If you have purchased a country house or are about to start building it, then sooner or later you will be faced with the question of connecting to the electrical network. Often, in connection with this, there is a need to install a power line support near the site. In general, the installation of poles should be carried out by government organizations and this work should be done for free, but in practice everything is not so smooth, and you will have to wait several years. Special organizations can solve this problem for some money.

When hiring specialists, there is no need to delve into the intricacies of the work, but you still need to know certain information. Electricity poles come in three types:

- wooden supports are the cheapest, but not particularly durable;

- reinforced concrete pillars are the most common in use;

- iron power line supports are the most expensive.

Which pole to choose depends on the climatic conditions and the power of the energy consumer.

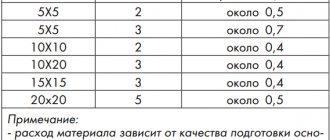

The approximate cost of installing electricity poles is as follows:

- installation of one pole - 30-35 thousand rubles;

- five pillars - 100 - 120 thousand rubles;

- ten supports – 170 thousand and above.

Let's figure out how these amounts are obtained. Firstly, the cost of installation also includes the price of the pole itself, and secondly, all installation features are taken into account.

Installation and features of installing electric poles in the country

How much it costs to install electricity poles in a dacha is influenced by five components:

- delivery of supports for supplying electricity (use of special transport - long lengths), and features of the use of this equipment;

- renting a lifting mechanism, such as a truck crane;

- Specialized equipment is also used to drill a hole;

- installation of the pillars in a strictly vertical position is carried out by a manipulator, the rental of which also costs money;

- Carrying out final electrical installation work, such as installing insulators and running wires.

All stages of installation must be carried out in strict accordance with the PUE (Rules for the Construction of Electrical Equipment), otherwise the organization that owns these electrical networks will not approve the legality of the connection. The operation of the entire power supply system will depend on the quality installation of electricity poles. The work of installing supports should only be entrusted to an organization with extensive experience and appropriate approvals.

electricity pole at the dacha

Do-it-yourself electric pole: types, installation method

Some time ago, when power lines were just being laid, only wooden poles for electricity were used. With the passage of time and the development of industry, wooden power transmission poles began to replace iron and reinforced concrete ones. What types of power line materials are used today?

Types of electric poles

Wooden homemade support

Metal supports are most often used for high-voltage lines because only a metal structure can support the enormous weight of wires and insulators.

Reinforced concrete pillars are most often found on damp and soft soil, where the metal corrodes and the wood simply rots.

Wooden poles are the cheapest compared to other types, and their installation is much simpler; such a pole can be installed without the help of special equipment and specialists.

Advantages of wooden poles for power lines

- The biggest advantage of wooden supports is their relatively low cost compared to other types

- Delivery to the installation site is much easier; several dozen poles can be delivered at once using special transport

- Wooden poles have no equal in seismically active zones; they are much easier to get there

- Not subject to displacement by gusts of wind

- The light weight of the poles allows them to withstand the heavy weight of wires

- Wooden poles are dielectrics, therefore they are much safer than their metal and reinforced concrete “brothers” even in the event of destruction of the insulating layer of the wires

- The service life of a wooden pole is at least forty years, while other types of poles can barely withstand 35.

Wooden power line support

What types of wooden poles are there?

Types and types of lighting poles

The first division of supports is into flanged supports and straight-post supports. The difference between these types of supports is the method of their installation.

Straight supports are mounted so that part of the support is in the ground. The length of the buried end depends on the purpose of the support, its length and the place of application.

Flange supports do not have an underground part. They have a supporting platform, called a thrust bearing, which is bolted to special foundation mortars (FAMs). You can find out more about the types and types of foundation mortgages (FAMs) produced on the website. Brief here.

ZDFs can be flanged or anchored. Anchor ZDFs are produced with studs (there are from 4 to 24 pieces) on which the lighting support is installed and secured. A flanged ZDF is a piece of pipe with a welded flange.

It is important to note that metal and concrete supports, as well as supporting structures of lighting masts, must be concreted.

Electricity pole at the dacha

A summer cottage without the ability to use lighting and household electrical appliances cannot fully satisfy the owners. Comfortable spending time at the dacha is ensured by creating conditions for this. And one of them is the installation of power poles.

