This article should begin by mentioning that the very concept of “bearing capacity of piles” is not entirely correct. In fact, the load-bearing capacity of a screw-pile foundation is determined by several factors. The main one is the characteristics of the soil, and only in second place are the geometric and design features of specific piles, which are determined by the characteristics of the soil and the load from the structure.

Thus, it makes sense to discuss the bearing capacity of piles only if it is known exactly in what soil they will be installed.

Soil load-bearing properties

Load-bearing properties are one of the most important factors in determining whether a foundation can support the load generated by the building's mass and transmitted by the foundation. When calculating this value for soils, the fluidity index and porosity coefficient are taken into account.

| Name | Flow rate, JL | Porosity coefficient, e | Design resistance R, kg/cm2 |

| Refractory clay | 0.25 < JL < 0.5 | 0,70 0,85 | 3,6 3,0 |

| Refractory loam | 0.25 < JL < 0.5 | 0,70 0,85 | 2,3 1,6 |

| Plastic sandy loam | 0<JL<0.25 | 0,60 0,70 | 2,0 1,7 |

| Soft plastic clay | 0.5 < JL < 0.75 | 0,70 0,85 1,00 | 2,4 1,9 1,5 |

| Soft plastic loam | 0.5 < JL < 0.75 | 0,70 0,85 1,00 | 1,5 1,8 0,9 |

| Sandy loam, soft plastic | 0.5 < JL < 0.75 | 0,70 0,85 | 1,1 0,8 |

| Coarse sand | 0,50 0,60 | 2,0 1,5 | |

| Medium sand | 0,50 0,60 | 1,8 1,4 | |

| Fine sand | 0,50 0,60 0,70 | 1,9 1,3 0,8 | |

| The sand is dusty, low-moisture and wet | 0,50 0,60 0,70 | 1,7 1,4 0,8 | |

| Sandy sand, saturated with water | 0,50 0,60 0,70 | 1,5 1,2 0,7 |

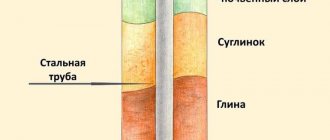

Due to the pressure of the layers above, the density of the soil increases as the depth increases.

| Kinds | Load-bearing capacity in kgf/cm2 at depth | |

| 1 – 1.5 m | 2 – 2.5 m | |

| Sandy loam | 1,0 – 2,0 | 2,0 – 3,0 |

| Loams | 0,9 – 2,5 | 1,0 – 3,0 |

| Hard clays | 2,0 – 4,0 | 2,5 – 6,0 |

| Plastic clays | 0,8 – 2,5 | 1,0 – 3,0 |

| Sands are gravelly and coarse | 2,6 – 3,9 | 5,0 – 6,0 |

| Medium sand | 1,9 – 3,0 | 4,0 – 5,0 |

| Sands are fine, low-moisture | 1,5 – 2,5 | 3,0 – 4,0 |

| The sands are shallow and very wet | 1,0 – 2,0 | 2,0 – 3,0 |

| Crushed and pebbly with sandy pore filling | 2,0 – 3,5 | 4,0 – 4,5 |

| Wood and gravel soils formed from crystalline rocks | 3,7 – 4,4 | 5,0 |

| Grass and gravel soils formed from sedimentary rocks | 2,0 – 2,5 | 3,5 – 4,0 |

In addition, the bearing capacity of soils can be influenced by climatic conditions in a given area.

What does the bearing capacity of soil depend on?

The density of the soil, along with the load-bearing capacity, determines the deformation stability of the soil. Low-density soils have a porous structure in which the free space between the fractions is filled with air or water. If the loads on low-density soil exceed the permissible norm, compaction of the soil will occur - shrinkage, which is fraught with destruction and deformation of foundations located in the soil.

The degree of soil compressibility depends on the density of the soil. In any area, the surface soil layer, in most cases, is represented by low-density rocks (with the exception of regions with coarse-grained and rocky terrain), and at a depth of 5-6 meters there are layers of high-density, incompressible soil that can withstand heavy large buildings.

That is why in areas with problematic soil conditions it is recommended to use pile foundations, which transfer the load emanating from the house to a deep, incompressible soil layer with

Load-bearing capacity of screw piles

All piles can be divided into two large groups depending on the nature of the load perception:

- Narrow-bladed - the diameter of the blade exceeds the diameter of the trunk by less than 1.5 times.

- Broad-bladed (lobed) - the diameter of the blade exceeds the diameter of the trunk by 1.5 times or more.

When using narrow-bladed products, loads are perceived due to:

- precisely calculated width and pitch of the blade, as well as the number of turns - to fully take into account friction on the side surface of the barrel;

- good soil bearing capacity.

Such structures are effective in soils with a high inherent bearing capacity - permafrost

and

dense seasonally freezing soils

. However, strong friction on the side surface of the trunk requires calculations to counteract the tangential forces of frost heave.

Unlike modifications with narrow blades, wide-bladed piles cope well with design loads even when installed in soil with low bearing capacity.

