Aerated concrete is used not only in the construction of houses and buildings, but also for beautification of personal plots.

Aerated concrete fence is an excellent option for a continuous structure. It is laid out much faster than a brick one and costs several times less.

If you decide to start construction yourself, then, following the recommendations of the masters, you will not experience any difficulties with its installation.

Users often search for:

The basis of the material is cement. Additional components - lime, aluminum powder. Aerated concrete is a type of cellular concrete. Its structure is porous. The blocks undergo long-term heat treatment under high pressure, which increases the strength of the raw material.

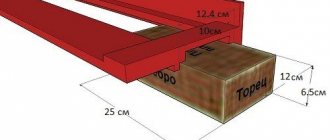

Photo: varieties of cellular concrete block shapes

Among the important advantages of aerated concrete are:

- Light weight, which is obtained due to the porous structure. This makes it easier to transport the material.

- Large block sizes. Significantly speed up the laying process.

- Excellent heat retention.

- It doesn't burn. therefore, it will become an obstacle to the spread of fire.

- Has excellent sound insulation. Therefore, it is convenient to install fences made of aerated concrete blocks near highways and railway tracks.

- High strength and durability.

- Easy to install. Even a beginner can handle masonry. The main thing is a little patience and accuracy.

- Low price. A fence will cost less than a brick or metal one.

But this material has a drawback that is worth paying attention to - the property of absorbing moisture, which is why the blocks become fragile and crack over time. To prevent damage to the material, finished fences are finished with protective agents and periodically plastered or painted.

In addition, the fence needs a foundation. But this is not a minus, but one of the stages of construction.

What to consider when choosing a material

There are two types of gas silicate blocks available for sale:

- full-bodied;

- hollow.

It is more economical to use the latter to create fences. In addition, hollow products are convenient to reinforce and hide wiring in them.

When purchasing, pay attention to:

- identical block sizes;

- uniform, uniform color coverage;

- smooth edges.

It is better to take material from one batch so that during construction there are no differences in dimensions or shades.

In addition to standard aerated concrete, decorative blocks began to be produced for exterior use. They are several times more expensive than regular ones, but are protected from moisture and do not require additional finishing.

A large selection of colors and textures allows you to make a fence that will harmoniously combine with other structures on the site.

Selection of aerated concrete blocks for fencing

Aerated concrete is produced on a cement base, it is a type of cellular concrete and has a porous structure, which helps reduce the weight of the blocks and improve qualities such as thermal insulation and sound insulation.

The blocks are available in several types - solid and hollow. To build a fence made of aerated concrete, experts advise using hollow products, as this will not only reduce costs, but will also allow additional reinforcement of the fence or hidden wiring.

You can erect an aerated concrete fence yourself and in a short time. This is facilitated by such qualities as:

- Large block sizes;

- Smooth product geometry;

- Ease of processing;

- Light weight.

Some manufacturers produce decorative aerated concrete blocks for fences. The blocks have different colors and textures, and are additionally protected from external influences, but their cost is quite high compared to conventional gas blocks.

The fence must be strong and reliable, so it is important not only to choose the right material, but also to carefully consider each stage of construction.

Installation of a fence made of aerated concrete blocks consists of three stages:

- Foundation installation;

- Construction of a fence;

- Exterior finishing.

Let's take a closer look at each of them and identify the key points at each stage of work.

Foundation

The construction of the foundation for an aerated concrete fence proceeds according to the following algorithm:

- Mark the area of the future fence and places for posts (2-3 meters from each other);

- Along the marking, dig a ditch half a meter wide and 50 to 80 cm deep (50 cm in dense soil, 80 cm in a wetland or unstable loose foundation);

- At the places where the pillars are installed, widen and deepen the ditch by 50 cm;

- Place a cushion of gravel and sand in the resulting holes - the layer thickness is about 20 cm;

- Install vertical pipes and check their levelness. Insert plugs into the pipes to prevent water from entering there.