How much does it cost and what type of electricity pole should be installed at the dacha?

If you have purchased a country house or are about to start building it, then sooner or later you will be faced with the question of connecting to the electrical network. Often, in connection with this, there is a need to install a power line support near the site. In general, the installation of poles should be carried out by government organizations and this work should be done for free, but in practice everything is not so smooth, and you will have to wait several years. Special organizations can solve this problem for some money.

When hiring specialists, there is no need to delve into the intricacies of the work, but you still need to know certain information. Electricity poles come in three types:

wooden supports are the cheapest, but not particularly durable

reinforced concrete pillars are the most common in use

iron power line supports are the most expensive.

Which pole to choose depends on the climatic conditions and the power of the energy consumer.

The approximate cost of installing electricity poles is as follows:

1. installation of one pole - 30-35 thousand rubles

2. five pillars - 100 - 120 thousand rubles

3. ten supports – 170 thousand and above.

Let's figure out how these amounts are obtained. Firstly, the cost of installation also includes the price of the pole itself, and secondly, all installation features are taken into account.

Installation and features of installing electric poles in the country

How much it costs to install electricity poles in a dacha is influenced by five components:

delivery of supports for supplying electricity (use of special transport - long length), and features of the use of this equipment

renting a lifting mechanism, such as a truck crane

Specialized equipment is also used to drill a hole

installation of poles in a strictly vertical position is carried out by a manipulator, the rental of which also costs money

carrying out final electrical installation robot. what kind, installation of insulators and wiring.

All stages of installation must be carried out in strict accordance with the PUE (Rules for the Construction of Electrical Equipment), otherwise the organization that owns these electrical networks will not approve the legality of the connection.

The operation of the entire power supply system will depend on the quality installation of electricity poles. The work of installing supports should only be entrusted to an organization with extensive experience and appropriate approvals.

Electric pole for a summer residence: installation and connection rules

Where can I install an electricity pole in my dacha? What distances should you keep from surrounding objects? What should the wires and insulators be like?

How much will it cost to connect the cottage to the power supply? Let's try to find the answers.

Our task #8212 is to find out how difficult it is to electrify a country house.

Regulatory Requirements

Let's start with regulatory requirements. They are prescribed in PUE #8212 rules for electrical installations. We have to study the latest, seventh edition of the document, adopted by the Ministry of Energy of the Russian Federation in 2003 (

Installation of fence posts

There are several installation methods:

- concreting;

- backfill;

- driving;

- screwing in

The most common option is concreting. Pits are dug, supports are installed in them and filled with concrete. This method is indispensable for heaving soils.

A similar method is backfilling, the only difference being the use of crushed stone instead of concrete. This “cushion” breathes and allows water to pass through, which is not recommended for metal and wooden supports, but is excellent for concrete pillars.

The most inexpensive way is driving. Suitable for lightweight structures and non-heaving soils. The depth varies from 60 to 80 cm, while the height should not exceed 1.8-2 meters.

Screw-in - used for screw piles, with a characteristic detail at the end (blade), which allows them to easily enter the ground and resist frost heaving.

Where can I install an electricity pole in my dacha? What distances should you keep from surrounding objects? What should the wires and insulators be like?

How much will it cost to connect the cottage to the power supply? Let's try to find the answers.

Our task is to find out how difficult it is to electrify a country house.

Regulatory Requirements

Let's start with regulatory requirements. They are prescribed in the PUE - the rules for the construction of electrical installations. We have to study the latest, seventh edition of the document, adopted by the Ministry of Energy of the Russian Federation in 2003 ().

Please note: the adopted document canceled the validity of the older PUE. The changes affect, among other things, the chapter “Electricity sewerage” that is relevant to us.

Let's pay attention to the most important points of the document in our case.

General requirements for lines with voltage up to 1 kV

- When hanging any unprotected wires on supports, the distance from them to windows or balconies at maximum deviation should not be less than 1.5 meters.

- Above the carriageway, the wires are hung at a height of at least 6 meters, above the impassable part - at least 3.5 m.

- The distance between the wires when spanning up to six meters must be at least 10 cm, when spanning over 6 meters - at least 15 cm.

- Entry into the building is carried out at a height of at least 2.75 m; in this case, an insulating pipe is used for entry, the shape of which prevents water from entering the house.

