Selection of plaster

When selecting a protective coating for finishing the surface of penoplex, you should take into account the technical characteristics of the insulation. According to experts, silicone compounds are best suited for this purpose. The surface of such coatings is highly resistant to precipitation in the form of rain, snow and hail.

Scheme of facade plastering using penoplex

A good result can be obtained by finishing the surface of penoplex with mineral plasters, to which polymer components have been added. Such solutions are quickly fixed to the base, have low water absorption rates, and resist the appearance of fungus and mold.

Now let’s look at the features of specific types of decorative plaster.

Bark beetle

This solution contains white powder and small stones. According to the builders, the final pattern painted on the wall will depend on the size of these pebbles and the movements carried out by the plasterer.

Plaster type "Bark beetle"

Typically, granules with a particle diameter of 2.5 millimeters are added to such mixtures. Bark beetle is a mineral plaster with polymer additives. Its advantages are excellent frost resistance and the absence of harmful additives.

Pebble plaster

It is a textured coating consisting of small pebbles, similar in appearance to pebbles. For the manufacture of the material in question, such types of natural raw materials as marble or granite with a particle size of up to 4 millimeters are used.

The structure of pebble plaster

This mixture is held together using a binder and sand. The main advantages of pebble mortars are resistance to sunlight and moisture, plasticity of the composition and strength with respect to mechanical loads.

Lamb plaster

It is supplied to hardware stores in the form of a dry mixture, which consists of white cement, as well as fine aggregates such as marble, quartz and dolomite. The material is well fixed to the base surface, has excellent water-repellent properties, and resists mechanical stress and the effects of fungus and mold.

Mosaic decorative plaster

It is made on the basis of acrylic resin with the addition of colored chips. Such compositions have good elasticity and mechanical strength.

Mosaic plaster

To finish the facade of a building using insulation, solutions with a diameter of colored particles from 1 to 3 millimeters are used.

Is it possible to paint penoplex? What to paint with?

The final finish of the insulation will be more wear-resistant and aesthetically beautiful if it is subjected to the dyeing process. But be careful: not all putties benefit from staining, so read the instructions on the packaging of the putty you are using. In the instructions you should probably find all the answers to your questions: is it possible to use paint, and what composition should the paint have in order to ideally match your putty. When choosing paint, you should also take into account the chemical characteristics of the insulation itself, since not all paint is suitable for penoplex. Only if you choose the right paint, taking into account all the nuances, will your facade be durable and of high quality.

Preparing the base and gluing the slabs

Penoplex slabs serve as the base surface for applying plaster. This material must be attached to the wall using a special glue, and the products must be located on the surface of the facade according to the principle of brickwork.

The joints are sealed with special polyurethane foam for penoplex. The remaining protruding foam can be cut off with a sharp stationery knife. This type of insulation will prevent the formation of cold bridges.

The adhesive mixture is applied with a notched trowel, after which the slabs are secured to the surface. If the surface of the walls is uneven, then the required layer of mortar is glued onto the insulation boards, then the product is fixed to the surface according to the building level indications.

The final fixation of the insulation is carried out with plastic dowels made in the form of a parachute, but this work is carried out the next day after gluing the insulation boards. At the end of the work, we should have a perfectly level base. The places where umbrellas are hammered are sealed with mortar, with 5 dowels for each sheet.

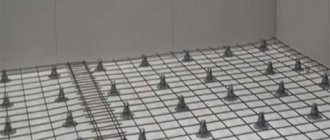

Mesh reinforcement

To securely fix the decorative finishing layer, it is necessary to lay a special mesh on the surface of the insulation. For this purpose, it is recommended to choose materials with a density of 140 to 160 grams per m2.

Mesh for reinforcement

This mesh has sufficient density to obtain an even layer of plaster. Similar products can be used for pasting corners.

Installation of the mesh begins with the corners of the building, as well as slopes on window and door openings. To glue the material in these places, cut a 30-centimeter piece with a length equal to the length of the slope. We bend the strip in the middle and apply it to the corner part. After this, using a spatula, apply a universal adhesive mixture with a thickness of 2 to 3 millimeters.

At the next stage of work, it is necessary to attach the mesh to the solution and carefully press it with a spatula. The reinforced fabric is attached to the surface by smoothing from the center to the sides. To cover the rest of the surface, cut the mesh into equal pieces 1 meter in length, then apply the adhesive mixture over the area of the product and apply reinforced fiber.

We press the mesh against the wall using a spatula from the center in the upper and lower direction. We glue the materials overlapping, matching the joints by 5 centimeters. It is recommended to avoid joining the mesh to the joints of thermal insulation boards.

