For cutting massive, capital structures made of reinforced concrete, in cases where the use of wall cutting machines is impossible, the technology of diamond cutting with rope is used. This method allows you to obtain an accurate cut, even when working with very durable materials or substrates over 1 meter thick. The cutting rope is a cable with inserts made of diamond-coated elements. Dragging the rope along the cutting line allows you to get an even and finished cut. If more delicate work is required, we can offer cutting with a diamond wire, which allows us to achieve jewelry precision during dismantling.

Diamond wire rope cutting technology

For diamond cutting with rope, ropes of various thicknesses are selected, taking into account the strength of the material being cut and the level of accuracy of the work performed. The rope cutting procedure is carried out in several stages:

- On the surface to be cut, the outline of an opening or a cut of a different shape is outlined;

- At the corners and joints of the marked figure, through holes are drilled with diamond bits, allowing the desired cutting shape to be obtained when connecting the contour;

- Insert the rope into the holes drilled with a diamond core so that the marking line coincides with the cutting line;

- The tension force of the rope is adjusted, the cutting system is started, regulating the tension force of the rope, allowing for uniform wear of the equipment.

Rope cutting is used not only for walls, but also for free-standing structures such as columns, pillars, etc. When cutting columns or supports, a cable is encircled around the surface at the level where the cut is supposed to be made.

What is diamond wire

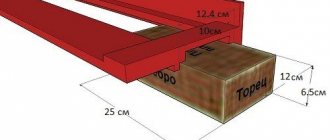

The base of the cutting rope consists of a galvanized cable made of high-strength steel fibers. On its surface, noticeably after 200-250 mm, special steel bushings with a diamond coating are fixed, which is sprayed in a special chamber.

Diamond bushings can have a diameter in the range of 9.6-10.6 mm. They are fixed to the surface of the cable with special crimps. For additional strength, the rope is equipped with a reinforcing metal spring and small rubber bushings, which increase its flexibility. In addition, the rope can be covered with a special coating of vulcanized rubber.

Application area of diamond wire cutting

Due to the complexity and high productivity of wire diamond cutting technology, it is worth using this method when dismantling large objects or high-strength structures. In particular, wire cutting is used in the following cases:

- Dismantling of columns, supporting structures with a diameter of 2 meters or more;

- Cutting walls with a thickness of 1 meter and a cut length of 2 meters or more;

- Cutting using the immersion method, in the absence of access to the surface being processed on both sides;

- Cutting foundations of increased thickness;

- Cutting structures with double or reinforced reinforcement belts and the use of reinforcement with a thickness of 1 cm.

Thus, rope cutting is an effective solution to the problems of dismantling capital structures, which otherwise can only be demolished using a controlled detonation method.

Diamond wire cutting of concrete and reinforced concrete structures

It is not uncommon for situations when, when performing construction work, it is first necessary to dismantle old foundations and wire rope diamond cutting of reinforced concrete structures. In such cases, impact tools and diamond cutting are most often used. However, the use of impact installations is not always considered effective, since they are not capable of dismantling the foundation and guaranteeing complete safety of the main structure. Impact installations are especially inconvenient to use in confined areas, residential buildings, as well as for dismantling ceilings and reinforced concrete walls. The most correct solution is diamond wire cutting.

The main advantages of the service include a fairly low noise level. In addition, the work process can be carried out at the desired angle even in a limited space, thereby ensuring high accuracy of the work done.

The use of a diamond wire is possible even in rather uncomfortable conditions, especially if direct access to the structure is difficult. For example, in a limited workspace, diamond wire cutting is rightfully considered an effective way to create the desired window or door opening. This service is especially relevant if the work is carried out in close proximity to an adjacent wall.

To ensure a complete working process, the installation of the wire machine is carried out externally, and the diamond wire itself is brought out to the drive drum through a hole in the wall.

Using this service allows you to cope with the following tasks:

- Cut door and window openings to the required size;

- Make precise cuts of hard materials such as: concrete, reinforced concrete, thick natural stone, brick;

- Perform efficient cable cutting of concrete, cable cutting of reinforced concrete, cable cutting of stone, cable cutting of brick, cable cutting of monolithic structures, as well as cable cutting of walls made of heavily reinforced concrete, including cutting of armored chambers and bank vaults;

- Carry out high-quality dismantling of foundations without damaging load-bearing structures and much more.

Due to the complete absence of shock loads, the work process is carried out completely without vibration, allowing the integrity of capital structures to be maintained.

As a rule, the choice of rope length is made depending on the thickness of the structure. The main advantages of choosing this method of work can be considered a fairly high speed of its implementation. In addition, the finished openings are perfectly smooth and have the desired shape, without requiring additional subsequent processing.

This technology is also unique in that cutting is also possible under water. The quality of work will always be carried out at the highest level.

Advantages of diamond wire cutting

- There are no dynamic shock or vibration loads, cutting is carried out without destroying nearby structures;

- Low level of noise and dust, the ability to operate in conditions requiring the absence of sparks or dust in the object;

- Possibility of cutting structures partially or completely under water;

- High performance compared to other technologies.

If you are interested in wire cutting services, our company is ready to offer professional solutions and affordable prices.