- The space remaining after installing the pillars should be filled with stone or coarse gravel and filled with concrete mortar;

- Prepare and install permanent formwork around the perimeter of the future foundation; you can use sheets of plywood, pour crushed stone into the resulting space and fill it with concrete mortar;

- Leave the structure to dry for 7 – 10 days; to protect it from moisture, you can cover it with polyethylene;

- After the foundation has dried, it is necessary to carry out waterproofing; for this, the surface is covered with a special mastic and roofing felt is laid.

Depending on weather conditions, concrete structures gain full strength after 3 weeks, so it is important to begin further work no earlier than this period. Failure to comply with this rule may lead to the fact that the foundation will not support the weight of the fence and will bend or crack.

For installation work you will need a special adhesive solution for cellular concrete, cement-sand mortar, reinforcement and a spatula.

Block laying process:

- Clean the surface of the foundation from dust and dirt;

- Apply 20 mm thick cement mortar to the base;

- Lay out the first row of blocks. It is necessary to constantly check the horizontality of the blocks;

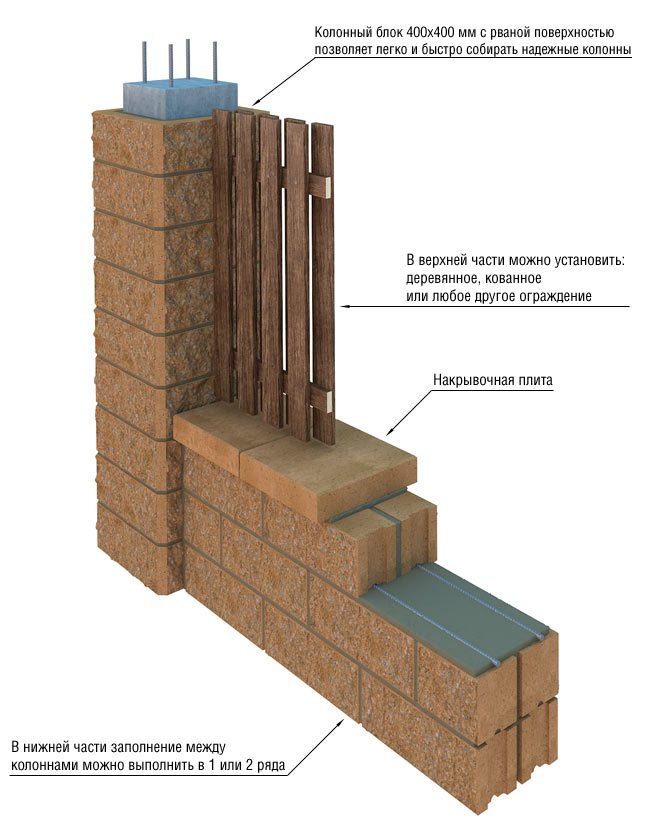

- Columns are laid out around the previously installed pipes, aerated concrete blocks for the fence posts are installed with a dressing of one and a half blocks, the first and subsequent rows of aerated concrete blocks are placed there;

- Lay reinforcement - a rod with a diameter of 6 mm is used as reinforcement; it is stretched between the fence columns and firmly fixed there;

- Lay the second and subsequent rows until the desired height is reached, glue is applied for fastening, the layer thickness should not exceed 3 mm;

- Strengthen fence posts made of aerated concrete blocks by pouring concrete mortar into the space between the pipe and aerated concrete blocks;

- Cover the upper part of the fence with tiles or profiles to protect it from moisture.

The first and third rows of blocks are reinforced.

To build a fence without installing posts, it is worth using solid blocks and reinforcing every few rows.

Finishing work

Finishing is one of the most important stages of installing a fence; it not only gives a finished look, but also protects the fence from premature destruction.

For the external finishing of the aerated concrete surface of the finished fence, the following materials will be needed: deep penetration primer for cellular concrete, reinforcing mesh or fiberglass mesh, plaster for aerated concrete.

Work process:

- Clean the base from dust and oil stains (if any);

- Cover the entire surface with a primer solution;

- Install reinforcing mesh;

- Apply the plaster in two layers, after the first has dried, the surface is primed again, the thickness of the second layer should not exceed 10 mm;

- After the plaster has dried, the base must be carefully primed; it is better to use solutions with a waterproof effect for additional protection from moisture;

- A special impregnation is applied to the resulting surface, which protects it from external influences. If desired, the fence can be painted.

