To ensure that the water in the pool is always maintained in good condition and never becomes dirty, you need to regularly turn on the circular system. Passing through it, the water is cleared of debris and microbes, heated and returned to the bowl. And the first component of this system is the skimmer. Let's look at what it is and how to install a skimmer in a pool.

What is a pool skimmer?

A clear example of the device

A skimmer is a simple device designed to draw water from a pool, which then goes to a pump, filter and heater. In addition, most models have a mesh for primary cleaning of leaves and other large debris.

It is worth noting that the skimmer removes the top layer of water in the tank. It is also the dirtiest. To completely drain the water if necessary, bottom nozzles are installed.

The skimmer will also help you when cleaning the pool with an underwater vacuum cleaner. Those models that are not equipped with their own filtration system are usually connected with a hose to the water intake. Thus, the water directly flows to the main filter, where it is cleaned.

For attractions

Plate and nozzles for air massage

These devices are used to have fun and relieve stress after a hard day at work. With their help, you can create bubbling water, which will have a beneficial effect on the muscles of the body.

Hydromassage jets

They, unlike previous systems, create a strong pressure of water in the form of jets that are saturated with air.

Water intakes

Water intake devices are used for water intake in the presence of hydromassage systems.

Pneumatic button

It is a device that can be used without leaving the pool. With its help you can turn on the hydromassage or air massage system.

For lighting

Such an element can be installed if a person wants the artificial pond to be illuminated. Floodlights are safe for people around them because they have low voltage. They are usually installed in a prepared niche.

Underwater speakers

With them you can swim and listen to music at the same time. Such devices are actively used by people who like to organize parties near swimming pools. The speakers allow you to produce sound without distortion underwater.

Built-in counterflow

This is a pump that is installed during the construction phase of the pool and is used to create an artificial flow of water. The countercurrent creates a strong oncoming flow of water, and an intense load is placed on the swimmer’s muscles, which allows a professional athlete to train when there is no time in the sports complex.

What types of skimmers are there?

These devices are divided into two categories: built-in and wall-mounted. They differ in design and installation method, but the operating principle remains the same.

Built-in water intake

Built-in models should be included in the drawings before tank construction begins. They are used in permanent pools made of concrete, brick or blocks. It is not always possible to install such a skimmer in a frame structure or an inflatable one.

Mounted model

But there is a way out - mounted models of water intakes. They are made of lightweight material and have a special device for attaching to the wall of the pool. Installation of mounted models takes literally 10-20 minutes.

Selecting and installing a pool skimmer

On hot summer days, the presence of a swimming pool on site pleases all family members with the opportunity to swim in cool water. But the water in this kind of reservoir gradually becomes polluted, becomes cloudy, and leaves, insects and other debris get into it. The process of contamination and then stagnation of water causes an unpleasant odor and not only spoils the pleasure of bathing, but also makes it harmful. To avoid such troubles, the water in the pool must be changed every week, and this is costly and troublesome. Or there is another option - it can be cleaned and disinfected. One of the devices that will help keep water clean is a skimmer. A pool skimmer is a device that takes in the top layer of water and purifies it. We will discuss what kinds of skimmers there are, how they work and how to install such a device in a pool.

Pool skimmer

Types of skimmers, their design, functions and operating features

The pool on your site can be either permanent or seasonal. Stationary pools, in turn, are divided into overflow and skimmer. The very name of the pool category indicates the cleaning system that will be used for it.

An overflow pool is a more complex design from an engineering point of view. A special room is required for its operation. In short, the water in the overflow pool, overflowing the sides, flows into the tank. From the tank it enters the filter unit, which is located in this room, undergoes a cleaning process with reagents, heats up and flows back into the pool through nozzles at the bottom.

A skimmer pool does not have a similar cleaning system, but installing such a pool is much cheaper. Accordingly, skimmers are used to clean skimmer pools.

A skimmer is a hydraulic device that is equipped with an overflow system.

- It controls the water level, which should not be higher than 15-25 cm from the top edge of the pool.

