How we sawed warm ceramic blocks | ImhoDom.Ru

So, out of common interest, the most curious of the forum members gathered in Vitaly’s hospitable courtyard, for which I thank him very much. A table was prepared, and on it was a block. Now, we will cut it:

The first was a hacksaw for metal. It cuts slowly, although evenly. But slowly - overall rating - 2

We changed the sawyer (kam) - the result was no better. Although there was talk - maybe the dust is getting in the way - and shouldn't it be moistened?

Then the builder of his own furnace modestly came out from the group of comrades and took out a metal blade from a metal-cutting machine. This way the quarters of the brick are cut evenly. Of course, poroton turned out to be simpler - the saw quickly moved along the block. Solid four” It’s quite possible to cut. But the length of the canvas is a bit short...

This is the canvas itself - there is an optical illusion here. It’s as if there’s an ordinary blade from a hacksaw lying on an ordinary brick. But this is not an ordinary brick, but a half-meter block, and a manicure file - the size of a knife. Remember - the blade is from a metal-cutting machine. Another plus is that this saw will obviously have a decent resource.

Bow saw. Despite her fiddling, she went down surprisingly cheerfully.

And what - the larger the tooth, the faster it turns out. The truth begs the question: how long will the holiday last, how long will it take to carry the canvas for installation? In total, the total is a solid three.

We tried it in the wet (in the snow) ... well, no, the saw goes down, and there everything is dry and dust flies again. Unless you water it with a hose - but that’s for those who love heavy equipment.

Along the way, questions arose about the geometry of the blocks. The 50 block somehow didn’t fit well with the 30 block. Is this how it was intended, or do different block models have different styles?

This is how quickly a vertical groove is made. It turns out to be an ideal ceramic channel - stick some channels in there, even a stash from your wife...

A drill was used - needless to say, the blast went off very well.

But they hammered a nail. Ten. The nail holds, although of course it easily passes through voids, but after 4 partitions it freezes firmly...

Don't loosen it with your fingers. In my opinion, it can easily hold a bookshelf. Everyone shook the nail - fig. I had to loosen it with a hammer.

Well, okay, nails - but the block needs to be cut! They also struck with a grinder - it’s easy to understand. But the grinder’s disc sticks out at most 12.5 cm. It's clearly not enough for a block. All the files turned out to be short!!

And then the hostess suggested chirping with a two-handed saw “Friendship”

Here it is!

Kam and I entered easily, passed through easily...

a few more moments...

And here's the cut. Two-handed saw - 5! The brush is not tired at all. But in truth, the saw turned out to be old, the Solzhenitsyn model. And what kind of saws and axes there were under Vissarionich - legends still circulate! I don’t know how a modern two-handed saw of the Sichuan model would behave - but the fact remains that the grip is large and the speed is vigorous.

In conclusion, we used the favorite method of masons with a cigarette - hammering. Well, thanks to the sectionality, the blocks are easily split into sections and, in extreme cases, you can use this “dirty method” - remove part of the block with a fairly smooth edge. In any case, a crack will not run diagonally - the tubular sections set the logic for their formation.

In conclusion, the conclusions are that the blocks are sawn, and, if necessary, quite well. Theoretically, another option arose - to take a performer with a tip and produce a block of the required length in the spirit of Rodin. But there was no hammer drill nearby.

For those who do not want to saw, there is, as an option, additional brick. You can even buy the same poroton one. 3 bricks = one block (in height).

But be that as it may, the legend about the difficulty of sawing a paroton block has been destroyed.

We thank the management of the Kopylovsky ceramic plant (Tomsk) for providing the blocks for a test drive!

imhodom.ru

How can you saw ceramic blocks?

In the process of constructing walls for houses, wall blocks are used, which have to be cut to give them the necessary parameters and prepare a place for installing windows or doors. For this, various tools are used, the choice of which depends on the type of product. The ceramic block has a fairly dense structure, so you will need to choose the right tool.

Specialized saw

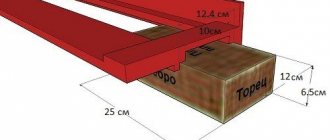

Outwardly, they are similar to conventional electric saws, but at the same time they differ significantly from them, making it possible to saw ceramic blocks. They have a guide along which two files move, constantly moving towards each other. The result is a smooth and neat cut, so that blocks can be divided with very high precision.

