Features of dismantling various types of floors

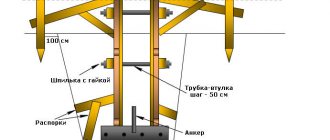

Figure 1. Dismantling floor slabs

for proper dismantling of floor slabs . First, all plumbing communications, electrical wires, and water pipes are removed. The floor covering is also removed. The lower levels, as well as the area around the entire building, are fenced off, because parts of the concrete structures may fall.

If it is necessary to dismantle the ceiling on several floors, then this should not be done at the same time. To disassemble the structure you will need a crane or winch. As for the order of work, first remove the cement screed and divide the slab into parts 30 cm wide using grooves. Next, the pieces of the structure are separated with a jackhammer.

Since there is a frame made of reinforcement inside the slabs, a gas cutter is used to dismantle it. Lastly, the supporting beams are removed. To disassemble a concrete vault, a longitudinal or transverse method is used. When destroying monolithic floors, the same principle is used as with slabs. To carry out the work yourself, you will need: a sledgehammer and a hammer, a hammer drill, a grinder, a nail puller, a crowbar, a hydraulic jack, supports, a gas cutter.

Kinds

To destroy a concrete structure, impact and non-impact methods are used. In the first case, a jackhammer is used. It is characterized by noise and dust. This type of destruction is economical, effective, and relatively safe. Impact-free methods involve the use of various cutting options. They are silent and therefore suitable for use in apartment buildings.

Figure 2. Dismantling floor slabs

Diamond cutting

Destruction of concrete slabs using diamond cutting is an effective and new method. A diamond-coated drill or disk is used for the work. It allows you to destroy hard concrete structures. The method has the following advantages:

- accuracy;

- minimal noise and dust levels;

- no vibration.

This option is optimal for partial or complete dismantling of concrete structures.

Rope cutting

technology is silent and completely safe. It is used to work with slabs of a certain thickness. To carry out destruction quickly and efficiently, the help of several people will be required.

Other methods of disassembling the structure

Today, ultrasonic and thermal dismantling . In this case, mechanized or manual devices are also required. Thermal effects are provided by high-power gas or plasma devices. As the concrete slab heats up, cracks and evaporation zones appear in it.

After ultrasonic treatment of the structure, the processes of tension and compression are activated in it, and erosion appears. Before using this method, a small hole is made in the material through which an ultrasonic wave is directed. Operation requires a special installation that creates destructive microvibrations inside the slab.

Application of special mixtures

In some cases, chemical compounds are used to dismantle concrete floors: NVR-80 or NRS-1M. They are initially embedded in the structure and lead to its cracking. The slab simply crumbles. You can remove fragments after 2 days.

Explosion

Large structures are destroyed with the help of explosions, since other methods will take a long time to work. However, this method is not used if there are other buildings nearby, since the shock wave can damage them. This technology is used to destroy dangerous buildings. It is effective, but expensive.

Electric arc

Concrete floors can be dismantled using electric arc technology. It is considered high quality. When heated by electric current, the composite melts. This method of destruction is combined with others.

Dismantling the ceiling

| House dismantling | Foundation | Paula | Balcony | Prices | Reviews about the company |

Dismantling floor slabs is a complex task, the solution of which is determined by their type and condition. Working with slabs that are in disrepair requires installers to be especially careful.

The following types of floors are distinguished:

- monolithic - several slabs tightly connected to each other, which separate the floors from each other and at the same time serve as load-bearing structures;

- wooden - beams made of solid wood. Working with them takes less time compared to other types of floor dismantling;

- concrete – reinforced concrete panels. Prices for dismantling this type of flooring are listed below.

Our works

Dismantling the ceiling, regardless of the material of the panels, is fraught with certain difficulties. When performing this procedure, there is always a risk of the building collapsing (if the approach is incorrect and safety precautions are neglected). And this can lead to the death of people. Therefore, the work should be entrusted to professionals in their field - our specialists. We guarantee safe execution of work using modern equipment and technologies.

Prices for dismantling floor slabs

Type of dismantling Concrete/m³ Reinforced concrete/m3 Brick/m3

| Jackhammer | 7400 | 11100 | 5500 |

| Hydro wedges | 7400 | 14800 | 3700 |

Cost of dismantling structures

Material to be dismantled Unit of measurement Cost

| Dismantling brick floors | Cubic meter | 3500 |

| Dismantling concrete floors | Cubic meter | 10000 |

| Dismantling reinforced concrete floors | Cubic meter | 12000 |

Technology

Dismantling of floor slabs is usually carried out using diamond cutting technology. This process can be carried out even in partially destroyed buildings. This type of work is carried out in stages and is the most gentle. Diamond cutting allows for the dismantling of floors in a non-impact manner, which reduces the risk of building collapse to a minimum.

This approach is also characterized by the absence of dust and vibration and guarantees an accurate cut to the size of the slab. Using diamond cutting technology, you can dismantle floors made of any material, including reinforced concrete. The risk of cracks or damage to communications is reduced to zero, so this method can be used in residential or already renovated buildings.

Dismantling process

Dismantling work must be carried out in conditions that completely exclude access to the site by unauthorized persons. Before starting work, the site must be inspected, a work plan drawn up and key characteristics highlighted. It is mandatory to obtain all permits for this type of work. Before the actual start of the procedure, all plumbing equipment is dismantled and ceilings are installed.

