Pros of choosing a concrete fence

In everyday life, a fence made of this material is increasingly called a “Euro fence”. It has a whole list of advantages, which is why it is increasingly being chosen by the population for fencing and decorating private property or work enterprises. These advantages distinguish it from other fences not only by its decorative appearance, but also by the following technical characteristics:

- A large selection of sizes, designs and color palettes - this allows you to ideally select a sketch to match the style of the site, which expresses the taste and character of the owner. It is also possible to make it to order - completely unique and inimitable.

- Reliability is the best protection from strangers and animals on the site.

- Durability – longer service life compared to other types of materials.

- Strength - concrete retains all its properties, despite climatic reasons - humidity and temperature changes.

- Easy to care for.

- Ideal price-quality ratio.

Advantages of concrete fences

Such fences have already become firmly established in everyday life as “Euro fences”. Thanks to the list of advantages, concrete fences have become one of the most common ways to fence off an area, decorate it and distinguish it from the mass of similar ones. The advantages of concrete fencing over other types of fences are:

- reliable protection against intrusion into the site by strangers, including animals;

- an elegant and original element of site decoration; you can choose absolutely any design and color scheme, right down to an individual sketch of the form;

- concrete is a material that can withstand sudden changes in temperature and does not lose properties at high humidity;

- compared with other types of fencing, longer service life;

- optimal combination of quality and cost.

Return to contents

Types of forms

Looking at the growing popularity of concrete fencing, leading manufacturers of building materials began to develop a line of forms of different types and materials for the manufacture of fence elements. When choosing, focus on the desired end result - if you need a clear pattern, then you will need a rigid shape. If you want to make a product with irregular smooth outlines, then it is better to take a soft one.

These containers can be purchased at any construction supermarket, including online, or you can also make them yourself. Prices in stores vary depending on the material, pattern and number of sections. Usually there are two of them - upper and lower. For business, it is better to take several sets for non-stop production, and also to allocate a special place for drying concrete slabs and posts. Please note that you will need matrices not only for the fence sections, but also for the supports. Custom-made products will be even more expensive.

Installation of fences and posts

We need to make a few more recommendations for assembling fences:

- remove all obstacles from the place where the fence will be located and take careful measurements, mark key places with pegs;

- make holes for the foundation of the pillars and, after installing at the level of the first pillar, fill the base, secure with slats until the strength is gained with concrete;

- place a second post while simultaneously installing the lower panel of the fence, fill it with concrete and leave it for a day;

- Continue installing the posts and bottom panels, then insert the remaining elements into the grooves of the posts until the concrete fence is completely assembled.

The result is an aesthetically attractive design that only takes two people to assemble. To order forms for the production of fences and pillars from concrete, you need to place this order on the Mold Factory website using the “cart” button. The company’s specialists will call you back by phone and competently explain all questions regarding the transaction.

Polyurethane

This material makes it possible to produce fairly strong, non-flexible shapes. Polyurethane is quite rigid, which increases its service life - up to a thousand cycles of manufacturing sections from concrete mortar. Most often, these containers are used specifically to create fences. Fence elements are attractive on both sides. You can choose almost any relief and pattern. The disadvantages of this material include the following parameters:

- It is not easy to remove the finished product from the mold; there is a high probability of damage during this process,

- quite high price

- chips and cracks may appear on the product,

- Air may be retained on the surface of the concrete solution, which leads to defects in the product.

ABS plastic

This material is quite hard and is considered chemically resistant. Thickness 1-2 mm. Using this form, be sure that you will receive a high-quality finished product for installation, with precise adherence to geometry. Such forms are most often used by manufacturers of concrete fences. In addition, the material has the following advantages:

- durability,

- ease of removing sections due to the flexibility of the container,

- strength – withstands up to 200 pouring cycles,

- easily combined with any technology, facilitating the manufacturing process,

- compact when assembled,

- do not require mandatory lubrication before pouring concrete.

Production of decorative fences

The process of making decorative sections is simple; the main difficulty lies in preparing the necessary materials and tools.

Necessary equipment

- forms for concrete sections;

- concrete mixer;

- vibrating table for forming concrete products;

- vibrating sieve for cement and sand;

- trays for drying finished sections.

To produce concrete sections on a production scale, the most expensive cost is purchasing the molds. A lot of them are required to ensure variety and a normal volume of products per shift. To make decorative sections for your own needs, you can buy one or two molds, and they are not very expensive.

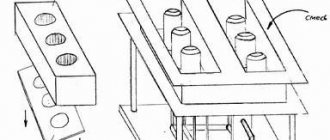

Another important tool for creating decorative sections is a vibrating table. With the help of vibrations, the concrete in the molds is compacted and gets rid of air bubbles and voids, which reduce the strength of the concrete structure. You can buy a vibration table, rent it, or make it yourself. On the Internet you can find ready-made drawings of a homemade vibrating table.

This is what a vibrating table for casting concrete products looks like

When making concrete products, using a concrete mixer is preferable to manual mixing; it mixes the components more thoroughly. A mechanical vibrating sieve is designed to clean sand and cement from debris. For small volumes, bulk materials can be sifted manually.

Raw materials

To make decorative sections you will need the following materials:

- Portland cement grade 500;

- wire reinforcement;

- quartz sand GOST 8736-93;

- crushed stone;

- various plasticizers to speed up the setting process.

Stages of making a decorative fence

- Preparation of concrete mixture. An important stage of production is the preparation of a high-quality solution.

To do this, crushed stone is poured into a concrete mixer and filled with water. After washing the stone, the dirty water is drained and sand, cement and plasticizer can be added. The composition proportions are as follows: 3 parts sand, 2 parts crushed stone and 1 part cement. Water is added to the required consistency.

