The construction of a concrete bowl, despite the emergence of new designs, is the most common option for constructing stationary pools. However, this material tends to absorb moisture, which subsequently destroys the structure.

Agree, I wouldn’t want to spend a lot of money on building an artificial reservoir only to find cracks in a couple of years. Timely waterproofing of the pool will help prevent the appearance of defects in the concrete bowl.

We will tell you about the most effective methods of moisture protection, and also describe step by step the technology for constructing a water barrier.

Why waterproof your pool?

Concrete is a strong and durable material, but it is characterized by increased porosity. Water that has seeped into the thickness of the material is easily absorbed and retained for a long time, becoming a favorable environment for the development of mold.

When exposed to sub-zero temperatures, such a wall becomes a conductor of cold, and freezing of the liquid leads to the appearance of cracks and mechanical destruction of the structure.

Due to the porous structure, concrete or reinforced concrete mass is not able to resist water seepage into the structure

The installation of reliable waterproofing of the inner surface of the pool bowl is beyond doubt, since it is filled with water. However, destruction can also occur from the outside.

Concrete is characterized by the so-called “capillary suction” of liquid, when moisture is drawn in from the environment - soil, air with high humidity, and precipitation. In this regard, the outer side of the pool bowl is also necessarily subject to waterproofing measures.

When constructing a pool bowl from individual concrete slabs or blocks, poor-quality waterproofing leads to gradual destruction and leaching of the mortar in the seams and the occurrence of active leaks

Often the walls of the pool are built from separate blocks. In this case, the connecting seams pose a danger. The strength of the connecting mortar is significantly lower than the strength of concrete slabs. Therefore, if water begins to seep in such a place, then under the influence of the pressure of the mass of the liquid, the material quickly collapses.

There is first a drip of seepage, then a small drip that washes away the solution particles and turns into a decent leak.

The material for waterproofing the pool bowl must be compatible with adhesives for ceramic cladding or polymer finishing (+)

Liquid rubber

https://www.youtube.com/watch?v=h3-VIzMKLlA

Read more: Do-it-yourself pyrolysis boiler, drawings and principle of operation

Liquid rubber

Liquid rubber is called bitumen-polymer mastic. It adheres well to the surface and has good waterproofing qualities. It must be sprayed onto the surface in several layers. For this work you will need a special compressor or brush (using a roller or brush will take much longer).

Application of liquid waterproofing

How to make waterproofing with liquid rubber? Immediately before applying the composition, the entire surface of the pool bowl must be leveled and treated with a composition that will degrease it. After that, using a special compressor or a brush (if we are talking about independent work), the rubber must be applied to the surface so that the composition evenly covers it.

Liquid glass

Liquid glass is a solution consisting of potassium or sodium silicates. This waterproofing option can be performed during the construction of the pool. Liquid glass is added to the concrete itself, in a ratio of 1 liter of glass per 100 liters of finished concrete. Thanks to this, it becomes more durable, resistant to mechanical damage and will last longer. And what is most important for you, liquid glass will allow concrete to reduce its ability to absorb moisture.

Application of liquid glass

The work is not difficult, all you need is:

- Prepare the surface by removing all dust, dirt and grease stains. If the concrete is smooth, it should be sanded to roughen it so that the glass will adhere better, penetrating deeper.

- Prepare liquid glass according to the instructions on the package.

- Apply the composition evenly to the surface. As the glass dries, begin applying the second coat. Use a wide brush or roller.

- After drying, everything is ready for the next decorative layer.

Methods for moisture protection of concrete structures

Waterproofing can be surface, internal or combined.

To ensure moisture protection of structures made of monolithic concrete or concrete blocks, the following means are used:

- Deep penetration compositions - clog even microscopic cracks, working at the capillary level.

- Additives for sand-cement mixtures increase the hydrophobicity of concrete.

- Liquid glass is a composition that, after hardening, forms a solid, moisture-proof layer on the surface.

- Liquid and viscous compositions – so-called liquid rubbers and coating waterproofing, forming a strong elastic membrane.

- Rolled film coatings glued to the surface of concrete.

Each product has its own characteristics, which determine the scope of application and method of application.

Image gallery

Photo from

Carrying out waterproofing measures

Cement-based treatment

Spraying polymer waterproofing

Laying the polymer membrane

Penetrating waterproofing compounds

Penetrating materials are cement-sand mixtures with active chemical additives. Dilute with water and apply to a well-moistened surface.