Next, the surface is grouted using a special trowel with an attached emery cloth. The wall treatment should be carried out using a dried adhesive solution. If in warm weather such a mixture dries within 2-3 hours, then in cloudy weather with low air temperatures, you need to wait at least a day to carry out such operations.

Surface treatment

Next, preliminary leveling of the base is carried out, which will allow you to obtain a high-quality plaster finish. The described work is carried out in the following sequence:

- Apply small portions of glue to a wide spatula;

- Apply the solution to the wall with light movements;

- After the adhesive mixture has dried, the surface is thoroughly grouted.

Application of decorative plaster

To securely attach the plaster layer, it is necessary to prime the surface. When using a primer, the base receives protection from the effects of mold and mildew, and surface adhesion increases.

The finishing mixture is applied to the facade using a wide spatula. During this work, you need to ensure that the solution is placed on the wall in an equal layer. Its value will depend on the fraction of plaster grains.

Final application of plaster

To obtain a textured surface, rollers or sponges are used. Such tools are especially effective when laying bark beetles. At the last stage of work, after the finishing layer has completely dried, the facade is painted or additional protection of the coating is done with colorless varnish.

Some nuances of the process of facade plastering using penoplex:

- It is recommended to carry out the work in the warm season at positive air temperatures;

- Plaster adheres better to the facade if a mesh with small cells was used for reinforcement;

- When finishing, you need to use plaster, adhesive mixture and primer from the same manufacturer;

- Allow some time for the individual layers to dry;

- The primer is applied using a short-haired paint roller;

The absence of a reinforcing mesh will soon lead to peeling of the plaster.

Some tips

Now let's look at a few tips that will help you avoid possible troubles:

- If you are plastering penoplex near a doorway, it is recommended to place the solution a little “flush”.

- If after plastering the wall you have a little mortar left, you do not need to spread it on the dry wall, since over time the new layer may move away from the old one. This is due to the temperature and thickness of the plaster layer.

- The optimal temperature for applying plaster ranges from +10 to +20. degrees Celsius.

How to apply plaster to a façade insulated with penoplex?

To insulate the facade, foam plastic, penoplex or polyurethane are often used. These synthetic materials perform their functions well, but they need to be protected from external adverse factors.

This may include wind, rain, snow and hail. To create a protective barrier and at the same time give the building an attractive appearance, facade plaster using penoplex is used.

Mixtures

Construction stores offer several types of plaster mixtures that are suitable for working with penoplex. It can be:

- Mineral. The composition includes Portland cement and various polymer additives. They make the mixture more plastic than, for example, ordinary sand and cement, so the solution is easier to apply. This plaster resists precipitation well and is not affected by fungi and mold.

- Silicate. Excellent elastic plaster. Permits moisture from the room, but does not absorb water from the atmosphere. Has antistatic properties. Manufacturers claim that such compositions can be used for both external and internal wall decoration.

- Acrylic. This option is perfect if the plane can be deformed or located in a place where there is constantly high humidity. Both the liquid solution and the frozen layer are elastic. The plastered surface repels atmospheric moisture and perfectly resists ultraviolet radiation, so it remains attractive for a long time.

If the home owner does not know which option to choose, then you need to pay attention to the service life of the plastered surface. Acrylic compositions are considered long-lived. Their service life can exceed 20-25 years. But this takes into account the fact that all the work was carried out correctly. Then come the silicate ones and then the mineral ones.

The duration of service will depend on the invoice. Ideally smooth surfaces lose their original attractiveness much faster. But rough and textured ones are much less susceptible to deformation.

Choosing the composition

Several types of plaster are used for cladding penoplex. They all differ in their component composition and are characterized by certain properties. So, there are the following types of solution:

- Plaster based on mineral components;

- Silicate mixture;

- Acrylic plaster.

Silicate plaster from Ceresit

Mineral mixture

Thus, the mineral composition is made from cement and various polymer additives. This plaster is characterized by high resistance to moisture, resistance to fungus and mold. The price of such plaster is quite affordable. Due to the elasticity of the mixture, it is easy to apply to the surface to be treated. This is an excellent option for protecting insulation.

Silicate mixture

The silicate composition has unique properties. In the production of such plaster, liquid glass is used, which gives the solution excellent properties. Thanks to these components, the plaster adheres perfectly to the surface, becomes durable after drying, and is not afraid of water and moisture. Therefore, it is used both for interior decoration and facades.

Acrylic plaster

Acrylic plaster is used to finish surfaces that are exposed to moisture and sun. This is all possible due to the components that are present in such a mixture. So, where cement mortar cannot cope with the task, acrylic mixture will come to the rescue. And the cost of such a solution is naturally higher.