When using decorative aerated concrete blocks, a primer and varnish or hydrophobic impregnation are used for finishing.

Step-by-step construction of aerated concrete fence with your own hands

We will analyze step by step how to build a fence from aerated concrete blocks for a summer cottage or a private house.

For high-quality creation, you must first draw up a diagram of the future fence and calculate the consumption of materials. To simplify the calculations, we recommend using a construction calculator.

Photo: solid

Materials, tools

For construction you will need:

- aerated concrete blocks;

- cement grade M 200;

- sand;

- crushed stone of small or medium fraction;

- Master OK;

- level;

- electric saw;

- electric plane;

- roofing felt, bitumen mastic (for waterproofing);

- profile pipes with a cross section of 10 cm (for poles).

A detailed list of materials and tools depends on the type of base chosen, as well as on whether the fence will be completely solid, made of blocks or combined with other materials (corrugated board, wood, metal).

Foundation arrangement

Despite the light weight of the blocks, the fencing is still oversized in size and requires reinforcement in the form of a strong, durable foundation.

- belt (on stable, rocky soils);

- ribbon-columnar (for soils with a large freezing depth, heaving);

- screw piles (on swampy, peaty soil).

Photo: territories

In some cases, it is possible to install a columnar foundation when the fence does not bear a large load. For example, the supports are made of aerated concrete blocks, and the sections are made of wood or corrugated board.

You can learn about methods of laying this type of base from the article: “”.

Installation of pillars

Often performed at the stage of foundation construction. The evenness and durability of the entire structure depends on the verticality of the mounted supports.

Popular rack types:

- round profile pipes with a diameter of 10 cm, wall thickness 3 cm;

- pipes with a square section 80*80*3 mm;

- screw piles with a monolithic grillage.

Metal supports must be coated with anti-corrosion compounds. It is better to treat the lower part with bitumen mastic. The distance between the pillars is from 2 to 3 m.

Laying work can be started after the foundation and supports have completely hardened, no earlier than 7–14 days.

The process of laying aerated blocks

Photo: the process of laying aerated concrete blocks using an adhesive mixture, for example: “Pobedit-Aegis-G-31”

At the initial stage, it is necessary to lay aerated concrete pillars around the metal supports. Dressing is carried out in one and a half blocks using cement-sand mortar. The layout is carried out so that the first and all subsequent rows of blocks go there.

The voids in the columns between the blocks and the metal pipe are filled with liquid concrete.

If necessary, elements are cut to the required size.

The rest of the laying process looks like this:

In the case where solid aerated concrete is used for laying the fence, you can do without installing pillars, but it is important to reinforce every 2-3 rows of blocks.

Finishing the finished fence

If the main material of the structure is standard aerated concrete, then finishing is a mandatory stage of construction. This will not only give the product aesthetics, but also perform a protective function.

After which it is allowed to begin applying decorative plaster or painting.

For plastering, reinforcement or fiberglass mesh is first attached, the first layer is applied, then time is given to dry. Next, a primer is treated, a second layer is applied, and painting is carried out if desired.

If you want to get a solid, reliable fence in a short time and at an affordable price, then aerated concrete will be a good choice. In addition, you can do the entire amount of work yourself.

A fence is the main attribute of any summer cottage. One of the main requirements for this design is strength and originality. Such parameters are typical for fence blocks. They are obtained from various solid materials with unique technical characteristics. Therefore, before purchasing this product, you should consider some of the subtleties of choosing blocks for the fence.

Features of the construction of garages made of aerated concrete

One of the important issues to be resolved at the design stage is the type of structure and its dimensions. The garage can be made as an extension to the house or a separate building, and its dimensions must be designed not only for the car, but also for the work area where the shelving will be located. Sometimes owners include an attic floor and a cellar in the project; the final estimate depends on these details.

The whole process can be divided into several stages:

- Clearing the site, marking and laying the foundation, laying a sand and gravel layer.

