All about crowns for drilling concrete

This is a special device that allows you to drill hard surfaces. Other names: core drill or cup. The crown is not used separately, but only with a powerful tool, for example, an impact drill or a hammer drill.

Note! Applying the designation “drill bit” to a device for processing artificial stone is not entirely correct. Here we are talking about nozzles with diagonal grooves on the outside. They are intended for materials such as plastic, wood, metal, but not for structures made of mineral mixtures.

Rating of the best models

Before moving on to specific models, you should take a closer look at the manufacturers. When buying drills, it is useful to have reference points in the form of well-known and reliable companies.

These include:

- A.E.G.

- Bosch.

- Makita.

- Milwaukee.

- Messer.

Makita 8406C

The Makita 8406C diamond drill has two operating modes: drilling and hammer drilling. The tool works on stone, concrete, wood and metal. The rotation speed is set using an electronic system. The maximum speed reaches 4000 per minute. When using a diamond core bit, the drilling diameter is 150 mm. The device weighs 4.5 kilograms.

Pros:

- High power level (for its class) of 1400 W.

- Reliable fixation of equipment using a key chuck.

- Ventilation holes for heat dissipation.

- The cord is 2.5 meters long.

Denis

I use this unit to drill slate, brick and sometimes stone. I am 100% satisfied with the quality of work. The drill does not vibrate, starts smoothly and passes through all materials without complications.

Vadim

I was looking for a machine that could cope with drilling reinforced concrete. Rotary hammers are not suitable, drills are expensive. The Makita drill helped out with its durability and reasonable price.

AEG DB 1500-2 XE

The professional drill AEG DB 1500-2 XE was developed specifically for dry diamond drilling. The tool program supports two operating speeds and a soft impact mode. The maximum operating speed of the device is 3000 rpm. Drilling is carried out at a power of 1500 W. The weight of the drill is 4.2 kilograms.

Pros:

- The presence of a metal gearbox, which increases wear resistance.

- Maintains a high number of shocks under high loads - 48,000 strokes per minute.

- Possibility to change the position of the side handle depending on working conditions.

- Safety coupling as additional protection.

Ivan

Drel holds speed well under load and does not lie like a dead weight in his hands. The case is good for frequent carrying, but the cord was too long for me.

Konstantin

I became familiar with this drill only when I started working with a vacuum cleaner. I was pleased with the handle, which was made of metal, not plastic as usual. The thing is effective, but very noisy - you can’t work with it without headphones.

Fortezzo SCY-1520/2BS

The Fortezzo SCY-1520/2BS diamond drill is designed for working with reinforced concrete, stone and brick. Thanks to the universal motor design, the device can be used manually or using a stand. The tool offers two speed modes. The maximum operating speed reaches 2770 rpm. The device weighs 12 kilograms.

Pros:

- The control panel is protected from moisture.

- Stepless speed control allows you to smoothly switch modes.

- Operator protection prcd.

- The drill comes in a suitcase with all accessories.

Vasily

I work with a drill by hand, which is a bit difficult. The instrument itself is strong and of high quality. Works great on both brick and concrete.

Alexander

I have been using this drill for more than three years - with and without a stand. I tried it on a variety of materials - from reinforced concrete to ordinary brick. So far I have not found any disadvantages for myself.

BOSCH GDB 2500 WE Professional

The BOSCH GDB 2500 WE Professional drill is one of the most powerful professional-class tools. The device breaks all power records and reaches a level of 2500 W. The drill makes holes from 32 to 212 mm and operates at two speeds. The tool was created for working on reinforced concrete, but is also suitable for working with other materials. When drilling reinforcement, it prevents the propagation of cracks. The weight of the drill is 11.8 kilograms.

Pros:

- Constant-Electronic system: maintains stable speed as load increases.

- Reduction of dust and sludge due to the flow of water into the bit (“wet drilling”).

- Simplified procedure for replacing carbon brushes.

- Reduced vibration due to built-in current limiters.

Anton

I worked with this monster for several months under construction conditions. In terms of power, no drill can compare with it. A separate advantage is the absence of dust during drilling. During the entire period of operation, the instrument never malfunctioned or turned off.

Milwaukee DD 2-160 XE

The Milwaukee DD 2-160 XE drill is designed for dry hole drilling. The diameter of these holes ranges from 32 to 82 mm - when processing reinforced concrete. For ordinary concrete and brick, the permissible diameter increases to 132 mm. The maximum speed of the tool reaches 3,000 rpm. The device operates in two modes. The weight of the drill is 4.2 kilograms.

Pros:

- Enhanced tool and operator protection due to mechanical and electronic clutch.

- Effective dust removal using a quick-release dust extraction system.

- The soft impact function makes the bit work smoothly during the drilling process.

- The micro-impact feature makes Diamond Hit crowns resistant to any material.

