Concrete caps for fence posts have recently become a mandatory element that can protect metal or wood from destruction. Such caps are both a protective and decorative element that can extend the life of the fence and significantly improve its appearance.

A concrete cap protects the fence from direct exposure to moisture and improves its appearance.

A concrete cap for a fence consists of a top, which serves as a decorative umbrella, and a lower part, through which the fastening takes place. More modern models of such caps allow even light bulbs for lanterns to be mounted on their top.

Caps for fence posts: what are they and why are they needed?

A cover installed on a fence post completes the fence design, giving it an exemplary appearance. The main function of this part is to protect the upper part of the fence from the influence of the external environment and destruction. Pole caps are made mainly of metal and concrete. The reasons why you should install caps on your fence are as follows.

- A new fence built on a property appears unfinished and looks less attractive if decorative caps are not installed on the fence posts.

- The structures protect the fence from rain, snow, hail and ice. A fence built from porous materials such as brick and natural stone is always susceptible to these influences. The caps will reliably protect it from natural factors.

- Installing special hoods to illuminate the area makes it possible to create original lighting effects.

What are the requirements?

Protective caps for poles, purchased ready-made or made independently, must meet a number of requirements:

- symmetry and compliance with the shape and size of the supports;

- declared angle of inclination (checked using special instruments);

- the presence of a frame overhang, its tight connection to the surface;

- the integrity of the packaging should be carefully checked upon purchase;

- compatibility with additional accessories of the original design (spans, podium for the lantern).

Construction of frame and formwork

The production of concrete fence posts primarily depends on a well-made mold for pouring. For handicraft production, ready-made plastic molds for filling with relief patterns are more suitable.

For monolithic supports for a chain-link fence, a collapsible form made from a pipe with a diameter of 100 or 150 mm can be used. Simple rectangular formwork can be made from boards or OSB.

The basis of the formwork in this case is a flat board or fiberboard 20 mm thick. With a size of 150x150 mm and a length of 2.4 meters, the width of the base must be at least 250 mm.

Filled installation

Identical boards 25–30 mm thick and 150 mm wide are used as the side walls of the formwork. The length of the boards should correspond to the length of the finished product.

Functions of fence covers

After the construction of the fence, the problem arises of protecting it from the aggressive effects of precipitation. Depending on what material the fence is made of, you should select the appropriate fence caps. Heads for fence posts can perform protective, aesthetic and support (for additional lighting) functions.

Protective function

By covering the tops of the fence supports, the caps protect the material from which the fence is made. This is reliable protection against moisture. Thus, brick and stone, having a porous structure, can lose rigidity, crumble and, ultimately, collapse. The materials from which the pole covers are made allow them to withstand any precipitation: rain, snow, hail and frozen ice. The configuration of the structure is such that penetration of liquid into the main structure of the fence is practically excluded. The cap for the fence is selected depending on the posts and fabric of the fence and can be made from several types of building materials:

- concrete;

- natural stone;

- plastic;

- metal (stainless steel, galvanized steel, tin);

- ceramics.

These materials are stable, durable, and the metal is not subject to corrosion.

Decorative value and lighting

The covering element of fences is not only protection, but can also be part of the design concept of the site owners. These details give the fence completeness and grace. Among the wide range offered by manufacturers, you can find caps for any fence posts that match the pattern and color of the overall landscape design. They can be combined with roof coverings, gazebos, and the design of a recreation area. To create an overall beautiful appearance of the territory, you can choose the following types of caps:

- imitation tiles;

- imitation scales;

- analogue of a pitched roof (in shape);

- simple cone;

- pyramid;

- hemisphere;

- decoration with a ball or forged elements.

In combination with such decorative elements on the posts, the fence will organically complement the overall appearance of the site, giving it a noble appearance.

The cap on the fence post serves as a reliable support for installing lamps on it. This solution will ensure illumination of the entire territory of the site and its surroundings, which is also important for safety. The main task is to choose the right type of lamp. Lighting elements are divided into two main groups:

- autonomous lamps, which are charged from a battery powered by photocells and do not require additional electrical wiring;

- lamps connected to an external network (12, 220 volts).

For lighting installation, concrete or metal caps are suitable, on which the lamps are mounted vertically.

Varieties

Heads that are installed on fence tables to decorate and protect them, depending on the material used, can be divided into several groups:

- metal caps. Use tin, galvanized steel or stainless steel;

- plastic caps;

- made of concrete;

- made of stone;

- ceramic lids.

Fiberglass fence caps

Nowadays, umbrellas for fence posts made of fiberglass are increasingly replacing heavy brick and stone. Modern high-tech materials - fiberglass and ABS plastic - are the best solution for bringing any design ideas to life.

Lighting devices inserted into such tips are not subject to getting wet and can withstand mechanical loads perfectly. In fiberglass hoods, fluorescent lamps can be used, providing the owner with energy savings (up to 80%). The material consists of fiberglass (70%) and polyester resins (30%). A fiberglass fence cap has the following qualities:

- strength;

- ease;

- flexibility and elasticity;

- UV resistance. Colored caps do not lose quality and depth of color;

- no corrosion;

- waterproof;

- resistance to temperature changes (-50...+80 degrees);

- wide range of colors.

