The need for concrete in a wide variety of construction industries is constantly increasing, and this is quite natural, because such structures are quite reliable and durable if special technologies for their production are observed. In addition to the fact that it is imperative to maintain the quality of the concrete mixture, the process of delivering concrete directly to the place where it is laid is also quite important. Here, special equipment comes first, which ensures continuous supply, namely concrete pumps.

Concreting scheme: 1 – Concrete mixer, 2 – Concrete pump, 3 – Rubber hose, 4 – Concrete pipe, 5 – Pipe hanger, 6 – Pipe.

Principle of operation

A concrete pump is a special device and is designed to supply concrete mixtures to the place of their laying through pipelines or concrete pipelines intended for this purpose during the construction of various buildings and various structures made of solid monolith or reinforced concrete. The work is based on the usual principle of displacement and consists in creating a changing volume in the system. If the volume is completely filled with concrete mixture, and then decreases somewhat, then it is forced out into a special concrete pipe.

Based on the principle of operation, they are divided into piston ones, which have a periodic supply, as well as hose ones, which are characterized by a continuous supply of the mixture. According to the principle of their operation, they can be standard, trailed, mobile, or they can be concrete pumps. Their drive can be hydraulic or mechanical. The most basic parameters of such construction equipment are feed height, distance and productivity.

Diagram of a piston tool.

The principle of operation is significantly different from each other, because they have completely different devices. The advantages of this type of pump include the simplicity of their hydraulic drive, fairly low power consumption and a constant hose cross-section, which facilitates better pumping, and the ability to supply concrete mixtures with lightweight aggregates and, of course, ensures ease of operation and subsequent maintenance. However, despite all the positive qualities, the concrete pump has some disadvantages, namely, high requirements for mobility and, naturally, the composition of the pumped concrete mixture and a rather limited concrete supply range.

It is necessary to take into account that the larger the diameter of the pipes, the higher its cost and, naturally, the lower the pressure created when supplying concrete. Recently, concrete pipelines have begun to gain enormous popularity, because with their help, the concrete mixture is supplied directly to the destination itself, and for this there is absolutely no need to lay an additional pipeline.

Truck-mounted concrete pumps are also very popular because they are small in size and can be easily moved for laying concrete.

Design and principle of operation of a concrete pump

The purpose of the concrete pump is to supply the solution to the laying object through a special pipeline or through branches if laying is planned in a continuous flow. This technology is relevant for the construction of residential buildings and industrial buildings, since the mixture is prone to rapid solidification and requires constant maintenance of its original state. The design of the concrete pump allows you to carry out the necessary processes that guarantee the safety of the technical characteristics of concrete and its quality indicators as a building material.

Concrete pump device

There are several current types of concrete pumps, differing in their operating principle. The differences between them lie in the type of functioning and technical structure. The required installation is selected by specialists for each specific project.

- Piston concrete pumps involve the operation of a cylinder and a piston. They have a cylinder to move the piston, which sucks up the concrete and directs it into the hopper. The flow is controlled by valves.

- Rotary concrete pumps demonstrate low productivity and delivery range of the solution due to the peristaltic technology of the influence on the composition. The principle of operation of a concrete pump is as follows: it looks like an elastic hose that is subjected to rolling rollers that press the solution and advance it in order to increase pressure.

- Screw concrete pumps are quite compact and are a screw shaft with a function similar to an auger. The shaft consists of several screws, and the holder, directed along the axis, is a cavity for them. Closed cavities are filled with solution as the shaft rotates along the axis. The operating principle of concrete pumps of this format excludes the possibility of the presence of large solid particles in the mixture, the diameter of which is more than 6 millimeters.

- Pneumatic blowers operate by supplying air into a hermetically sealed chamber under the influence of pressure, which splashes out the solution. With its help, you can simultaneously prepare a concrete mixture by loading all the components of the mixture into the bunker.

- The diaphragm device works due to the fact that the compressed walls act on the mixture entering the chamber, thereby closing the inlet valve and opening the outgoing valve.

All types of concrete pumps are relevant in modern construction and the choice when renting is made based on the characteristics of their functioning and the principle of supplying concrete solution to the treated area. Each device can be used both in the construction of residential buildings and in industrial construction.

Operating principle of a concrete pump

The operation of a concrete pump is due to the displacement of liquid. Depending on the principle of operation, devices can be classified into piston and hose, the difference between which will be the frequency of supply of the mixture. Experts distinguish the following types of concrete pumps:

- Typical (or standard)

- Mobile;

- Trailed;

- Truck-mounted concrete pumps.

Any model can have a hydraulic or mechanical drive, and the main indicators of equipment optionality are the height and delivery distance, as well as productivity.

The design and operating principle of each type of concrete pump differs from the alternatives. The most commonly used option is the piston type, which turns out to be much more economical and demonstrates high performance.

It is easy to operate and does not require specific maintenance, both during and after operation. The design of a piston concrete pump is such that it has limitations on the range of concrete distribution and is not characterized by mobility.