Gleb

I looked for this drill in stores for a long time, I had to buy it on the Internet. I liked the instrument for its weightlessness - compared to other heavyweights. Sometimes it overheats when drilling reinforced concrete. Otherwise, it copes with all tasks.

Mikhail

I was pleasantly surprised by the build quality and the metal body. During operation, the machine practically did not break the drills. The speed regulator is conveniently located. The 4 meter cord eliminates the need to run around for extension cords.

Messer DM 100

The Messer DM 100 drill is designed for processing concrete, brick and stone. It can be used both when drilling by hand and with an additional stand. The motor power of the device is 1500 W at two operating speeds (950 and 2,100 rpm). The maximum drilling diameter when processing reinforced concrete is 80 mm. The motor housing is made of metal. The weight of the drill is 7 kilograms.

Pros:

- Shoulder rests and side handle for comfortable drilling by hand.

- Built-in electric shock protection system.

- Availability of additional side handle.

- Drilling option with water supply to prevent the spread of dust.

Paul

I was looking for a budget drill for working on concrete. I had never heard of Messer before, but decided to take a chance. The tool drills well, but working with it is not very convenient due to the short cable - only two meters.

Makita DBM131

The Makita DBM131 drill is used for drilling holes in materials of special strength. Working attachments for the tool are supplied in the form of diamond-coated drill bits. The maximum diameter of the crowns is 132 mm. The tool provides two drilling options (dry-wet) and two speed modes. At idle, the device accelerates to 2,000 rpm. The weight of the drill is 6 kilograms.

Pros:

- Built-in electronic torque limiter + speed control system.

- Double protective insulation.

- Fixation of the switch for comfortable continuous operation.

- A release clutch that is activated when the tool jams.

Nikolay

The first thing I looked at when choosing was the presence of a coupling. The drill is fully suitable for this parameter. The only drawback is expensive consumables. But for a high-quality device this is natural. In terms of ergonomics, the model is very successful.

Vadim

I bought this drill because I have known Makita for a long time and am completely satisfied with the tools of this brand. The new device also turned out to be a successful purchase - it works without overheating, without breakdowns and without surprises.

The choice of a diamond drill is made taking into account the goals and specifics of the work. For some buyers, the light weight of the tool and the length of the cord are important. Others focus on the presence of a wet drilling option. An equally important criterion is the price of consumables that will need to be purchased while using the drill. If the master specifies all his requirements for the device, he will be able to buy a model that will last for many years.

Classification

By drilling method:

Cups with pobedite soldering. How do they affect the material? When penetrating inside, do not rub its walls, but knock it down with soldering in a circle. The result is a cyclic rotation process, not a constant one. At the same time, it is difficult to hold the unit. The scope of application has been expanded: drilling not only concrete structures, but also other minerals: putty, brickwork, cement plaster. It is optimal to drill to the facing coating.

Most models are equipped with a centering drill, which is secured with a bolt. If replacement is necessary, the bolt can be easily and quickly removed. Today, many manufacturers produce modifications with removable shanks.

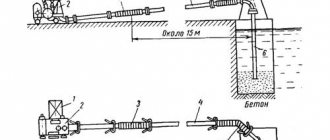

To drill a structure up to 1 m thick, the cup is unscrewed from the shank and then screwed onto the extension. This solution is relevant when performing tasks with professional equipment with high torque and impact power.

Diamond core bits are used for delicate drilling. They work on the principle of abrasive grinding of the processed material. This can be called delicate processing, which means that if you plan to lay communication channels along the cladding, such devices will be the best option. Useful for drilling large holes.

Cutting devices by design features:

- Toothed or carbide. Purpose: drilling with impact. Fixed to the tool with an SDS-type quick-locking shank. They are used primarily with rotary hammers. Cut out armholes with a maximum size of 100 mm. The resource of the heads is very low. Under the influence of intense shocks, the working teeth break. You can order crown restoration on our services page;

- Diamond. Modern devices with diamond or corundum abrasive coating. Designed for shock-free drilling of openings up to 650 mm in diameter, to a depth of up to one and a half meters. 100 mm models with a quick-release shank are perfect for solving everyday problems.

- Drilling single-layer CS. Cutting heads that help drill high-strength concrete (slabs, monoliths). They have protruding segments on which polycrystalline diamonds are embedded. This is a special high-tech spraying technique that ensures long-term operation of the drill ring. Used for work on modern buildings with high-strength concrete walls.

Next, it is advisable to understand the question of how to drill concrete using crown drills of various sizes.

For what purposes is it used?

Diamond drills are used to process the toughest materials.

The scope of application of this tool is much wider than the specialization of conventional drills.

It makes indentations in the following strong materials:

- Brick.

- Natural stone.

- Reinforced concrete (standard and reinforced).