- Construction of walls (including window openings and gates).

- Installation of floor and roof.

- Interior and exterior finishing.

After pouring concrete into the formwork, it needs to harden and construction can continue in about a month.

Peculiarities

Fence blocks are cubic artificial materials. They are made from various solutions, which, after hardening, form a strong and solid structure.

Outwardly, they resemble bricks and are large in size.

Most fence blocks are hollow. This structure allows you to obtain an optimal ratio of strength and light weight. There are also solid products that consist of solid concrete or other mortar.

Blocks are a universal building material used to construct not only fences, but also small posts or fences. Some manufacturers produce them in the form of prefabricated elements, which, when joined, form a brick with empty space inside. These products make it easy to hide metal fence posts , creating a consistent style between column and fence.

Advantages and disadvantages

Fence blocks are used everywhere in construction, as they have several advantages:

- The construction of fences is speeding up several times.

This is achieved not only due to its larger size, but also to its correct geometric shape. Laying a rectangle does not take much time, since it is easy to level it in all planes. - Low price.

The blocks are made artificially, which reduces the cost of production compared to natural stone. This is also influenced by the large volume of the element, which can replace several bricks at once.

- Strength.

This indicator may vary depending on the structure of the product. Some blocks tolerate frost well, do not absorb moisture, and can also withstand significant loads. - Minimal care.

Fences made from these products can be used for a long time without restoration. At the same time, the top layer practically does not lose its original characteristics. - Variety of designs.

Many manufacturers supplement the top layer with various decorative effects. This allows them to be used when creating original landscape solutions. The blocks combine perfectly with metal, wood and other building materials.

- The blocks do not burn and do not support combustion.

This makes them safe for use in factories and other specific places. - Durability.

Some types of blocks can last up to 100 years, which is not always possible with brick or wood.

Fence blocks do not always allow their use in specific conditions.

This is due to the following disadvantages of the material:

- Laying the substance takes a lot of physical effort, which is not always practical.

- Heavy weight. Only a strip foundation can support a fence made of blocks, which must be additionally constructed before laying the material.

- High price. This feature is relative, since it all depends on the size of the fence and the products used. For example, a brick building will be much more expensive, since more material will need to be spent.

Evaluating the positive and negative sides of the blocks, it can be noted that they are excellent for the construction of durable structures. Moreover, all the shortcomings are leveled out over time and are not so significant.

Advantages and disadvantages of concrete block fences

If we talk about decorative advantages, then a fence made of concrete blocks could theoretically be inferior only to a fence made of processed natural stone. But they don’t make these for fencing private houses, and its only competitors are fences made of rubble stone and facing bricks. But they are inferior to him in several respects:

- Higher resistance to mechanical stress. Thanks to a smaller number of masonry joints and filling hollow blocks with concrete mortar with vertical reinforcement of the column and spans, a monolithic structure is obtained.

High installation speed. One block is superior to a single ceramic brick in all three dimensions and is easier to lay. Not to mention the complex laying of multi-format “wild” stone.

Wide selection of different textures and colors. This allows for greater maneuverability for the harmonious arrangement of landscape design.

Optimal price-quality ratio both in terms of the cost of materials and installation costs.

The market offers a large selection of colors and shapes of blocks Source doka-metal.ru

Otherwise, the advantages of a fence made of blocks are the same as those of a fence made of brick and natural stone:

- high service life;

good protection of the area from dust and noise if there is a road nearby;

reliable protection of the internal territory from prying eyes;

fire resistance and prevention of the spread of “grassroots” fire (according to the classification of natural fires).

The fence and the concrete fence posts themselves, which are made from blocks, also have disadvantages:

- Only professionals can perform quality work;

heavy weight, which requires the construction of a strong strip foundation.

Kinds

Fence blocks are classified according to several criteria. Depending on the structure of the top layer, they are distinguished into the following types.

Construction

These are ordinary blocks that are used to build fences. They also have cavities inside, but the top layer is completely flat. Externally, such products are unattractive, so they are often used to equip fences in industrial enterprises. They are distinguished by significant weight, so their installation is not always convenient alone.