Manufacturers of building materials offer consumers a large selection of plasters. Various mixtures from Knauf and Ceresit have proven themselves to be excellent.

Experts recommend: When starting repairs, remember - for good interaction of materials, choose primer, putty and plaster of the same brand.

Inventory

If the owner of the house decided to apply facade plaster using penoplex with his own hands, then he will need to purchase the following materials and tools:

- Mixture for plastering.

- Reinforcing fiberglass mesh for outdoor use. It is better to choose with a density of 140–160 g/m2.

- The spatula is wide and narrow. The first is for applying the solution to the wall, the second is for laying the mixture on a wide spatula.

- Grinding grater with hard blade.

- Roller.

- Tools for creating texture. It may be a hard sponge or a special roller. Texture can also be created using a spatula.

If everything is clear with the tools, then how to calculate the required amount of mixture for plastering. Professionals recommend using the following data:

- 4 kg per square meter when securing reinforcing mesh

- 6 kg for finishing and creating texture.

How to paint penoplex?

Plastered insulation, prepared for finishing, can be painted with any facade paint: acrylic, silicate, latex or water-based.

Sometimes penoplex is used not as insulation, but as a material for decoration. For example, brick or stone masonry is cut out on its sheets.

In this case, when painting, you cannot use paints with solvents. They will corrode polystyrene foam. Acrylic or water-based compositions work well.

Let's summarize. Plastering penoplex does not require much experience or special skills. But you need to remember about the use of reinforcing mesh and adhesive plaster solutions. The simple technology provides great opportunities for decorating walls and allows you to create a unique look for warm facades .

We hope that this article was useful to you. Leave your feedback and questions in the comments below.

prodekorsten.ru

Step-by-step instruction

After the penoplex is glued and secured with dowels, you can begin applying facade plaster. When a person is applying plaster for the first time, he needs to try it on some surface. For example, on the remaining sheet of penoplex. Then you can understand how comfortable it is to hold the instrument.

Kneading the mixture

It is very important to approach the first stage responsibly. You need to prepare the mixture according to the instructions, which must be on the package. If you are doing this kind of finishing for the first time, do not prepare a large volume at once. The solution hardens quite quickly, and if you don’t have time to handle it, you’ll just have to throw it away.

To secure the reinforcing mesh, professionals recommend preparing the solution a little thinner than indicated on the package. Then you can slightly reduce the material consumption, and the mesh will be fixed much easier.

Installation of reinforcing mesh

First you need to cut the mesh into small pieces 30 cm wide. I fold them in half. These pieces will be used for laying on the corner, or you can buy ready-made corners with a mesh at a hardware store. It is from the corner of the house that they begin to install the reinforcing mesh on the penoplex.

After this, you can begin finishing. On both sides of the corner, at a distance of 15 cm, apply a plaster solution. The thickness should not exceed 3 mm. Then the bent reinforcing mesh is laid. It needs to be smoothed with a spatula and pressed a little into the solution. You need to move from the corner, starting from the top. The slopes of windows and doors are processed in the same way.

Then they work on the surface of the wall. A layer of solution is also applied that will correspond to the width of the mesh. Then the reinforcing layer is laid. Each piece should overlap the previous one, by 5–8 cm. Smooth the surface with a spatula and press the mesh. On a flat surface, move from the center of the piece.

How to align a layer

To create a final even layer you need to do a few more manipulations.

- About a day after completing the installation of the reinforcing mesh, you need to sand the surface. This is exactly how long it takes for the layer of plaster to dry well.

- A grater with sandpaper removes unevenness that could have formed when smoothing the mesh with a spatula. You need to rub in a circular motion with slight pressure.

- Then you need to apply a layer of primer. There is no need to skip this step. The primer will help the dried layer of plaster and the finishing layer adhere more firmly. In addition, if you choose antibacterial and antifungal properties, you can protect the coating from the effects of microorganisms.

- Now apply a leveling layer. The mixture is prepared according to the instructions. Apply with a large spatula, no more than 3 mm thick. Individual sections should not coincide with the joints of the reinforcing mesh.

- Then the layer is left to dry for 1–3 days. Drying time depends on the mixture itself and weather conditions. If the ambient temperature is high, it will dry out faster.

- Then you need to use the grater again. Remove small bumps and depressions.

Finishing

If you get a perfectly smooth wall surface and this texture suits the owner of the house, then you can leave this façade. To give it a more attractive look, you can use acrylic paint. A wide color palette will allow you to turn your wildest ideas into reality. But you can create a more original surface of the facade walls. Special decorative plasters are sold for this purpose. They are applied in a thin layer, and the texture is created by small inclusions.