- Preparing the form. If necessary, the mold is cleaned and lubricated with special products or waste machine oil. Lubrication makes the concrete surface smoother and makes it easier to remove the finished product.

- Pouring concrete into the matrix. The mold is placed on a vibrating table, and the cement mixture is poured into it up to half. A reinforcement frame is laid in the middle of the product, and concrete is poured to the edges. The surface is leveled, the excess is removed with a spatula.

- Vibration pressing. The vibrating table is turned on and the concrete is compacted until its surface becomes mirror-like. Often at home, the vibrations of a specialized table are replaced by hammer blows on the body of the mold.

- Instant formwork or exposure casting. Stripping can be carried out in two ways: instant stripping, when the product is removed immediately, and exposure casting, when the section is removed after complete hardening.

Fiberglass

This form is quite rough - it has a thickness of no more than 8 mm. The thinnest places in the matrix relief. Has a metal frame and handles for transportation. It can be used for both long-term daily drying and the quick release method. But the second method is used more often, since it is more cost-effective. With their help you can create three-dimensional structures. You can make up to 50 units per shift. Disadvantages of coverage:

- if dyes are added to a liquid solution, then after quick removal, defects may appear in the form of chips, cracks, etc.,

- To paint the fence in this case, an acrylic coating is applied to the finished structure after installation - that is, additional work is carried out.

Making fence sections with your own hands

We figured out how to install a concrete fence from prefabricated panels and decorate it. But what to do if you like beautiful shaped blocks that are quite expensive? To save your family budget, you can cast such beautiful sections yourself using ready-made molds. Of course, you will have to tinker, but the idea is worth it - your fence will be stylish and unique.

Types of molds for casting concrete sections

To create textured and relief surfaces, craftsmen use a variety of shapes. Due to the plasticity and pliability of concrete when poured, the solution fills all the unevenness of the form, and after drying, original double-sided sections are obtained that can be used for insertion between support pillars.

You can create such forms yourself or buy ready-made ones on the building materials market. The second option is preferable, since when making a mold yourself, it often turns out with errors, uneven and fragile.

On the construction market you can find forms for casting concrete for every taste and budget:

- Various PVC forms. Quite short-lived, can withstand no more than 100 pours. The workpiece will dry in them for at least a day, so if you have to make a large number of sections, it is better to buy several molds at once.

- Fiberglass mold with metal frame and special handles. They are convenient to use, thanks to the presence of handles, the workpiece can be turned over to harden on a metal surface, and a new portion of concrete can be poured into the mold. This is the fastest way to make many concrete sections in a short period of time.

- Polyurethane molds are good because the composition dries in them quite quickly - within about 12 hours. But the material also has its disadvantages - its cost is unreasonably high, and this form is enough for no more than 100 fills.

- ABS plastic is perhaps the most convenient way to make ready-made concrete sections. The durable material can withstand up to 200 pours, and the finished product is easily removed even without pre-treatment of the internal surface. The mold can be coated with paint, it will cover the concrete wonderfully and you will have a beautiful colored section.

After choosing the appropriate type of mold, you can proceed directly to casting the products.

PVC

This material has gained great popularity in modern construction, so it is not surprising that it has also taken part in the manufacture of forms for concrete fences. Polyvinyl chloride has a number of advantages:

- variety of choice of structure, color and shape, can be decorated like marble or granite,

- affordable price,

- products are of better quality,

- high fire safety, therefore suitable for use in a wide variety of places,

- service life – up to 100 concrete pours.

Tip: No matter what shape you choose, make sure that it has comfortable handles for carrying it.

Plastic forms for fences

The percentage of sales of concrete fences is increasing more and more. This method is the fastest and, in comparison with other inexpensive, methods of fencing the area near the house. In our company, which produces and sells plastic forms for fences, you can purchase completely inexpensive and high-quality forms for fences. For many years, the company has been selling high-quality and reliable materials for the construction of various fences. Every year the quantity and production of Euro fences increases, which is why forms for making fences are in great demand. Our company provides a wide range of different types of fences, as well as molds for stacked fences and molds for fence blocks. Qualified employees of our company will find an approach to each client, help and suggest an excellent option for fence forms. You can buy forms for concrete fences by contacting our company. Qualified specialists offer fence forms that are of high quality. They are also made exclusively from strong and durable materials. Decorative concrete fences are characterized by high strength, availability and versatility in almost all countries of the world. The main positive feature of this type of fence is that they can be installed on almost any soil.

Types of forms for fences

Plastic forms for fences can be bought very inexpensively, but they will last a long time only when there is the right amount of them. And stripping should be carried out only after complete drying. The decision to purchase a plastic fence form is entirely yours; our company guarantees the high quality and strength of its materials. Concrete fences are very popular today, and this provokes our company to create even more building materials and forms for concrete fences. There are these types of plastic forms for concrete fences:

- Fence molds, which are made of polyurethane, are quite durable and flexible. They have a high rigidity of the material from which they are directly made. This helps the fence last for many years. The main disadvantages of these forms are such factors as the high cost of the material, air, which can be retained on the surface of the concrete solution, can provoke the appearance of various cracks and defects.

- Molds for fiberglass fences are not rough and have special handles to make them easy to carry. The main disadvantage is that if the client wants the fence to have a certain color scheme, then after installation it is necessary to cover the product with acrylic paints, which will entail unnecessary waste.

- Forms for PVC fences have a low price, a wide range, and also high quality.

- ABS fence molds are made of rigid material. They have high strength and are also durable.