Portland cement Ultracem 500, 50 kg

355

In stock

A high-quality binder used in the production of dry construction mixtures, as well as in construction, finishing and repair work. Color grey. Weight 50 kg.

BUY

Art. 0053

To order

Moscow and region: Istrinsky district, village Zakharovo, vl. 57,253 Availability as of 07/14/2020 Central warehouse -840 Availability as of 07/14/2020

Composition of sand-cement mixture

To understand how floor screed occurs, it is important to understand what the substance consists of and what properties it has.

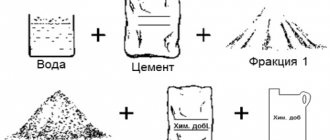

The components of the mixture are as follows:

- Portland cement is a special binder that can be bought at a hardware store;

- fine filler (it can be thought of as sifted sand for construction);

- water (ordinary drinking water is perfect, you can even use spring or technical water);

- polymer fibers - are used to give the material more strength and prevent it from cracking in the future.

Depending on what ingredients this solution includes and what additives it contains, the final characteristics of the resulting material may vary. There are several separate classes of sand-cement mixture, which differ in purpose and cost.

Dry mixture M150 Universal, 50 kg

202

To order

For various installation and repair work, laying walls and partitions, plastering surfaces, laying paving slabs, making manual floor screeds. Compressive strength – 15 MPa. For external and internal works. Color grey. Weight 50 kg.

BUY

Art. 0206

Moscow and region: Central warehouse 2203 Availability as of 07/14/2020 Istrinsky district, Zakharovo village, vl. 57 120 Availability as of 07/14/2020

Preparing the bed for the sidewalk

The process of preparing a bed for future paving with paving slabs consists of several stages. First of all, you need to choose the material and place where the coating will be installed.

Selection of location and material

When choosing a location for installing a tile covering, it is necessary to give preference to flat areas where there are no depressions and close groundwater.

Currently reading: How to choose adhesive for paving slabs: characteristics, laying, making at home

There are two types of paving slabs available for sale, which differ in their production method:

- Manufactured using vibration casting. Manufactured using vibrocompression.

When choosing the appropriate option, it is necessary to take into account the operating environment and expected loads. Vibropressed tiles are suitable for paths on which vehicles will travel. If you need to arrange a landscape design in the garden, it is better to choose a vibro-cast type.

Such paving stones are not able to withstand heavy loads, but have a wide variety of textures, shades and decorative solutions. So, the owner of the site can purchase tiles with an imitation of the texture of wood or stone.

When purchasing material, you need to carefully inspect it for defects, as well as surface features. Both varieties can have a shiny finish, which is explained by the presence of special additives or water in the composition.

But while additives help improve the strength properties of a structure, water worsens them. To assess the quality of the tiles, try hitting one against the other: when a ringing sound appears, you can be sure that the product is of high quality. A dull sound indicates excess water content.

When purchasing materials from different manufacturers and batches, check to see if they differ in shade. You also need to make sure that the sizes match, since sometimes it can be problematic to find similar products from different brands.

To prevent the problem of shortage of tiles, buy them with a margin of 7-10%, because... One batch may contain defective elements.

Preparing the base for installation

Starting the preparatory work, you should dig a 28 cm deepening (the layer consists of 15 cm of crushed stone, 10 cm of sand and 3 cm of dry mixture). If a lawn is being built near the path, then the calculation is performed using a different formula: 28 cm + height of the tile covering + thickness of fertile soil.

If the soil is soft, it must be moistened with water and then compacted. Then at the bottom of the recess a 15 cm layer of crushed stone is placed. The surface is leveled and compacted.

To prevent mixing of crushed stone with sand, the layer can be covered with geotextiles. A 10-centimeter layer of sand is poured on top of this material. After 2-3 days in sunny weather or the next day in cloudy weather conditions, the surface should be leveled.

The sand-cement mixture for laying paving slabs, the composition of which is selected in a ratio of 8:1, is poured over the sand and leveled. The screed should be level and have a height of 3-4 cm.

Mixture proportions

When choosing cement grade 300-400, the proportions of sand will be 5:1. The use of products under the 500-600 brand requires a different calculation: 1 part cement for 6 parts sand. Often the solution is diluted with PVA glue, which improves the bonding strength. The cement composition with sand and glue is mixed extremely carefully, and then used for its intended purpose.

Step-by-step production of the mixture consists of the following steps:

- 1 part of the cement mixture is combined with 3 parts of sand. Next, water is added to the composition - this will give it a creamy consistency. After 15 minutes, the components are mixed again.

The surface of the tile that comes into contact with the mortar should be moistened with water.

If the consistency is dry, the paving stones should be laid only after complete leveling. The rows should fit snugly together.

Dry mix M150 Plaster, 50 kg

204

In stock

For plastering walls made of concrete, brick, stone. It is easy to apply and level, has increased ductility and crack resistance. Compressive strength – 15 MPa. For external and internal works. Color grey. Weight 50 kg.

BUY

Art. 1128

Moscow and region: Central warehouse 1897 Availability as of 07/14/2020

Properties and Features

Before you start working with sand-cement mixture, you need to thoroughly understand its properties in order to avoid unforeseen situations in the future:

- After the resulting solution has already hardened, you should pay attention to its color. It should be darker than regular concrete. If everything is so, then you can be sure that everything was done correctly and there are no errors in the amount of water when diluting dry material. Otherwise, the color of the resulting mixture will be like concrete or lighter.