Active substances in the presence of water begin to react with particles of the concrete mixture - free lime. As a result, insoluble crystals of calcium hydrosilicates and hydroaluminates are formed.

In this way, the concrete is compacted deeply - the active components of the waterproofing, due to capillary suction, penetrate even the smallest cracks. A moisture barrier is formed.

When all the water molecules have reacted, the crystal formation process stops. Renewing contact with the liquid restarts it, causing even greater compaction and waterproofing.

Immediately after applying the protective layer, the active substances begin to interact with water molecules and concrete particles, forming insoluble crystals. Capillaries and microcracks are filled, which subsequently blocks the entry of water into the thickness of the material (+)

The thickness of the formed layer can reach 10-20 cm. The protection is not afraid of mechanical damage, increases the frost resistance of concrete and the durability of the entire structure.

However, penetrating waterproofing does not provide 100% protection against moisture during constant contact with liquid. Therefore, it is used as a pre-treatment before applying the main protective layer.

Image gallery

Photo from

Waterproofing slab joints

Sealing the pipe outlet

Application of polymer paste

Surface treatment with waterproofing

Hydrophobic additives for concrete

The principle of operation of waterproofing additives is the same as that of penetrating compounds. Only in this case, not only the layer at the surface is protected - the entire mass of material becomes hydrophobic.

The calcium hydroxide, or free lime, in ordinary concrete leaches over time, leaving a large number of microscopic capillaries and cavities.

Active additives added to the mixture already at the concrete hardening stage interact with calcium hydroxide and water molecules. Growing in the solution, they fill the resulting microcavities and pores.

A cast concrete structure or individual blocks acquire the properties of a stone monolith. With further exposure to water, the surface of the structure becomes even more compacted.

A structure made from such concrete not only has moisture resistance - it is characterized by increased strength, frost and heat resistance, and resistance to the aggressive effects of environmental chemical compounds.

Additives not only help fill micropores - larger cavities are lined with a layer of insoluble crystals. Due to this, the wettability of the surface is minimized and the effect of capillary retraction is eliminated.

Additives change the surface properties of concrete. The wettability is almost completely removed due to the fact that when it hardens, it becomes covered with a layer of insoluble crystals.

However, in addition to the positive properties, this characteristic also has a disadvantage. The formation of a waterproof layer leads to low adhesion with adhesives and plaster. Therefore, before applying finishing coatings, it is necessary to take measures to increase the surface roughness of the material.

Liquid glass is an effective remedy

Liquid glass is a solution of potassium or sodium silicates. The composition is a transparent liquid mass, which, when hardened, forms a solid glass-like layer. The principle of operation of such waterproofing is based on the ability of the solution to spontaneously harden.

Thanks to its fluid texture, liquid glass fills the pores and cracks of the protected surface. Due to this, possible paths for the passage of liquid are completely blocked. The composition makes the treated concrete surface waterproof and increases its strength.

Liquid glass has neither color nor odor. It fills pores and microcracks, forming a transparent moisture-proof layer on the surface

The composition is characterized by good adhesion and is easy to apply - by roller, brush or spray. The treatment is carried out in two or three layers, waiting for the applied solution to completely harden.

It should be borne in mind that liquid glass sets very quickly. Therefore, some skill is required to carry out the work. This creates difficulties when waterproofing the tank yourself.

The frozen layer has properties close to glass - it is hard and quite fragile. For treating surfaces that are constantly in contact with water, it is used only as a basis for gluing with polymer films.

Liquid and viscous waterproofing

Easy to apply and effective liquid products are becoming increasingly common. These are compositions based on bitumen, latex, silicone, and polymers. They are applied to the surface with a regular brush, spray or roller.

The compositions are characterized by good adhesion to the surface - they fill micro-irregularities, pores and cracks, forming a dense, moisture-proof membrane.

Viscous moisture-proofing compounds can be applied without the involvement of specialists - using a brush or spatula. The compositions allow non-simultaneous application of layers - adhesion of the material occurs at the molecular level, and as a result a seamless coating is formed

Liquid insulators are divided into two types:

- Aqueous emulsions . They have almost no smell, hardening occurs only due to polymerization processes.

- Compositions based on organic solvents . When applied and hardened, they release toxic substances and are therefore not recommended for indoor use. After application, the solvent evaporates, leaving an elastic hydrophobic base on the surface.