The range of fiberglass finials is huge; there is always an option that will be both convenient and beautiful. The products are available in two versions: matte and glossy.

Brick caps for pillars

This type of fence caps can be classified into a special group. These products look very impressive, so their cost is quite high. Caps for a ceramic fence can be chosen in almost any color, which will blend organically with the surrounding landscape. Brick pillars decorated with ceramic tops look stylish and beautiful. Clinker brick tolerates frost for up to 100 annual cycles, retains its original appearance well and has low water absorption. The products are quite fragile, so very careful transportation is required.

Stone caps for fence posts

Today on the market there are many blank covers for fence posts made of artificial stone (lithium). The pleasant texture of the material and the variety of colors make these caps widely in demand. Stone caps successfully perform their functions of ensuring the safety of support pillars. In addition, artificial stone can be chosen to suit every taste, depending on the type of structure, type of paving slabs or other type of surface paving.

Concrete

Concrete caps are often called a protective lantern, which fully reflects its functions, as well as a tip, a mushroom or a cap. The protective effect is provided by two factors:

- the outer sides have an inclined profile, which ensures complete water drainage;

- The dimensions of the concrete cap are significantly larger than those of the others. This increases the degree of protection of the support.

The nuances of using concrete covers

To obtain durable concrete covers, plasticizers and fiberglass, as well as anti-frost additives, are added to the base material. Manufacturers produce products with the inclusion of color pigments, producing multi-colored blocks. The blanks can be coated with the same paint as the façade of the house. Over time, it will need to be updated regularly. Concrete tops are easy to install yourself, they are original, but there is one limitation. A concrete cap is not suitable for metal fence posts , so it is never installed on such posts.

Metal caps for the fence

Metal fence caps are made hollow. This simplifies their installation. Materials – stainless steel, galvanized iron – perform an excellent protective function. They are durable and not subject to corrosion. Hollowness does not affect the strength of the products in any way, but it significantly reduces their price. The comparative lightness of the workpieces makes them easy to transport and install.

Canopies that are mounted on fences are another protective element made from sheet metal.

Wooden lids

Wooden finials, as a rule, are installed for economic reasons, for a short period of time and have a decorative purpose. Wood, as a material, cannot protect the fence from moisture, snow and other natural phenomena. The main advantage of wooden lids is the ability to make them yourself. This requires only desire, patience and the necessary set of tools.

Manufacturing methods

Metal products for protecting support pillars are manufactured by stamping, bending and welding.

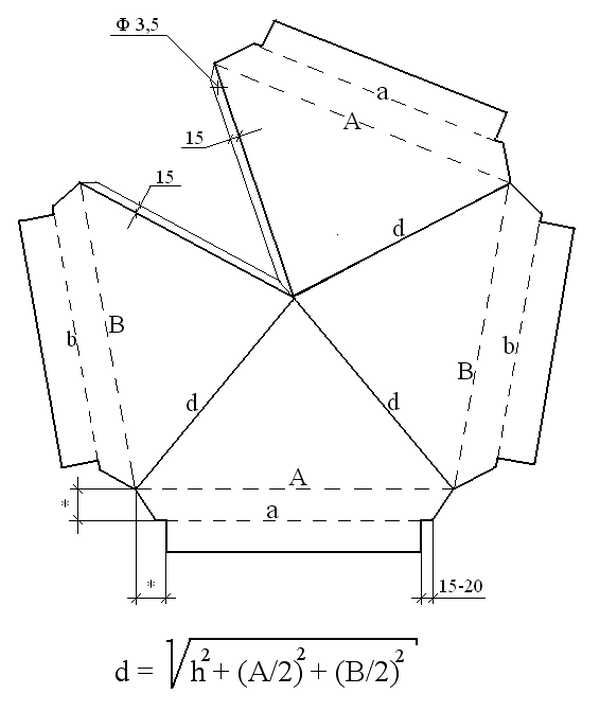

If desired, you can make a simple head from a steel sheet yourself. After measuring the upper surface of the support column, a drawing of the cap is made, according to which the development is cut out. Then the edges are bent, the product is assembled, fixed and painted.

Stamping

Tin roofing finials are made by stamping and bending. During the production process, it is done so that the number of folded locks (seams) is as small as possible. This is necessary in order to avoid even minimal penetration of moisture into the structure, which can cause damage to the support.

Bending

Forged protective caps for poles are made by cold forging and bending. The materials are steel sheet, round and square bars and steel strip. The cap is made of steel sheet. The blank has the shape of a cone or hipped roof. The rod is used to make decorative elements, just like a steel strip. The forged elements on the plugs look beautiful, but are still susceptible to corrosion.

Welding

The welding method is used quite often when working with protective structures made of metal. Welding is especially often used in the manufacture of chimney caps. Installation of such caps is carried out using dowel-nails or anchor bolts.

Casting

The casting method is used for the manufacture of metal caps and their components. As a rule, it is combined with other metalworking techniques.

