Reinforcing the floor is usually carried out in the process of redevelopment or renovation of an apartment, office, cottage, garage, warehouse or other construction site. This procedure helps to avoid unforeseen emergency situations during the operation of the building.

Floor beam diagram.

It may be necessary to strengthen the ceiling due to an increase in load or a decrease in its strength.

There are several types of overlap:

- wooden;

- ceiling made of reinforced concrete monolithic slabs;

- ribbed;

- Klein overlap.

Each type has its own way of strengthening. But at the same time, the process of working with any type of floor begins with the installation of support posts.

Strengthening wooden floors

Typically, such floors are repaired as a result of damage or destruction of beams. In this case, the beams are strengthened or changed, increasing their cross-section. If the room changes its function or the load on the floor increases, then it is necessary to strengthen the beams, replace them with larger ones or increase the number and place them more often.

Diagram of a reinforced floor slab: 1 – Mesh, 2 – Reinforcement of the main mesh, 3 – Reinforcement of the edges of the slab, 4 – Reinforcement of the corners of the slab, 5 – Load-bearing walls.

To work you will need:

- nails;

- hammer;

- glue for gluing wood with roofing felt.

- antiseptic.

You can’t do without the appropriate materials:

- boards or beams;

- roofing felt for wood insulation.

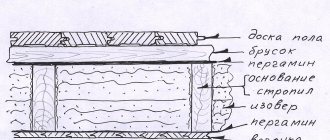

Reinforcement of beams is carried out using boards or beams of appropriate thickness, which are nailed on both sides. The boards used for overlays must have a thickness of at least 38 mm, but the calculation of the cross-section of the beams and thickness must be carried out by the designer.

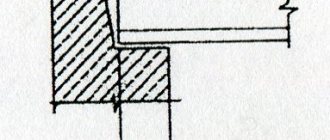

If the load on the floor increases, it will be necessary to increase the load-bearing capacity of the beams by attaching overlays along their entire length. When damaged beams need to be repaired, pads are used only in the required areas. They are usually attached at the ends. The reason for damage to the beams in this place is due to their improper support against the wall. The formation of condensation causes the wood to rot and lose strength at the point of contact with the wall. To avoid this problem, the ends of the beams must be treated with an antiseptic and covered with roofing felt.

To increase the number of beams, additional structures are inserted between existing ones, resulting in a significantly reduced distance between them. The cross-section and number of additional beams and their placement in certain areas or the entire floor depend on the load on the new floor.

When reinforcement is needed

In most cases, it is impossible to independently determine the need for repair and restoration of floors, since all changes are hidden under the finishing materials. Possible signs that the floor slab in the garage above the cellar needs to be strengthened in a house between floors are the following factors.

- Formation of cracks.

- Peeling of plaster or floor screed.

- The appearance of chips and stains on the surface.

The most common causes are corrosion of reinforcement bars, general unsatisfactory condition of the floors, and a serious increase in load.

Reinforcement of reinforced concrete slab floors

Strengthening a monolithic reinforced concrete floor is carried out in several ways. First of all, for work you will need tools and appropriate materials:

Reinforcement scheme for a reinforced concrete floor slab: 1 – Lower reinforcing mesh, 2 – Upper reinforcing mesh, 3 – Wall, 4 – Lower reinforcing reinforcement, 5 – Upper reinforcing reinforcement.

- electric hammer drill;

- electric jackhammer;

- concrete mixer;

- welding machine;

- I-beams, angles, channels;

- hairpins;

- boards for formwork;

- concrete (cement, sand, crushed stone, PVA paste).

Before cutting a small opening in reinforced concrete monolithic floors, it is first necessary to install support pillars. Next, you need to cut out the opening and break the end with an electric jackhammer so that the reinforcement protrudes by 15-20 cm. Then a channel is welded to it along the perimeter of the opening, formwork is placed below and the distance between the channel and the concrete is filled with a pre-prepared concrete solution. After the concrete has completely set, the temporary pillars and formwork must be removed.

When cutting a large opening in reinforced concrete floors and provided that the load-bearing walls of the lower level (6-12 m) are close to each other, it is necessary to use lower suspended support reinforcement fixed to the walls. It is important to perform such reinforcement of the monolithic floor even before cutting the opening. Channels or corners of the required size are installed from below close to the monolithic ceiling, as close as possible to the location of the planned opening and with both ends inserted into niches prepared in advance (if the walls are made of brick). After this, the niches and the distance between the floor slabs and metal reinforcements are caulked.

Klein design

Until the beginning of the twentieth century, Klein flooring was very popular in the construction of houses.

This type of reinforced concrete structures is rare, but at one time they were quite popular, and today there are enthusiasts who want to return them to the arsenal of developers. The Klein floor is made of I-beams 80-240 mm high, which are laid in increments of 100-160 cm. The slab is supported on the lower shelves of the log. This slab should be made of ceramic bricks and reinforced with steel strips with a cross-section of 2 x 20 mm or steel rods with a diameter of 6-8 mm. The load-bearing capacity of a monolithic brick floor can be strengthened by strengthening I-beams made of steel or by strengthening the brick filling.