- The structures on which the conductors are installed are made of fireproof materials and must have a fire resistance rating of at least a quarter of an hour.

Comment: it would seem that this point puts an end to wooden pillars. But... no, a loophole remains: wood impregnated with a protective composition does not support combustion.

- The minimum distance from bare wires to a pipeline for any purpose is 1 meter. If the wire is insulated, the distance is not standardized.

- Insulators must be fireproof. Traditionally, porcelain and glass are used for this purpose.

The photo shows porcelain insulators.

Requirements for overhead lines with voltage up to 1 kV

The supports should not impede passage and passage, or block entrances to courtyards.

Where there is a possibility of being run over by a car, the support is protected from collision with it by a bumper or any other method.

The pole should be marked at a height of 2.5 - 3 meters. It indicates the serial number of the support, the width of the security zone and the telephone number of the line owner.

All metal structures are protected from corrosion. The method of protecting the PUE is not specified; Traditionally, painting is used for this.

The minimum wire cross-section for an overhead line is limited by its mechanical strength and is determined by the material.

It’s curious: for a single-wire steel wire, it’s not the cross-sectional area that is limited, but the diameter. It should not be less than 4 mm.

The branch from the nearest support is carried out only and exclusively with an insulated wire. The maximum branch length is 25 meters.

To connect the wires, connecting clamps or welding are used. Single-wire wires can be connected by twisting followed by soldering; but you can’t butt weld them. In this case, a wire that differs in material or cross-section of the current-carrying core is connected only with clamps.

The minimum cross-section of the entrance to the house is also limited by the document; and in this case the cross-section is determined by the type of wire:

Supports

What should the actual pillar be like?

For low-voltage lines, reinforced concrete, metal, solid wood and wooden poles with a concrete base can be used. All types of wood, except larch, must be impregnated with an antiseptic; Larch wood itself is extremely resistant to rotting.

Wood is the most affordable material for a pole.

When using a wooden support, its minimum diameter (at the top end) should be:

- For the main power supply line - 14 cm;

- For a branch to a house (in particular, for a pole installed on a site) - 12 cm.

Regarding the deepening of supports, the document is somewhat vague - “depending on local conditions.”

What should be the minimum distance from the pole to surrounding objects and communications?

How is a lighting mast different from a support?

Both the mast and the lighting support are designed for installing street lights at height.

A support is a mounting structure in the form of a pillar resting on a supporting base. A striking example of a support is urban street lighting. Everyone is familiar with the rows of evenly spaced street lights along the roads. The height of the supports is from 3 to 12 meters.

A lighting mast is a taller structure on which groups of lamps or spotlights are mounted to illuminate entire areas. A striking example here would be the lighting of stadiums with high-rise floodlight masts. The height of the masts is from 16 to 40 meters.

Expenses and documents

What is the asking price? Are any documents required to install a pole and connect light in a dacha? We will leave the illegal demands of unscrupulous energy companies outside of our consideration: we are interested in the current legislation.

Among household appliances, this power may be insufficient except for an electric boiler.

- The maximum distance to the nearest power grid should not exceed 300 meters within the city and 500 in rural areas.

- If it is necessary to build a power transmission line and/or substation in a holiday village, the costs of its construction will be spread over everyone who is interested in connecting.

- The wires will only lead to the border of the dacha plot. All work on its territory is carried out by the owner.

What documents are needed to apply for connection?

- The actual application.

- Location plan of energy consumers.

- Copies of documents certifying ownership.

- A copy of the charter of the gardening partnership.

- A copy of the decision of the general meeting of the ST on concluding a connection agreement.

What should happen after submitting the package of documents?

Within a month, the network organization is obliged to issue technical conditions that future consumers will have to fulfill within their areas, and a draft contract.

After signing it, the performers begin work.

The deadline for its implementation is also regulated by law:

- With a total connected power of up to 100 kW - up to 6 months.

- With a power from 100 to 750 kW - up to a year.

- With a power over 750 kW - up to 2 years.

What to do all this time on a site without electricity? In addition to temporary wiring thrown from neighbors through a separate meter, the situation can be saved by purchasing or renting a diesel generator for the dacha. Of course, this is a solution for the summer: heating, for example, uninsulated country houses made from modular containers with generated electricity is prohibitively expensive.