The disadvantage of such devices is their high cost, as well as the need to buy equally expensive additional blades. Also, for each type of block, separate blades are used that ideally cope with the task, so you will have to have several cutting tools in your arsenal to choose from.

The special saw is distinguished by:

- high performance;

- safe operation, since the number of fragments during cutting is reduced to a minimum;

- high cost and the need to purchase expensive consumables.

It is worth noting that when using a saw, you should not press too hard on it. This gives a small increase in productivity, but at the same time significantly increases wear, leading to rapid failure of the cutting blades.

Ordinary grinder

An alternative option is to use a regular grinder equipped with a stone disc (diamond is preferable). With it you will have to saw the ceramic block on both sides, and then chip it off using other available tools. In this case, the split line will not always be quite even, and the material consumption may increase significantly.

In addition, the grinder is distinguished by:

- low productivity - the cutting speed is low, so large-scale construction using an angle grinder becomes simply impossible;

- high danger of work - during the cutting process, many fragments appear that fly in all directions, so it is necessary to wear glasses and durable equipment to protect against injury;

- the need for a large number of consumables - the discs will wear out quickly, so a large supply of them will be required on site.

Separately, we can note a method in which it is not necessary to cut the blocks much - preliminary adjustment of the object, even before its construction.

samanka.ru

Alligator saw

What do professional workers cut with? Builders use a special type of electric hacksaw - “Alligator”. An electric hacksaw has two saw blades that move back and forth, imitating the movements of a crocodile's jaws.

The tool is very popular among builders due to its advantages:

- Provides a straight cutting line

- There are no vibrations during operation of the tool

- When the mechanism jams there is no reactive recoil

- Sawing blocks of any thickness

- Convenient to work in hard-to-reach places.

When answering the question of what can be used to saw expanded clay concrete blocks, we can confidently answer that an electric hacksaw is a good option. But the Alligator saw also has some disadvantages:

- High price

- Cuts into the surface only from the edge

- The cutting accuracy is lower than, for example, that of a circular saw.

When choosing an alligator saw model, it is better to choose tools from Bosch and Dewalt.

The Bosch GFZ 16-35 AC model is popular, which has a number of advantages:

- Has an electronic stabilization system

- Hard tire

- Start blocking

- Second handle (for left-handers)

- The ergonomic design of the model ensures ease of operation and lack of fatigue

- Replacing discs without tools.

Builders also often purchase the Dewalt DWE 397 model. This electric hacksaw has the following advantages:

- A magnesium alloy is used to make the gear housing, which removes heat and dampens vibration

- Electronic system ensures optimal cutting speed

- Removing your fingers from the trigger button stops the tool in a second.

Let's look at a comparison table of these models

| Model | Power | Number of double strokes per minute | The amount of blade stroke | Guide bar length | Weight | average cost |

| Bosch GFZ 16-35 AC | 1.6 kW | 800-2500 | 50 mm | 350 mm | 5.2 kg | 35,000 rub. |

| Dewalt DWE 397 | 1.35 kW | 3300 | 38 mm | 425 mm | 4.3 kg | 21000 rub. |

To save money, you can purchase Russian or Chinese electric saws. But the cutting quality will be significantly lower, and such tools will last less .

