Asbestos cement pipe: what is it?

Asbestos pipes are made from two main components, which are Portland cement and asbestos fiber. Water is used to obtain a uniform consistency. The use of these materials makes it possible to obtain a material that is light in weight and has a low thermal conductivity. Asbestos cement is a cement mortar that is reinforced with asbestos fiber. Asbestos undergoes a grinding process to a powdery consistency, after which it is separated into fibers. It is these fibers that are the connecting link in the concrete mixture.

Asbestos pipes gain strength by reinforcing concrete with asbestos fiber. This allows you to increase strength by 40% compared to conventional concrete devices.

A significant advantage of asbestos is its low thermal conductivity. It is due to their low thermal conductivity that asbestos pipes are used for the construction of sewer pipelines with high freezing rates. A significant advantage of asbestos pipes is the absence of electrocorrosion properties. If the service life of metal pipelines, in which the phenomenon of stray currents is observed, is reduced to 4-5 years, then asbestos pipes, with such a negative influence, can last tens of times longer.

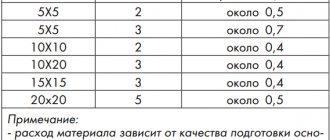

When choosing asbestos pipes, it is important to take into account such parameters as the diameter and length of the products. The products under consideration are of two types: pressure or non-pressure. Below is a table with technical parameters for pressure and non-pressure asbestos pipes.

Production

Asbestos cement is a concrete solution that is reinforced with asbestos fibers or fibres. The production technology for this material is as follows:

- After extraction, raw asbestos is mechanically crushed.

- The material is then fluffed to separate the fibers.

- Cement and asbestos are combined in proportions of 85 and 15 parts. Then add water to make a pulp.

- The suspension is placed on a drum with holes.

- Next, the composition is thoroughly mixed.

After squeezing, a kind of film remains, which is equal to the size of asbestos pipes 100 mm. This material is wound until the required dimensions of the product are obtained. When purchasing such products, you must require an epidemiological certificate guaranteeing the safety of your health and life.

What are the products in question?

In the Russian Federation, asbestos-cement pipes with a length of 3.9 to 5 meters are manufactured. The dimensions of asbestos-cement products are as follows:

- 100 mm;

- 150 mm;

- 200 mm;

- 250-500 mm.

The diameter of the pipes is an important parameter, therefore, depending on its size, pipes are used for various purposes. The strength of the products under consideration is influenced by such an important parameter as the thickness of the pipe walls. To connect asbestos-cement materials into the main line, special connectors made of a similar material or PVC are used.

Asbestos is a non-toxic substance that does not emit toxins or radiation. The only major danger is asbestos dust, which is formed when sawing pipes.

To avoid dust entering the body, work must be performed exclusively in respirators or masks.

Types of pipelines

Asbestos-cement types of pipes are used where it is impossible to use metal. Metal is not used where there is high humidity, so non-pressure options are taken into account.

The considered version of the products has a bending strength of 30 MPa. The compressive strength is equal to 90 MPa. These are quite significant figures, especially considering that the material has a low density.

Asbestos pipes can withstand 60 defrost cycles, which allows us to judge a long service life.

The material in question comes in two types: non-pressure and pressure, as discussed above. Let's look at the difference between an asbestos-cement non-pressure pipe and a pressure pipe.

- Non-pressure types of asbestos-cement pipes are used exclusively where there is no pressure. These application systems include: chimney, ventilation, sewerage. Non-pressure or gravity-flow products are used in construction, from which foundations and fences are constructed. This type of pipeline is used to construct underground channels for laying communications.

- Asbestos-cement options for pressure pipes are used where materials under pressure are transported through products. The medium of these materials can be presented not only in the form of liquid, but also gas. Pressure versions of the product are used for installation of water supply systems, gas supply and irrigation systems.

The differences between pressure and non-pressure pipes lie in their sizes. These dimensions are: wall thickness and pipeline diameters. In a free-flow pipeline, the wall thickness ranges from 7 to 18 mm. In pressure products, the wall thickness ranges from 9 to 43.5 mm. The internal diameter of the first option reaches values from 50 to 500 mm, and of the second type of pipes up to 600 mm. Pressure products can withstand pressure from 3 to 12 atmospheres.

To combine asbestos-cement products of pressure and non-pressure types, various types of couplings are used. For non-pressure products, ordinary asbestos rings are used, and for pressure products, rings with rubber seals are used.