- The skimmer basket, made of mesh, pre-purifies the water.

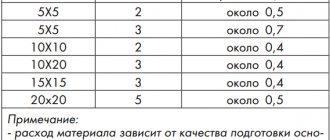

- Skimmers are installed one per 25-30 square meters of water.

Together with the top layer of water, the skimmer removes foam and debris from the surface of the pool.

The skimmer removes foam and debris from the pool surface

The skimmer consists of a tank made of plastic or stainless steel, and at its bottom there is a threaded connection. This thread connects the skimmer to the catchment pipe. There is a hole on the side of the device that serves to collect and flow water into the filter system.

The functions of the skimmer are:

- collecting garbage from the water,

- adding chemical reagents,

- pool depth control.

The skimmer can treat up to 70% of the water in the pool.

Skimmers are produced in two types:

- mounted,

- built-in

The mounted skimmer is made of plastic and is attached to the side of the pool. These skimmers are also great for seasonal pools. Simple models of skimmers can be equipped with a pipe, which will allow them to work both for the intake and return of water.

Built-in skimmers are installed into the side wall of the pool during its construction. The drainage holes are equipped with a damper.

Mounted skimmer installation

Installing a mounted or floating skimmer, as it is also called, with your own hands is quite simple. The mounted skimmer is installed on frame and inflatable pools, and can also be installed on a stationary pool that is not equipped with built-in skimmers.

The mounted skimmer is installed on special mounts at the required level. These fasteners regulate the location of the device relative to the water level.

Each skimmer includes two types of mounts:

- for inflatable pool,

- for frame.

Please note they are different.

A mesh bucket is placed in the skimmer tank, which must be removed periodically during use and washed with clean water. A float is installed on the top of the tank, the movements of which help draw debris into the skimmer. The skimmer package also includes several adapters with which you can connect the skimmer with a hose to the filter pump system.

Diagram of a mounted skimmer

Thanks to the operation of the skimmer, the load on the filtration system is reduced, increasing its service life.

Installing a built-in skimmer

Built-in skimmers differ in the material from which they are made and in their purpose:

- Some skimmers are suitable for installation under film cladding;

- others should be installed under the tiles;

- still others are installed only for monolithic concrete pools.

The built-in skimmer is selected based on the thickness of the pool walls. There are skimmers with short and long necks, but if necessary, you can buy neck attachments.

Installing a built-in skimmer is a simple process. In each box, from any device manufacturer, you will find instructions on how to assemble and install the skimmer yourself. The main thing in this process is the correct choice of installation location and selection of the optimal power for the pumps.

Installing the skimmer according to the instructions will eliminate the possibility of breakdown.

To perform installation correctly, read the instructions carefully and pay attention to the following rules:

- Do not replace the fasteners included in the kit. All bolts, screws, and other elements are made based on the materials from which the skimmer is made.

- If the equipment will be installed in an opening cut into a steel pool, then the edges must be well cleaned and treated with paint.

- Regardless of the size of the pool, the installation of the skimmer is carried out exclusively horizontally of the pool, excluding any distortions.

- The height of the lid can be increased with only two rings. “Skirts” can be glued with Tangit or SABA glue; regular Moment is not suitable for such purposes.

- All devices have marks to determine the maximum and minimum levels. If the skimmer is installed so that the water level is below the minimum level mark, the device may fail.

- Skimmers made of plastic will fit any type of pool, but don't buy too cheap models. They are made from low quality plastic, and it turns yellow over time.

A skimmer is a device that ensures full operation of the pool. Properly selected devices in combination with a filter system will provide you with clean water in the pool and a pleasant rest.

Skimmer installation

We have already touched a little on installing a skimmer in a pool, but it is still worth focusing on. Let's consider each type of model separately.

Installation of mounted models

There should be no problems with the installation of such a device. The kit usually comes with two types of fastenings - for frame and inflatable pools. You need to select the one you need, attach the mount to the skimmer, and then the entire structure to the pool wall.