The pressure when supplying the solution, as well as the cost of the device, directly depends on the diameter of the pipes. This is why the popularity of concrete pipes has increased so much.

Types

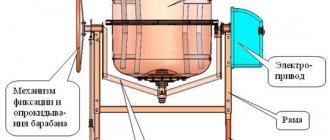

Trailed tool diagram: 1 – Chassis, 2 – Cylinder block, 3 – Receiving hopper, 4 – Drive, 5 – Casing.

Tools vary in type, they can be mechanical and hydraulic, and in terms of pump design they can be piston or pistonless, stationary or car-based.

The principle of operation of the piston is based on the fact that the concrete mixture is sucked directly from the bunker itself, but the return movement of the piston, to which the gate elbow switches, pushes it into the concrete pipe. A significant advantage is that such units have a hydraulic drive, which takes into account the flow rate of the mixture, which is practically unchanged, because the piston has a fairly large stroke and operates smoothly, which is why the mixture moves along the concrete pipeline quite evenly, without any unnecessary impulse jumps.

Thanks to this, the resistance to moving the mixture in the concrete pipeline is greatly reduced, which makes it possible to use an engine of much lower power than in the structure itself with a mechanical or connecting rod drive. Hydraulic is capable of moving a concrete mixture to a very large height and distance. Compared to similar mechanical drives, hydraulic ones create unusually high pressure in the concrete pipeline.

A concrete pump with a piston drive is subject to wear of the pistons due to constant friction, which is caused by special microparticles of the concrete mixture and cement laitance, penetrating directly between the walls of the pistons and the piston cylinder itself. Wear with a mechanical drive occurs much faster than with similar hydraulic ones, because they have a much smaller piston stroke reserve, and forces them to perform a much larger number of cycles to achieve the required pressure in the concrete pipeline.

Diagram of a concrete pump.

Pershnev with two cylinders is capable of supplying concrete almost constantly and continuously, which is ensured by alternating cycles of pumping the concrete itself into the cylinders. A concrete pump with one cylinder operates with some interruptions, because the concrete mixture it supplies in the concrete pipeline pulsates from maximum to minimum pressure, just as the piston itself moves.

In hydraulic piston engines, the special filler is water or mineral oil, which has quite strong pressure and ensures rapid pumping of concrete.

Piston group of concrete pumps

In order for us to answer the question posed about how a concrete pump works, let’s take as an example the piston group of special equipment. In Russia, the CIS countries, as well as in most countries of the world, the piston version of special equipment is recognized as rational and effective for a number of reasons. The operating principle of a piston concrete pump provides for portioned supply of solution from the bunker reservoir to the concrete supply system. The presence of a hydraulic drive system ensures the supply of material in a smooth mode, without visible sudden jumps and drops. Installation of a hydraulic pump on the unit allows for increased performance of the pump itself, which in turn ensures efficient processing of the supplied concrete mixture. Another advantage is the fact that hydraulics allow the solution to be supplied to an acceptable height on the construction site.

Operating principle of a rotary concrete pump

This type of special equipment is rarely used, but for some technological techniques on a construction site this option will be a rational solution. Unlike the piston group, the material is supplied not into the hopper chamber, but directly into the rubber hose. On the outside of the concrete hose pipe there are rollers that are involved in the process of supplying the material, thereby ensuring the pushing of the substance to the exit.

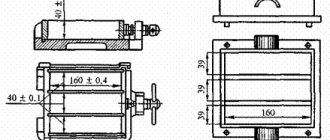

Overall dimensions of a standard concrete pump

Overall dimensions of the concrete pump

How to choose the right category of special equipment?

Now you know how a concrete pump works, how special equipment is selected for carrying out technological construction operations. The rotor design allows the use of material with coarse filler, while the feeding process ensures uniform pushing of the substance through the concrete pipeline. There is an additional advantage of this system: when washing, the rotor part of the special equipment is easily treated with ordinary artesian water, that is, it is easier to clean in preparation for additional work.

In addition to positive factors, there are disadvantages to both the rotary system and the piston group of special equipment. For piston-type special equipment, wear characteristics are very common due to the ingress of concrete milk and other aggressive products into the main mechanism of the piston group.

For some production operations, the piston mechanism is not capable of providing portioned supply of material to the production facility, that is, there is no proper effect from portioned supply of material. The rotary version effectively copes with the task of portioned supply of the mixture to the object. At the same time, the obvious disadvantage of the rotary version is its very low productivity, which is unacceptable for large volumes of construction.

Rapid wear of the main supply element - the hose of the rotor system very often fails, which creates additional inconvenience in work, requiring frequent replacement and washing of the concrete pipeline.

More information about concrete pumping technology

To extend the service life of a concrete pump, technologists use a special concrete mix loading map for a certain type of specialized equipment. Large crushed stone and foreign particles are a problem with the quality of the concrete mixture, and, therefore, this affects the operation of the equipment as a whole. For the rotary type of concrete pump, a concrete mixture with small fractions of crushed stone is used, and for the piston group, higher fractions of crushed stone material are used.

