Plywood is a material made from many natural wood layers that are glued together using a press. When carrying out various repair work, depending on the application, the most important role is played by the size and thickness of the plywood sheet. The production of modern products is also carried out taking into account the required external and functional features. Let's figure out what purpose the different sizes are used for.

Table

The most common sheet sizes

To accurately calculate the required amount of material, you should know the standard size of a plywood sheet. The sheet of material is:

- square;

- rectangular.

The most common sizes are the following (values are indicated in mm): 1525x1525, 2440x1220, 2500x1250, 3000x1500, 3050x1525.

Knowing the standard size, you can calculate the amount of material required for the work, as well as determine the cost estimate.

The dimensions and quality of plywood produced in Russia are regulated by GOST 3919-96, which has 2 editions - GOST 3916.1-96, GOST 3916.2-96. The first relates to the regulation of the quality of products made from coniferous wood, and the other, accordingly, relates to deciduous varieties.

Standard plywood sheet sizes

Sheets can be divided by size into standard and large format. GOST regulates them as follows:

General Purpose Plywood Sheets

| Standard dimensions of sheets, mm | Large format plywood sheets, mm |

| 1220.00 to 1220.00 | 1830.00 to 1525.00 |

| 1525.00 to 1220.00 | 2440.00 to 1220.00 |

| 1525.00 to 1525.00 | 2500.00 to 1250.00 |

| 3000.00 to 1500.00 | |

| 3050.00 to 1525.00 |

Dimensions of laminated moisture-resistant plywood

Dimensions of waterproof sheets are based on the dimensions of plywood products for general use. For example, the size range of a well-known domestic product looks like this:

1) 1220/1250x2440/2500 mm;

2) 2440/2500x1220/1250 mm;

3) 1200/1500/1525x2500/2745/3000/3050 mm Dimensions of the popular Finnish WISA plywood: 1220*2440 mm and 1250*2500 mm.

| sheet thickness, mm | 6,5 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | 30 | >30 |

| number of veneer layers | 5 | 7 | 9 | 11 | 13 | 15 | 17 | 19 | 21 |

Bakelite plywood dimensions

Dimensions 5700 mm x 1250 mm or 2800 mm x 1250 mm. Sheet thickness ranges from 5 mm to 40 mm.

Like any other sheet material, plywood does not have ideal geometry. Errors occur during the cutting process. They are not so large as to be noticeable to the naked eye, but you need to know that they exist and that this is normal. This is especially important for furniture makers who cut parts from sheets to exact dimensions.

GOST 3916.1-96 regulates the maximum permissible geometric deviations in relation to the length and width of the plane. These data are shown in the table below.

Permissible geometric deviations

| Length/width of the plywood sheet plane, mm | Critical deviation, mm |

| 1200 | +/- 3,0 |

| 1220 | |

| 1250 | |

| 1500 | +/- 4,0 |

| 1525 | |

| 1800 | |

| 1830 | |

| 2100 | +/- 4,0 |

| 2135 | |

| 2440 | |

| 2500 | |

| 2700 | +/- 5,0 |

| 2745 | |

| 3050 | |

| 3600 | |

| 3660 |

There is also a permissible deviation in terms of thickness. It depends not only on the standard value, but also on the degree of processing of the planes. The pivot table looks like this:

| Standard thickness of plywood sheets, mm | Number of wood layers, not less | Critical deviation for sanded plywood, mm | Critical deviation for unsanded plywood, mm |

| 3,00 | 3 | from +0.30 to -0.40 | from +0.40 to -0.30 |

| 6,50 | 5 | from +0.40 to -0.50 | from +0.90 to -0.40 |

| 9,00 | 7 | from +0.40 to -0.60 | from +1.00 to -0.50 |

| 12,00 | 9 | from +0.50 to -0.70 | from +1.10 to -0.60 |

| 15,00 | 11 | from +0.60 to -0.80 | from +1.20 to -0.70 |

| 18,00 | 13 | from +0.70 to -0.90 | from +1.30 to -0.80 |

| 21,00 | 15 | from +0.80 to -1.00 | from +1.40 to -0.90 |

| 24,00 | 17 | from +0.90 to -1.10 | from +1.50 to -1.00 |

| 27,00 | 19 | +1.00 to -1.20 | from +1.60 to -1.10 |

| 30,00 | 21 | from +1.10 to -1.30 | from +1.70 to -1.20 |

The presence of deviations in the geometry of the sheet does not mean that it needs to be rejected. First, you should make sure that this run exceeds the tolerance allowed by the standards. And after this, plywood needs to look for another application that does not require maintaining strict geometric shapes.

