Modern types of panels

Currently, the range of building materials is growing every day. The development of industry has led to the emergence of new polymers, which are not inferior in quality to natural products, but have a lower cost. In addition, such products made from artificial materials are a more practical solution. The flexibility of materials allows manufacturers to produce a huge range of products that differ in their appearance and texture.

Plastic facade samples

One of the most affordable options that is becoming increasingly popular. Previously, they were used exclusively in dachas, but modern plastic facades boast:

- Beautiful and neat appearance. Visually, the material is difficult to distinguish from natural stone or treated wood.

- Light weight, which allows the use of plastic panels for finishing old houses with weak foundations or walls.

- High degree of resistance to precipitation and temperature changes. Plastic facade panels practically do not fade in the sun and do not oxidize under the influence of moisture.

- Easy to care for. Plastic is very easy to clean. Thanks to its dense structure, the material does not absorb dirt, and dust does not linger on the smooth surface.

The popularity of this decorative material is growing every day. Its low cost and practicality play a major role. In addition, the quality of products has increased significantly. Today you can purchase samples that will decorate both an elegant home and a small country cottage.

Laminated wall panels

Glazier wall panels using high-quality chipboards EGEER (Austria) and MDF.

The Glazier wall panel system consists of large flat panels of laminated particleboard and an aluminum separator profile. Wall panels from the leading manufacturer of particle boards EGEER (Austria)! Various colors and textures. The aluminum profile is anodized and can be painted to match the wall panels.

MDF wall panels are an environmentally friendly, modern material. MDF is made by dry pressing fine wood chips at high temperature and pressure. Well processed.

What is so attractive about MDF wall panels? First of all, this is a great way to quickly get a high-quality wall surface, while insulating it and isolating the room from noise. MDF panels are installed very quickly and do not require further finishing. Decorating premises with such panels does not require preliminary finishing of the walls. The low cost of MDF panels, simplicity and ease of installation provide significant savings in time and money.

Glazier wall panels can be used both at home and in country houses: halls, offices, corridors, loggias, and in any public places: offices, shopping centers, fitness clubs, shops, reception areas, offices...

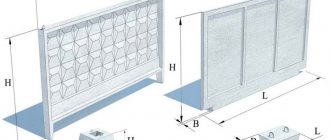

The thickness of the wall panels is 10mm. In case of curvature of the walls, it is possible to use a special profile system, with the help of which the total thickness of the structure will increase by 40-60mm. Standard panel sizes - width: 400-500-670 mm. length: 2750 mm. It is possible to produce any non-standard sizes (up to 900 x 2800 mm) to order. When designing panels, their location is taken into account. When positioned vertically, the panels are cut or extended using special inserts. When the panels are arranged horizontally, their width is calculated depending on the number of rows of panels and the height of the walls.

Glazier wall panels are easy to install. Without preliminary preparation, wall panels can be mounted on walls, columns, ceilings, and other interior elements. This way you can decorate any room in the shortest possible time. The color range is represented by more than 30 types of wood structures and solid colors of laminated particle boards: wenge, fino, beech, cherry, titanium and many others. This allows you to choose the right texture and color for your interior design. Wall panels based on laminated particleboard can be used in any indoor interior.

Characteristics of our wall panels:

- The panels are based on a lightweight and durable anodized aluminum profile

- for finishing there are corner (internal/external), connecting and end aluminum profiles

- width of laminated wall panels from 400, 500, 670mm or upon request up to 900mm

- panel height 2750mm or up to 2800mm on request

- large selection of color and texture finishes

- reasonable price for turnkey wall finishing because... no wall preparation required

- Order fulfillment time up to 2 weeks

- easy and quick installation

Siding

One of the first materials for finishing the walls of a house outside. This includes any products that are overlapped. In this way, it is possible to achieve maximum insulation of the wall from the outside. Nowadays, products made from polyvinyl chloride are becoming a popular option. This is due to the reduction in the cost of PVC. In addition, the variety of colors and shapes has increased significantly.

Of particular importance in construction and repair work is the external cladding of structures. Today, a wide range of facade panels for exterior decoration with enhanced fire safety characteristics is produced. Facade panel building materials successfully perform the following functions:

- aesthetic (thanks to the panels it is possible to create exclusive design projects for facades);

- utilitarian (in order to protect the structure from the harmful effects of atmospheric factors on the structure, including wind, sun rays, precipitation).