Special diamond bits allow diamond drills to successfully cope with such complex work. Externally, the crown is a section of pipe with diamonds on the cutting surfaces. Crowns are divided into groups according to size, hole diameter and purpose of use.

Some types of diamond bits are designed to work with “fragile” materials, such as:

- Ceramics.

- Tile.

- Roof tiles.

Expert opinion

Torsunov Pavel Maksimovich

Unlike a universal drill, diamond drills do not drill through the entire surface, but only with a thin cutting edge. Thanks to this option, extraneous noise and the likelihood of cracks during processing are reduced.

Equipment

What kind of material have you ever processed with a diamond drill?

BrickConcrete

The crown cuts the material by constantly wearing away the ligament. This process exposes the sharp edges of the diamond inclusions. As the tool is used, the edges become dull and small diamond particles break off. The operating time of crowns depends on the specific material.

There are two possible scenarios:

- Bundle of harder workpieces

The erasing of crowns occurs slowly, since the material gives in easily and does not require effort on the part of the master.

- Bundle softer than processed workpieces

If the material is difficult to drill, the wear resistance of the cutting elements is reduced.

In order for the drill to last longer, when choosing, it is important to pay attention to what area of application the manufacturer indicates in the product description.

Features of the use of ring drills

On a note! It is important to hold the drilling machine firmly and confidently. The rotational force is very high, so if you loosen your grip for a moment, you risk losing control of the situation and completing the job poorly or even getting injured. Be careful, follow safety precautions, and proceed prepared.

Thanks to the presence of a centering drill, the device is able to drill a hole with maximum accuracy. Possible deviation is 1-2 mm. The magnitude of the error depends on the characteristics of the density and friability of the material.

To ensure that the nozzle fits correctly, make sure that it is located at right angles to the structure where the opening is being drilled. Thoughtful placement also prevents sudden jerks from operating equipment. Most often, this danger concerns the processing of brickwork. In places where there are cement joints, the nozzle goes smoothly, but when it rests specifically on a brick or granite stone, a sharp blow can occur. Keep this in mind when planning to work with an electric drill. But if you work on concrete using a hammer drill, then there is a special shock absorption system (damper) for this purpose.

How to drill a wall that is already lined with ceramic masonry? Crowns for concrete should definitely not be used. Cracks, chips, and broken edges are guaranteed, especially when you have to make openings in low-quality tiles. A smart decision is to choose a crown with a solid tip and diamond coating. You can buy it as a set or separately. The kits include nozzles of different diameters. Their strength varies, but the quality of the final result does not change.

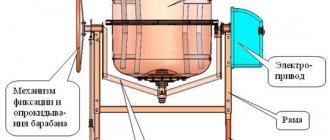

I would like to repeat that diamond cutters are used for hammerless drilling. Following this, they are attached to tools for which the main characteristic is the rotation speed, but not the impact power. It is wise to use a corded drill, a hammer drill (in drilling mode only) or special diamond drilling units.

Are you planning to work from home? Then a crown with a diameter of 60, 80 and 100 mm is suitable for you. These are quite popular diameters that allow you to make neat, even openings for connecting household communications, installing socket boxes and other types of work. The main thing is to be careful and follow safety rules.

For larger-scale operations, it is not practical to purchase expensive equipment. You can also use the service of a specialized organization. Professionals in their field will quickly and efficiently drill holes of any parameters using a special device.

Selection options

You should buy a drill or any other tool based on its technical specifications.

When choosing a diamond drill, several parameters are important:

- Drilling diameter . Models indicate the minimum and maximum hole sizes - in millimeters. Tools that drill holes of different sizes have an advantage.

- Engine power . Drills are available in power ratings of 1400, 1500, 2000 W and more. The standard value is 1500 W. Larger rates apply to expensive professional models.

- Dust removal . Drills are divided into two categories - dry and/or wet drilling. Wet drilling involves the supply of water during the processing of the material. This function helps to remove the old stuff and make work more comfortable.

- Speed of work . The description for the models indicates the number of revolutions per minute at idle. This parameter may differ significantly for different devices. Mid-price drills stop at 2,000 – 3,000 rpm. Advanced models reach 4,000 or more.

There are also additional options that manufacturers add to make the device user-friendly.

Options include:

- Air channels and pipes, thanks to which a vacuum cleaner is connected to the drill (to remove dust).

- Automatic overload level control system (ensures the drill turns off if it jams).

- Protective fuses against power outages.

In order not to purchase a separate vacuum cleaner for the drill, you should look for models that provide a dust removal system.

conclusions

Drilling with crown cups is performed in domestic and industrial conditions during construction or renovation of premises. It is also carried out on already coated surfaces.

In this article, I talked in detail about the types of crowns and how to use them in various situations. Now you know which models are used for impact and non-impact drilling, and when it is advisable to use which mode. Follow simple recommendations, and also do not forget that you need to work carefully, confidently, and safely.