Dry construction mixture M150 (universal) is intended for interior work. Quite often it is used for those works related to exterior finishing.

This mixture can rightfully be called multifunctional. Hence the name - universal. Dry building mixture M150 is used not only for plastering walls, but also for concreting foundations, as well as for sealing joints.

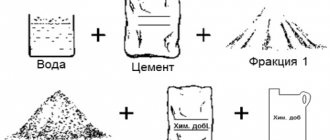

Considering the special composition of this mixture (sand and Portland cement, to which mineral additives are added), the product is not afraid of moisture, is quite resistant to low temperatures, and is very plastic.

It is worth noting that the unique quality of the M150 (universal) dry construction mixture is that no preparatory work is needed to prepare solutions. In other words, mixtures of this brand and the indicated manufacturer are completely ready for the subsequent preparation of the solution.

At the same time, the surface on which the solution is planned to be used must be carefully prepared. This surface must be free of grease, dirt and dust.

Composition and use of universal dry mixture M150

The universal mixture M150 is a factory-prepared set of components, strictly dosed in accordance with technology. M150 is used in: masonry work, plastering walls, floor preparation, laying paving stones, hydra and thermal insulation work. Preparation simply involves adding water, which significantly reduces the time required to prepare the solution. The best substrates for applying the M150 mixture are: concrete, brick, cement-lime or cement-sand substrates.

Our universal mixture M150 complies with GOST 28013-98.

| Material Specifications | ||

| No./item | Indicator name | Standard for the brand |

| 1. | Color | grey |

| 2. | Required amount of water per 1 kg of dry mixture, l | 0,17-0,19 |

| 3. | Water holding capacity (not less), % | 92 |

| 4. | Compressive strength after 28 days, MPa | 15,0 |

| 5. | Adhesion strength at separation, MPa | 0,5 |

| 6. | Consumption, kg/m² | 17-18 |

| 7. | Layer thickness, mm | 5-10 |

| 8. | Bag kg. | 50 |

Dry masonry mixture REZOLIT M-150 winter

AREA OF APPLICATION: The mixture is intended for interior and exterior installation and masonry work of all types of ceramic and sand-lime bricks, concrete blocks and slabs, for the installation of horizontal foundations in interior and exterior spaces with subsequent laying of floor coverings, and can be used to level significant unevenness. It is used in conditions of low temperatures down to -15 ° C.

COMPOSITION: Prepared on the basis of cement binder, fractionated sand, mineral modifying fillers with anti-frost effect.

| TECHNICAL DATA: | Indicators | Values |

| Recommended layer thickness, mm | 5-25 | |

| Water consumption per 1 kg of dry mixture, l | 0,18-0,20 | |

| Consumption of the finished mixture at a layer thickness of 10 mm, kg/m2 | 15,0-17,0 | |

| Maximum aggregate fraction, mm | 1,25 | |

| Open time, at t -5 °C, min. | from 5 | |

| air temperature during application, °C. | up to 15 | |

| Viability of solution, at t -5 oC, min | from 50 | |

| Strength of adhesion to the base, kg/cm2 | from 4 | |

| Compressive strength, kg/cm2 | from 150 |

TEMPERATURE CONDITION: Work should be carried out at a temperature of the base and ambient air not lower than -15 ºС.

PREPARATION OF THE SOLUTION: To prepare the solution, pour the dry mixture into clean warm water at a temperature of 30-40 ° C, in the ratio of 0.24-0.26 liters of water per 1 kg of dry mixture (6-6.5 liters per 25 kg bag), mix thoroughly by hand or machine method to obtain a homogeneous plastic mass without lumps, leave the solution to mature for 4 minutes, then mix thoroughly again. ATTENTION! To prepare the solution at negative temperatures, use clean water with a temperature not lower than +30 °C (promotes accelerated dissolution of additives). Do not exceed the dosage and water temperature above 40 °C, as this leads to a decrease in the strength characteristics of the solution and a decrease in the anti-frost effect!

PREPARATION OF THE BASE: The base must be smooth, strong, hard and free from separating substances: dust, dirt, oil, paint, snow, ice and have a temperature not lower than -15 ° C. When laying bricks or blocks in winter, you must first remove snow and ice from the base using compressed air, a mechanical method or a gas burner.

METHOD OF APPLICATION: Leveling the bases: Apply the resulting solution to the base and level it with a rule, metal ruler, float or spatula. In low temperature conditions it is used for single-layer coatings; their surface should be leveled immediately after applying the solution. When leveling large areas, it is recommended to install anti-shrink joints. The applied solution should be protected from exposure to heating devices, drafts, precipitation and direct sunlight. Installation and masonry: The building mixture allows bricks to be laid on a thin layer of mortar with a joint width of 5-10 mm, which reduces the cost of mortar by 2-3 times compared to traditional masonry methods. ATTENTION! It is forbidden to pre-moisten highly absorbent surfaces! The prepared solution is alkaline; avoid contact with exposed parts of the body and eyes. Possible manifestations of “efflorescence” on the walls of façade bricks. When performing work, use protective equipment. Warming up and using frozen mortar is unacceptable. The hardened solution does not emit toxic substances and does not react with the environment.