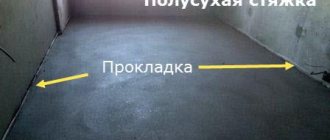

- Do not forget that cement stone is very sensitive to temperature changes. It is for this reason that it is important not to forget about the damper gaps when pouring, otherwise the slab may simply crack.

- During the hardening process, you can notice a tendency that the slab moves up or down. It should be avoided in strong contact with adjacent walls - for a sand-cement mixture this can lead to cracking.

- When screeding, it is necessary to isolate the room from moisture penetration. When the sand-cement mixture hardens, its structure becomes porous and can absorb moisture, and this should absolutely not be allowed.

Dry mix Sand concrete 300R, 50 kg

234

In stock

For the construction of walls and structures from (solid ordinary bricks, solid concrete blocks and natural stone), installation of high-strength screeds with a strength grade of up to M300, and when adding crushed stone - up to M350, used, including in electric and water heating systems floors For external and internal works. Color grey. Weight 50 kg.

BUY

Art. 0060

Moscow and region: Central warehouse 393 Availability as of 07/14/2020 Istrinsky district, Zakharovo village, vl. 57 118 Availability as of 07/14/2020

Main advantages

Sand-cement mixture for floor screed has a number of distinct advantages, which distinguishes it from other building materials:

- This is the easiest semi-finished product to use. Simply add the required amount of the substance with water and stir well. The result will be a concrete solution of the required quality. Dry mixtures are produced in special factories, where proportions are strictly monitored. Moreover, it includes special additives that improve the quality of the material.

- This mixture will significantly reduce labor costs, and construction work will also take much less time. It is for this reason that dry material is very popular not only for screeding floors, but also for laying bricks and even paving slabs.

- If you need to save a little money during construction, then the best way to do this is a sand-cement mixture. The consumption of this solution is small compared to other materials, so its use is an excellent way to reduce costs.

Marking of cement-sand compositions

The brand of the mixture depends on the ratio of sand and cement in its composition. The determining factor here is the purpose of the DSP, which dictates the requirements for its strength characteristics.

Frequently used DSP brands and types of work for which they are used:

- M100 - a solution prepared from it is used for rough plastering of walls, filling small potholes and cracks.

- M150 is a universal option, widely used in construction. The mixture can be used for screed, plaster, and as a masonry mortar when constructing walls made of bricks and blocks.

- M200 - differs little from M100, has approximately the same scope of application, but sets faster and has greater hardness of the finished surface.

- M300 is sand concrete, referred to as the “foundation grade”. Indispensable for increased requirements for surface hardness and strength - for foundations, thick screeds, block masonry. Not suitable for plastering.

- M400 - used to create structures of increased strength: foundations, wear-resistant screeds in places with high traffic. Hardens quickly and requires quick processing.

Numbers on the markings of cement compositions.

Cement-sand mixtures: classification and performance properties

It is necessary to buy a DSP for any construction work. Cement is the basis of construction, so special attention must be paid to the choice of the cement-sand mixture from which it is made.

There are several types of cement, each of which has its own characteristics:

- Portland cement. CPS St. Petersburg with a predominance of alite. One of the most common types of cement, there are many varieties of it.

- Magnesia cement. The mixture is based on magnesite.

- Alumina cement. The aluminate phase predominates in the mixture. This material hardens quickly in the open air and is highly durable when dry.

- Mixed cement. The mixture is obtained by combining the above types of cements, often adding slag, air binders, and mineral impurities.

- Acid-resistant cement. The main element of the mixture is sodium hydrosilicate, sodium fluoride, and quartz sand.

When people want to buy cementitious cement, they usually mean one of the types of Portland cement. Although there are more than 30 types of cements today, Portland cement is the most common.

DSP marking

To buy DSPs for specific work, you need to know their operational features. Here are the most commonly used brands of cement-sand mixtures:

- TsPS M-100. A mixture for hand plastering and finishing with the addition of river sand and carbonate lime.

- TsPS M-150. The most popular mixture for any finishing work.

- TsPS M-200. The mixture, which has characteristics similar to TsPS M-150, but is more durable and therefore better suited for concreting, is used when laying concrete blocks.

- TsPS M-300 Sand concrete. The composition contains fine-grained concrete, used to create impact-resistant concrete screeds, foundations of industrial zones and concrete walls.

- TsPS M-400 Dry concrete. The mixture contains plasticizers that reduce the porosity of the material, while maintaining the mobility and frost resistance of the bonded mass.

When purchasing cement, it is necessary to take into account the operating load limit. It is easy to see by the markings. For example, the TsPS M 150 has an operating load limit of 150 kg per cubic centimeter.

Advantages of TsPS M 150 cement

If you need to buy a DSP for finishing work, then in most cases the choice is made in favor of the M-150 DSP. This mixture is suitable for puttying, filling cracks, concreting stairs, eliminating uneven ceilings and walls. Also, this type of cement is indispensable during masonry and installation work. DSP M-150 works best on brick, cement-sand and cement-lime bases.

The production of dry construction mixture TsPS M-150 is carried out in accordance with GOST 28013-98.

It is possible to buy DSP of this type in several varieties:

- Universal mixture. Designed for sealing joints in concrete, for creating lightweight foundations and concreting floors.

- Plaster mixture. Ideal for hand finishing interior finishing.

- Installation and laying mixture. Designed for concreting stairs and laying concrete blocks.

Although DSP M-150 is used very widely, there are also restrictions that should be adhered to when working with the mixture. It is not recommended to apply ready-made cement to tiles, as well as surfaces coated with paints or varnish. Adhesion with these materials is poor, so the dried mixture may simply fall off. Before application, ensure that the surface is sound, dry, clean and free of grease.