You can prepare the floor screed mixture yourself or buy it in a specialized department. In each specific case, the master chooses a rational option. When purchasing factory-made compounds of different brands, you should ask: what substrates it is intended for, what the intended layer thickness is, find out the strength limits and complete drying time. Experts remind you that not all mixtures are suitable for creating a heated floor, so before making a targeted purchase you need to carefully study all available information about the product and consult with specialists.

Types of solution

There are quite a few types of screed: they should be selected based on considerations of the availability of materials, the quality of the base, the thickness of the intended layer, etc. Purified white sand is usually used as a filler, to which mineral or polymer plating agents and additives are added that improve the technical characteristics of the screed. Cement and gypsum are usually used as a binding element.

Floor screed is the best option for preparing the floor for finishing coating

- The gypsum solution (anhydride) is very plastic: it is easy to lay and level. The drying time of the layer is approximately two days. Main advantages: gypsum does not shrink, does not crack and can withstand heavy loads (laying in a layer of up to 2 cm is allowed, while cement - at least 3 cm). Disadvantage: It is not recommended for use in rooms with high humidity.

- Cement mortar is considered cheaper and more versatile. It can also withstand high loads, but is not afraid of moisture. The disadvantages include serious shrinkage and the need to create a layer of at least 3 centimeters (if you do less, the surface will tear). In principle, it is possible to avoid ruptures by creating a grid of reinforcement.

Cement and gypsum can be bought both in pure form (much cheaper) and in the form of a ready-made mixture (more expensive). The mixtures only need to be diluted with water according to the instructions and stirred - after that they are immediately ready for use. They often contain various plasticizers and additives that prevent the solution from setting prematurely or reduce the shrinkage process. But most often cement is used in everyday life - it is more accessible, cheaper and can be installed in any room.

Features of pouring the base for heated floors

If until recently a heated floor was a curiosity, today owners of premises equipped with individual heating often reconstruct old floor coverings and then install a heated floor. This type of heating is becoming increasingly popular due to ease of use, saving space, and a comfortable room climate.

Regardless of the type of heating element (water, electricity) used when installing a heated floor, the base for it must be made correctly in order to avoid unforeseen moments during operation.

The method of preparing the solution, the ingredients used, and the order of work do not differ much from generally accepted rules. But since the underfloor heating needs to provide additional reliability, there are some nuances. Before preparing a solution for screeding a warm coating, tidy up the base on which the heating elements will be laid. Remove cracks, chips, and level the base of the floor horizontally. Place the heating elements and secure them carefully to avoid movement during subsequent pouring.

The technology for preparing concrete or sand-cement screed is labor-intensive and painstaking work, requiring strict adherence to the ratios of components and instructions

There are three types of screeds used when installing heated floors:

- Liquid.

It is chosen most often, since due to unhindered penetration into all voids, a homogeneous, dense layer is created that protects coolants from damage. The cement for the screed is selected based on the functional tasks assigned to the base. The higher the grade of cement, the stronger the mass into which the coolants are placed. - Semi-dry.

The name itself indicates the minimum amount of water in the mixture. Strength characteristics are increased by adding special construction additives (fiber, plasticizers, hardening catalysts). - Dry.

Finely crushed expanded clay, less often sand, is used as filler. Customers choose this option quite rarely, since construction activities require additional financial investments for the purchase of special fiberboards, and installation work is also more complicated.

Having decided on the question of how to make a solution for pouring, you need to decide what thickness is optimal in your particular case. Its size is determined by adding the diameter of the pipes and the height of the layer above the communications (30-50 mm).

Once the work is completed, be patient and do not plan to continue the repairs for a month. The composition should dry evenly without additional loads, which could lead to the formation of cracks.

How to make cement mortar

Have you decided to make a mortar composition for a cement floor screed? Then you will need:

Note:

cement, which is stored for a long time even in a dry room, gradually reduces its quality and grade. We recommend that you use cement no older than four months - the date of its manufacture is printed on the bag.