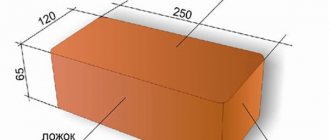

MIXTURE CONSUMPTION FOR MASONRY: Depends on the thickness of the seam and the cost of falling mortar, approximately 25 kg for 16-40 single bricks.

STORAGE AND PACKING: Store the mixture in a dry, moisture-free room in undamaged original packaging. Shelf life 6 months from the date of release. Available in 25 kg bags. Manufactured in accordance with TU 5745-001-75504882-2006 The mixture complies with the standards in force in the Russian Federation. The use of a mixture of doubtful and controversial conditions is possible after testing on a small area.

MANUFACTURER: LLC "REZOLIT" 614023 Perm, st. Promuchastok 42. Tel.fax e-mail website: tdrezolit.ru

Why should you buy from us?

When performing construction work, one of the main rough materials is mortar , which is made on the basis of dry mix M150. The advantages of the M150 are undeniable: versatility, economical consumption, reliability and high quality (due to compliance with GOST 28013-98). Today there is a wide variety of different brands of dry mixtures, but they all have almost the same composition. It is IMPORTANT to pay attention to the mixture’s compliance with GOST in order to be sure of the quality of the purchased M150 mixture.

This mixture is universal, as it is used in a variety of construction works:

- Alignment of walls

- Plastering surfaces

- Concreting stairs and floors (it is worth noting that in this case it is better to use the M300 mixture, which we also produce)

- Finishing slopes when installing doors and windows

- Laying paving stones

- And in many other cases

Simple use and quick drying (within 24 hours) of this material will reduce the time of any construction process. The economical consumption of our mixture at the recommended thickness (5-10 mm) contributes to its wide distribution. Using the M150, you will save money, effort and time for any construction and installation work, routine or major repairs. Excellent strength characteristics , due to careful adherence to manufacturing technology, guarantee the reliability, safety and durability of surfaces finished with its help and the entire structure constructed.

Heat-resistant masonry mixture for stoves and fireplaces “Pechnik” 40.0 kg

Main characteristics

- Color: Grey;

- Fire resistance: +1350 °C;

- Consumption: 1 pack/80 bricks;

815 rub.

In stock: 6899 pcs.

Buy Added pcs

- Compare

- To favorites

Full description (expand)

PURPOSE

The dry cement-clay masonry mixture is intended for the preparation of mortar used for masonry and repair of household stoves and fireplaces.

COMPOSITION

Fire-resistant clay, cement binder, mineral fillers, modifying polymer additives.

PREPARATION FOR WORK Attention!

The properties of the product are guaranteed only if the recommendations for preparation for use are strictly followed. To obtain a thin and durable seam, all red ceramic bricks must be soaked in water before use until air bubbles stop escaping from them, and the refractory brick should simply be moistened with water.

When dry brick comes into contact with the mortar, it quickly absorbs moisture from it, which reduces the astringency of the mortar and makes the masonry weak. It is not allowed to lay stoves made of slotted and sand-lime bricks. It is possible to use old, used bricks. In this case, the brick must be thoroughly cleaned of old mortar and must not have limescale or traces of soot. PREPARATION OF THE SOLUTION

To obtain the finished solution, you need to dilute 1 kg of dry mixture in 0.34 liters of clean tap water.

Constantly stirring, bring to a working consistency - the solution does not flow from the shovel, but is so mobile that it is squeezed out of the masonry seam without stress. To prepare the solution, use only clean water, without a musty odor, and free of suspended particles and dissolved salts. It is possible to use settled rainwater. Attention ! The finished solution must be used within 1 hour; a longer period will lead to a decrease in the strength of the seam. CONSUMPTION

The amount of ready-made mortar obtained from a package of 18.0 kg of dry mixture for laying stoves and fireplaces is consumed for 40-50 pieces of single brick, from a package of 40.0 kg - for 80-90 pieces of single brick.

Consumption directly depends on the thickness of the seam. METHOD OF APPLICATION

The laying of stoves and fireplaces is carried out in rows, according to their row patterns, using a trowel and jointing.

The seams of the furnace masonry are filled with mortar to the full depth, preventing smoke from entering the room during further operation. Immediately carefully remove any remaining solution from the side of the firebox and chimneys, and wipe the surface with a washbrush or wet rag. The surface of the fireboxes, channels and chimney from the inside should be as smooth as possible. Attention ! This solution is suitable for laying chimneys outdoors. Attention ! After the oven has dried, the color of the seam is GRAY. COMMISSIONING THE READY OVEN Attention!

Improper drying can cause cracks to form on the surface of the oven. After the construction of the furnace, a significant amount of moisture remains in the masonry joints and bricks.