Next, adjust the depth. Typically, the upper part of the water intake drops no more than 3-4 centimeters from the surface of the water.

Installation of a built-in skimmer

Such models must initially be provided for in the drawings and installed simultaneously with the pipes of the circular system. The installation method and its nuances differ for each model. You will learn about them in detail in the attached instructions. Here we will provide basic recommendations that will help you successfully complete the installation of a skimmer in the pool.

- Read the instructions carefully before starting work. Even if you have watched videos on the Internet and installed other models of water intakes, read the recommendations from the manufacturer;

- Calculate the water level in your bowl. Next, install the skimmer at the desired height;

- Use only those fasteners and parts that come with the device. The use of analogues is excluded;

- You may need to use glue. Use the one specified in the instructions. Other adhesives will not work, even if they are waterproof.

The principle remains the same - strictly follow the instructions. Conscientious manufacturers describe in detail the entire process of installing the device.

POOLS

Installation of embedded parts: skimmers

The skimmer is designed to remove contaminated surface water from the pool bowl.

When the sides of the pool bowl are poured with concrete, boxes are installed into the formwork for openings for the skimmer. The depth and width must be sufficient to install the skimmer specified in the design. Skimmers with auto-topping and emergency water removal are wider than regular standard skimmers. Therefore, the opening should be wider. Often you have to expand the space with a large hammer drill. The size of the plywood board for the skimmer should be 5 cm larger on each side of the width of the opening for the mortgage, 5 cm below and 5 cm above the hole for the skimmer cover. The result is a rectangular plywood board, elongated vertically. Marking the plywood board. We make markings on the front side. Draw a median vertical line. We retreat 5 cm from the top and draw a “zero” line for finishing the edge of the pool perpendicular to the median line. From the “zero” line of the finish we retreat down 15 cm and also draw the “water level” line perpendicular to the median line. The marking is ready. Mounting the skimmer on a plywood panel. There are, regardless of the material of manufacture, skimmers with and without a flange socket. There are skimmers for “concrete” and “film”. Let's start with "film". Skimmers for film must have a flange socket for the crimp frame and front frame. The crimp frame can be self-tapping or screw-based. On screws is preferable. The skimmer is securely attached to the plywood with screws. On self-tapping screws, “black” self-tapping screws are used for fastening, which cut right through the plastic. If it is above the water level, then nothing, if below, you need to be more careful when waterproofing. These through holes must be sealed as they will leak into the concrete. Skimmers for “concrete” can be either with or without a flange. Skimmers without a flange socket are the cheapest skimmer options. Skimmers with a flange socket are mounted in the same way as above. Skimmers with a flangeless socket require a flight of imagination from the installer when attaching it to a plywood panel. The skimmer mounting is secured to the plywood; all that remains is to secure it to the side wall of the pool. Unfortunately, we are not able to move the skimmer mounting horizontally. In large skimmer pools there may be several skimmers. In the project, of course, they stand exactly the same distance from each other. In practice, you have to place a mortgage like the opening is laid when pouring concrete. But in the vertical plane we have complete freedom of action. Before installing the skimmer, first of all, it is necessary to obtain from the foreman responsible for this object a documented “zero” of the side finishing. If installers work in parallel with pool finishers, then they may already have this “zero”. Still, it is better for it to be confirmed. The thing is that the middle of the skimmer's bell corresponds to the water level, and the water level sets us the depth of the pool, which is initially agreed upon based on the consumer qualities of the pool. Using a level or laser level, a horizontal line of the water level is drawn in the area of the opening. Now everything is simple - the plywood and the mortgage are combined with lines of the same name. One installer can easily handle the installation. However, two people are more convenient. Tools and materials. Tools and materials required: - a hammer drill with an x6 drill, - a hammer of any size, but not a sledgehammer, - a screwdriver, - a laser level or level, - 30 mm plastic dowels, - 50 mm self-tapping screws, a 30 cm mounting level. Some “advanced” installers use dowel-nails to fasten mortgages. Somewhat risky, since a large opening, for example under a skimmer or counterflow, requires several bags of filling. If the mortgage is for “film”, then the opening is filled with a simple mortar, if for “concrete” it is filled with non-shrink mortar, which has a high cost. A stuck-out embed requires reinstallation and at the same time entails the rejection of the non-shrink composition. Before pouring, it would be a good idea to plug the drain hole of the skimmer and generally seal the hole under the lid with tape.