You can also use a regular plaster mixture and special texture tools (roller, sponge, spatula or improvised materials). The texture is created from the raw surface, both with decorative compositions and with ordinary ones. After hardening, it will no longer be possible to create a drawing.

Is it possible to putty penoplex?

Putty is the finishing of walls using special putty mixtures. Most often, acrylic or powder putty intended for facade work is used for this work.

What types of finishing putties are there?

All putties from the Ceresit brand have proven themselves to be the most effective, but if you trust another manufacturer, you can also use putties from another company. The putty should be selected based on the surface it will be applied to. For puttying walls, there are both powder and paste mixtures. Paste mixtures, in turn, are divided into acrylic, adhesive, silicone, latex, oil and combination. For penoplex, acrylic putty and powdered putty have proven themselves well.

When choosing a putty mixture for facade work, first of all, you need to pay attention to the binders contained in it and how high quality these substances are. Depending on the quality of the binding element, the putty can be very resistant or, conversely, unstable to various weather conditions: cold, damp, heat, frost. So, for example, if you subsequently plan to paint the facade, then you can use good quality putty Ceresit CT-225, which is a good base for painting and has qualities such as frost resistance, impact resistance and moisture resistance. By choosing a high-quality putty, you can be sure that over time your finish will not crack or crumble.

Also, when choosing putty for your facade, consult with the seller so that he can help you choose the one that is moisture resistant and not afraid of temperature changes, otherwise you will simply waste money and time on exterior work. It is important to remember that those putties that are intended for interior work are completely unsuitable for the facade, so you should not save so that you do not have to redo the work.

The process of applying putty to the wall. Preparing the putty

If you decide to use powder putty, then first you should dilute it. To do this, fill a bucket with water (a little less than half) and carefully add the powder, stirring continuously with a mixer. The consistency should be approximately similar to mashed potatoes. After the mixture reaches the desired consistency, it should be left for 5 minutes in a calm state, and then beat again and you can start working. Acrylic plaster is applied to the wall immediately without prior preparation.

The process of applying putty to the wall

To apply the putty, you should use a very wide spatula, on which the mixture is placed using a small, narrow spatula that fits freely in a bucket. When finishing, it is very important that each new finishing area merges with the previous one, previously puttied. The joints should be almost invisible, so if you are not confident in your skills, then it is better to invite a specialist for this work who will do everything quickly and efficiently.

Before applying putty, do not forget to treat the wall with a special primer, which will provide additional waterproofing. The layer of putty applied should not exceed 5 ml; after it has completely dried, the entire surface should be grouted. Rubbing should be done in a counterclockwise circular motion, using an abrasive mesh. Do not forget that grouting should be done no earlier than 3-4 hours after applying the mixture. Having finished grouting, you need to apply the primer again, this will help get rid of dust particles on the surface of the walls and make the surface of the facade perfectly smooth.

Once the primer has dried, the next process of work begins - painting.

Recommendations from experts

In order for the end result to please the owner for a long time, everything must be done by adhering to the following recommendations. This applies not only to plastering a facade insulated with penoplex.

- The packaging of the plaster indicates in what temperature range it can be worked. You should not ignore it, otherwise the layer will not be as strong as the manufacturer predicts.

- Be sure to use reinforcing mesh. If it is not there, the plaster will simply fall off after a short period of time.

- You need to buy a plaster mixture from one manufacturer for the entire facade and preferably with a small margin.

- Manufacturers also indicate the time for complete drying. The recommended time frame should be adhered to.

- And don't forget about the primer.

Penoplex plaster application guide

Penoplex is considered one of the most popular types of insulation on the domestic market. The material is actively used for finishing interior walls and facades of residential buildings and industrial premises. Since synthetic heat insulation is not a finishing coating, it needs to be covered with special Penoplex plaster. The application technology is not very difficult, so it is quite possible to cope with the work on your own.

Selection Guide

Penoplex facing material – reliable protection of thermal insulating boards from biological and mechanical damage, extending their service life. Inside the room, plaster not only protects the insulation from fumes, but also serves as an effective decoration. Therefore, before you buy a finishing material, you need to study its composition and find out the nature of the surfaces being treated.

1. Mineral plaster - a combination of Portland cement and polymers shows high resistance to biological aggression and precipitation. The solution is suitable for cladding walls outside and inside the building. It has good adhesion and is easily and evenly applied to the base.

2. Acrylic finish is a material with good elasticity, moisture resistance and resistance to solar radiation. The use of acrylic resin plaster is recommended for deformed surfaces and areas with high humidity.