Self-installation

Is it difficult to install a pole on the site with your own hands?

Here are the simplest instructions for making it from timber with a cross-section of 150 mm.

- We treat the timber with an antiseptic in two or three layers.

- We assemble a cross measuring approximately 2x2 meters at one of the ends of the future pillar. The crosspiece itself is connected halfway across the tree; Galvanized corners are used for fastening to the pole.

- Four jibs are attached between the post and the crosspiece, after which the entire underground part (about one and a half meters) is painted with bitumen mastic.

- A cross-shaped hole is torn off under the support, into which the post can easily be installed by two people using a rope tied to its top. All that remains is to level it plumb, bury the base and compact the soil.

Power lines are needed in both big cities and small villages because they supply electricity to every home. Until recently, only wooden poles were installed, but they are impractical and eventually rot from rainy weather and the scorching sun. Today, reinforced concrete and metal structures are installed; they are more durable and reliable.

If we compare all these three types, we can note that wooden structures are still popular due to their low cost. However, you will no longer see them in the city; they are most often installed in villages.

The most common today are considered to be resistant to various types of corrosion and destruction and have high strength. They are able to withstand even the lowest temperatures (down to -55 degrees). According to their size, they are ring-shaped and rectangular.

Classification of poles and lighting supports

To organize street lighting, a number of different poles and supports are used, on which complex structures connected to the general electrical network are mounted. These pillars and supports are classified according to various criteria, among which the most important are:

- material for making a pole or support;

- type of pillar (support) manufacturing;

- intended purpose.

As for the material of manufacture, this is probably one of the simplest criteria - mainly modern construction uses wooden and metal (or wooden and galvanized reinforced concrete), reinforced concrete (with metal reinforcement) pillars, and less often - fiberglass.

By design, they are divided into cone-shaped, lattice, tubular (wooden - solid) and multifaceted. The type of pillar that is selected for installation is determined by the terrain conditions, the intended purpose of the pillar, the expected load on it and a number of other factors.

As for the purpose, this classification category is very broad, since poles and supports can be used on a permanent or temporary basis, for industrial or decorative purposes, etc. The supports vary in diameter and height - these parameters are also selected in connection with the future functions that the support will perform. It is worth noting that the support (unlike a pole) may not have a strict cylindrical shape - it could be a mast, a cable, a wall, or some other existing platform for installing a lighting fixture. When selecting a suitable pole or location for its installation, consideration should be given to weatherproofing, light distribution, proximity to a power source, etc.

Sometimes non-standard options are included in a number of supports - for example, multi-tiered metal structures intended for installing New Year's lighting. They can be installed permanently or temporarily, built into the foundation or simply secured. Of course, the use of such structures is in demand due to their mobility and the ability to dismantle any object at any time, as well as their almost absolute fire safety.

Installing outdoor lighting is a complex and responsible task that includes many details that need to be taken into account during the process. Therefore, it is not recommended to do it yourself (and if we are talking about municipal buildings, it is completely prohibited). So, contact specialists who have sufficient qualifications in industrial mountaineering and installation of electrical systems so that they can quickly, efficiently and safely solve your task.

You can resort to the help of specialists when you need to install permanent lighting, decorative lighting, signs, illuminated advertising blocks, etc. In all these cases, our company will carry out the high-quality industrial height work that you may need.

17.09.2013

Features of installing electric poles made of reinforced concrete

In order for the supports to be strong, durable and reliable, it is imperative to take into account the natural landscape of the area, the possible maximum wind load on them and the distance between the two supports. The following types have proven themselves to be excellent for street lighting: SV 105-3, SV 95-2, SV 105-5 and SV 110-4.9.

The installation of electricity poles begins, first of all, with marking the ground, after which you need to install the poles themselves under the supports and run electrical wires on them. You can pre-mark the installation location using wooden pegs. In this case, the distance between the two supports should not be more than 45 meters, otherwise the wires will sag and break in strong gusts of wind.

When preparing holes for supports, one important detail should also be taken into account - the depth of the hole itself should be deeper than the freezing level of the soil. If you do not follow this advice, this may result in the support being pushed out of the ground as a result of its expansion.