ART

All those who believe that an opinion that does not suit the reader does not give a fuck - are automatically sent to hell without a response comment. Let those people who have excellent communication with society and are ready to listen to their interlocutor and clearly process the information speak out (If you are a stupid schoolboy or just a redneck, don’t read, because constructive criticism is difficult for you and it’s much easier to crap on a person, right?). -due to the fact that Shevtsov, who began to judge the animation of Dobryak, the people of the first and second immediately caught on and began to throw shit at each other. And you know, some part of the people (including me) in such a situation turned out to be neutral. A good guy, not taking into account the animation, can raise quite relevant or “hot” topics in which he is, relatively speaking, right. On the other hand (!!! TO ALL HAPPY GOOD FANS: PLEASE SIT ON A BUCKET OF COLD WATER AND ICE) his animations leave much to be desired. After all, this is NOT professional animation. If any viewer and Alexey wishes, we can make exactly the same animation style. Therefore, Shevtsov was relatively right about animation, but he did not take into account the position of the artist himself. IN SOME places the latter is very right. Lech was also bombarded by the fact that there are quite a lot of good animators on YouTube, but, unlike Dobryak, they receive few views, money, and no one really knows about them. Here ITPIDIA)0) is right - this is not fair to the animators who are sawing up the quality. Also, I would like to add that a person, independent of his hobbies and activities, has the right to criticize the actions of another person with completely different interests. Therefore, those who like to say: “TRY DRAWING YOURSELF!” — I have a question for you: When you eat something in a cafe/restaurant/eatery, etc., do you tell the cook when the food is not tasty? If so, why don't you cook it yourself? Don't you know how? That's exactly why, if you judge something, you don't have to be a cook. From all this I want to say that Dobryak is right in SOME of his videos regarding any public issues/discussions, but at the same time he has poor animation drawing skills. And Lyokha only pointed out his simple style and bombed because of people like him (I already indicated why above). If you are already writing or wanted to write some kind of groundless insult, as I already said, you automatically and without a response comment go to hell and with all the desire, I am counting on your death because you, with such an approach to people, become worse than a dog.

vnclip.net

Electric diamond chain saw for cutting bricks Cardi ALLIGATORE

The Cardi ALLIGATORE electric diamond chain saw is specially designed for dry diamond cutting of hard and hollow bricks, expanded clay concrete blocks, proton, tuff, aerated concrete, siporex and other abrasive materials, as well as brick and stone masonry. It is an ideal diamond tool for cutting small holes and adjusting door and window openings during the construction and reconstruction of buildings and structures. Manufacturer: CARDI (CARDI) - Italy.

The Cardi ALLIGATORE electric chain saw is a dry cutting machine using a carbide metal chain. This is the ideal chain saw for cutting brick and light structures, also during the construction phase.

Fast, accurate, lightweight and easy to use, this saw is an essential tool on the construction site.

Cardi ALLIGATORE can be used in combination with the DA VINCI system to achieve a precise, effortless linear cut.

Advantages of the Cardi ALLIGATORE Electric Diamond Brick Chain Saw:

- Lightweight, simple and easy to use

- Specially designed for dry diamond cutting

- Uses oil lubrication to cool the carbide chain with diamond segments

- The electric motor allows you to work safely in enclosed spaces

- Multifunctional electronics: soft start, electronic switch

- Allows you to cut directly in the area where construction is taking place, eliminating the need to push blocks to a cutting machine with a table

- Allows you to cut large blocks

- Suitable for cutting solid and hollow bricks, expanded clay concrete blocks, tuff, aerated concrete and other abrasive materials

- Equipped with CARDI's "Anti-Chain Stretch" system, designed to minimize chain stretching, which typically results in long downtime and operator inconvenience.

- CARDI Total Protection System: The combination of 3 functions, electronic and mechanical, implemented simultaneously, provides maximum protection for the operator and equipment: CARDI Electronic Clutch or Electronic Load Limiter: – protects against overloads and prevents engine damage – no interruptions in operation and low operating costs service

- Smooth start: – ensures the saw is connected to a standard network (voltage 230 V) – safe operation for the operator at any stage of cutting – chain brake, which immediately stops the rotation of the chain if necessary

The ProfTechSnab company sells and delivers the product Electric diamond chain saw for cutting bricks Cardi ALLIGATORE from the manufacturer Cardi (Cardi) - Italy to all regions of Russia. On the website you will find reviews, photos, descriptions and equipment of the tool. Cardi equipment is covered by warranty and service.

tool-tech.ru

Choosing a power saw for aerated concrete for cutting blocks

Builders cope with this work using a drill with a large-diameter drill bit with pobedite or diamond teeth. Such a tool will overcome any material of increased strength, including solid expanded clay blocks.

Read our article about the pros and cons of a house made of expanded clay concrete blocks, as well as expert advice. There are several ways to cut an expanded clay concrete block into several parts, since different cutting tools are used, depending on the type of blocks, their quantity, and purpose. Which option should I choose?

The pros and cons of each method are easy to understand in practice. And since our builders have extensive experience working with this material, we share their advice with you.

Please correct e-mail address. Please correct phone number.