3. Silicate composition - elastic plaster has antistatic properties, excellent vapor permeability and resistance to precipitation. The instructions contain recommendations for use on the external and internal finishing of Penoplex.

The service life of solutions varies, so special attention should be paid to this indicator. Acrylic mixtures show the best resistance to mechanical stress and durability. The service life of such cladding is 15-25 years. The next in order are silicate and mineral. The durability of the finish also depends on the texture of the coating. Rough and embossed surfaces have increased resistance to various types of deformation.

There are several main brands of special-purpose materials on the Russian market.

1. Ceresit - the company presents a large assortment of Penoplex finishing mixtures of all types. Adding granular fillers to the composition allows you to obtain textured surfaces. A package of 25 kg of cement plaster “Pebble Winter” costs 660-990 rubles on the market. An acrylic type with the same texture will cost 1300-1500. The cost of the most expensive silicone solution is 1760-1900. For acrylic plaster called “bark beetle” you will have to pay approximately 1350-1580 rubles. The price of a similar texture made of silicone is 570-850.

2. Ecomix - application technology provides for high-quality processing of external and internal surfaces made of Penoplex. The Economy mixture is effective in filling cracks, seams, and irregularities. The average cost of plaster is 140-170 rubles per 25 kg. “Bark beetle” costs 90-120 rubles.

3. Stolite – the basis is Portland cement M-500. It features excellent performance characteristics and aesthetics. A package weighing 25 kg of bark beetle costs 300-390 rubles. The textured composition “lamb” with polymer modifiers costs 1120-1300.

4. Bergauf Decor - a classic version of decorative finishing using Penoplex on the facades of residential buildings. The cost of the “bark beetle” is 390-580 rubles. Dry mixture “pebble” is offered for 560-640, “fur coat Diadema” for 395-520.

Preparation for plastering

The implementation of the technological scheme for finishing Penoplex begins with calculations of the required amount of materials. In accordance with practical knowledge, construction specialists offer the following consumption rates per 1 m2:

- 4 kg – for installation of reinforcing mesh;

- 6 kg – for creating and leveling the finishing layer.

To plaster Penoplex with your own hands, you should purchase several tools:

1. wide spatula (at least 350 mm) - for basic work;

2. narrow spatula - for applying the solution;

3. grater with a hard cloth - for grating over a grid;

4. foam rubber or fur roller with short pile - for priming;

5. hard, large-pored sponge - for decorative plaster.

You can also create texture on the facade yourself using a grater or spatulas.

How to plaster Penoplex with your own hands?

The technology of application to the facade includes several stages.

1. Preparation of the adhesive solution - the sequence of actions is usually indicated in the instructions on the package. First pour water into the container and only then add the dry mixture.

2. Starting coating - evenly distribute the plaster over the Penoplex slabs in a layer of 1-2 mm. Move the spatula from bottom to top, maintaining an angle of inclination to the wall of about 30 degrees.

3. Reinforcement - attach the end of the roll with the mounting mesh to the treated area, starting from the corner. Unroll gradually, pressing the material against the wall with a spatula. Smooth out from the middle of the fabric, moving from top to bottom.

4. Creating a leveling layer - the dried surface is rubbed with sandpaper and a fresh solution about 3 mm thick is applied. Apply the leveling layer in parts. Check the joints of the plaster and the mounting mesh to ensure they do not overlap.

5. Priming - when the mixture dries well, carefully level the surface with a float. After this, cover with a primer composition, leaving no streaks.

6. Applying decorative plaster - apply the finishing layer of mortar in small fragments, maintaining the same layer thickness. Form the decorative texture on a damp surface. Leave the finished finish to dry for several days.

7. Painting - indoors the plaster layer is covered with a protective varnish. Acrylic paint is more suitable for decoration on the outside.

1. The finishing technological scheme provides for the mandatory use of fiberglass mounting mesh. It provides reliable adhesion of the smooth surface of Penoplex to the façade plaster. It is advisable to choose a material with a density of 140-160 g/m2. The smaller the cells, the stronger the adhesion.

2. If work on Penoplex is carried out in the summer, then you need to take into account that the solution on the facade dries out very quickly in hot weather. Therefore, it should be applied in fragments, not exceeding the width of the roll. It is better to invite an assistant to secure the reinforced mesh.

3. To glue the mounting mesh onto Penoplex, use a mixture with a thinner consistency than indicated in the instructions. The same composition is used for finishing leveling.

Grouting of treated walls is carried out only after the plaster has completely dried. The duration of setting outside depends on weather conditions, inside - on the temperature of the room. The technological scheme allows a time period from applying the solution to grouting for a period of no more than four days. Otherwise, the plaster will harden greatly and it will be difficult to sand.