Decorative

They are made from the same materials as the previous type. They differ in their textured outer layer, imitating a different structure. These blocks are valued in construction and are used almost everywhere.

Clay, artificial stone and concrete are used in the production of blocks. But in the manufacture of such products, many fillers are used. Depending on this, several more types of materials can be distinguished.

cinder block

Slag is used as a filler, which retains heat well and is lightweight. Different types of this substance can change the shade of the block. This allows you to change its color, but without applying an additional layer of paint.

Expanded clay concrete blocks

In their structure, they are largely reminiscent of the previous type, since expanded clay is baked clay. With its help, they reduce weight and also give the block texture.

Concrete blocks

Almost no filler is used here. Such products are also called besser, which corresponds to the well-known manufacturer of these blocks. Many manufacturers add gravel, screenings or crushed stone to the composition. They allow you to strengthen the structure and increase the strength and durability of the blocks.

Foam blocks

This group includes blocks that are produced from various components using foaming technology. Prominent representatives of foam blocks are gas silicate and aerated concrete products. Most manufacturers produce solid foam blocks, but there are also hollow options.

Sand block products are used to construct pillars. These column materials may differ in small dimensions and weight. Standard block dimensions are 20x20x40 cm.

There are other sizes on the market:

- 39x19x18.8 cm.

- 38x9.5x18.8 cm.

- 39x19x40 cm.

Construction of the fence base

Scheme of a strip foundation for a fence: A – the distance between the axes of the fence posts.

The foundation is, without a doubt, a mandatory component for creating a permanent fence. It is also called the “sole” of the structure; the entire load acting on the fence falls on it. In the case of laying blocks, it is advisable to lay a strip foundation along the entire perimeter of the future fence, so that it runs under the entire length of the fence.

To build a strip foundation, it will be enough to go 40 cm deep into the ground, but if the soil is soft, the recess should be at least 60 cm.

The width of the foundation is selected based on the size of the blocks you will use (for example, if the width of a hollow concrete block is 20 cm, it is advisable to make a foundation 40 cm wide). We should not forget about the reinforcement of the foundation. As a rule, steel reinforcement is used as an element for its reinforcement (the most popular in construction is A-3 reinforcement, which has a diameter of 12 mm).

According to experts, there is no need to build a three-dimensional frame: it will be more than enough to use a steel mesh with a mesh size of no more than 20 cm. Concrete for pouring the foundation is prepared directly at the construction site. If you have a power source nearby, it is best to use an electric gravity concrete mixer. This way you will significantly increase your productivity.

All work on the construction of the foundation is best carried out in the warm summer season, since the concrete solution sets very poorly at a fairly low temperature (-10°C). But if there is still a need to carry out work during the cold season, it will be necessary to add special frost-resistant additives to the concrete mixture, which will lead to higher construction costs. It should also be taken into account that when carrying out construction work in a very hot season (at temperatures above +25°C), it will be necessary to add more water to the concrete mixture, otherwise the concrete will not gain all the necessary parameters for sufficient strength.

Form

Today, all types of fence blocks are rectangular in shape. But they can only differ in the structure of the top decorative layer. The simplest products are made with a smooth surface. The advantage of such options is their high-quality joining during installation. Externally, they do not carry any decorative load and are used only as a building material in places where decoration is not so important.

Particular attention should be paid to the decorative block, which has a torn surface. On the surface of these products, a rough structure is individually formed, which resembles crushed stone (the second name for these products). With the help of such products it is easy to imitate almost any texture of natural materials. But the cost of such a block is much lower than natural products.

Decorative design

Today, many manufacturers are trying to diversify the style of blocks to give them an attractive look. This expands the scope of their application and makes similar building materials more popular.

Fence blocks can imitate several types of substances:

- Brick.

- Slate.

- A natural stone.

- Tile.

To add naturalness, the blocks are painted in different colors. Colored structures can be painted directly on site after installation. This approach is often used by designers to create unique structures and styles. Particular attention is paid to shades that are present in nature.