The supports are installed using a device that is indispensable for these purposes - a manipulator, but before installation you need to very carefully check the support for various damages. The support must be vertical; plumb lines and levels will help to install it evenly. After it is correctly installed vertically, its base must be secured with thick concrete mortar.

Only specialists should connect electrical wires, otherwise the commission will not accept the work and ultimately will not allow the pole to be connected to the main power source.

Installation of concrete poles for electricity

The design features and dimensions of the pillars are selected depending on:

- on purpose and location.

- technologies for laying power lines, taking into account the length of the power line span.

The minimum height of the pole according to the rules for electrical installations (PEU) is 5 m, the maximum is 12 m. In practice, 7-meter products are most in demand.

The installation process begins with marking, which involves accurately determining the number of poles and their location on the electrical network wiring area. In this case, the terrain landscape, soil properties and design loads are taken into account.

The next stage is drilling a well under concrete pillars, for which special equipment is used: platforms on which drills are installed (earth or telescopic). The depth of the hole and its diameter depend on the type of post and the properties of the soil. Typically, the laying depth is designed below the soil freezing mark. Next, the pillars are immersed one by one into the prepared holes. Installation is carried out using a manipulator. Be sure to check the vertical position of the stand. For power lines with a voltage value of 10 kV and below, you can use a plumb line; for networks with voltage parameters of 35 kV and above, a theodolite is used.

Fix each concrete pole for electricity in the prepared hole with thick cement mortar. First, waterproof the bottom of the rack. This step prevents the concrete structure from coming into contact with groundwater. To ensure the impeccable strength of the pillar (especially in soft soils), it is rational to provide for the installation of additional supports during the process of securing it. They use elements made of reinforced concrete, install metal crossbars that are pre-fixed to the racks with half-clamps, or install internal cross metal connections.

One of the important points before installing electricity poles is checking the quality of the products. They must not have defects or damage.

After installing the racks, they begin laying electrical wires, which starts with fastening the insulators or traverses.

Important! The final stage of installation of electrical wires can only be performed by qualified electricians who have a special permit to carry out such work.

When building a fence, proper support is of particular importance. To ensure that the fence does not sag and stands for a long time without warping, several nuances are taken into account, such as material, installation method, length and width (diameter) of the posts.

In this article we will look at some characteristics of fence posts and use one example to calculate what diameter and thickness to choose.

What is the price of electric poles?

If we consider the prices of electricity poles in general, we can note that they depend on the size of the pole, its material and, of course, on the quality.

Reinforced concrete structures are considered the most expensive; their prices range from 11,000 ($330) rubles. and up to 15850 rub. ($475) for one section. Cheaper models are a regular empty rack, while more expensive models are a beautiful square rack. This rack is designed to accommodate nine wires, in addition to this lighting wire and 4 broadcast wires. They are able to withstand voltages from 0.38 kV to 10 kV.

A big city or a small village cannot do without a power line. It is the source of electricity in every home. More recently, electricity poles were made only of wood. But such structures are not very practical, since over time they begin to rot under the influence of precipitation.

This is what a new wooden electrical pole looks like

Reinforced concrete pillars have a longer service life. Their strength far exceeds the parameters of wooden structures.

However, even with such disadvantages, wooden electrical poles do not lose their popularity, since their price differs from the cost of concrete structures. In urban environments, such lighting poles are practically not installed; they are installed only in rural areas.

Replacing an old wooden pole

Wooden poles date back to the first construction of power lines. They were replaced by lighting poles made from other, more reliable materials: steel, reinforced concrete.

However, such lighting poles have not lost their popularity; they are still widely used today. The support material is pine. It is least susceptible to rotting; such wood has a high resistance to harmful insects. Its shape is distinguished by regular geometry.

Processing of wooden poles

To ensure that wooden lighting poles can serve for a long time, they undergo special treatment in factories, and the poles are coated with antiseptic compounds.

A few years ago, creosote was considered the base composition. To obtain it, the resin produced by coal was used.

This is what wooden poles processed using new technology look like

Time passed, and they began to abandon creosote: scientists managed to develop materials that gave a greater effect.

Special water-soluble antiseptics have appeared, which contain substances that penetrate deeply into the wood and do not allow harmful biological organisms to develop.