For the first time, exterior cladding panels were used by builders and designers in the United States in the 19th century. In those days, painted and deliberately planed boards were attached to the walls at an angle and layer by layer so that the layers sagged somewhat. This method of fastening wooden boards made it possible for precipitation to descend without obstacles. This type of wall panels for the exterior decoration of buildings was then called siding. Later, vinyl siding began to be produced, which was characterized by a long shelf life, as well as a better indicator of resistance to a range of external influences. At the same time, cement siding, metal siding and plinth panels appeared.

What are the advantageous features of siding?

The main advantages of siding include the following characteristics:

- excellent preservation of all initial aesthetic indicators throughout the entire service life;

- extremely resistant to atmospheric factors affecting the panels, including precipitation, ultraviolet radiation, a wide range of temperatures and humidity, acid-base environments;

- Using exterior siding there is no need for special care. Provided that the panels are installed efficiently and correctly, caring for them means washing them with plain water using the most common and affordable detergent;

- resistance to mechanical damage, including scratches;

- installation and use of panels is possible in a wide temperature range;

- the use of cement siding avoids the formation of cracks, peeling and damage;

- Quite a simple installation process, not complicated maintenance. When covering any type of siding, only minor experience in this area is required.

The range and price of facade panels for a private home is shown in our catalog.

Siding is divided according to the installation method and fastening option:

- horizontal cladding wall panels perfectly imitate the most current types of wood cladding, namely: herringbone and special shiplap.

- Vertical siding has a range of features when installing panels, so it is not often used by specialists. It is most often used in the process of finishing work in non-residential premises, shopping centers, and car washes.

Also, for high-quality, quick and durable finishing, they often use cladding panels for the facade under a log. In other words, this type of siding is called "block house." Fiber cement panels for exterior decoration of houses are produced in accordance with different technology and requirements.

Metal panels

Cladding panels that are very popular. They boast a high level of strength and durability. Finishes can last virtually forever if cared for properly. If exterior metal wall panels become unsightly, they can simply be repainted.

The base material is stainless or galvanized steel, as well as aluminum. The latter option boasts better performance, but its main disadvantage is its high cost.

Finishing material made of steel has a set of significant advantages for our country:

- Long service life. Depending on the manufacturer, the warranty period can range from thirty years.

- Resistant to moisture, wind and ultraviolet radiation. Due to the fact that the material is coated with a layer of zinc and special paint, it is able to repel moisture.

- Resistant to temperature changes. When correctly laid, façade panels can easily withstand severe frosts or heat without deformation. But you need to take into account the fact that steel has a fairly high coefficient of thermal expansion, so the fasteners on one side must be free.

- Fire safety. The material not only does not burn itself, but is also able to protect the walls of the house from fire in case of danger.

All these advantages make steel cladding a good choice. The disadvantages include the low level of heat and noise insulation, as well as the rather large weight of the products. It is necessary to carry out additional insulation of the house and take into account the strength of the foundation.

New: external wall panels "INSI"

The new proposal of the INSI holding is lightweight thin-walled structures for monolithic frame construction, increasing the usable area inside the building and reducing the load on the foundation and frame.

Wall panels of element-by-element assembly "INSI" are used for the construction of external wall fences of newly constructed or reconstructed buildings for various purposes with a load-bearing reinforced concrete or steel frame in any geographical area.

Quick installation, high reliability and reduced cost of the facility are the main characteristics of these structures.

Facade panels

Porcelain tiles

Facade cassettes

External wall panels are recommended for use in the following types of buildings:

- Multi-storey residential buildings

- Office buildings

- Hotels

- Residential complexes

- Social infrastructure buildings (hospitals, clinics, kindergartens, dormitories, etc.)

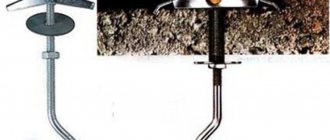

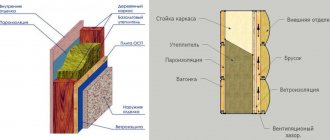

The design of the wall panels is a frame made of thermal profiles, filled with mineral wool insulation, which is covered from the inside of the building with a vapor-proof film, and two layers of gypsum fiber board of 12.5 mm each, or an internal aquapanel. From the outside, the frame to protect the insulation is covered with a windproof diffusion membrane, and then, using special profiles, a variety of facade materials (facade panels, facade cassettes, porcelain tiles, aquapanel) can be attached to the frame, providing the building with a beautiful appearance in accordance with the intended design.