Plastering penoplex

Penoplex plaster has a certain technology. If these steps are performed correctly, we will get an excellent result. So, the order is:

- Preparing the solution

- Installation of reinforcing mesh;

- Grouting the surface;

- Padding;

- Surface leveling;

- Grout.

Preparing the mixture

The first stage of our work is preparing the mixture. The solution must be prepared following the instructions in the instructions. To process expanded polystyrene, craftsmen use both universal mixtures, which are used to glue segments of insulation to the wall and apply on top, and mixtures for narrow purposes.

Usually the manufacturer indicates the consumption on the packaging. But on average you can calculate it using the formula:

- When reinforcing, you need about 4 kg of mixture per 1 square meter;

- For leveling - 6 kg per 1 square meter.

These figures also depend on the thickness of the plaster layer: the thicker the layer, the greater the consumption.

Advice from the expert: To glue the reinforcing mesh, make the solution thinner than indicated on the package. And for leveling, the solution should have the consistency of jelly.

Installation of reinforcing mesh

The use of reinforcing mesh for penoplex plaster is a prerequisite for high-quality finishing of insulation. Otherwise, after drying, the solution will crack and fall off.

We begin to attach the reinforcement from the corners and slopes. To save on mounting corners, you can make such profiles from mesh with your own hands. We cut a strip about 35 cm wide and bend it in the center along the entire length. Next, apply the solution to the surface and apply our workpiece, slightly pressing it into the mixture. And we do this with all angles. After this, glue the mesh over the entire remaining surface. At the same time, as if drowning our mesh in the solution. We glue the strips overlapping each other - about 5 cm. Smooth the mesh from the center to the bottom, and from the center - up.

Applying plaster

Next we move on to grouting the surface. To do this, we use a plastic grater with an abrasive strip. This operation is done after the plaster is completely dry. If it's hot outside, this will take a couple of hours. Well, if it’s damp and cold, you’ll have to wait a day. We make movements with the tool in a circle counterclockwise.

After this, the surface needs to be primed. The primer promotes good adhesion of the finishing layer and the surface. Now let's start leveling the surface. To do this we need two spatulas - large and small. Using a large spatula, apply the plaster evenly to the surface. The layer thickness should be about 3 mm.

After the solution has dried, we begin grouting. This work can be done in a day, not earlier. Rub the surface until smooth.

Often during renovations the question arises: how to paint penoplex without plaster. Experts advise the following: taking into account the features of this insulation, you can paint it with mineral paint, water-emulsion or a composition based on liquid glass.

otdelkasam.ru

DIY repairs. All about penoplex plaster

Penoplex is made from extruded polystyrene and is used for thermal insulation of the ceiling, floor and walls of the house. After the installation of the material is completed, the question arises - how to properly plaster it. The advantage is that this is a fairly simple process that does not require any special skills. However, it is simply necessary to know all the stages of plastering. In this article we will look at all the subtleties and nuances of penoplex plaster.

Why cover insulation with plaster?

Now let’s take a closer look at what exactly a layer of plaster provides for insulation:

- Protection from physical impact. Plaster gives the surface additional strength and protects it from the appearance of random dents and cracks, which will lead to peeling of the material and deterioration of its heat-insulating properties.

- Overheat protection. The problem is that when exposed to high temperatures, the insulation releases styrene, which is a toxic substance. A layer of plaster will protect residents from this unpleasant side effect.

- Weather protection. Without a protective layer, penoplex can collapse in one season under the influence of temperature changes, humidity and direct sunlight.

- Additional thermal insulation. The joints between sheets of insulation can allow cold to pass through. A plaster coating will help avoid this.

Do-it-yourself technology

Next we will look at the process of plastering walls. But in the same way you can apply the plaster mixture to any surfaces insulated with penoplex.

Before plastering, you need to prepare all the necessary tools:

- Plaster.

- Construction mixer.

- Spatulas of different sizes.

- Grater.

- Sandpaper.

- Reinforcing mesh.

- Dry plastic container for diluting the mixture.

- Gloves.

- Roller.

Now you need to choose a plaster mixture. For plastering the facade of a building, it is better to choose mixtures with cement. Moreover, it should be a connecting component, and not the main one.

The use of ordinary cement mortars is unacceptable, as they can corrode the surface of the insulation in one season. To finish the interior surfaces of a room, you can choose not only cement, but also gypsum mortars. It is also necessary to choose the right reinforcing mesh. This material must be sufficiently dense and resistant to alkaline environments.

Keep in mind that very rigid meshes are not suitable, as they are difficult to install in corners and openings . Therefore, the most suitable option is a mesh with a density of 160 g per square meter. m.