Such lighting poles are produced only in the factory using special vacuum equipment. As a result, the pole receives excellent technical characteristics and an attractive appearance. It is much easier to transport compared to concrete and steel structures. Installation of such a wooden electrical support is not very labor intensive.

Classification by product purpose

This division of power transmission route supports is made based on the nature of the loads perceived, i.e. there are pillars that are capable of holding the tension force of wires and cables, and there are also supports that are designed for a different load. Thus, electrically supporting structures are divided into intermediate and anchor installations. The first ones are mounted on straight sections. Capable of withstanding vertical load from cable congestion and the weight of insulators, as well as horizontal stability from wind exposure.

An anchor support is a structure that is placed in areas where the direction of a power line changes, at the beginning and end of the route, at the intersection of roads, railway lines, water bodies, and ravines. It is stable and strong compared to intermediate posts. The installation absorbs the tension (force) of wires and cables from spans adjacent to the support, so the installation of anchor supports is a huge necessity for creating powerful power line systems.

Price

It must be said that the price of such electricity poles is considered the lowest. It ranges around $26 per section. Such poles are used only in rural areas, as this helps save local budgets.

When modern supports are installed, it is not necessary to pour a reinforced concrete foundation; installation can be carried out directly into the ground. Each line must begin and end with end supports. The gaps are filled with corner posts.

If installed correctly, a wooden support will last a very long time. If verticality was not maintained during installation, the support will begin to tilt after a while, and over time it will simply fall. If the distance between the poles is large, the wires will begin to sag. In this regard, the installation of supports made of any material must be carried out strictly according to the developed technology.

Electric pole installation process

Production of electrical supports

As mentioned above, the material for a wooden post is pine. Each such support is treated with a special impregnation of the SCA+ brand. In fact, this remedy is a strong antiseptic. It includes:

- Copper salts;

- Chromium;

- Arsenic.

The technological process of impregnation is carried out in three steps:

- Dry thoroughly.

- The pole is impregnated with an antiseptic under high pressure.

- The antiseptic agent in a vacuum environment is evenly distributed over the surface of the column.

The minimum impregnation depth must be at least 22 mm. Today there are two brands of SSA+ antiseptic:

- Ultan;

- Elemsept.

Wooden support impregnated with the following compounds:

- Does not absorb moisture;

- Remains dry for a long time;

- Odorless;

- There are no traces left on the wood after contact with other substances.

To enhance the properties of the antiseptic, wooden electricity poles are subjected to additional drying. As a result, the antiseptic becomes an insoluble compound. In other words, the SSA composition is constantly located inside the wood. As a result, the properties of the support improve, and it becomes:

- Fireproof;

- Resistant to natural phenomena.

In addition, the service life of wooden supports is significantly increased. The technological process for manufacturing such structures must fully comply with the developed construction standards.

Before the finished product is sent for sale, several tests are carried out on wooden poles to identify any existing defects. If they are detected, the supports are rejected and not allowed for use.

Advantages of wooden power lines

- Easy installation;

- Easy transportation;

- Pillars very rarely fall.

Option for installing a wooden power line support

Since wood is highly elastic and has high levels of flexibility, such electrical supports work well in areas where strong winds constantly blow and wires are subject to high wind loads.

Such supports have a long service life. If they are well impregnated with a high-quality antiseptic, then their service life can reach 50 years. In addition, the cost of manufacturing wooden poles is much lower than the production of their concrete counterparts.

Characteristics of wooden power transmission poles

When producing impregnated wooden supports, the following factors are taken into account:

- ⇒ The minimum diameter of logs is 16-22 cm;

- ⇒ The deviation of logs from the nominal length does not exceed 0.3-0.1 m;

- ⇒ The logs do not contain knots and are not subject to tobacco rot;

- ⇒ Wormholes are not allowed in the first grade wood, and when using the 2nd grade, the wormhole is no more than 5 pcs. per 1 meter of length on average.

Wooden poles for power transmission lines can differ in butt diameter, top diameter, curvature and length. Standard pole lengths are 9.5, 11 and 13 m.

When making them, only the butt part of the trunk is used; are produced in accordance with GOST 9363-88, and the main overall dimensions are the upper and lower diameters of the ends, which correspond to the type of support and nominal length.

Wooden electric poles are sometimes equipped with a plastic cover designed to protect the ends of the products from precipitation.