Products most often do not require pre-treatment of the surface. Apply in several layers. The result is a strong and elastic membrane that has no joints or seams.

Such a waterproof barrier is not afraid of the water hammer of the water supply system, nor the pressure of the liquid, nor the shrinkage of the concrete structure and the appearance of small cracks in it. The film will remain intact.

When using colored liquid rubber, the waterproofing layer can also serve as a finishing coating, allowing you to save significant money

There are the following compositions of liquid and coating waterproofing:

- Bituminous . This is a traditional waterproofing - a viscous organic compound of deep black color. It is applied hot, which makes the technology a fire hazard. In addition, the coating does not withstand low temperatures and lasts only 6-7 years.

- Bitumen-polymer. The composition does not require heating before application. The addition of polymers makes the composition more elastic and frost-resistant. Increases adhesion to the treated surface. Used outdoors or in ventilated areas.

- Bitumen-latex, or liquid rubber. Latex is harmless and odorless, so the product can be used for interior work.

- Water-based acrylic solutions. Contains mineral fillers and pigments. They can be white or colored. These are used for the finishing layer, which does not require additional painting or lining.

Colored polymer mastics are often used independently, without any finishing coating. In this case, to increase the wear resistance and strength of the coating, a reinforcing fiberglass mesh is embedded in the first layer of the applied mass. Wait for complete polymerization and cover with a second layer.

Such a protective barrier can withstand even severe mechanical stress.

Image gallery

Photo from

Waterproofing a small pool

Preparing a reservoir for protection

Waterproofing the pool bowl

Composition application technology

The disadvantage of almost all such compositions is that ultraviolet radiation has a negative effect on the finished coating, including loss of elasticity and cracking. Therefore, outdoor pools are additionally coated with a protective agent.

Coating with polymer films

Covering the concrete surface with PVC film is the most economical method of waterproofing a swimming pool. The film is a ready-made membrane with a thickness of 1-1.5 mm, supplied in rolls. It is lightweight, resistant to aggressive chemicals, and completely waterproof.

Membranes can be smooth - for easy cleaning, or with a rough surface - for covering stairs and the bottom of children's pools. Those reinforced with fiberglass mesh are more durable and last longer. Non-reinforced ones are cheaper, but their service life is only 5-6 years. After this, the polymer film must be replaced.

Waterproofing concrete with polymer membranes requires a professional approach, and doing it yourself is quite difficult. Preliminary surface treatment with penetrating waterproofing or liquid glass is required.

The film should be laid on a layer of geotextile to avoid condensation and prevent friction of the membrane on a rough surface.

In this case, good adhesion of the film to the surface should be ensured to prevent peeling. Welding of seams is carried out using special equipment. The connection must be tight - the slightest inaccuracy will lead to liquid penetration under the waterproofing layer.

Polymer membranes for waterproofing can be either plain or imitating tiles or mosaics. This is an inexpensive way to create an interesting, unique design for an artificial pond.

How to prepare a pool for waterproofing installation

When preparing a structure for treatment with moisture-proof materials, special attention should be paid to the condition of the concrete.

Instructions for effectively waterproofing a swimming pool assume that the bowl will initially be endowed with the necessary moisture resistance. This is ensured by compliance with construction technology:

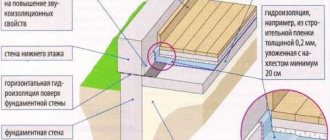

- Filling the bottom of the pit. The first moisture-protective contour of the base is a sand and gravel backfill. After leveling the bottom of the pit, it is filled with a sand-gravel mixture in a layer of approximately 20 cm. The mixture is thoroughly moistened and compacted. Then reinforcing bars and beacons are laid on the base, which are used as guides when filling the bottom.

- External waterproofing of formwork. The formwork for the walls of the pool bowl is assembled from thick plywood or boards. The outside of the structure must be wrapped with thick polyethylene film, which will prevent concrete from leaking during pouring and will facilitate further external processing.

- Pool bottom concreting. Concrete the bottom using a high-quality mortar with a high degree of frost resistance. The optimal layer thickness at the bottom is 30 cm or more.

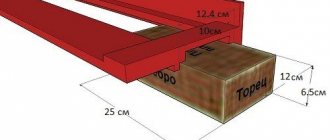

- Pouring formwork with concrete. After the initial polymerization of concrete at the bottom, you need to pour the formwork. In order for the walls to have sufficient moisture resistance, their thickness must be at least 20 cm. The filling solution is prepared on the basis of cement not lower than M400 with the addition of sifted sand 1.5-2 mm and gravel with a fraction of up to 10-20 mm. The solution must be compacted using a deep vibrator or bayonet.