“Stone” products are suitable for almost any structure, as they can withstand high loads and are compatible with various construction approaches. If you use smooth blocks, then they can be decorated with additional finishing. It is easy to glue ceramic tiles, natural stone or apply decorative plaster to a concrete surface.

Any private house needs protection from inquisitive glances and ill-wishers, and in order for it to be not only beautiful and reliable, but also affordable, then for its construction you need to use lightweight and. Their prominent representative is foam products, and a self-built foam concrete fence meets all requirements, even the most stringent ones.

Lightweight concrete products

For the construction of fences, the buyer can choose from 2 types of cellular blocks: foam concrete and aerated concrete; we can talk for a long time about their advantages and remarkable characteristics. The best option for fencing is gas silicate products; they will make a fence more durable than foam products. Aerated concrete is more susceptible to the destructive effects of moisture than its cellular relative, however, with high-quality waterproofing, this problem is completely solvable.

As for durability, having purchased high-quality aerated concrete, you can fully count on its service for more than a decade. The costs of such blocks will be reduced significantly not only due to their low cost, but also to their impressive size, with the help of which a beautiful and reliable fence will literally grow before your eyes.

Advantages of a foam concrete fence

When choosing a material for building a fence, the first thing you choose is brick. A fence made from it is very durable and solid, it can make any house, even a modest one, look presentable, but its price and the cost of the masonry itself increase the cost of construction several dozen times. Such a barrier structure is very heavy and puts a lot of pressure on the foundation. The metal structure, although reliable, does not fully protect the entire area from prying eyes, and this is important. You can completely forget about protection from strong winds, and the cost of custom-made metal structures is not small.

Corrugated sheet metal as a fencing is a fairly common material; it is cheap, durable, lightweight and, what is very important, inexpensive. There is one significant drawback - it gives any, even a solid building, the atmosphere of a construction site.

Why aerated concrete

There are many variations in the construction of a good fence, the main range of materials that are presented to the buyer are corrugated sheets, bricks, metal structures, cellular concrete blocks of various types and types, and less often wood.

The first thing that attracts with its solidity and solidity is, of course, brick. At all times, high-quality structures have been erected from it, but there is a small “but” - this is an almost sky-high price not only for the material itself, but also for labor, and the weight of such a fence will be rather considerable. Again, you will have to spend money on a more solid foundation.

Tree

Wood as a fence is an expensive option, has low strength and durability, and, moreover, although it is treated with special chemical fire-retarding solutions, it is prone to fire. Maintenance and constant repair of such a structure is very tedious and expensive. The foam block is a fairly reliable structure, moreover, it puts minimal load on the base, and a high-quality foam concrete block allows you to build in a short time a good noise-imitating, durable, fireproof and, most importantly, a solid fence. Today, this is the best option for fencing buildings of a private, especially country house.

Choosing foam concrete

Usually, for maximum savings when building a fence, developers purchase low-density blocks, because this is not a load-bearing structure. The train of thought is correct, but the main point was missed that such material is very soft, and even a lazy person can make a hole in your fence with a simple movement of his hand, or foot, but it’s not so easy to spoil a more durable material. Therefore, it is better to take foam concrete products starting from a density grade of D700 and higher; large ones, more than 10 cm thick, are preferable. Another thing worth knowing when buying a foam block is that under the direct influence of water it will begin to deteriorate; in the kit for the foam block, immediately buy a protective one from moisture material. The best option is special liquid waterproofing agents; they are a bit expensive, but this will be more than offset by the low cost of the blocks and future durability. In any case, this option is much cheaper than brick and metal.

Construction stages

- Any construction begins with the choice of material; for a fence, a more acceptable option would be blocks that have dimensions of 50 * 60 * 17.5 cm.

- The foundation for such an aerated concrete structure is quite suitable for a pile, fastened with a grillage; for vertical reinforcement, you can use an ordinary pipe with a diameter of 4 mm, which is mounted into the grillage every 2 meters. For horizontal reinforcement, ordinary wire rod d = 8 mm is suitable, which is laid through each row.