Requirements

Initially, these pipes were used only for the construction of reclamation structures and were manufactured in accordance with the requirements necessary for this. GOST asbestos-cement pipes number 11310-90 determined the loads that they must withstand, and GOST 539-80 determined the standard sizes.

Later they began to be used in industrial and residential construction, but GOST remained the same. In addition to it, SNiP 41-02-2003 was drawn up, which regulated the parameters of the coolant that the pipes can withstand:

- Temperature up to 115 0C.

- Pressure up to 16 atm.

SNiP 2.04.02-84 was also issued, which specifies the use of asbestos pipes for laying underground water transportation systems. In this case, the length of the pipe should be 3.95 m or 5 m, and its cross-section should be up to 500 mm.

Advantages

Compared to other pipeline options, the products in question have a number of different advantages. These products are easy to install, highly reliable and durable. They are highly resistant to both aggressive environments and moisture. If we compare products with metal counterparts, the latter option has a much shorter service life.

Metal products require replacement or repair after 5-10 years. Moreover, metal pipes are subject to negative influences not only from the outside, but also from the inside. Corrosion causes a narrowing of the internal diameter, which results in a decrease in pressure. Even when carrying out repairs, which involves blowing out metal devices, the problem cannot be solved. This is explained by the fact that rust does not disappear on the walls and continues to destroy the material.

If water is supplied through asbestos pipes, the material only gets stronger over time. This is explained by the compaction of the walls due to the hydration of the cement mixture.

Some of the main advantages of asbestos-cement products include the following factors:

- The material does not require waterproofing.

- Resistance to temperature fluctuations.

- There is no electrical conductivity.

- High resistance to aggressive environments and moisture.

- There is no condensation when cold water is supplied through pipes.

- Fire safety.

- Possibility of transporting liquid through pipes with a maximum pressure of up to 12 atmospheres.

- The average service life is 30-35 years.

Studies that were carried out in Germany, Switzerland and the USA confirmed the fact that asbestos is a safe substance among its analogues. Once it enters the body, rapid elimination occurs.

Features and technical characteristics of a/c pipes

Asbestos-cement pipes are usually used for laying straight pipelines, since the material is quite fragile and the use of a/c tees and corners is irrational.

We recommend that you read: Is it dangerous to use galvanized pipes in water supply systems?

The fragility is due to the fact that during rotation in a centrifuge, asbestos fibers are randomly located in the product. For a solid pipe this does not matter, however, for shaped products it is critical.

If it is necessary to turn or branch the pipeline, cast iron fittings are used. When working with small diameters, it is permissible to use polymer products.

Advantages and disadvantages

The advantages of asbestos-cement pipes include:

- immunity to moisture, anti-corrosion properties (can be laid directly in the ground without additional protection, even in conditions of high humidity);

- resistance to stray currents (in underground pipelines), since the material is a dielectric;

- the lowest coefficient of linear expansion compared to all other materials from which they are made;

- fire resistance (asbestos cement does not burn, and melting begins at temperatures above 1500 ºС);

- the material also withstands low temperatures typical of northern climates;

- the heat loss coefficient is lower than that of metal products;

- the internal walls of the product have an absolutely smooth surface, thanks to which there is no risk of pipe “overgrowing”, and the level of resistance to moving media is reduced;

- a/c pipes are very easy to install and do not require special equipment;

- asbestos cement’s immunity to external influences and chemical inertness ensure a long service life;

- the cost of a/c products is lower than the price of metal ones.

The disadvantages of asbestos cement include the rather large weight of structures, as well as poor resistance to mechanical impact damage (it can break due to external force).

Specifications

Asbestos-cement pipes are produced in accordance with GOST No. 1839-80 (for non-pressure systems) and GOST No. 539-80 (for pressure pipelines). The type determines the scope of its application and installation features.

Flaws

Like any material, asbestos-cement pipes have some disadvantages. It is important to note them in order to determine the need to use them for certain purposes. The main disadvantage of the materials under consideration is fragility. During transportation or installation, any mechanical impact can lead to damage to the integrity of the product.

Asbestos-cement pipes cannot withstand heavy weight, which leads to damage to sewer lines and pipelines. When installing chimneys made of asbestos, there is a violation of the integrity of the products, and when exposed to high temperatures, such materials can explode. The products also do not have sufficient heat capacity, so they are not able to maintain the necessary traction. Soot settles on the inner walls of the pipes, which over time helps to reduce the diameter, and therefore the throughput and traction.