- Drying a concrete pool. Dismantling of the formwork is carried out 10–14 days after pouring. Then you need to do a rough leveling of the surfaces, rubbing out all the defects. Leave the structure to dry, not allowing the concrete to dry out. It takes about 28 days for concrete mortar without additives to fully gain strength.

- Aligning the walls to the grid. We level the internal surfaces of the pool with a moisture-resistant cement composition. To ensure maximum traction, alkali-resistant fiberglass mesh should be used. Before leveling the pool walls, you can additionally protect them from moisture using a penetrating compound.

- Sealing joints between walls and floors. The area where the walls meet the floor most often suffers from leaks. To prevent leakage, the corners must be glued with a strip of plaster mesh and carefully sealed with mortar. If possible, use a special sealing tape, which must be glued to the concrete under a layer of leveling mortar.

After this, the bowl is protected internally and externally from water using selected materials.

Internal and external waterproofing of the pool

Measures to protect the structural elements of the tank from moisture should be carried out on both sides during the construction stage of the pool. There are internal and external waterproofing of the pool. External waterproofing is installed to protect the structure from the penetration of groundwater.

Internal - protects the structure from the effects of liquid, which with its mass presses on the surface of the bowl.

The choice of waterproofing methods depends on the location of the pool - outdoors or indoors, air humidity, the height of the aquifer, and the type of soil.

Protecting the reservoir from groundwater

The pool should be protected from groundwater penetration at the construction stage - before the bowl is erected. A sand cushion is placed under the structure, on which an overlapping sheet of roofing material or other dense waterproof material is laid.

If groundwater is close, it will also be necessary to install a waterproofing screen made of clay or loam with a thickness of at least 30 cm.

Applying a penetrating waterproofing solution does not require special skills. This can be done with a hard brush. If the structure is built from separate blocks, then the seams must be treated with this composition

To strengthen concrete and increase its hydrophobic properties, special additives or liquid glass are added to the sand-cement mixture. However, this requires strict adherence to the recipe and proportions.

This is quite difficult to do when building a pool yourself. At home, it is easier to treat the finished structure from the outside with liquid glass or penetrating waterproofing.

When installing a swimming pool in a house, penetrating waterproofing will protect against water seepage from the pool bowl. In this case, the concrete will begin to harden inward - towards the movement of the liquid, preventing it from passing out and preventing flooding of the space surrounding the pool.

On immovable soils (rocky, semi-rocky rocks, low-moisture sands with a low-lying aquifer), treatment with a penetrating composition is sufficient.

But clay soils are susceptible to frost heaving and seasonal changes. In such areas, microcracks may appear, into which moisture will begin to be drawn. Surface coating, especially liquid glass, will not help in this case.

To ensure that the movements of heaving soils do not affect the technical condition of the structure, they are removed from the pit before construction of the pool. The free space is filled with river or quarry sand without clay inclusions

Therefore, before constructing a concrete bowl, soils that are unstable during frosts are removed from the pit. Peat removal and loess loam and sandy loam removal are mandatory.

Reliable moisture protection is ensured by applying coating waterproofing or liquid rubber. The durable film formed after polymerization withstands aggressive influences and soil pressure and is not damaged by shrinkage of the concrete structure

Treating the outer walls of the pool with coating waterproofing creates a seamless elastic layer of moisture protection. In this case, the surface shape can be absolutely any

Waterproofing the inner surface of the bowl

Work to protect the inner surface from exposure to water must be carried out especially carefully. Errors in the waterproofing device lead to leaks and/or dampening of the concrete, which may not even be noticed. As a result, the material is destroyed and mold appears. Repair work ends up being very expensive.

Therefore, it is better not to skimp on internal waterproofing. To increase efficiency, several different methods are used at once.

The protective coating of the bowl must meet the following requirements:

- absolute moisture resistance;

- elasticity at the same time as strength;

- ability to withstand hydrostatic and dynamic loads;

- good adhesion to the surface;

- resistance to biological destruction by microorganisms, aggressive effects of water and antimicrobial additives contained in it (chlorine-containing preparations);

The material for internal waterproofing of the pool bowl must be environmentally friendly and resistant to ultraviolet radiation and temperature changes.