Rules for calculating the load on a roof made of corrugated sheets

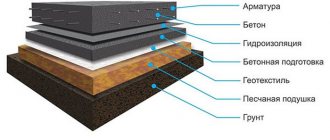

Proper design of any home involves the formation of a sloped roof, which helps prevent water or debris from settling on it. Therefore, when calculating the load-bearing capacity of a profiled sheet, only the effect of wind, the direct weight of the material and the possible amount of snow are taken into account.

For the calculation, some features are taken into account:

- The weight of the profiled sheet depends on its specific gravity per 1 square meter. m. This information is contained in the documentation for the purchased material, and you can also read GOST or the reference book. During the calculation, it is imperative to take into account that the corrugated sheeting is laid with an overlap.

- The load from wind and snow depends on the slope of the roof itself, as well as in what region the house construction procedure is carried out. Using the angle of the slope, you can find out what correction factors should be used to determine how the weight of the snow is distributed over the entire available surface. Additionally, it is decided how much aerodynamic wind resistance the roof has.

- The above three loads are added together. Based on the obtained indicator, as well as taking into account the layout of the corrugated sheets, a corrugated sheet with the required load-bearing capacity is selected.

Important! The load-bearing capacity of the corrugated sheet should be slightly greater than the value obtained in the calculations, so that if the load increases for any reason, the coating can still easily cope with the tasks.

In addition to independent calculations, you can use standard indicators, which are averaged. They are calculated for standard roofs with one, two, three or four spans. But if the roof on the house has any specific dimensions or parameters, then you will still have to make your own calculations. The support diagram looks like this.

Based on the support pattern of the profiled sheet, the load per 1 m2 is determined. These indicators are shown in the table below.

After calculations, load-bearing corrugated sheeting with the required parameters is selected. Often, property owners are faced with the impossibility of purchasing suitable material, and in this case, the only correct solution would be to change the design of the sheathing on which the material is laid.

Video on the topic:

Effectiveness factors:

- sufficiently large support area;

- calculation of the angle of inclination of the blades, the pitch of the blades and the distance between them for structures in which two or more blades are used;

- selection of blade characteristics depending on soil type.

In this case, the load-bearing properties of soils are of great importance at the calculation and design stage. So, for example, a bladed pile with a shaft with a diameter of 57 mm in soil with good bearing capacity can withstand a load of up to 10 tons. At the same time, a design with a 325 mm barrel in soft soil will only withstand 1 ton.

Figure 1 – Graph of the dependence of the load-bearing capacity of screw piles on soil characteristics and structural characteristics of the pile

dS1, dS2, dS3

– nominal diameter of the blade of screw piles (version 1, 2, 3).

ds1, ds2, ds3

– nominal diameter of the shaft of screw piles (version 1, 2, 3).

e/Il

– ratio of soil porosity to fluidity coefficient.

h

– immersion depth.

The figure clearly shows that the bearing capacity of the foundation is displayed in the form of a nonlinear relationship. When calculating it, it is important to take into account all significant factors.

In what areas is this material used?

Corrugated sheeting, which has an excellent load-bearing capacity, is considered the most popular among all varieties. This is ensured by the presence of not only numerous positive parameters and high strength, but also versatility, since it can actually be used in different areas of construction.

Important! A high-quality load-bearing profiled sheet not only has good strength, but also does not weigh too much, so it can be used in different directions.

Most often this material is used for:

- formation of a roofing covering, and if you have the skills, you can use it even on the most complex and curved roof shapes, and the sheathing pitch can reach three or more meters;

- installation of permanent formwork, and a high-quality corrugated sheet designed for creating floors can easily withstand the weight of a concrete composition or frame without deformation or destruction, and is also used as sheet reinforcement;

- the formation of composite floors between floors, as well as the organization of rigidity diaphragms for structures with a load-bearing metal frame;

- creating wall enclosures for various buildings, and they can be insulated or cold, and the buildings themselves can be intended for a variety of purposes;

- installation of a metal fence, and it looks great both on a private plot and next to an industrial facility;

- effective application in industrial construction.

Important! The use of high-quality metal profiled sheets, characterized by excellent load-bearing capacity, makes it possible to carry out all the work in a short period of time and not spend too much money on this process.

Due to the good qualities of the material, it is often used to create floors between floors for which really high and constant operational loads are planned. Another undeniable advantage of the material is its reasonable price.

Thus, a profiled sheet may have different load-bearing capacity depending on the brand, wave shape and height, as well as other parameters. It is considered light and durable, affordable and attractive, and also resistant to various external factors. A profiled sheet with a high load-bearing capacity is considered universal, as it can be used in different areas.

Calculation of a foundation made of screw piles

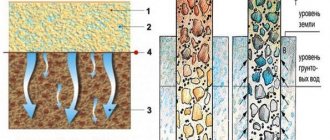

Before starting to calculate the bearing capacity of a pile foundation, it is necessary to conduct geological surveys

. With proper data analysis, the result will help to select the best combination of design and geometric parameters of screw piles for effective load distribution.

When designing a pile foundation with optimal characteristics for a particular building, you can use simple ready-made calculators. However, a more reliable and effective option would be for a geologist to visit the area and then prepare calculations.