Asbestos cement pressure pipes

All pipes are divided into two types: pressure and non-pressure. First, let's look at the scope and dimensions of pressure pipes.

These pipes are designed for transporting liquids under pressure. More often they lay heating mains, as well as hot and cold water supply systems. Such pipes undergo additional quality testing, since any irregularities in the inner wall can lead to deformation of the pipe under the influence of high pressure.

The length of the pressure pipes is 3.95 m or 5 m, but the cross-section varies more:

- 100 and 150 mm – pipes for laying water supply and ventilation systems;

- 200 mm and 250 mm – used for laying network lines;

- 300 mm - used for arranging drainage;

- 400 mm – also for water supply systems;

- 500 mm is the maximum internal diameter, which is used only in industrial buildings.

All asbestos-cement pressure pipes also have markings indicating the operating pressure of the product:

- VT6 – 6 kgf/cm2.

- VT9 – 9 kgf/cm2.

- VT12 – 12 kgf/cm2.

- VT15 – 15 kgf/cm2.

Production Features

The manufacturing process of the products in question involves performing the following manipulations in production:

- Initially, asbestos must be crushed.

- 85% cement and water are added to 15% asbestos.

- The prepared mixture is poured into a special drum in the form of a mesh, in which the solution takes the shape of a pipe.

- After squeezing, a film is formed, the thickness of which does not exceed 0.2 mm. The width of this film is equal to the future length of the product.

- The film is wound onto the drum, resulting in the formation of a product.

The result is a pipe of a certain size and appropriate diameter, which is ready for use.

Characteristics

An asbestos-cement pipe, the dimensions of which we will consider below, is produced by chemically mixing asbestos fibers and a cement composition. The result is a unique material that becomes safe for the human body, since no further release of dust is observed.

In 2001, the Russian Ministry of Health adopted a resolution on hygienic standards related to the use and processing of asbestos cement. According to them, such products are not dangerous and are comparable in terms of the level of threat to the body with many other materials used in industry and everyday life.

As an example: at the Sukholzhskabocement plant (Sverdlovsk region), not a single case of cancer was registered among 700 workers. The products produced are in demand not only on the domestic market, but also abroad. More than one million kilometers of pipes of this nature are produced in Russia, and the total annual turnover is about 3 million km.

Installation features

Pipe laying is carried out according to certain requirements. These requirements include the following factors:

- Pipes with an internal diameter exceeding 150 mm require additional processing. It is required in order to obtain the appropriate dimensions and roughness.

- The products are connected using special couplings. These couplings are equipped with grooves as well as corresponding rubber sealing rings. For a certain pipe size, appropriate couplings are used. This type of connection design allows for a high-quality fit of the pipe to the coupling, which is important in the presence of internal pressure in the pipeline.

- A radial gap is left at the junction of the products. Such a gap is required in order to ensure deflection of the pipeline when the seal fails.

- Installation of pipes with diameters of more than 150 mm is carried out directly with indentations. This is done for the purpose of eliminating the need to install additional linear compensators.

When asbestos pipes are heated to temperatures above 100 degrees, the walls increase (asbestos modification) by 0.4 mm. To avoid failure of the rubber seal, it is deformed by the end parts by 0.2 mm.

When installing asbestos-cement pipes, the need for welding work is eliminated. This makes the job easier and also speeds up the installation process.

Pipe laying

Pipes with a diameter of up to 200 mm are laid on the bottom of the trench manually, and pipes over 200 mm are laid by a crane, and in places inaccessible, using ropes or soft cables, tripods and other devices. In this case, care must be taken not to damage the walls or ends of the lowered products (Fig. 5).

Rice. 5

At the ends of each pipe, make marks with a pencil at a distance equal to 0.5 l + 0.5 cm from the end (where l is the length of the coupling), which make it possible to determine the correct position of the coupling after installing it in place (Fig. 6).

Rice. 6

To speed up the process and avoid errors, marking should be done using a template.

Before lowering the pipe into the trench, a coupling equipped with rubber rings is put on one end of it. For heating systems, rubber rings made of heat-resistant rubber are used according to TU 59-279-97.

When installing the rings into the grooves of the coupling, it is necessary to distribute them evenly so that the rings protrude equally from the grooves. The recesses in the body of the rings must face the inside of the coupling. Then the coupling is completely placed on the pipe so that the end of the pipe is visible (Fig. 7).