This is how you mix the floor screed solution in a bucket

Types and purpose of concrete floor screed

Before mixing the cement composition, you need to understand why it is necessary. A screed is a concrete layer that needs to be poured between the subfloor and the finishing coating. The technology for preparing the solution may be different. It all depends on the brand of cement, type, floor covering and other factors.

Functions performed by a concrete screed:

- Levels the floor;

- Hides wires and pipes that are in the floor;

- Performs the protective function of the subfloor and evenly distributes the load;

- Insulates the floor.

Sometimes pouring is done to slope the floor. For example, in the bathroom, when a drain is installed in the floor. The composition and method of preparing the subfloor determine the types of screeds.

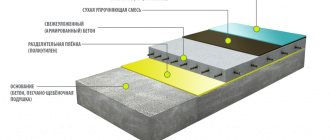

Classification of screeds

:

- Separating

– a mixture of cement-sand fraction, which is laid on a waterproofing layer. This method is used when arranging a subfloor under the ground, as well as in houses where there is a high probability of moisture getting under the floor. - Bound

is a cement mortar that needs to be poured onto the floor at low humidity levels. This type is used by a team of workers when pouring the floor between floors. - Floating

– screed for insulating the base. The mixture is poured onto the insulation and reinforcing mesh. Contact between walls and subfloor is not allowed. The thickness of the layer of this screed is 6 cm.

Each type is used for a specific purpose. Some can waterproof the floor, others can insulate it. The main thing is to properly prepare the solution and make the screed.

Screening is often used to create a solution. This material is obtained after processing concrete into crumbs. A mixture of screenings is the cheapest option than buying cement.

Mixture proportions

It is necessary to understand that the quality of the screed and the proportions depend on the cement you have. Here is the dependency table:

| Cement brand | Brand of solution | Proportion (cement to sand) |

| 600 | M300 | 1/3 |

| 600 | M200 | 1/4 |

| 500 | M300 | 1/2 |

| 500 | M200 | 1/3 |

| 400 | M300 | 1/1 |

| 400 | M150 | 1/3 |

| 300 | M200 | 1/1 |

| 300 | M100 | 1/3 |

It is recommended to use the M200 brand for the floor (in extreme cases, M150).

How to mix

Note:

if you stir the mixture in a large trough, then instead of a shovel you can use a hoe - it is much more convenient for it to work. If you prepare the mixture in a bucket, use a drill with a special attachment. The more viscous the solution, the fewer cracks will appear when drying.

A concrete mixer and a trough greatly facilitate the process of creating a solution

Calculation of required materials

In order to calculate the composition of the floor screed, you should know the area of the room and the expected thickness of the future layer. For example, the area of the room is 20 sq.m., and the thickness is 5 cm. We multiply these values by 20*0.05=1 cubic meter of mixture. Next, we calculate the amount of sand and cement (from considerations ⅓ you will need 0.75 and 0.25 cubic meters, respectively). One cube of cement weighs approximately 1.3 tons, that is, we will need 0.25 * 1.3 = 320 kilograms (7 bags). Knowing these proportions of cement and sand for floor screed, you can purchase the required amount of material in advance.

Note:

These calculations are valid for a dry mixture, but as soon as you fill it with water, the volume will decrease slightly. That is why take cement and sand with a 20 percent reserve.

If you do not want to equip the reinforcing mesh, you can save money by purchasing fiberglass. It is added to the solution at the mixing stage and perfectly keeps it from spreading.

Durability of the screed

The compressive strength of all produced adhesives can be read on the packaging (indicator 10 MPa). As for concrete, the closest to this number is grade M 150, where the figure is 2.8 MPa higher.

In the future, when you derive the proportion for this homogeneous mixture, focus exclusively on the “150” caementum indicators. What will you have at the finish line? And the fact that the solution will become several times stronger than the glue that was described above, and this, as you know, fully confirms the correctness of the law on the strength of layers.

Despite this, few builders take into account one small “but”, which quickly negates all of the above. If you calculate the binder, then M400 cement will be used as the basis.

At the same time, many people forget to take into account that almost every month a homogeneous mixture will lose a small percentage of its strength, and this is important.