The logs are strengthened by welding strip steel to two I-profile flanges or by constructing an additional monolithic slab. In this case, clamps made of steel rods are welded to the logs and concrete is laid.

The second method of strengthening reinforced concrete floors

Scheme of strengthening the ribbed floor.

In this case, channels and I-beams are secured to monolithic walls using specially developed locking systems. If, when cutting an opening, the slab is not able to attach to the load-bearing walls located below and the opening is quite large, in addition to the lower reinforcement, pillars are installed in the corners of the opening between the floor located below and the one in which the opening is being cut. Such pillars partially take over the damaged load-bearing capacity of the slab.

The process of cutting reinforced concrete panel slabs must be carried out carefully, because factory samples have a width of 60 cm to 2 m. And if you cut off part of such a slab along the entire width, the second half will certainly fall down. To avoid falling reinforced concrete slabs, it is necessary to temporarily strengthen the monolithic floor before cutting the opening.

When the opening is small and work can be done on both sides of reinforced concrete slabs, it is not so difficult to make reinforcements. The cut part of the slab is secured to the adjacent ones, in which the opening will not be cut, using a channel supplied from below and pulled through with pins through the strip laid on top. As a result, it turns out that two untouched adjacent slabs act as load-bearing beams on which the partially sawn-off floor panel rests.

This method of amplification is low-cost and requires less time to work. This method eliminates the presence of a large number of lower supporting pillars that clutter the space.

Technologies used

The appropriate method for strengthening the floor slab from above or below is chosen by a specialist with a sufficient level of qualifications and experience in construction work. A professional relies on the following features.

- Integrity of the reinforcing frame.

- Geometric dimensions.

- Margin of safety.

- The amount of deflection of the structure.

- Finish thickness.

- Floor defects.

To determine these features, visual inspection and instrumental measurement methods are used.

Experts use various methods for restoring a floor or ceiling, including reinforcing floor slabs with carbon fiber . A bidirectional fabric is located along the long part of the structure; unidirectional carbon fiber can be used below. With the help of several layers of such material, the compressive strength of the reinforced concrete slab is increased, which is always below the permissible level of tensile loads. At the same time, the work is carried out quickly, simply, without increasing the cross-section of structures.

Strengthening the ribbed floor

Reinforcement of ribbed floors is carried out in the same way as in the case of reinforced concrete slabs, that is, concrete is laid on top. Accordingly, the same tools and materials will be needed. Another option is to make additional ribs that are placed parallel to the existing ones. To do this, in the place where the new rib will be made, concrete is dismantled above the hollow filling blocks. Part of the top surface is then cut out of the visible blocks, exposing their middle. As a result, a space is formed into which, after cleaning and removing the crushed stone, reinforcement can be laid, and then concrete.

Thanks to additional ribs in ribbed floors, the load is reduced, which makes them more reliable.

Strengthening monolithic floor slabs

Monolithic floors in construction are rightfully considered the most durable, while having increased material consumption, weight and, as a result, a fairly high price category. In this regard, the use of monolithic structures is not always justified from an economic point of view and is a necessary and justified measure in the presence of high design loads.

The most popular way to strengthen floor slabs of a monolithic structure is to erect another slab of similar structure, which is located on the surface of the old one. However, in some cases this method is considered ineffective, creating, in addition to the nominal, additional load on the existing floor.

Alternatively, steel support structures made from beams of various profiles are used. All types of profile metal products are used in their quality, namely: angle and channel, T-beam and I-beam. On their basis, support structures are formed to redistribute the workload. Just like in rib slabs, elements in the form of trussed reinforcement can be installed, as well as, if possible, additional supports in the form of columns. At the same time, it is necessary to correctly assess the possibility of their installation, especially in multi-story buildings and structures.

If it is necessary to strengthen the slabs when the load increases or the uniform wear of monolithic floors, it is rational to use carbon composite materials in the form of tape coatings applied in layers.

Features of increasing strength by various methods

The choice of method for increasing load-bearing capacity and load-carrying capacity depends on the material and characteristics of the building itself. So, for example, wooden ones most often need to be completely replaced, while metal and reinforced concrete ones can be reinforced using classical methods or using carbon fiber.

Reinforced concrete structures are spans that come in several configurations:

- Prefabricated hollow cores - used for arranging interfloor floors in residential and public buildings;

- Prefabricated ribbed - mainly intended for industrial buildings during roof construction;

- Monolithic - the most universal, used in all types of buildings and structures.

A universal solution for any type of slab is considered to be carbon composite and, above all, FibArm Tape carbon tape or FibArm Grid carbon mesh. Depending on the type of plate, the following actions are carried out:

- Reinforcement of hollow-core floor slabs with FibArm material is carried out by gluing the canvas to the surface from below. It is glued with a certain step. In this case, several layers of canvas can be applied, which determines the degree of increase in strength.

- Monolithic slabs used for flooring are reinforced in a similar way, but the carbon tape is glued longitudinally over the entire surface. This also improves seismic resistance.

- To strengthen ribbed floor slabs, carbon composite is glued to the bottom of the ribs. The number of layers determines the gain level. The supporting part of such a system is also strengthened with clamps made of unidirectional tape.