Cutting with a grinder. We make a cut on each side of the block. A circle of even the largest diameter will not cut the block completely, but only to a depth of 5.5 cm. For this reason, the expanded clay concrete block is cut along the perimeter to the maximum possible depth, and then it is split along the cut line.

There are several types of electric saws: chain saws, circular saws, miter saws, jigsaws, reciprocating saws. Relatively recently, a new tool appeared - the alligator saw. Externally, the alligator saw resembles the well-known chain saw, while the tire literally copies the blade of a hand saw for wood or aerated concrete. In terms of design, the closest analogue is the electric reciprocating saw.

Use only segmented metal discs with diamond coating on the cutting edge - even if they are deformed from heating, they will not burst, since the load is taken by the slots of the disc sectors. And here is the result!

Myths about Warm Ceramics

Low strength of ceramic blocks.

All wall materials have a compressive strength, which has a different abbreviation depending on the product. For example, for brick and ceramic blocks it is M75 (M100, M125, M150), for cellular concrete it is B1.5 (B2.0=M25, B2.5=M35, B3.5=M50), etc. Now let's figure out what this means at the everyday level. The strength of a single M75 brick means that every 1 cm2 of brick will withstand a load of 75 kg. The surface area of the brick is 300 cm2 (25 cm * 12 cm), which means that a single brick can withstand a load of 22,500 kg or 22.5 tons! For practical use, this figure, like the brand of brick or ceramic block, is not very informative, and here’s why. It is important for the customer that the walls, not the bricks, are strong and can withstand the applied loads. The strength of the walls will depend on the strength of its constituent elements and the qualifications of the mason. Due to the unevenness of the brick surface and the non-uniform density of the mortar, the brick in the masonry will experience bending and shear loads. Therefore, the strength of the masonry will also depend on the bending and shear strength of the brick. As a result, it turns out that when the masonry is compressed, its elements are in a complex state of stress and it is this that is the reason for the significant difference between the strength of the masonry itself and its constituent bricks and mortar. For example, the strength of brickwork on mortar of similar strength (we place M-100 brick on M-100 mortar) is about 35% of the strength of the brick itself, that is, 3 times less! The quality of the masonry also matters for its strength. If we take the average tensile strength as 100%, then with a lower quality the strength of the masonry will be 80-85%, and with a higher quality it will be 140-150%. The greater the height of the wall stone, the greater its cross-section and moment of resistance, which increases the strength of the masonry. The presence of voids in the stone increases the unevenness of stress, which, on the contrary, reduces the strength of the masonry. This is why some manufacturers test bricks or blocks directly in the masonry, because It is this strength, and not the strength of the brick, that determines the reliability and durability of the walls of your home. Let's look at the issue of the strength of warm ceramics using the example of building a country house with an area of 200 m2, overall dimensions 10 * 12 m, foundation perimeter 44 m/p. To understand the adequacy of the strength of the masonry, we need to determine the weight of the house (without taking into account the foundation, since it is lower than the walls), taking into account all the maximum loads on the floors and roof, as well as the area of support of the first row of ceramic blocks on the foundation. The weight of the house will consist of the main loads: - walls, about 85 tons - floors, about 100 tons - roof, about 75 tons Total 260 tons or 260,000 kg. We will find the support area of the first row of blocks (in cm2) as the product of the perimeter by the thickness of the block or the thickness of the wall: 44*100*38=167,200 cm2 We will obtain the load on the first row of blocks by dividing the weight by the calculated area: 260,000 kg/167,200 cm2=1 .55 kg/cm2 Now we see that the strength of masonry made of ceramic blocks is 18 times (safety factor) greater than the maximum load! Even if we assume that the masonry will be of lower quality and its strength will be 80% of the nominal value, then in this case the safety factor will be at least 14 times! For reference: when designing military facilities, the safety factor is assumed to be 4-5, which is considered more than enough for any unforeseen situations. PS In 2003, on the initiative and with the support of the Gosstroy of Russia, the “Center for Cellular Concrete” was created in St. Petersburg, which is designed, together with government agencies, to pursue a technical policy for the development of the use of cellular concrete in the Russian Federation. As part of this task, the Center tested masonry made of cellular concrete. According to the results of the test report, it turned out that the calculated strength of the masonry with adhesive made of cellular concrete D400 B2.5 M35 was only 11 kg/cm2 (see paragraph 11 in the Test Report), which is more than 2.5 times less than that of the masonry made of warm ceramics!