In order for the concrete mixture not to lose its characteristics, it is necessary to calculate the volume of the material mass for 15-20 minutes of work, so that a new portion can be prepared for loading into concrete pumping equipment. When loading concrete material, the time interval must be strictly observed to ensure the quality of the concrete mixture for the production cycle.

Stationary

Scheme of a stationary concrete pump.

The most common stationary one is made in several different versions and is installed mainly on a flatbed truck or a special platform that provides ease of transportation. It should be noted that this design is made in the form of a trailer with a chassis and works to ensure a continuous supply of concrete. This one can be transported from one construction site to another by simply hooking it onto a special attachment to the truck. The operating principle is based on the fact that this unit can continuously pump large quantities of concrete. The design of such a device supports two different modes at once, such as supplying concrete under fairly high pressure, however, with this operating mode, productivity drops very much, and a very low pressure mode, but with much higher productivity. This need is due to the fact that when laying concrete pipes at sharp corners, it is necessary to develop very high pressure in the cylinders themselves, thereby slightly raising the concrete itself underneath them.

There are not only stationary concrete pumps

In this article we are talking specifically about stationary type mechanisms. But a few words are worth saying that they are not the only devices designed for pumping concrete.

Automobile concrete pumps (ACP) are devices transported on the chassis of most truck manufacturers. It is advisable to use such transportable massive devices in cases where it is important to quickly deliver large quantities of solution and quickly transport the equipment to another location. Most often, mobile concrete pumps are used to create the foundations of buildings. In addition, such devices can be much larger than stationary ones, and therefore more powerful.

This concludes the description of mobile concrete pumps within the framework of this article; let’s move on to other devices.

Job

Installing a stationary one on a special platform or in the back of a truck cannot provide it with mobility, because it can only be transported from one area of the territory to another. A full-fledged concrete pump is a car one, because it is a unique structure of its kind, which is located directly on the car chassis and is often reinforced by a much larger number of chassis than the standard production version of a car for a similar purpose. The work is much more advanced because it ensures a constant supply of concrete and mobility of the structure itself.

An important element of this design is the presence of a special folding boom of the concrete pipeline, which consists of several separate bends, each of which is fixed. Turns, as well as lifts of each individual section of each boom, are carried out using special special controls and make it possible to give such a structure the required position and immediately begin pouring concrete. There are concrete conveyors with booms of various lengths, which provide ease and maneuverability of control.

Technical characteristics of the concrete pump

The documentation for each ABN model must contain a list of characteristics that determine its capabilities. First of all, the manufacturer indicates how many cubic meters of solution the pumping device pumps per hour. Almost all modern ABN models satisfy the needs of the vast majority of tasks for pouring mortar into formwork.

The speed limit is not related to the power of the pump, but to the ability of the crew to accept a particular volume of mixture under certain conditions. Depending on the brand of the pumping device, its productivity can be between 60 and 180 m³/h.

In addition to performance, ABN is characterized by the type of drive and the power of the drive motor. The diameter of the concrete pipeline inside the distribution boom is standard - 125 mm. The technique has certain limitations when working with the solution. The settlement of the mixture cone should be within 6-12 cm, and the maximum size of the aggregate fraction should not be larger than that specified in the specification for the pump.

For each ABN, the type of chassis is indicated, that is, the model of the truck on which the pumping equipment and boom are installed. In addition, an automobile concrete pump is characterized by a certain weight and dimensions. Different models have their own bunker capacity and pressure on the concrete mixture created by the pumping unit.

Most large construction companies use concrete pumps. With their help, the mixture is transported for the manufacture of foundations and various monolithic structures in the shortest possible time. In this article, devices installed on a vehicle chassis, for example, a used concrete pump, will be provided and reviewed.

The photo shows the supply of the solution directly to the construction site

Piston

Nowadays, two-piston units are used; single-piston systems are gradually becoming a thing of the past. These pumps are equipped with a diesel or electric motor.

A stationary diesel concrete pump is capable of providing high speed concrete delivery. Per second, such a pump can transfer up to 60 liters of mixture to its destination.

In an hour of operation, a standard diesel concrete pump pumps about 60 cubic meters of solution. In the horizontal plane, the mixture can be transmitted over a distance of up to 300 meters. The height feasible for an average diesel stationary pump is 70 m.

The two pistons are connected by a hydraulic drive cylinder.

The system can be not only hydraulic, but also electro-hydraulic, single-circuit and double-circuit. Each variety has advantages and disadvantages.

Existing types of stationary devices

It doesn’t matter whether you choose a mobile concrete pump or a stationary concrete pump, the characteristics depend not on the method of movement of the mechanism, but on the type of its device.

Devices of the second type may have fundamental differences in their design. To know which pump to choose for a particular purpose, you need to know this difference.

The unit may be a piston unit. In such a system, concrete is directed through pipes using two pistons. There are also single-piston devices.

In curtain-type pumps, the concrete supply system is hidden by so-called curtains, which are located immediately in front of the concrete pipeline. In gate devices, instead of curtains, a gate unit is installed.