The following types of waterproofing meet these requirements:

- liquid rubber and water-based polymer compounds;

- deep penetration materials;

- protection by polymer membranes.

You can use a combination of three products at once, or limit yourself to two.

Finishing with tiles or mosaics looks aesthetically pleasing and can turn a simple pool into a work of art. This is a durable coating that can last for several decades. To protect the concrete structure from possible penetration of water through the seams, a reliable layer of waterproofing under the cladding is required

Covering the surface of the tank bowl with ceramic tiles or mosaics also remains relevant. This coating is durable - it is resistant to any impact, washes well and can easily withstand water pressure.

Individual elements are completely waterproof. The seams are dangerous. Even the use of waterproof grout does not guarantee against liquid penetration.

Therefore, before cladding, the surface must be treated with moisture-protective agents. The combination of a penetrating composition with a coating mastic is the most effective waterproofing of the pool bowl applied under the tiles.

For swimming pools located indoors, proper ventilation will play an important role in maintaining normal humidity.

Purpose of waterproofing in the pool

A person who has encountered construction at least once already knows the basics of waterproofing and what it comes with. But amateurs can quite seriously limit their knowledge in this area with the concept: “concrete and tiles are enough.”

And this is fundamentally wrong. Just waterproofing serves to prevent water from penetrating into the concrete, otherwise such constant seepage will lead to the destruction of your pool as a whole. Professionals distinguish two types of waterproofing: external and internal.

External waterproofing protects the pool from moisture penetration from the soil. This could be groundwater and sediment. And the internal one comes directly from the water that is in the bowl of the pool, and since the contact with moisture in the second option is constant, the attention is special and the work is more scrupulous.

If your pool is located outdoors, then both types should be performed; being indoors will allow you to get by only with internal waterproofing work.

When carrying out external waterproofing, plasticizing and mineral additives are added to the concrete mixture, which increase the water resistance and mechanical strength of the bowl and pool structure. You can use another option for waterproofing a pool with your own hands - installing special profiles made of self-expanding rubber. To secure both options, you can apply a special water-repellent mastic to the outer concrete wall of the pool. It is applied very easily and does not cause any questions or problems during operation.

But now we will take a look at the internal waterproofing, which is carried out directly inside the bowl and is of great importance for the proper and long-term functioning of your pool. Let's start with a description of the materials and tools that you will need to prepare before starting work.

Types of materials for waterproofing work in the pool

Waterproofing materials can be divided into two large categories: bitumen and polymer.

Bituminous waterproofing is materials made from tar. Tar is a processed product created under very high temperatures. Bitumen compositions are presented on the market in the form of roll materials and bitumen mastic. Mastic does not dissolve in water. When applied to the prepared surface of the bowl, a stable and durable coating is obtained that is not subject to corrosion.

Using bitumen products, the artificial reservoir will last a long time under protection from the threat of water destruction.

Polymer waterproofing is a product for waterproofing work that contains polyurethane. When applied to a surface, the substance forms a durable elastic film. Polymer protection has a long service life and is resistant to temperature changes. Due to its composition and release form, waterproofing is easy to work with and can be easily applied to objects of various shapes. In interior decoration, an important advantage of the polymer option is its ease of adhesion to concrete, tiles, glass and other building materials.

When choosing polymer waterproofing, the buyer considers the form of mastic, sealant and liquid rubber of varying costs. It is convenient to use mastic in hard-to-reach places with uneven surfaces. The gaps between joints and seams are filled with a viscous sealant. Liquid rubber is applied by direct spraying and immediately creates a strong connection with the surface, forming a protective layer.

According to the method of application, materials are divided into:

Coating

Mastics and penetrating impregnations, which are used in seamless waterproofing. The vulnerable areas of the concrete bowl - pores and cracks - are filled with a continuous layer. The advantage of the coating material is high-quality protection from moisture with little labor: the substance is applied with a spatula or brush and does not require special skills.

Sprayable

Presented with liquid rubber. The material is sprayed onto a previously prepared base. The mechanical method of application (using a compressor) allows you to treat a large surface area in a short period of time. The result is a seamless protective layer.

Rolled

They are rolls of roofing felt, PVC film, and film membrane. Placed manually on a concrete surface. The material must be hot to bond to the concrete. Gas burners are used for this. The resulting seams between the layers of material are subsequently fastened and additionally waterproofed.