Rice. 7

To make it easier to slide the coupling onto the pipe, it is necessary to lubricate the outer surface of the pipe at both ends for a length of 200-250 mm with a soap solution; pastes or shampoos can be used. The pipes lowered to the bottom of the trench are laid along a cord, a plumb line and a sight line, for which the bottom of the trench must first be carefully checked and leveled. The ends of the connected pipes in the trench are centered. The distance between the pipes is 10-12 mm. To level the pipes during installation, additional soil is tamped from the sides of the pipe.

The maximum deviation of the axes of two adjacent pipes (bending at the joint), if necessary, is allowed up to 3°. It is necessary to ensure that each pipe being laid touches the bottom of the trench along its entire length with at least a quarter of its circumference.

Requirements for the production of asbestos-cement pipes

There are some requirements for the production of asbestos-cement pipes. Manufactured products must meet the following state standards:

- The diameters of the pipelines must comply with the requirements in accordance with GOST 539-80.

- After manufacturing the materials in question, they must be tested in accordance with GOST 11310-90.

During the Soviet Union, the products in question were used for the construction of reclamation canals. In those days, the use of such products for the construction of civil and industrial construction projects was not envisaged. The reason for this was a worldwide ban due to the harmfulness of asbestos. They became popular after the collapse of the Soviet Union, as chrysotile asbestos, which is harmless, began to be used for the manufacture of products. It was after this that appropriate standards were developed for the production of asbestos pipes for any needs.

In Simferopol, during the Soviet Union, an asbestos-cement highway was built, the length of which is 20 km. To construct this structure, pipes with a diameter of 700 mm were used. Today, products of this diameter are not produced.

Pipe material and safety

Many consumers believe that asbestos-cement pipes are harmful to humans, but in the modern world this is a myth. A negative attitude towards them arose due to the widespread use of amphibilic asbestos, which is resistant to acids, which settled in the lungs for a long time and led to the occurrence of malignant neoplasms. Now such asbestos is completely prohibited, and it has been replaced by a new one - chrysotile, part of which dissolves in the lungs, and the other part is excreted. This is what will be discussed further.

Asbestos is made from hydrous magnesium silicate, a natural material with the addition of various additives. When making a pipe, it is tied with cement, which gives the final product additional strength and also minimizes the formation of asbestos dust when working with it.

Features of cutting products yourself

During the installation of asbestos cement pipelines, the need arises not only for connecting products, but also for cutting them. To perform this procedure, you will need to use a grinder and a diamond-coated disk.

Initially, you need to mark the place where the cutting will be done. To do this, use a tape measure, as well as chalk or a pencil. After the product has been marked (preferably along the entire outer diameter), it should be securely fixed. It is impossible to use a vice or similar devices for such purposes, as the integrity of the product will be compromised. At home, you can fix the product using two bricks or bars of the appropriate size.

After this, be sure to wear a mask or respirator to prevent inhalation of asbestos dust. A tool with any disk is suitable for cutting products of various diameters. After all, cutting will be performed sequentially along the marking line. The video below shows the process of how to properly cut asbestos products at home.

Another important point is the possibility of connecting asbestos products using plastic couplings. Such couplings are used for products with a diameter of up to 150 mm. The connection using PVC couplings is made by heating the coupling with a hair dryer. Instead of a hairdryer, a tank of hot water is used, into which the muff is lowered for 10 minutes. After this, the coupling is put on one end of the pipe, and then on the other until it stops.

Asbestos-cement products are popular. With their help, the process of constructing sewer lines is simplified not only for drainage, but also for laying communications.

Pipeline repair

Despite the good load-bearing capacity of chrysotile cement pipes, when damage occurs (cracks, breaks), there is a need to replace the pipe. To replace a chrysotile cement pipe, determine its location in the ground based on traces of water leakage. Remove the top layer of soil with an excavator, remove the remaining layer of soil 100-150 mm manually with shovels. Clean the damaged pipe and the two outer couplings, as well as the ends of adjacent pipes. Dig pits under the couplings and slide them onto the pipe being replaced using the devices specified in point 8 and remove the pipe from the trench with a crane (Fig. 12).

Rice. 12

Install couplings with rubber rings at the ends of the new pipe, lower it to the bottom of the trench and align it with the axis of the pipeline. Clean the adjacent ends of the pipes from dirt and, if necessary, rinse with water.

Shift the couplings to the designed location using the devices in point 8. If there are no new couplings, you can use old couplings that are suitable for use after cleaning the internal part from dirt and installing new rubber rings.

Pack soil from the sides of the pipe using a manual wooden tamper and backfill the excavated soil into the trench.