How to properly insulate the facade outside the house?

The plastering process consists of several important steps, none of which should be skipped.

Preparation

When the installation of insulation on the walls is completed, sand its surface using sandpaper. This is necessary to remove any irregularities, bumps and depressions that can cause rapid destruction of the plaster layer. The protruding parts of the construction foam that connects the joints between the foam panels must be cut off. Do this carefully so that there are no dents or bumps.

Installation of reinforcing mesh

This stage cannot be skipped, since without a façade mesh the plaster layer will begin to crack and quickly collapse . Apply a layer of special glue, no more than 2–3 mm thick, to the rubbed surface of the insulation, and glue the mesh onto it. The following points must be taken into account:

- Press the mesh into the adhesive base and immerse it completely, but no more than to the middle of the layer. This should be done using a smooth spatula.

- The mesh should only be glued onto fresh adhesive.

- Sheets of material must be laid overlapping each other. In this case, the allowance should be at least 10 cm.

- Pasting the walls must begin from the corners, as this is the most difficult stage of the work.

- To properly glue a corner, you need to take sheets of mesh 30 cm wide and about 1 meter long, bend it in half, and attach it in this form to the corner.

Preparation and application of the solution

The mixture must be prepared according to the instructions on the packaging, which always indicates the consumption of plaster per 1 square meter. m of wall, based on the thickness of the applied layer. Please note that the thickness of the applied layer of plaster for penoplex should be from 3 to 5 mm.

- Multiply the mixture consumption rate by the thickness of the applied layer, and you will get the required volume of finished plaster per 1 square meter. m. walls (we told you how to correctly calculate different types of plaster here).

- After the calculations are ready, pour cold water into a plastic container, add the required amount of the mixture and stir everything with a construction mixer.

- Now apply the plaster to the wall using a trowel and trowel and smooth it out using the rule. It is better to start this process from corners or from doorways.

Try to place the joints of the plaster mixture so that they are in the middle of the sheets of reinforcing mesh. This will help make the joints less thick and noticeable.

- 45-60 minutes after completing the process of plastering the walls, level and trim the dried layer using a trapezoidal rule or a wide spatula. Also, do not forget to check the evenness of the plastered surface using a building level.

- Now wait until the wall is dry. This will take from 1 to 4 days.

Sequence of façade plastering using penoplex

Before you start finishing the penoplex, you should prepare for this process. First you need to prepare the necessary tools and materials. Once everything is in place, you can begin the plaster itself.

What tools will you need?

Plastering a penoplex facade must be done using different tools, so it is imperative to collect all the equipment for the work process:

- a bucket or other container for diluting the plaster base;

- the presence of a construction mixer will greatly facilitate the process of stirring the base;

- construction mesh of painting type;

- corner;

- sandpaper;

- plaster mixture with gypsum structure;

- scissors;

- primer mixture;

- putty knife;

- paint rollers.

Tools

Preparing the mixture

Facade plaster using penoplex should begin with preparing the mixture. Since all mixtures are available in dry form, they must be properly prepared. It is advisable to carry out preparation strictly according to the instructions that should be included with the plaster.

Important nuances of preparing the mixture:

- for plaster, the most suitable mixtures are Ceresit, Ecomix and Stolit brands;

- during work on finishing the surface of penoplex, it is necessary to use a mixture of only one manufacturer, because differences in the constituent properties of the mixtures will negatively affect the basis of all finishing;

- Sometimes a set may contain two types of mixture. In this case, one mixture is used to finish the protective layer on top of the penoplex, and the second is used to attach it to the base. If the mixture comes alone, then it is universal and can be used both for finishing the facade and for attaching polystyrene foam;

- When calculating the required amount of finishing material, it is worth remembering that for 1 square meter it will require about 4 kilograms, plus for further leveling the surface of the walls you will need 6 kilograms;

- The consistency of the mixture should not be very liquid, but not very thick. When applied to the wall, it should flow slowly towards the floor.

The mixture is prepared according to the instructions, which can be found on the back of the package.

Preparing the base

Then the base surface is prepared. In order for the plaster base to last a long time, you need to clean the base from various bumps and deformations. If there are bumps on the surface, they should be carefully removed using a utility knife.

It is necessary to glue a construction or painting-type reinforcing mesh onto the surface of the polystyrene foam. Due to it, the degree of adhesion of the plaster to the wall surface increases, and the service life of the coating also increases.

Diagram of a wall with plaster and foam

Gluing the mesh

For the surface of the facade, a construction mesh made from an alkaline base should be used. The density of the mesh should be 160 g/sq m. The mesh made from an alkaline base has a high cost, but despite this, it increases the shelf life of the finish and the plaster applied to it will not crack or collapse for a long time.