How to choose a skimmer

Prices for water intakes have a fairly wide range of prices. Some models differ in cost by 15-20 times. How to make the right choice and not waste your money.

First, decide what type of device you need - built-in or wall-mounted. Next, calculate how much area the skimmer must handle and take into account the pool lining material. This directly affects the choice of model.

The area to be processed and adaptation to cladding is indicated in the model characteristics.

Small models work with pools of 25 m2, wider water intakes - 35 m2. If your bowl has a larger volume, you will need to install several skimmers.

How to install mortgages when building swimming pools

The construction of the pool does not allow for the technology of Soviet times, when repeated laying of asphalt was interspersed with no less repeated laying of communications. After pouring and hardening of concrete during the construction of swimming pools, work related to violating its integrity is unacceptable. Otherwise, the bowl will leak and be destroyed.

Therefore, after arranging the formwork and the frame from the reinforcement, we fix all the mortgages in the right places during the construction of the pools: for the counterflow, nozzles, as well as skimmers, bottom drain, headlights. We connect the elements with the necessary pipes and cables. Only after this we carry out all concrete work. We do not allow voids and shells to appear during the construction of swimming pools. To do this, we use vibrators, since welding cannot be used; we carefully fasten all the mortgages using soft wire and bolts. This is done during any construction of swimming pools. If the fastening is not rigid enough, the concrete may move elements during shrinkage and disrupt the cable and pipe system.

All work after pouring concrete must be carried out very carefully, avoiding the appearance of cracks and chips. It is very troublesome to seal and seal them; in such places, during operation, water leaks still occur, so when constructing swimming pools, all necessary rules must be strictly observed.

To pour concrete in cases where plastic is not used, it is necessary to arrange formwork. This is a very serious moment during the construction of swimming pools. Very precisely aligned formwork will allow you to maintain the geometry of the bowl.

In standard situations, a reusable plywood or metal form is used during the construction of swimming pools. Following the fantasies of a private customer, it is necessary to make formwork from wood “just for this occasion.” At the same time, it is necessary to ensure that the necessary curves, broken lines, unusual steps and other non-standard elements are obtained. Thus, the work of arranging formwork most often requires high professionalism during the construction of swimming pools, combined with precision and high reliability.

The use of non-standard wooden formwork during the construction of swimming pools usually leads to the fact that the given bowl shape can be obtained very approximately. The surfaces have to be “finished” using leveling mixtures. These are expensive imported mixtures. The more of them you have to use, the more expensive it naturally becomes to make a bowl. Therefore, wherever possible, standard factory-made formwork should be used when constructing swimming pools.

Equipment characteristics

A skimmer is a tank made of plastic or any other metal material. A pipeline is connected to this tank through which water is drawn. There is a window on the side of the skimmer that has a floating flap.

The operating principle of such a device is quite primitive and consists of the following processes:

- Through the side window of the skimmer, clogged water enters the tank.

- The provided valve separates the clean layers of water from the clogged upper layers, thus, purification occurs only of the water that has become clogged.

- Large pieces of debris entering the tank are retained using the installed filter.

- At the last stage, the purified water is sent for heating , after which it is returned back to the pool.

To increase the efficiency of the skimmer, you can connect a water vacuum cleaner to the connector provided by the design.

Skimmers for pools are produced not only on the surface; there are also simpler designs, such as mounted and deep-mounted devices. Mounted skimmers are installed when the pool structure is integral and does not require the installation of any additional devices.

Submersible devices are used not only as water purifiers. The functionality of this device allows you to drain water through it , which is necessary when the design of swimming pools or water tanks does not provide other drainage mechanisms.