Calculation of soil bearing capacity

The work is carried out after determining the location of rocks inside the well and obtaining a diagram of geological sections of the building site.

Bearing capacity is calculated using formulas, but first specialists take samples and set the following parameters - axial compression resistance (R0), freezing depth and foundation depth level.

R=R0x[1+k1x(b-100)/100]x(d+200)/2x200 - with foundation depth up to 2 m and R=R0x[1+k1x(b-100)/100]+k2xGx(d -200) - more than 2 m, where:

- k1 - 0.125 - for coarse or sandy rocks and 0.5 - for clay, sandy loam and loam;

- k2 – for calculating the bearing capacity of compacted coarse-clastic or sandy soils;

- G – to find the specific gravity of the soil from the bottom layer to the lower plane of the foundation or subsequent layer;

- b – the width of the foundation or its part that rests on the base;

- d is the depth of the foundation.

The resulting indicator is compared with the required parameter. If the second figure exceeds the first, then the foundation design should be adjusted - increase the area of its support on the base, or the level of depth, or even change the type of foundation, or move the building site to an area with other, stronger and more reliable soils.

will perform engineering surveys for construction in Moscow and the Moscow region at affordable prices. You can ask questions and fill out an application by phone.

Methodology for calculating the strength of roofing and choosing the brand of supporting profiled sheet

Calculation of the load-bearing capacity of corrugated sheets is necessary for the correct selection of profiled sheets. It is relatively simple and allows you to select a profile with the optimal ratio of load-bearing capacity and price of the material.

Let's consider an example of calculating the load on a profiled roofing sheet and select the corrugated sheet taking into account the data obtained as a result of the calculation.

To begin with, we take the following initial data for the calculation: the building has a gable roof with an inclination angle of 35°, the projection of the slope onto the horizontal plane is 6.0 m, the construction is located in the Moscow region.

The total load on a profiled roofing sheet is obtained by adding the snow and wind loads, as well as the own weight of the corrugated sheet.

The weight of the corrugated sheet is determined by the area of the roofing, the size of the required installation overlaps and is equal to 8.6 kg/m2.

The design snow load is determined by the location of the construction. The Moscow region belongs to the III snow region, for which the snow load is 180 kg/m2. Taking into account the roof slope, the snow load for our building is 180x(60°-35°)/(60°-25°)=128.6 kg/m2, where 35° is the accepted roof slope angle.

Private house with a classic gable roof covered with corrugated sheets

According to the wind load map, we find that the Moscow region belongs to wind region I, for which the wind load is 32 kg/m2. Taking into account the roof slope, the aerodynamic resistance coefficient of the corrugated sheet covering will be approximately 0.3, respectively, the wind load will be 32x0.3 = 9.6 kg/m2.

Therefore, the total load on the corrugated roofing in our case will be 8.6 + 128.6 + 9.6 = 146.8 kg/m2.

Taking into account the length of the roof slope and the selected pitch of the sheathing, the load-bearing capacity of the corrugated sheet is selected (the table of permissible loads is given above). Based on the obtained value of the load on the roofing and the tabular data, C21-1000-0.6 corrugated sheeting with a maximum permissible load of 195 kg/m2 is suitable for our building.

The cost of a profiled sheet depends on the height of the profile, the thickness of the metal and the quality of its protective and decorative coating. Below is a table showing the cost of the most popular brand of load-bearing corrugated sheeting - H75, made of galvanized steel with an amount of zinc in the coating of 140 g/m2.

Despite the fact that most often you can get by with cheaper options, most developers prefer to use corrugated sheets with a large margin of safety relative to the design characteristics.

This is especially true for areas where, over the past 20 years, cases of abnormally high levels of precipitation falling over a short period have been recorded. Load-bearing corrugated sheeting for floors, price profile H75 with various protective coatings.

| Metal thickness, mm | Weight m/p, kg | Width, mm. | Supporting corrugated sheeting, price RUB. for 1 m.p. VAT included | ||

| galvanized | with polymer coating | ||||

| working | full | ||||

| 0,60 | 6,4 | 750 | 800 | 220 | 305 |

| 0,65 | 6,9 | 230 | 315 | ||

| 0,70 | 5,5 | 245 | 318 | ||

| 0,75 | 7,4 | 268 | 372 | ||

| 0,80 | 8,5 | 280 | 383 | ||

| 0,90 | 9,6 | 300 | 421 | ||

| 1,0 | 10,6 | 325 | 458 | ||

Useful article? Save it on social networks so you don’t lose the link!

Top ↑

Team oprofnastile.ru

Read on topic:

Corrugated sheet consumption rates

Consumption rate for corrugated sheets on a roof, façade or fence. Are there general standards for the consumption of corrugated sheets? What should you consider when calculating the consumption of corrugated sheets per 1 m2? All this is in the article.

Profiled sheet service life

What is the service life of galvanized corrugated sheeting? What types of corrugated sheet coatings are there? How much does each of them increase the service life of corrugated sheets? And where is the best place to use them? Read in the article.