Advantages and disadvantages of diamond drilling

Diamond drilling has a number of advantages. Among them:

- Capabilities for producing precise round holes.

- Low noise level during work.

- No large amounts of dust.

- Capable of working on curved surfaces.

- Preservation of the bearing capacity of the foundations.

- Capable of drilling (diamond) holes with a diameter of up to 1 meter and a depth of up to 3 meters.

- High speed of work.

To work using diamond installations, you only need access to an electrical outlet (220 or 380 W) and running water (for cooling).

Drilling installations are not without their drawbacks. These include:

- Maximum productivity possible only by increasing axial force and peripheral speed.

- The need for water supply.

- Inadmissibility of beatings and distortions of the installation.

Drilling tools

The main installations for creating holes in concrete include:

- Conventional and impact drills;

- Hammers;

- Drilling and drilling rigs (electric and hydraulic).

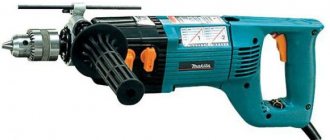

Impact drill, rotary hammer and diamond drilling machine.

Drilling and drilling are performed using special drives, which are a machine with an electric motor. Manual versions of the equipment are also available that maintain optimal rotation speed. To ensure high accuracy of the drill angle, the drives are complemented by a support flange with rods attached to it. The mechanism moves along such rods. Coolant is supplied to the working area using a special device.

Electric machines for drilling (diamond) and other operations are produced in several versions:

- Pistol type. Such installations are suitable for creating holes with a diameter of up to 10 mm.

- With handle. Such products allow you to create recesses with a diameter of up to 15 mm.

- With two handles. Such installations allow making recesses of large diameters.

Special electromagnetic drills are actively used for drilling.

Such devices are equipped with two motors. One rotates the drill, and the second provides up to 3 thousand blows per minute. The rotation speed of the unit is adjusted by the operator. Special drills that provide drilling have a 3-stage speed control. This system is more reliable than the standard electronic one. When creating holes with large diameters, a frame is required, on which the motor and chuck are mounted. The frame allows you to create recesses at an angle of up to 45 degrees to the wall. Some frames are equipped with a vacuum mounting plate. This allows you to better secure the base to the surface being treated.

The modern instrument has many advantages

. Among them:

- Wide range of possibilities for diamond drilling and other operations

. Using the equipment, you can create niches in concrete and other materials, make grooves for laying cables, ensure the installation of heating and sewer pipes, install ventilation systems, and even drill rocks to take samples. - Relatively small in size

. Diamond drilling rigs are suitable even for use in cramped conditions. At the same time, diamond processing is carried out at a high quality level. - Minimum level of vibration and noise

. Even complex drilling does not increase the risk of foundation destruction. This is due to the fact that the installations are supplemented with special noise suppression systems and protective covers. - Safety and convenience for the operator

. The devices reduce the effort required for drilling operations to a minimum. The specialist only needs to monitor the operations being performed. - Availability

. The lines of many manufacturers offer relatively inexpensive drilling devices.

The right drill bit for a concrete hammer drill: dimensions are important

The main criteria when choosing consumables for your own needs are the dimensions of the hammer drills, to be precise, length and diameter. Moreover, the diameter will depend on what you are going to drill, that is, you first need to decide on the purpose of purchasing drills. Exactly the same can be said about the length, since one person just wants to hang shelves or a picture, while another needs to drill concrete for electrical outlets.

Diameter and length of concrete drills

Photo from website: bsf.ru

In everyday life, drills of small diameters are most often required, which are easy and simple to buy in a set. As a standard, there will be drills with gradations from four to ten millimeters. However, there are complete sets that include both small drills and large ones, for example, from 10 to 20 millimeters. It is worth knowing that all manufacturers have agreed to produce drills exclusively with a diameter that is a multiple of even numbers, and therefore the fasteners correspond to a similar pattern. Please note that the diameter of the drill and the hole you require must be identical, otherwise a problem may arise, for example, with a small dowel.

Regarding the length, the choice is also quite wide. On the modern market there is a huge assortment of drills, the length of which varies from ten centimeters, including the tail fastening part, and up to one meter. The use of drills that are too long sometimes leads to uncontrolled beating, which can easily lead to damage to both the drill itself and the expensive power tool. If you figure out which drills are best for a rotary hammer, then you should pay attention to the minimum long ones, depending on the required hole depth.