How to attach caps to fence posts

The fastening of the protective structure to the support depends on the type of protective cover. For installation, you should prepare a small amount of cement mortar, glue, screws, and bolts that will be installed in the pillar elements. Several points are important:

- when installing the cap on the laid glue, it is necessary to ensure that the product protrudes beyond the boundaries of the support (so that the glue is not washed away by precipitation);

- caps made of galvanized steel are secured with dowels;

- When using any other installation technology, the main rule should be observed - ensuring the tightness of the seam after installing the cap.

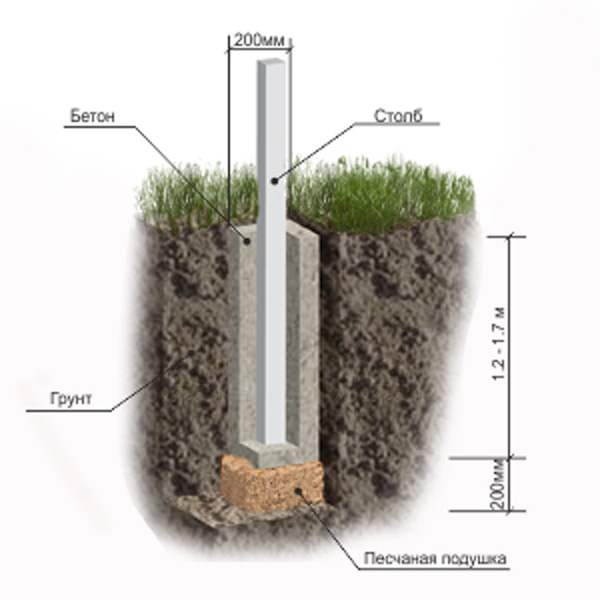

Installation of concrete headers on poles

You can install a concrete cap on a brick pillar yourself. For this, a special adhesive composition or cement mortar is used. It is applied to the cleaned and primed upper surface of the support, and then the top is placed on it.

It is important that the headrest hangs slightly over the post on all four sides. This will keep the seam from washing out. If it is planned to install a concrete cap flush with the side surfaces of the support, then the seams, in this case, are treated with water-repellent compounds.

The installation method described above is also used when laying covers on concrete or stone pillars.

What are the different forms of protective covers for fence posts?

Each owner strives to make his site special and tries to make a fence cap with his own hands. To become the owner of an interesting plot, there is nothing else to do but make the caps yourself. However, even the unique caps on the most original fence fall into a general gradation. Several types can be distinguished by shape.

- "Tile". Reminds me of a roof in design. The caps will harmonize well with brick supports. Columns decorated with “Tiles” of the desired shade and size will really decorate the site.

- “Under the roof” design. The shape is suitable for any type of hedge. Has various colors and sizes.

- Gabled concrete covers.

- "Medusa" is a form of metallic jellyfish.

Non-standard plugs

Unusual forms include samples:

- "Star". The pommel harmonizes well with a fence of complex design;

- corner plug for several supports;

- "Rectangle". Nozzle for area with geometric design;

- "Diamond-shaped." Ideal attachment for lamps.

In pursuit of originality, you can make your own caps. Caps for poles, made with caps and complemented with decorative elements, will decorate the area to the envy of the neighbors.

Design of protective covers

Choosing fence caps is the first step of a new design project. Depending on which pommels were chosen, the next steps will depend. Using metal products, you can decorate them with forged elements and original inserts. Plastic caps themselves come in different colors; they can be selected to match the leading color scheme of the site.

Protective structures can be of different shapes and designs. Nowadays, an abundance of materials with pleasant textures and original colors allows you to show all your talents in this area.

Requirements

The general requirements for protective structures, be they caps for brick fence posts, cast or metal posts, are as follows:

- the product must not have chips or surface defects;

- during manufacturing, proportions are observed and symmetry of angles and planes is ensured;

- the side adjacent to the support will ensure a tight fit when fastening using the recommended mounting compound;

- The packaging is dense, allowing you to transfer the required number of products without the risk of damage by standard vehicles.

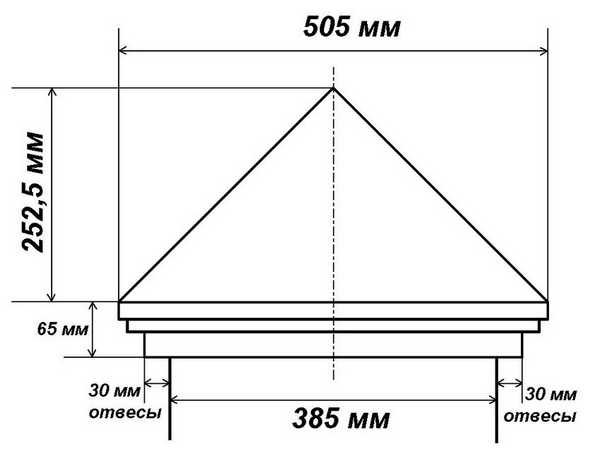

Scheme for assembling the cap to the required dimensions of the pole

It is mandatory to check the certificate of product compliance with sanitary standards and technological requirements.

This document will confirm the quality of the product and the provision of a guarantee for the product.

Scheme for calculating the top for a pillar