You can choose different mesh densities, the optimal one will be from 120 to 160 g/sq meter. The greater the density, the smoother the layer of plaster will be applied. But there is only one drawback - the high-density mesh is inconvenient for attaching to the corners.

Installation diagram of the plaster mesh

Features of gluing the mesh to the wall:

- to begin with, it is worth separating a strip with a side length of 1 meter and a wide side of 0.3 meters;

- in the central part the strip must be bent; after bending, there should be a protrusion in the form of an edge on the surface of the strip;

- Next, using a special spatula, you need to apply the plaster mixture to the corners of the building. The thickness of the application layer should be 2-3 mm;

- a mesh is applied to the layer of plaster, which is pressed and smoothed on all sides with a spatula;

- After gluing the corners, you need to stick the mesh onto the surface of the wall planes. The mesh is cut into pieces with dimensions of 1 meter; material of this size is much simpler and faster to glue;

- Next, a mixture with a thickness of 3 mm must be applied to the wall surface;

- A mesh is applied to the mixture, pressed and smoothed with a spatula on all sides. It is better to use a spatula with a width of 35 cm;

- the mesh must be smoothed from top to bottom, while it must be pressed into the mixture;

- After gluing one sheet, the next one is glued. It needs to be glued overlapping so that there are no gaps between them.

Plastic plastering mesh

Laying the mesh

Grouting mesh

After the plaster has dried, the mesh is rubbed over. Grouting should be done using sandpaper. Grouting is carried out using circular movements with gentle pressure on the surface. All movements should be carried out counterclockwise. If wet plaster gets into the emery cloth, then no further grouting should be done. Grouting will help remove bumps, deformations and various protrusions of the mixture on the surface.

Leveling the surface with plaster

After preparing the surface of the mesh, it is necessary to level the entire wall. The plaster mixture that was used to install the mesh will be used for this process. Penoplex plaster must be carried out strictly according to the instructions, so during leveling you should follow important recommendations:

- A plaster base is applied to a spatula with a width of 35 cm. You need to spread it out using an additional small spatula;

- then the base must be evenly distributed over all surfaces of the wall;

- the plaster layer must be at least 3 mm;

- The joint areas of individual sections should not coincide with the joint areas of grid sections. It is better to place them as far away as possible.

In order for the plaster to adhere well to the penoplex, it is necessary to use a special mesh

Pressing the mesh into the putty layer

Grouting the leveling layer

Grouting should be carried out according to the following scheme:

- Grouting should begin at least 24 hours after applying the last layer of plaster. The maximum period between drying and the start of grouting should be 4 days;

- all movements during grouting should be circular and counterclockwise;

- Grouting should be carried out until the surface of the wall becomes perfectly flat, without bumps or deformations;

- After the wall becomes smooth, the grouting can be completed.

Grouting on the façade cage

Applying primer

For some reason, many inexperienced or novice craftsmen do not prime the plastered surface, but in vain. This process is low-cost financially and also brings high benefits in the future.

Applying a primer will allow any residual materials from grouting to be absorbed, resulting in a reduced absorption rate on the surface of the materials being applied.

Recommendations for applying the primer mixture:

- Any composition can be used for processing. An antifungal primer will eliminate increased dampness of wall surfaces and the appearance of mold. In addition, in the future this composition will ensure high-quality application of the final decorative finish;

- the primer mixture should be applied using a short-haired roller; it is permissible to use a tool with a foam base;

- the entire work process must be carried out with extreme care so that no drips remain;

- After this, you need to wait until the primer is completely absorbed. Then you can begin applying decorative plaster.

Surface primer

Application of decorative plaster

Decorative plaster is very popular because from the outside it gives a beautiful appearance to the outer surface of the wall. It is applied to a well-primed wall surface, only after complete drying.

Rules for applying decorative plaster:

- a worker will need a spatula with a width of 35 cm;

- Place the plaster mixture on a wide spatula and apply it in an even layer;

- it is important that the applied layer is uniform on all areas of the wall surface;

- then, using available construction tools, we form the texture of the plaster. You can use special rollers for this. You can make a texture in the form of bark beetles, it looks beautiful, unusual, and is done quickly;

- after giving the plaster a texture, it should be left until completely dry;

- at the end the surface can be painted any color.

Applying decorative plaster

Knowledge of the process of finishing penoplex will help not only make the wall beautiful, but also extend its service life for a long period. It is important to remember that this material is susceptible to various environmental influences, so it is important to protect it at the first stage after installation on the wall. And in order for the protection to last a long time, the entire plastering process must be carried out according to the rules.