- Having laid the foundation, it must be thoroughly waterproofed, after which the main masonry can begin. The first row of blocks, for more thorough fixation, are laid on ordinary mortar, all subsequent ones on. It is imperative to follow the rules for ligating blocks.

- Having built it to the required height, a seismic belt is laid on top of the fence; its construction is no different from installing a conventional armored belt on aerated concrete masonry.

- The columns for the gates were embedded in the base.

After this work, you can begin waterproofing the walls of the fence; it is carried out by priming in several layers with a special liquid solution suitable for these purposes. After the waterproofing has completely dried, a chain-link mesh is glued onto the walls for subsequent finishing, and plaster is laid on it. After which, the surface is treated with a hydrophobic primer.

Installation of corrugated board fencing, video

Conclusion

When planning the construction of a fence for your site from foam blocks, remember that high-quality material is the key to a reliable and aesthetic structure. When choosing blocks, do not give preference to price at the expense of the quality of foam concrete, otherwise such a building will not last you long. Be sure to waterproof both the foundation and the foam block walls themselves.

Foam concrete is one of the relatively inexpensive and accessible varieties of cellular concrete. That is why a fence made of foam blocks is in considerable demand, both among residents of private houses and owners of summer cottages. In terms of strength, foam concrete is significantly inferior to materials such as brick, but do not forget about the degree of environmental friendliness, which can only be compared with wooden fences.

The site begins with a fence

A fence made of foam blocks has unique characteristics, such as excellent mechanical strength and high insulation rates. Foam block is a porous stone. It is made by mechanically mixing cement, water, sand and synthetic foaming agents, which contribute to the creation of closed pores, which significantly improves its waterproofing properties.

There is no need to create certain atmospheric conditions for foam blocks to harden. This process occurs naturally. As for financial costs, a cinder block fence will be somewhat more expensive.

The options for finishing a foam block fence are very diverse.

In the manufacture of foam blocks, various synthetic foaming agents are used. The mass obtained as a result of mixing is poured into special molds, where the hardening (setting) process occurs. Thanks to this, each of the blocks has a clear shape and a complete absence of chips (at first). It is very convenient to apply subsequent layers of plaster.

Contains only five components

The process of making blocks is quite simple

For the production of foam concrete, exclusively organic components and minerals are used, which are considered environmentally friendly. It is also classified as a chemically neutral substance that is not capable of causing harm to the human body.

Finished product

Storage and transportation is carried out on pallets

What properties does the material used have:

- fire resistance;

- relatively light weight;

- low cost;

- simplicity and ease of installation;

- excellent sound insulation properties (like cinder block);

- the ability to combine with other finishing and building materials;

- low consumption of auxiliary materials (glue);

- primitive form;

- low thermal conductivity and density;

- resistance to possible temperature changes;

- high threshold of fragility.

Material advantages

Due to the negligible use of minerals, these fence blocks weigh almost nothing. This will allow you to save on building a fence by erecting it yourself, without resorting to outside help or renting expensive equipment. The low density of the material affects the overall load and weight of the structure, which eliminates the need to create a solid foundation.

Table of foam block weight depending on its size and brand of foam concrete

Preparing the fence foundation for concreting

Thick-walled pipes are perfect for arranging gates or wickets.

The use of cinder block is encouraged, however, only to create stronger pillars. The top layer of the fence foundation also needs additional waterproofing treatment. So, its surface is covered with a primer and a layer of bitumen-based paint.

Ready foundation before performing coating waterproofing and subsequent laying of blocks

Arrangement of fence posts and plinths

After completing the masonry process, it is recommended to think about arranging a reinforced fence belt that would be resistant to various seismological activities. In order to build an armored belt, you need to have wire, metal reinforcement with a ribbed surface, steel rods and a special hook for tying the rods together.

Do-it-yourself foam block laying

Fence installation

When the owners of the private sector have finally decided and bet on a fence made of aerated concrete blocks, they should begin alternate installation steps:

- First it is necessary. To do this, you need to dig to a depth of 50-60 cm. As for the type of foundation, for a fairly light material - aerated concrete, it is quite enough, for reliability it can be fastened with a grillage.