Therefore, within 24 hours after complete completion of masonry work, ignition and operation of the finished stove is strictly prohibited. Then, over the next 3-7 days, depending on the size of your stove, you need to burn a small amount of fuel (wood chips, dry branches) in the furnace firebox at least twice a day for 1-1.5 hours. As the oven dries out, the amount of fuel must be increased. In this case, all doors (furnace, blower, cleanout) and valves must be open. This is necessary to remove water vapor from the masonry. Attention !

High humidity and low temperatures can increase oven drying time. To give your stove an aesthetic appearance, improve operational, sanitary, hygienic and fire safety characteristics, we recommend using “Pechnik” plaster for plastering and “Pechnik” heat-resistant adhesive for cladding the surface of your stove with ceramic tiles or natural stone.

SPECIFICATIONS

| Fire resistance, °C not less | +1350,0 |

| Water consumption for cooking, l/kg | 0,34 |

| Application temperature, °C | from +10 to +40 |

| Hardening time, hour | 20-24 |

| Compressive strength (grade), kg/cm2 | 75 |

| Mobility grade, PC | PC3 |

| Humidity of the dry mixture, % | 0,1 |

| Water holding capacity,% | 97,3 |

| Bulk density, kg/m2 | 1045,0 |

STORAGE LIFE

The dry mixture must be stored in a dry place at a temperature from - 40 °C to + 40 °C.

Shelf life in original packaging is 12 months from the date of manufacture. Where can I buy?

All sales addresses in Russia >>>

Quality certificates and declaration of conformity can be downloaded from the following link

>>>

Portland cement Ultracem 500, 50 kg

355

In stock

A high-quality binder used in the production of dry construction mixtures, as well as in construction, finishing and repair work. Color grey. Weight 50 kg.

BUY

Art. 0053

To order

Moscow and region: Istrinsky district, village Zakharovo, vl. 57,253 Availability as of 07/14/2020 Central warehouse -840 Availability as of 07/14/2020

Dry mix Sand concrete 300R, 50 kg

234

In stock

For the construction of walls and structures from (solid ordinary bricks, solid concrete blocks and natural stone), installation of high-strength screeds with a strength grade of up to M300, and when adding crushed stone - up to M350, used, including in electric and water heating systems floors For external and internal works. Color grey. Weight 50 kg.

BUY

Art. 0060

Moscow and region: Central warehouse 393 Availability as of 07/14/2020 Istrinsky district, Zakharovo village, vl. 57 118 Availability as of 07/14/2020

Recommendations for working with dry mix M150

The M150 brand building mixture in dry form is poured into a container and diluted with water in an approximate proportion of 1.8-2 liters per 10 kg of packaged product. It is better to mix with a mixer until a homogeneous solution of moderate consistency is obtained.

For masonry, it is necessary to apply a plastic composition to the surface of the block or brick and level the mortar with a trowel to the desired thickness of the layer (seam). The optimal value here is 1-5 mm, which is determined by the size and weight of a single block. When plastering surfaces, the liquid mixture is applied with a spatula or using an automated plastering station and leveled using a rule until an even layer is obtained. If the thickness of the latter exceeds 3 cm, pre-installed beacons should be used. For better adhesion, the wall must be cleaned in advance from uneven surfaces, mold and mildew, and then treated with a deep penetration primer.

Although the specification composition of factory-made domestic dry mixes is almost the same, the performance qualities of the product from different manufacturers can vary markedly. This is due to the difference in the brands of cement used, the grain size and nature of the filler, the amount of special additives and other technological factors. When purchasing a material, it is useful to study information about the manufacturer, become familiar with the full composition of a particular mixture, factory warranties, production date and shelf life.

Dry construction mixture brand M150 should be stored in packaged form in a dark, dry room at a humidity of up to 70% and above-zero temperatures (best from +10 to +35 degrees C). The product must be used within six months after purchase to avoid losing its working properties.

How to prepare masonry mixture

If you are planning construction, you should first think about how you will prepare the mixture for laying bricks. There are three options for preparing it:

- order a ready-made solution with delivery;

- make the solution yourself;

- use dry ready-made mixtures.

The first case is convenient because there is no need to think about what and where to make the mortar for masonry. I ordered it from a concrete plant and received it delivered. But the main disadvantage of this option is that the volume of one-time delivery is too large; ordering less is no longer profitable. In addition, the finished solution has a limited period of time to maintain technical characteristics; even the addition of plasticizers does not save it from hardening.

The second option is relevant only if you are planning a grand construction, for example, a cottage, country house or summer house. Here you will have to purchase separately the components of the future mortar (sand, cement, slaked lime) and a mixing tool (concrete mixer). For the construction of small structures, for example, an interior partition, or the jointing of brick joints, it is easier to use the third option for preparing mortars. This makes it easier to calculate the consumption of masonry mixture and eliminate unnecessary costs.

Photo 3. Dry adhesive mixtures are often used for grouting joints between bricks, increasing the service life of brick structures

To prepare a solution from ready-made dry mixtures, you do not need to have any special skills or knowledge. The recipe for masonry concrete is on every bag of the product. It is enough to fulfill all the conditions indicated on it, and you will receive a solution of the desired consistency.