The minimum cost of traveling around Moscow for rope cutting work is 25,000 rubles

Diamond cutting

| Structure thickness (mm) | Monolith (rub/m.p.) | Concrete (rub/m.p.) | Brick (rub/m.p.) |

| up to 100 | 900 | 800 | 600 |

| 100 — 150 | 1200 | 1000 | 800 |

| 160 — 200 | 1700 | 1400 | 1000 |

| 210 — 250 | 2250 | 1800 | 1400 |

| 260 — 300 | 2750 | 2200 | 1600 |

| 310 — 350 | 3300 | 2700 | 2000 |

| 360 — 400 | 3800 | 3000 | 2300 |

| 410 — 450 | 4300 | 3400 | 2600 |

| 460 — 500 | 4800 | 3900 | 2900 |

| 510 — 550 | 5350 | 4300 | 3200 |

| 560 — 600 | 5850 | 4600 | 3500 |

| 610 — 710 | 6700 | 5400 | 4000 |

In what cases is the use of diamond cutting justified?

If you are interested in cutting openings in concrete when remodeling an apartment, making openings in walls or ceilings, then diamond cutting will be the only right solution. In addition to the advantages described above, the equipment allows you to work even in fairly small spaces. At the same time, a diamond disc is able to easily and quickly cut through any materials, be it brick, concrete or metal reinforcement. Therefore, if you want to move the door, expand it, or make an elegant niche in the wall, then contact Almaz-Ryazan. Our specialists will perform diamond cutting of reinforced concrete structures and bricks professionally and on time.

Equipment used.

Depending on the working conditions, the material being processed, its thickness, orientation in space and the tasks at hand, the appropriate, most suitable equipment is selected.

1. Hand carvers.

Depending on the principle and method of forming a cut, there are such designs as:

- disk cutter;

- chain Saw;

- Cut-and-break;

- ring cutter

Each tool has its own strengths and weaknesses, but all of them are distinguished by high mobility, no need for preparatory operations and a high power-to-weight-to-cost ratio.

Most models have an electric or gasoline engine, but there are modifications with hydraulic and pneumatic drives. Often these devices are used when carrying out cutting work in private households.

2. Seam cutter (seam cutter)

A simple and reliable design consists of a motor mounted on a movable cart and a cutting element - a disk with a diameter of up to 1200 mm. It is used for cutting reinforced concrete floors, cutting thermal joints, repairing roads and runways. The rotation of the disk - depending on the design and feed - is carried out either by an electric motor or an internal combustion engine.

The advantages of this equipment include:

- simplicity of design;

- high power and performance;

- no need for preparatory procedures;

The ability to work only with floors limits the scope of application of the joint cutter.

3. Wall cutting machine.

The design consists of a rail that is mounted on the surface being processed, a “head” that moves along the rail, deepens the disk and rotates the disk and remote control.

The following features allow us to safely - by analogy with “Artillery - the god of war” - call the wall saw the god of diamond cutting:

- High power - up to 40 kW;

- Possibility to use discs with a diameter of up to 2000 mm;

- Possibility of cutting floors, walls, ceilings at right and arbitrary angles;

- Ability to work underwater.

4. Rope.

A distinctive feature of this device is the absence of a diamond disk - cutting is carried out using a flexible steel rope with diamond “beads” attached to it. The prototype of this equipment was an invention two centuries ago: the French engineer Duvalier used steel wire for industrial cutting.

The undeniable advantages include:

- the ability to work with objects of significant linear dimensions;

- possibility of processing all-metal structures;

- possibility of underwater cutting;

- possibility of cutting in rooms with limited area;

- cutting without cuts.

Diamond cutting with

We use only professional, proven equipment, which allows us to complete the work with the required quality and within the agreed time frame.

The cost of the work is very affordable - each order is calculated individually, so you can be sure that you will not have to overpay extra money for the services of professionals. For large volumes of work, you can always count on a good discount.

All you need to do is call the phone number listed on our website and discuss the details of cooperation with company representatives.

We carry out diamond cutting work in the cities of: Kasimov, Skopin, Sasovo, Ryazhsk, Rybnoye, Novomichurinsk, Shilovo, Korablino, Mikhailov, Lesnoy, Spassk-Ryazansky, Polyany, Shatsk, Tuma, Spas-Klepiki, Oktyabrsky, Sarai, Kadom, Starozhilovo, Ukholovo, Miloslavskoye, Pronsk and other cities of the Ryazan region

Prices for cutting with diamond wire

| Material | Price for 1m2 (rub) |

| Reinforced concrete | 12950 |

| Concrete | 12025 |

| Brick | 11100 |

The price for cutting with a diamond wire is given per 1 m2 of cut (length of cut * depth of cut)

- When calculating the cost of work, it is necessary to take into account the conditions in which the work is carried out.

- The cost of a minimum visit within the Moscow Ring Road (for work with hand cutters is 7,000 rubles). — (for work with wall cutting machines and joint cutters — 22,000 rubles)

- For an accurate calculation of the cost of work, call;

- Discounts are available for large volumes!

Design and capabilities of installations with cutting diamond wire

This type of tool is characterized by a high coefficient of friction between the rope (sometimes called wire) and the material being cut.

For this purpose, the cutting device includes:

- Drive pulley.

- Driven pulley.

- Tension unit.

- Force measuring device.

- Drive unit.

- Frame.

The rope system is designed for a certain range of reinforced concrete blocks, but can also be used for cutting granite or high-strength steel. A diamond wire for cutting reinforced concrete has no restrictions on the depth of cut or the profile of the workpiece.

Machines with tools in the form of a diamond wire are available in two types - with electromechanical and hydraulic drives. The former usually have a stationary design, the latter, due to their compactness and flexibility, are used directly on construction sites. Cutting can be “dry” or “wet”.