As a result of the use of panels, the thickness of the walls can reach 150 mm (example for Chelyabinsk), which leads to a reduction in the weight of the external walls of the building, and therefore to a reduction in the cost of the frame and foundation. The cost of delivery and installation work is also reduced - the materials are supplied compactly packaged from the factory and assembled into panels on site. The small thickness does not affect the thermal characteristics, but it significantly expands the usable area inside the building.

The absence of “wet” processes, high speed of installation, ideal flatness of panel surfaces, 100% readiness for finishing, environmental friendliness, excellent appearance and long service life are not yet a complete set of characteristics of this product.

External wall panels are the development of the holding’s specialists. INSI has a technical certificate confirming the suitability of using panels for construction work. Each component of the panel design is certified.

You can find out more about INSI external wall panels by calling 8-800-100-20-11, or in offices in your city.

facades facade cassettes facade panels porcelain tiles thermoprofile frame

comments powered by HyperComments

Polymer panels

A very popular material that was previously used exclusively indoors. Modern advances in the chemical industry have made it possible to enhance its technical characteristics.

There are many benefits to using vinyl siding panels. Modern polymer materials are highly durable and resistant to aggressive environmental factors. But at the same time they are lighter and do not load the foundation. That is why their popularity is growing rapidly. Another important factor is ease of installation. Almost everyone can cope with the installation of this finishing material.

They are used both for finishing walls and for decorating the basement. The material repels moisture, which makes it a good choice for the microclimate of our country. In addition, PVC has virtually no thermal expansion. However, it is worth understanding that lining for interior and exterior decoration are two different materials.

Sizes and cost of sandwich panels

Speed and quality in construction are two seemingly completely different concepts that do not intersect or interact in the complex process of building construction. However, modern technologies are breaking established stereotypes.

Today, the most popular and practical material for building construction is sandwich panels. They make it possible to implement architectural solutions of varying complexity in record time.

Sandwich panels make a building warm, durable and aesthetically attractive. There are different types and purposes: it all depends on the thermal insulation and the material from which the framing sheets are made.

There are wall and roofing ones. When choosing a material, you need to know how they differ, what is their operational feature and what is their advantage? How not to get lost in a wide range of manufacturers and follow the path of least resistance?

Sandwich panels

One of the most versatile options for facade panels, the use of which allows you to solve two problems at once. The finishing material is a multilayer rectangle with:

- thermal insulation;

- vapor barrier;

- decorative outer layer.

Thanks to this, it is possible to protect the house from low and high temperatures, shift the dew point outward and beautifully decorate the exterior. The main advantages include long service life and ease of installation.

But the panels also have disadvantages that prevent them from gaining widespread popularity in our country. At the joints, slabs can freeze quite strongly if the temperature drops below twenty degrees below zero. In addition, the material is quite fragile and can be easily damaged. For these reasons, the use of this material for installation on basement floors is not practical.

Fiber cement boards

They are long planks made of a solution of cement and polymer fibers. As a result, it is possible to obtain a durable and moderately elastic material. At the same time, the plates themselves have a high degree of rigidity. This makes it possible to use them to align the outer corners of the building.

Technical characteristics of fiber cement boards

| Maximum deviations in the dimensions of external wall panels made of fiber cement, according to: | ||

| — length, mm | ± 3 | |

| — width, mm | ± 3 | |

| — thickness,% | ± 10 | |

| Deviation from flatness and edges from straightness, mm, no more | 1 | |

| Deviation from rectangularity (deviation of the sheet shape from rectangular), mm, no more | 1 | |

| Density of external wall panels for a house, kg/m3, not less | GOST 8747-88 | 1550 |

| Modulus of elasticity in bending of finishing materials, MPa (for reference): | GOST 8747-88 | |

| - along the fibers | 13000 | |

| - across the fibers | 15000 | |

| Bending strength, MPa, not less | GOST 8747-88 | 24 |

| Frost resistance: | GOST 8747-88 | |

| — number of cycles | 150 | |

| — residual strength,%, not less | 90 | |

| Water absorption, %, no more | GOST 8747-88 | 20 |

The main advantages include relatively low cost, reliability and versatility. The outside of the panels can be painted with any color, which allows you to create your own original exterior.

It is worth noting that the material is able to withstand fairly high mechanical loads.

Selection of wall panels according to main characteristics

When planning to build a house from expanded clay concrete panels with your own hands, it is important to choose them correctly according to their purpose, size, strength and other indicators. Therefore, first you need to understand their types.

Types of panels

The range of expanded clay concrete panels is very wide. This is due to the different purposes of the products, their design differences, the ratio of components in the concrete composition, etc.