Save the page to your browser bookmarks. It is impossible to do without size information when calculating the cost to estimate losses in the form of trimmings. In addition, there are logistical aspects. Before transportation, it is necessary to calculate how much space (what volume) the plywood will take up. Storage also involves calculating the capacity of the room.

Various types of plywood

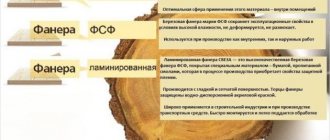

The most common types are FC, FSF, and laminated. They differ in moisture resistance, top sheet coating and type of glue.

What size and thickness of products are best to use for floor finishing? Square panels 1525x1525 are best suited; depending on the layout, you can choose a material of a different length and width.

For the floor, it is best to use a moisture-resistant material with a thickness of 12 to 20; you can lay two layers of boards 10 mm thick in a checkerboard pattern. It will provide a more uniform surface of the future floor, as well as its strength.

In this case, it will be easier to lay them out, cutting and sawing will be much easier. Additionally, thinner sheets are easier to move.

For a very flat floor, one layer of 10 mm is enough.

There is also thinner FSF plywood, the thickness of which is only 8 mm. The most popular sizes of such products made from hardwood are 1525x1525, 2440x1220 mm. Coniferous plywood sheets with a thickness of 8 are: 2500x1250 and 2440x1220 mm.

The area of application of 8 mm plywood is interior and exterior decoration. Coniferous varieties are suitable for flooring due to their resistance to fungi.

Plywood thickness

For different conditions of use, plywood of a certain grade and thickness is used. These indicators determine performance characteristics, resistance to various influences and durability.

What is the thickness of plywood:

- thin;

- medium thickness;

- thick.

To make your choice, you need to study the characteristics of each type of plywood.

Thin plywood

It is a material with a thickness of 0.4 to 6 mm. The advantage of thin plywood is its low price and good flexibility, which allows it to be used in the manufacture of furniture and decorative finishing. However, the sheets cannot withstand heavy loads and may break if bent. Therefore, you need to work with thin plywood as carefully as possible.

Thin plywood comes in two types:

- Finnish (aviation). Thickness from 0.4 to 6 mm. The material is actively used in aircraft modeling, as well as in the manufacture of souvenirs. It is easy to cut and does not require the purchase of special equipment.

- Plywood FC, FSF. Thickness from 3 to 6 mm. The main use of the material is making souvenirs and crafts. It is used extremely rarely for decorative finishing due to its small thickness and fragility.

Medium plywood

This is the most popular material that can be used for decoration. Available in thicknesses of 8, 9, 10, 12 and 15 mm. The surface can be unpolished or polished.

The range of applications for medium-thick sheets is quite wide. This:

- aromatic furniture production;

- automotive industry;

- carriage building;

- advertising industry, etc.

Thick plywood

The main advantage of this type is its high strength, which is not surprising - plywood is produced in thicknesses from 18 to 30 mm. It has good endurance, resistance to external loads, while maintaining flexibility, although it is an order of magnitude worse than that of thin sheets.

Thick plywood is used in carriage building, construction and interior decoration.

← How to cut plywood? MDF and chipboard: what is the difference? →

Plywood 10 mm thick

The most common sizes of 10 mm plywood sheets:

- square 1525x1525;

- plywood sheet size 10 mm rectangular 2440x1220, 3000x1500, 1525x3050. This applies to finished products available in stores. When contacting manufacturers, it is possible to order custom sizes.