It is also worth adding that, subject to any proportions, people use only ideal materials, in other words, you will never find even the slightest traces of clay in sand.

You should always remember this, because due to its properties, clay envelops all grains of sand, which reduces adhesion and, as a result, reduces strength. Therefore, it is very difficult to prescribe any specific indicators. Is this a hopeless case?

Do not despair: increase the proportion of cement in the homogeneous mixture by a few percent, and the liquid should decrease accordingly. Of course, if this is all possible.

Concrete pavement must be durable , but quality is based not only on the materials used. SPC is a combination of sand and caementum, which is often used as an intermediate layer in flooring.

Concrete covering

Many people prefer to prepare the cement mortar themselves, but to do this, a person must have some knowledge, skills, and take into account all the necessary proportions.

If you pay attention to the overall picture, then the indicators of the correct proportions should depend on the floor load; the higher this indicator, the more caementum is used in the solution (especially if we take into account industrial premises and large supermarkets).

In addition to everything described above, there are also known factors that affect the proportions:

- leveling the floor surface;

- some owners decide to raise the floor a little;

- if necessary, various pipelines are hidden, in addition, do not forget about communication systems;

- As a result, the question arises of how to correctly distribute the load on the thermal and all sound insulating balls.

These combinations may vary, but the caementum brand should always be the basis. What is the proportion of cement and sand for screed? For “one hundredth” of a homogeneous mixture and “three hundredth” caementum, it is necessary to take the proportion 1:3 as a basis.

For caementum “three hundred” and a homogeneous mixture “one hundred fifty” it is necessary to take the proportion 1:2 as a basis. “Two hundredth” homogeneous mixture and three hundredth caementum should be taken in equal quantities.

A homogeneous mixture of “one hundred and fifty” and caementum “four hundred” have a ratio of 1:3 . “Two hundredth” caementum and a homogeneous mixture 1:1.

Proportion

What is the proportion of cement to sand for screed? The homogeneous mixture and caementum "three hundred" should also be used in equal quantities. A homogeneous mixture of “two hundred” and caementum “five hundred” 1:3. A solution of “two hundred” with caementum “six hundred”. The ratio of sand and cement in the screed mortar is 4:1.

When equipping an intermediate layer for flooring, it is rational to use a homogeneous mixture “150” or “two hundredth”.

What should be the ratio of materials that are used? Initially, the brand of caementum used is the basis of the required ratio. The second most commonly used brand of construction caementum is M400 and M500.

Proportions M 400, M 500

With the correct ratio of materials, the finishing solution will fully comply with the required grades M150, M200.

To properly prepare a homogeneous mixture, it is necessary to take into account the amount of liquid used. It must be administered, keeping the volume to half a liter.

If the indicator is several times higher, this will significantly affect the strength of the finished intermediate layer when installing floors.

A warm floor is necessary to provide the room with heat, without taking up free space in the room, because it is located directly under the floor. Here you will learn how to make a screed for a heated floor.

Currently, various types of primers are very popular, but when choosing, you should take into account all the characteristics of the material when using it. Here's everything about deep penetration acrylic primer for interior work.

It is impossible to imagine the modern decoration of any room without the use of tile adhesive. By clicking on the link, you will become familiar with the different types and characteristics of tile adhesive.

For several years now, the global building materials market has been overflowing with options that are used to prepare a variety of homogeneous mixtures. If you arm yourself with a purchased dry mixture, the quality of the finishing coating improves.

Dry mix

All this is possible due to the fact that all the components included in the composition take into account the ideal ratio of all indicators for the screed. The finished components are characterized by an excellent stable recipe , and all proportions are always observed, which can be difficult to achieve at the stage of preparing mixtures yourself.

How to fill correctly

Pouring is an important stage on which the future fate of your floor depends. Therefore, approach the process with full responsibility. It can be divided into three stages:

Lay the mortar along the beacons - this facilitates the leveling process

Note:

It is recommended to water the drying surface with water every day. This will prevent it from drying out and cracking. You can cover it with polyethylene - this will reduce the evaporation process.