ton | from 20 tons | |||

| Navalny | Cement tanker | from 20 tons | |||

| PC-500 D0 PC-500 D20 | on pallets | Car | 50 kg (40 bags per pallet) | from 20 tons | |

| Railway carriage | 64 tons | ||||

| BIG RUNNING | Car | 1 ton | from 20 tons | ||

| Navalny | Cement tanker | from 20 tons | |||

| Ulyanovsk cement plant | PC-400 D0 PC-400 D20 PC-500 D20 | Navalny | Railway carriage | from 60 tons |

The Eurocement Group holding is the flagship of cement production in Russia, producing the widest range of high-quality products.

The products of Hoding Eurocement Group are:

- High early strength and strength in the finished object

- No “false grasp”

- Low specific consumption in concrete

- High workability, ensuring good mobility of the concrete mixture

- Radiation safety

Advantages of the products of the Eurocement Group Holding

- Possibility of selecting optimal raw material mixtures

- Strict product quality control at all stages of production

- Optimal range of cement produced

Which is better – cement D0 or cement D20

To answer this question, you need to know the conditions under which this or that cement will be used.

M500 D0 and M400 D0 are used in monolithic housing construction, in the production of prefabricated reinforced concrete structures, in private, industrial and civil construction.

Cement with additives is somewhat inferior to “pure” materials in terms of strength indicators. Depending on the components, it may have a longer hardening time and lower moisture resistance. This cement is widely used in industrial and civil construction, for foundations, and when performing finishing work.

The difference between D0 and D20 cements also lies in their cost. Please note that material without additives has a higher price. Therefore, when choosing a material for work, it is necessary to take into account not only all operating parameters, but also the cost of the material.

Certificates for cement

MOR Sert Gost 31108 2003 CEM II AP 425 N 2017

MOR Sert Gost 31108 2003 CEM I 425 N 2017

SE Sert Gost 31108 2003 CEM I 425B 2017

YC Sert Gost 31102 2003 CEM I 325B 2017

YC Sert Gost 31102 2003 CEM I 425H 2017

The following buildings were built using cement from the Eurocement Group Holding:

Moscow metro stations, the Olimpiysky complex, the Kazan Arena stadium, the runway of the Kazan international airport and KAPO named after. Gorbunova, aircraft manufacturing, trade (Ulyanovsk), SABMiller RUS brewery, TANECO oil refining complex (Nizhnekamsk), “Presidential” bridge across the river. Volga, (Mirny village), shopping, sports and recreational complex "Stroitel" (Novoulyanovsk), federal highway M-7 on the Kazan - Naberezhnye Chelny section.

Leroy Merlin, Kirov

Megastroy, Ulyanovsk

Incomcenter, Cheboksary

Saray, Ulyanovsk

Mordovian cement is used in the dams of a whole cascade of hydroelectric power stations on the Volga and Kama, in the hydraulic structures of the irrigation systems of the Central Asian republics, the ports of Murmansk, Tallinn, Nakhodka, Arkhangelsk; in the construction of the Nizhny Novgorod and St. Petersburg metro systems, the Volga and Kama auto giants, the Cherepovets Metallurgical Plant, the Cheboksary Industrial Tractor Plant, sports facilities for the XXVII World Summer Universiade 2013 in Kazan, the XXII Winter Olympic Games 2014 in Sochi. Currently, the company is actively involved in the implementation of a number of large infrastructure projects. In particular, the products are used in the construction of sports and infrastructure facilities for the 2018 FIFA World Cup in Saransk, Samara and Kazan.

About company

The general partner of our company for a long time is the leading holding company in the Russian construction industry - EUROCEMENT group.

Our main activity is WHOLESALE sale of cement with DELIVERY BY OUR OWN VEHICLES, as well as by rail and river transport to the following regions of RUSSIA:

- Ulyanovsk region

- Penza region

- Chuvash Republic

- Saratov region

- Samara Region

- Orenburg region

- Kirov region

Our main goal is to provide cement not only to the main construction projects in the above-mentioned regions, but also to bring the products of the EUROCEMENT group Holding at the lowest price to small wholesale retail outlets.

By ordering cement from EUROCEMENT group Holding you will receive the following benefits:

- Prompt delivery of products

- Competitive price

- Any form of payment

- High quality products that comply with GOST 31108-2016

- Details of Baza Velikan LLC

- Details of Kurtrans LLC

Details of Baza Velikan LLC

Full name Limited Liability Company "Baza Velikan" abbreviated name Baza Velikan LLC Legal address 432018, Ulyanovsk, Khvatkova st., 32G, office 21 Mailing address 433320, Ulyanovsk, OPS No. 65 “On demand” Director Mursalimov Ildar Nailovich acts on the basis of the Charter INN/KPP 7327076956/732701001 Checking account 40702810269000002263 Bank Ulyanovsk branch No. 8588 of PJSC Sberbank City Ulyanovsk Correspondent account 30101810000000000602 BIC 047308602 OGRN 1167325053081

M500, cement: technical characteristics, application, marking and reviews

General Food. Alfa-Bank credit card. Issuing a credit card is free. Tinkoff credit card - Platinum. The composition of M speaks volumes about its quality. It is produced in accordance with GOST and meets all quality standards. Only reliable materials are used. Depending on the additives, the price of cement also changes. It can be either cheap or expensive. Portland cement is a universal type of building material.

It consists of gypsum and clinker. As required, various additives are added to enhance properties. This type of building material is necessary for mixing concrete and various construction works, such as: Exactly and cement, two inseparable things. Therefore, only an experienced craftsman will be able to use cement as economically as possible. Use sand and water wisely. And if you don’t have enough experience in this topic, then in order not to spend extra money on work, just don’t be lazy to look at the tables on the use and dilution of cement.

You only need to find one line there, how much cement should be used per 1 cubic meter of solution. This indicator depends on several characteristics. What brand of cement, if there are additives or not. What percentage of additives does the material contain? All this affects the ratio of three components: water, sand and cement. If we take an example, then for M in the usual configuration the consumption per 1 cubic meter is kg of the substance. But if we consider grade M cement, then the consumption will be more than half a ton.

The question arises. What determines such a big difference?

see also

This is all due to the technical characteristics and composition of cement. Changes in temperature and water greatly affect this.

As for M, this affects him less. Mix M so that for 1 bucket of cement, you need to add 6 buckets of water and 3 buckets of sand. From the outside it may seem that the consumption of cement itself is small. Yes, that is right. But this is only with this cement.

Services for residents of Moscow

This will not work with earlier types. And this is another of a number of features of M. As for water, the amount of it added to the solution depends not on the visual effect, but on the mass. Water is added by weight. And the mass of added water should be 2 times less than the mass of the rest of the solution.

In this case, the solution should not be too liquid. It is necessary to monitor the consistency when kneading. Specific gravity is a measure of the ratio of mass to volume.

How much it weighs and what is the bulk density - these questions are relevant so that you can correctly draw up the proportions of the material. In everyday understanding, weight and bulk density are essentially the same thing. Paying attention to the packaging, you can see that the characteristics and proportions for making solutions can be noted in mass ratio. Depending on the condition, the specific gravity of the building material can vary significantly. The bulk density of Portland cement is one of the lowest when the material is just unloaded from the tank.