For example, according to their purpose, they are divided into structural, heat-insulating and structural-thermal-insulating boards:

- Structural expanded clay concrete has the greatest strength (up to 500 kg/sq.m.), density (up to 1800 kg/cub.m.) and frost resistance (up to 500 cycles). It is used to produce external wall panels made of expanded clay concrete for the construction of basement and lower floors of buildings.

Basement floor made of expanded clay concrete panels

- Thermal insulation material , on the contrary, is characterized by minimal strength (up to 25 kg/sq.m.) and density (no more than 600 kg/cub.m.). Plates made from it are used for thermal insulation of external walls and the formation of internal structures.

Partition panels

- Structural thermal insulation products used for the construction of walls of above-ground floors and attics are the most common. Their density (700-1200 kg/cub.m.), strength (350-1000 kg/sq.m.) and frost resistance (up to 100 cycles) are quite suitable for low-rise construction and use as hanging enclosing structures.

Structural thermal insulation wall panels with openings

GOST also classifies expanded clay concrete wall panels according to the following criteria:

- According to the static operating scheme - load-bearing, self-supporting and mounted.

- By design - solid (cast as a whole) and prefabricated (assembled from individual blocks held together by welding, mortar or glue).

House box built from prefabricated wall panels

Note. Prefabricated panels have increased crack resistance and can be cut into elements of the required dimensions.

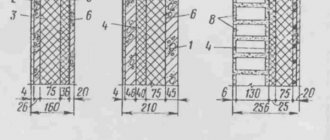

- By the number of layers - one-, two- and three-layer. Single-layer - with an internal air cavity and finishing layers: the outer one is made of vapor-permeable concrete and the inner one is made of heavy cement mortar. Two-layer ones consist of a load-bearing layer of dense light or heavy concrete and an insulating layer of light cellular concrete. In three-layer panels, between these layers there is thermal insulation from a layer of foam plastic, foam glass or glass wool.

For reference. GOST 11024-84 divides all expanded clay concrete panels into external ones for unheated buildings, single-layer and layered ones made of heavy concrete with thermal insulation, and partition panels made of concrete of different grades.

- When cut into elements, panels are produced in the form of single-row corner and row, as well as strip elements of vertical and horizontal cutting.

In Figure 2 - horizontal strip panel, 3 - plinth panel, 4 - corner panel, 5 - vertical inter-window insert

- By strength grade - from M10 to M500.

The strength and density of the panels depend on the concrete formulation, the number of layers, and the type of thermal insulation filler. These and other characteristics should correspond to the maximum with the place in the building structure that this or that wall panel will occupy: it will be a partition, a load-bearing wall of the basement or attic floor.

Fencing element made of wall panels

For example, three-layer panels, which have excellent sound insulation, are not used as load-bearing enclosing structures due to their low strength. Only hinged ones in frame-panel housing construction. The instructions require mandatory calculations of the load on such slabs and its correlation with their characteristics.

In the photo - the construction of a frame-panel expanded clay concrete house

Dimensions and weight

One of the important factors according to which expanded clay concrete wall panels are chosen is the weight of the product. It affects the total mass of the structure, the choice of foundation design, and even the installation process. On average, their use makes it possible to reduce the total weight of a building by 30% compared to the same structure made of reinforced concrete panels.

The main parameters that influence how much expanded clay concrete panels weigh are the dimensions of the slabs and the grade of concrete used to make them. Overall dimensions, in turn, depend on the purpose of the element, and they may differ from one manufacturer to another.

Note. When marking wall panels, rounded dimensions of length and height are used in decimeters, and thickness – in centimeters. For example, a two-layer external wall panel with dimensions 3995x2650x30 mm is designated 2НСН 40.27.30.

Expanded clay concrete wall panels – dimensions L and H in dm, B in cm

For comparison, here are a few examples of the mass of panels of different sizes made from M50 concrete:

| Length, mm | Width, mm | Thickness, mm | Slab weight, kg |

| 5980 | 1180 | 30 | 2510 |

| 5980 | 1780 | 30 | 3760 |

| 1180 | 1180 | 30 | 500 |

| 6330 | 1180 | 30 | 2660 |

| 5980 | 880 | 40 | 3920 |

| 5980 | 1180 | 40 | 5250 |

| 6430 | 1180 | 40 | 5640 |

| 6430 | 1780 | 40 | 8420 |

| 2980 | 1180 | 40 | 2600 |

| 2980 | 1780 | 40 | 3950 |