The scope of application of such sheets is as follows:

- construction;

- furniture manufacture;

- industrial production.

Most often, 10 mm sheets are required for furniture production and interior decoration.

Plywood boards with a thickness of 11 mm are extremely rare; the most common are sheets of 10, or thicker ones of 12 and 20 mm. Commercially available 11 mm products are most often presented in squares of 1525x1525.

Main dimensions

The veneer layers from which plywood is made are connected with various adhesives and kept under pressure until they fully adhere. These layers are laid on top of each other so that the direction of the wood fibers in the previous layer does not coincide with the direction of the next layer. This method improves the strength of the material to bending and other mechanical damage. The minimum number of veneer layers in a plywood sheet is made at least 3 - in this case, the size of the sheet thickness is marked as 3 mm. The largest number of them is 21 sheets, but the thickness of the finished material can be in the range of 30-40 mm.

Plywood dimensions may vary in width and length; each parameter is measured in millimeters. According to their size range, plywood sheets can be large, for example, 2000x3000 or 2000x3500 mm, and small, for example, squares 1220x1220 mm. The standard size of the thickness of the material directly depends on the number of veneer sheets glued together. The greater the thickness of the slab or sheet, the stronger the material.

Standard

Small errors in the dimensional parameters of a plywood sheet are also regulated by the state standard. GOST, adopted in our country, allows the production of these woodworking products in any size, according to the consumer’s order.

The most common width dimensions for plywood are 1220 and 1525 mm. The length of the product can be limited to 1525 or 2440 mm. Such parameters are in demand among consumers, since they are easier to use during work, and they can be transported by light-duty vehicles. Plywood materials with large format or non-standard parameters have a length of 3500 or 3660 mm and a width of 1500 or 1525 mm. Sheet materials with similar cutting are often used for finishing work when finishing large areas or for production needs.

Non-standard

Small-format wood-based sheet materials are also popular. On sale you can see products with the following dimensions: 1220 by 1220, 1220 by 1525 or 1525 by 1525 mm. Such minimal cutting is convenient because one person can handle a sheet of plywood without the involvement of third-party assistants. On the other hand, when facing with such sheets, there are too many joining seams, which sometimes is not a good solution.

With large formats, sheets are most often in demand, the dimensions of which are: 1525x1830, 1220x2440, 2500x1250, 1500x3000 or 1525x3050 mm. Such product parameters are not found by every manufacturer - some produce only part of the listed formats or are guided by their own dimensional standards.

Based on the GOST standards adopted in 1975, the dimensions of the sheet material are as follows:

- The length of the sheet is made from 1000 to 1525 mm, the interval for increasing the dimension is 25 mm;

- The width of the sheet is made from 800 to 1525 mm, the interval for increasing the dimension is also 25 mm.

Due to the fact that plywood is not subject to particularly precise requirements for compliance with dimensions, typical values can deviate from the standard requirements by up to 0.5-4 mm in length and width, and by 0.5 mm in thickness.

Dimensions of plywood 20 mm thick

Traditionally, the production of finished material 20 requires gluing together 15 layers of veneer. At the same time, this value is not always the same, since the thickness of the veneer used cannot be ignored. For example, sliced veneer up to 3 mm is less flexible, but its strength is higher. On the contrary, if peeled veneer is up to 1.9 mm, it is more elastic, but its resistance to loads is less.

The standard size is a square 1525x1525. The material is very durable and has a large weight - 30.7 kg. You can also purchase a larger format.

Such products are used for laying interfloor floors, as flooring for parquet, for interior decoration, for creating formwork (for pouring foundations), and in the production of furniture. Shields and stands often have a base made of 20 mm plywood. Children's playgrounds are also being built from it.

This material comes with the FC or FSF markings; there is also the FB marking. It is the most moisture-resistant and can even withstand exposure to sea water.

It should be taken into account that plywood thickness of 20 is not a sheet. This product is a plate. This applies to all material whose thickness is greater than 12.

How thick is plywood, its types and features

Plywood is a universal building material from which a large number of different products are made. How thick is plywood for use in different types of work?