Photo from the site: stroisovety.org

Interestingly, if the standard length is not enough, you can use a drill bit extension for a rotary hammer, which is available on the market from many manufacturers, for example, Drebo. The kit immediately includes couplings for fastening, which is important.

Types and types of drills for concrete

All drills for concrete can be divided into two main types - breaking and through. The first ones are designed to destroy the surface, while the second ones are designed to make holes, so this point must be taken into account. But that's not all, since there are several more basic types that differ structurally from each other.

Photo from the site: recn.ru

- Flat drills are used for drilling holes of great depth, but the slurry is removed slowly, due to the shallow angle of the spiral cutting. Moreover, when drilling you will have to make additional efforts, that is, working with such a drill is difficult. But the service life of such drills is the longest and this makes sense.

- Self-sharpening drills, that is, auger drills, can also drill concrete to greater depths, but there is no need to apply physical force. Most often, such drills are specially brazed from pobedite for greater strength.

- Spiral drills are most often used for making large diameter holes. Such drills are suitable for dismantling not very thick walls, installing air conditioners, switches and sockets, and the behavior of electrical wiring.

Special drills for rotary hammers

In addition to all of the above, there are also special drills that have a specific purpose. Moreover, if you have a need for something similar, then it is better to be prepared for such a situation.

Photo from the site: recn.ru

- A special chisel, made in the form of a peak, is designed to destroy concrete and reinforced concrete structures.

- Using a flat chisel you can chip away concrete quite accurately.

- To make large-diameter holes, for example, for sockets and junction boxes, you should use a special drill bit.

- Laying the leads also requires a special approach; a channel drill can be used for this purpose.

Important

You should know that an earth drill for a rotary hammer is not provided by any manufacturer. True, craftsmen from time to time manage to solder or twist something, but according to safety regulations, such actions are prohibited and are fraught with severed fingers and knocked out teeth. Therefore, you should think ten times before doing something like that.

Diamond drills and augers

The cutting part of the entire equipment is diamond chips ranging in size from 150 to 500 microns.

A mixture of diamond chips and metal powder is pressed to form individual segments. They are first sintered and applied to discs, drills, cutters, crowns and other tools. A large range of drills and drills are used for drilling work. They are available in various sizes.

Small diameter drills are popular: from 8 to 16 mm. Such products have a length of 250 mm and the following markings:

- SKA1. Such drills are suitable for creating recesses in concrete grades M250-M300.

- SKA2. Such drills drill M300-M500 concrete.

- SKA3. Such drills are suitable for drilling concrete grades above M500.

Unlike drills, drills are cylinders made of steel. Drills can have a diameter of up to 1000 mm.

Design features of SDS-Plus concrete drills

The innovative design of SDS drills allows for fast and easy impact drilling in even the toughest concrete structures

Like other drills for concrete hammer drills, SDS-Plus type equipment has a shank

for mounting in a chuck,

a drilling part

for forming a hole and

a head

in direct contact with the material. The main distinctive features of such drills are:

- Special shape of the shank , corresponding to the chuck mounting system: there are 4 grooves on the body of the shank - 2 open and 2 closed. Open grooves are designed for engagement with guide wedges, closed grooves provide fixation using locking balls;

- Drilling part of the "groove in a groove" type ("double flute"): this solution forms an effective slag removal spiral for quick cleaning of the drilled hole;

- Heavy-duty head : Thanks to the carbide tip, the SDS-Plus concrete drill bit easily penetrates even particularly hard concrete materials and stone.

Chrome-molybdenum tool steel is used for the manufacture of drills

, the head soldering is made of

tungsten carbide

.

On our website you can buy SDS-Plus concrete drills with a diameter of 5.0 and 5.5 mm with different lengths of the drilling part.

How to make a choice?

When choosing devices for creating various holes (drilling work), you should focus on the performance and power indicators of the devices, features of their design and functionality, and ease of drilling.

Take into account the parameters of the hole you need to obtain. Drilling rigs are suitable for drilling work, but for creating large holes in concrete, it is better to choose drilling devices. Experienced specialists are always ready to help you. They will talk about the features of the tool, announce its cost and performance characteristics. This will greatly simplify the selection process.