- After the foundation is ready, it should be installed, placed in a vertical position. Their diameter should be approximately 4 mm. The distance between pipes should be no more than 2 m.

- The next step is laying aerated concrete blocks. The process is carried out using bitumen mastic, then roofing material is laid on top of the mastic. Then the pre-purchased blocks are laid one by one on top of the composition. The first layer is laid on a mortar, which is 2 cm thick, while the remaining rows are attached to a mortar, the thickness of which varies from 2 to 3 mm.

Scheme of the design and installation of a fence made of aerated concrete blocks

- When the fence is erected to the required height, you need to glue the seismic belt on top of the blocks.

- Shingles are then laid to add aesthetics to the fence.

An example of laying tiles on a fence made of aerated concrete blocks

- The final stage of construction is the application of primer and facade plaster.

Plastering a fence made of aerated blocksAn example of finishing a fence made of aerated concrete blocks

By carrying out all the steps one by one and choosing the right material, you can be sure that the fence structure will last for many 50 years, and if the raw materials are of high quality, then even longer.

Building a fence is one of the main procedures for construction and landscaping of a site. A fence made of blocks is a quick, aesthetic and fairly economical solution for both residential, industrial and public areas.

But even in block construction, everything is not so simple: there are different types of blocks, their shapes, as well as the characteristics of each type. We will try to figure this out.

Why fence blocks?

Blocks are ready-made parts of a future structure. They are the main alternative to traditional construction, and for good reason: they have a number of significant advantages.

- Speed of installation and the ability to do it yourself.

- The following advantage follows from the previous advantage - possible savings on the construction of such a fence.

- Resistant to fire and the destructive effects of high temperatures.

- Frost resistance.

- The presence of internal cavities, which allows you to hide the necessary communications.

- A large assortment. You can build a fence from cinder blocks, a fence from foam blocks, etc. And also use various kinds of decorative blocks for the fence (for example, under a stone), but here everything is limited only by your imagination and preferences.

- High strength and reliability of the finished fence.

- Large selection of design solutions.

- Ideal ratio of quality and pricing policy. If you use natural crushed stone, building a fence will cost much more.

- Durability is another advantage of such structures.

1.1 Foam blocks in the construction of fences

Recently, this material has become especially popular in the construction of fences. It is light both in weight and in processing, its price is low, and at the same time it is possible to create similar blocks at home.

The composition of foam concrete includes cement, sand and a chemical reagent, which, in fact, is a foaming agent. After pouring this mixture into molds, you need to wait a while for it to harden.

A fence made of foam blocks has excellent sound insulating properties. Now, even if your site is located near the road, this will not prevent you from enjoying the silence in your cozy yard. Another important factor that speaks in favor of choosing this material is that it is environmentally friendly.

1.2 Cinder block fence

Cinder block is called a building stone, the filler of which can be:

- slag;

- crushed stone;

- sand:

- waste of building materials;

- expanded clay, gravel;

- ash;

- perlite

Cinder blocks are produced by vibration pressing directly into molds.

This is an inexpensive and reliable material that has high sound insulation characteristics. In addition, it is easy to install and anyone can “create” it at home.

Making a cinder block fence with your own hands is quite simple.

- Making molds for blocks. It is necessary to take metal elements and build boxes from them without a bottom, but with handles, connecting them by welding.

- To form the voids of the block, you can take empty glass bottles. This procedure will reduce the weight of the structure and reduce the cost of manufacturing.

- The proportion of the solution is important. The standard ratio of cement, sand and slag (or other components indicated above) is 1:3:5.

- The composition is poured into molds, and with the help of compaction and vibration for two minutes (a machine for making cinder blocks or a vibrating table would be an excellent assistant in this matter), the cinder block is finally formed. The finished product is removed.

- This is followed by drying the block for two to four days, and then construction occurs.

When the cinder blocks are ready to “turn” into a fence, you need to remember about the foundation.

Don’t forget about the posts that form the spans of the fence: they are usually mounted at a distance of two meters. Then follow the two final stages of foundation formation: pouring and curing of concrete.