Ceramic blocks are slotted with thin walls, so it is difficult to hang equipment, kitchen furniture, etc. on them.

Block manufacturers solved this “problem” at the dawn of production, i.e. more than a dozen years ago. Together with fastener manufacturers, dowels for slotted ceramics or lightweight bases were developed, which are sold today in any hardware store. For fastening into a wall made of hollow-porous ceramic blocks, dowels made of synthetic material with a spacer area along the entire length are usually used. Due to this fastening, that is, passing through many walls, sufficient resistance to tearing is created, which is confirmed by the “HILTI Test Report”. Examples of fasteners can be found here. These tests tested dowels with diameters from 8 mm to 12 mm (d) and lengths from 40 mm to 100 mm (l). The test results showed that the use of a polyamide dowel with d=8 mm and l=50 mm + a screw d=5mm and l=70 mm gives a maximum pulling force of 151 kg, and an average of 115 kg! Increasing the diameter and length of the dowel increases the pulling force to a maximum value of 397 kg! For reference: as a rule, fastening of attachments is carried out using two or more anchors, the weight of a 55-inch (140 cm) LCD TV is about 20 kg, the weight of a large kitchen cabinet (80*36*32 cm) is about 25 kg + 25 kg of kitchen utensils, total 50 kg. As can be seen from the example, household items do not create significant loads on the anchor; moreover, the force from the weight of the equipment will be mainly directed vertically (shear), and the anchors were tested in the horizontal direction (pulling). In order for the anchor to fall out of the wall, the internal partitions and the outer wall, which determine the compressive strength of the block, must be crushed. Such a development of events is practically impossible, because in this case, the weight should be an order of magnitude greater than our 20 or 50 kg. If it is necessary to attach significantly heavier equipment to the wall, chemical anchors are used. The chemical anchor consists of a two-component, highly effective chemical composition and a rod. Basalt-plastic connections, threaded rods, reinforcement, pins, bolts, etc. are used as rods. The operating principle of a chemical anchor is based on the curing of the chemical composition of the anchor in a pre-drilled hole without the effect of self-stressing and the development of temperature deformations. After curing of the composition, multiple bonds of the chemical composition with the base material arise due to the roughness of the inner surface of the hole and molecular adhesion. Due to the similar values of the coefficients of thermal expansion of the chemical composition and base material, the anchor fastening in working condition is a monolithic connection.

When cutting ceramic blocks or warm ceramics, a lot of breakage occurs; the blocks cannot be sawed off smoothly.

If you follow the technology for processing ceramic blocks and select suitable equipment, destruction of warm ceramics does not occur. Ceramic blocks are cut in two ways: 1. Using special saws: reciprocating or Alligator type. Many well-known European manufacturers produce such slabs, and you can buy them in any store that sells tools. For cutting, you should use a particularly wear-resistant blade, usually black. 2. On a stationary machine, which, as a rule, is rented during the construction of external load-bearing walls. It makes sense to use the machine when cutting a significant number of blocks, for example, when building a house with complex architecture or multi-story residential construction.

Application area

This type of saw is recommended for use when carrying out carpentry work, when the use of other tools will not bring the desired result or their use is unsafe.

In addition, this device is in demand in construction during the construction of:

- Wooden structures.

- Frame type objects.

- Buildings made of gas silicate or ceramic blocks.

The alligator saw allows you to:

- Correctly form connecting nodes of wooden objects.

- Sawing blocks of porous materials.

- Saw off the required amount of insulating material, which includes mineral wool, polystyrene foam and other similar products.

To perform these procedures, manufacturers offer users special tools of this type:

- For the tree.

- For porous concrete.

- For insulating products.

An alligator saw is not recommended for cutting firewood. This is due to the fact that the work will be too labor intensive. In addition, the working part wears out quickly and has a high cost. For these reasons, cutting firewood with an alligator saw is also unprofitable from an economic point of view. It is not recommended to use the tool for carpentry work. This is due to the fact that the cut is wide and imprecise.

Rules of care

In order for a tool to last for a long time, it should be properly cared for. It is recommended to regularly lubricate the blades with oil and drop the liquid into the holes on the guide. Professionals advise performing this procedure every 20-30 minutes of work.