Kinds

Plywood fragments are essentially compressed sheets of wood. Taking into account the glued layers, they are divided into three, five and multi-layer.

Plywood sheets with many layers

Note!

Cedar is used more often for production; deciduous trees are used much less often due to their high cost.

Due to different levels of moisture resistance, the following types are distinguished:

- FC - sheets with layers that are connected with urea glue. Its moisture resistance is relatively low. They are used more often for finishing rooms or for industrial furniture.

The thickness can be 3, 10; 12; 15; 18 and 21 mm. The density of the sheets is, respectively, 640 - 700 kg per cubic meter.

- FSF - made using phenolic resin. It is considered one of the most popular in construction. It has a high level of moisture resistance, strength and wear resistance. Used for interior decoration and roofing work. The nominal humidity indicator cannot exceed 10%.

Thickness can be 6; 9; 12; 15; 18; 21; 24; 27; thirty; 35; 40 mm. The density of the sheets is, respectively, 640 – 700 kg per cubic meter.

- FB, BS, FBS - produced by gluing veneer using varnish or bakelite glue. Used in aviation structures and in the shipbuilding industry. They have increased strength and water resistance, which allows them to be used in difficult conditions. The maximum nominal humidity is 10%.

The thickness is 0.5; 0.7; 1; 1.2; 1.4; 1.6; 1.8 cm. Density - about 1200 kg per cubic meter.

- BV - impregnation contains a special water-soluble glue - bakelite. Indicators and characteristics are generally identical to the previous type.

- FOF - called a laminated type of material. The upper part is distinguished by a facing film coating, impregnation of the tiles using synthetic resin.

Thickness 0.4; 0.65; 0.9; 1.2; 1.5; 1.8; 2.1; 2.4; 2.7; 3; 3.5 and 4 cm. The density of the sheets is, respectively, 640 - 700 kg per cubic meter.

According to the quality level, the following types are distinguished:

- The minimum number of errors is external;

- The presence of small veneer inserts or knots;

- There are defects, cracks, knots;

- Low level when gluing.

Thin sheets of material

Varieties

The following main types of plywood are distinguished:

- E – elite. It has few shortcomings and flaws, minimal deviations in structure are possible. To completely hide defects, there is a good method of varnishing.

- I – high quality. Cracks and defects no larger than 20 mm in size are acceptable. Suitable for exterior decoration.

- II – quality is at the proper level. Can be coated with different paints during finishing work. Defects can occur up to 200 mm, and there are also small leaks of glue.

- III – average level of quality. Can be used for arranging internal and hidden types of structures. The presence of a significant number of cracks and knots is allowed.

- VI – low level. Any shortcomings can be found here. It is used in any field - for roofing, flooring, wall installation, various packaging.

Types of plywood sheets

Of course, for each type the price will be appropriate.

Laminated plywood

This material is very moisture resistant. This plywood is produced by applying a special polymer film to its surface on one or both sides.

This panel can withstand temperature changes and other influences well. Due to this, laminated products are widely used in various industries. The standard dimensions of laminated plywood sheet are as follows (mm):

- 2440x1220;

- 2500x1250;

- 1220x2440;

- 1250x2500.

Essence of the question

Currently, the market offers a wide range of plywood, which differs in terms of strength, moisture resistance, environmental friendliness, etc. An equally important factor influencing the choice of lumber products is dimensions.

But due to the variety of offers, the selection instructions are difficult, since an inexperienced buyer sometimes does not have a clear idea of what dimensions of lumber products will correspond to the specifics of the planned work.

Marking with dimensions applied to the surface of lumber products

For example, slabs that are not thick enough cannot be used when making furniture with your own hands or when laying floors on wooden logs. Again, excessively thick lumber is not suitable for covering floors, since it is quite possible to get by with thinner materials with less weight.

Correctly selected dimensions, in turn, will allow you to cope with certain jobs without wasting lumber. Again, choosing the right format will allow you to complete the wall cladding faster, since it will be possible to cover an impressive space with a single slab and thus reduce labor costs.