Specialists are able to work in non-standard conditions and quickly find a way out of difficult situations. Properly planned work completely eliminates damage to existing utilities and electrical networks.

Professionals, when dismantling floor slabs, comply with all safety regulations and work according to a pre-drawn plan, which allows them to reduce the cost of time and money. All work is carried out under strict control, excluding the occurrence of emergency situations.

Technologies for dismantling work in Moscow and St. Petersburg are constantly evolving, and our company tries to keep up with the times. By contacting us, you receive a guarantee for all types of work performed.

spb.almaznaja-rezka.ru

Dismantling of individual parts of the building

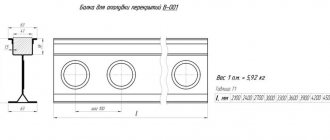

Figure 3. Dismantling concrete floors

The choice of method for dismantling concrete floors depends on many factors: the number of floors, the presence of a building in the neighborhood, and financial capabilities.

Concrete floors

This process is complex and dangerous. The presented design is the basis for the walls of the highest level (attic or floor). High quality concrete is used for its manufacture, so destruction requires careful preparation. It is not recommended to carry out this process yourself.

To work, you will need a hydraulic cushion, a crane, a jack, and diamond-coated cutters. If necessary, pneumatic devices are selected. Dismantling can be complete or fragmentary. The second option is necessary to organize a passage between the levels of the building. The work is carried out as follows:

- First of all, the floor is milled and the floor covering is removed.

- Next, supports are installed under the slab, after which direct disassembly begins. Impact methods cannot be used for work, as they can destroy adjacent or adjacent structures. This is especially true for multi-story or old buildings.

If the slab needs to be partially disassembled, the use of jack stands will be required.

Dismantling the floor screed

To dismantle the concrete floor screed, use a hammer drill or hydraulic hammer. You need to work in gloves, a mask and protective clothing. If disassembly of part of the flooring is required, milling is used.

Step-by-step dismantling of formwork

Dismantling the formwork can begin as soon as the concrete or other building mixture has acquired a sufficient percentage of strength. The drying time of the solution depends on construction conditions, type of building mixture, humidity, temperature, etc. When pouring concrete, gradual dismantling of the formwork can begin as soon as the concrete reaches 40% of the design strength. This usually happens after three days.

Thus, after three days you can dismantle the supports of the transverse beams and racks. In this case, the stiffening beams must still be supported by appropriate racks. Next, you can dismantle all the cross beams and racks, as well as disassemble the flooring panels. Stiffening beams with their racks are removed only 21 days after concreting, taking into account that the solution has reached its design strength.

Advice from experienced professionals

For high-quality and safe dismantling slabs, you need to take into account the recommendations of experienced specialists:

- the use of impact dismantling methods is expensive, since they negatively affect not only adjacent structures, but also human health;

- work on dismantling concrete structures is accompanied by the appearance of garbage and dust, so transport for waste removal and the place for their disposal are provided in advance;

- It is prohibited to perform destructive work without the appropriate skills.

During dismantling, it is necessary to use protective glasses and gloves, a helmet, and clothing. If necessary, use headphones, as some work is accompanied by strong noise.

How to dismantle an emergency building

If, due to the influence of external or internal factors, the concrete structures have worn out and the building has lost its strength, it is dismantled. The structure is also demolished if it is necessary to free up the site for the construction of a new facility.

The dismantling of entire buildings is carried out by companies that reconstruct old structures and erect new ones. They demolish both single-story and multi-level buildings, regardless of their design.

Hydraulic tools are used for work, and they can be used both inside and outside the structure. Such technical devices can be operated at a distance using remote control. Excavators, small loaders, and bulldozers are used to remove debris. In addition to technical devices, the following is required:

- design documentation;

- permission to carry out dismantling;

- expert documents.

To transport building fragments you will need cables, hooks and ropes. The area in which the building will be destroyed is fenced off for safety.

No matter how complex the job, safety precautions are a must. It is better not to carry out such a procedure on your own if you do not have experience or special knowledge. It is better to use the services of a construction company that specializes in dismantling.

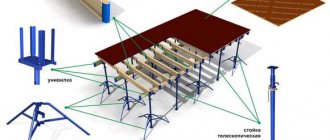

Features of dismantling horizontal formwork

Modern floor formwork is a construction set in which all the parts are clearly matched to each other. At the same time, the formwork racks can withstand numerous cycles of use, the height of the racks is adjustable, and accordingly, different ceiling heights can be set. The formwork system consists of a wide range of supporting structures, forming elements and fasteners. In rare cases, the formwork system becomes part of the building structure. However, in most cases the formwork is dismantled.

Dismantling of horizontal formwork is possible only after all technical checks of the building, complete drying of the concrete or other building mixture, that is, after achieving a certain strength of the structure.

During dismantling, the cross beams, their supports, floor panels, and heads are usually removed. In some cases, the floor continues to be supported by stiffening beams. Thus, the removed elements can be used for concreting another area or the next floor. At the same time, before you start pouring the building mixture on another floor, you need to wait until the concrete of the lower floor becomes strong enough. Otherwise, the lower floor will not withstand the load of the upper one.

Due to the simplicity of the formwork design, its dismantling is quick and easy.