What to do when choosing a material for covering a sidewalk, garden path, or home area? Paving stones or paving slabs, to prefer - which is better to use to obtain a reliable structure? Both product options are similar, but what are their differences? Let's look at these questions in more detail.

Figure 1. Paving stones or paving slabs - which is better?

What are paving stones?

Paving stones are a paving element that has the shape of a cube or rectangular parallelepiped. The height of the product is comparable to its other dimensions, sometimes even exceeds them. Due to the strength of the material, it is recommended to install it where there is high activity of human flows: in city squares, near metro entrances, in front of shopping centers. This road construction product is made from natural materials: sandstone or granite, or concrete stone is used.

The most common products are those made from concrete using the vibration pressing method. This allows you to achieve a successful combination of strength, immunity to atmospheric conditions and obtain a cheap product. The main equipment used in production is a brick press. Technological diagram of the production process:

- concrete preparation;

- feeding it into dies placed on a vibrating press;

- the punch forms products;

- finished products enter the conveyor and are moved onto pallets.

Technology for the production of concrete paving stones

The production of concrete paving stones takes place using special equipment and high-quality paving stones can only be produced using modern equipment. Our factory uses German technology, imported high-quality molds and high-quality raw materials. There are several methods for making concrete paving stones; we use the vibropressing method.

Thanks to the use of modern equipment, the dimensions of rectangular paving stones in our company are standardized and meet all quality requirements. Our website presents a wide range of such products. Customers can order paving stones of any type through our online catalog or directly from company representatives by phone.

What you should know about paving slabs

Now let's look at how paving slabs differ from paving stones. The starting material for it is fine-grained concrete. The finished product has a thickness of 60 mm, which allows it to be used to cover garden paths, sidewalks, and entry points for passenger vehicles. They also produce products with a greater thickness - 80 mm. Such paving slabs cover areas of heavy pedestrian traffic and vehicle routes to the loading/unloading area.

This paving material is produced using vibration casting or vibrocompression technology. The pressed product is significantly superior to cast products in its resistance to any weather influences and mechanical loads. It has a non-slip surface, so it is safe to walk even in bad weather.

Concrete rectangular paving stones from the manufacturer

Today, rectangular paving stones of various shades are used for paving squares, park paths, sidewalks and street landscaping. Such versatility and widespread use of high-quality rectangular paving stones is explained by the properties of the material:

- a wide dimensional grid and color range, which allows you to create different ornaments and designs on the paths;

- stability and reliability of the surface (concrete paving stones can withstand significant physical stress, temperature changes, exposure to ultraviolet radiation and moisture);

- durability and environmental friendliness of the material.

What to choose

Figure 2. Flooring options

It is worth taking a closer look at what is the difference between paving slabs and paving stones, which product is cheaper, what is the difference. It is necessary to take into account the expected operating conditions of the paved area, to know everything about the performance characteristics of both the natural product and the paving slabs.

Difference in operating conditions

Looking carefully at these two types of products, it immediately becomes clear that they will differ in the quality of the resulting coating. Cheaper paving products are easier to lay, and it is convenient to create paths from them that can last for decades, easily withstanding light and medium loads. The material allows you to configure any style of coating, change its color and shape.

Stone has significantly fewer options for variety. The product is more expensive and more difficult to install. However, in the end it guarantees much more acceptable strength and durability indicators.

To pave garden paths, it is preferable to use a paving product. But it is better to cover the parking area and the entrance to the site for transport with stones. The situation is similar in the difficult conditions of upcoming operation. Stone is much more stable and durable as a coating. However, there is not always a need to use such expensive material. It is often worth choosing tiles without spending money on characteristics that are not relevant for a particular situation.

Comparing the advantages of paving stones and tiles

Figure 3. Comparison of paving stones and tiles

Which paving stones and paving slabs have advantages and what is their difference - let’s look at them in detail:

- Duration of operation - for paving stones this is a century, and for tiles it is four times less.

- Comfort of use. Tile wins here, since its surface is almost smooth, the products are laid tightly with minimal gaps. Walking on paving stones is not very convenient.

- Resistance to sub-zero temperatures. Here, paving stones have an undoubted advantage - they are more durable.

- Slip. The surface covered with paving stones is dangerous for movement in slippery weather. The most problematic in this regard are polished products made of marble or granite. But the tiles are produced with different coatings; there are completely non-slip options.

- Diversity. Tile comes first here because it comes in all shapes and colors. Although even the most beautiful version of the product cannot outshine the elegant style of natural stone.

- Price. Tiles are always cheaper than paving stones.

Paving stones

Paving stones are small pieces of turned stone. Intended for paving roads, local areas, courtyards of private buildings. It differs from paving slabs in the same thickness, length and width.

The main material configurations are cubes and bricks. The paving stones are based on solid rock. It could be:

- Basalt

- Granite

The structure of these stones allows the paving stones to withstand heavy loads for many years. Over time, the stone is polished and looks even more interesting than immediately after installation.

A little earlier, when making paving stones, the stones were split into approximately equal-sized fragments and then the pavement was laid from them on the road. This manufacturing option was called chipped. This surface is not ideally even, however, it looks quite interesting. It is these paving stones that tourists visiting ancient European cities pay attention to.

Crushed paving stones on the streets of ancient cities Source stroyday.ru

Nowadays sawn stone is mainly used. This technology makes it possible to give all the bars almost the same size. Due to the fact that all sides of the stone blocks are processed, the material is called full-sawn. Laying such paving stones is simpler, and walking on a flat sidewalk or path is much more convenient. Now it is quite popular, despite the high cost.

Smooth, fully sawn paving stones Source stela-memorial.ru

The third option for paving stones is split-sawn. Its production takes place in two stages:

- The stone blank is sawn into pieces of approximately the same thickness.

- The sawn pieces are split to create paving stones of equal size.

A sidewalk path laid out in a combined way, combining split-sawn and full-sawn paving stones, looks especially advantageous.

Sidewalks and paths look very advantageous, where full-sawn and split-sawn paving stones are successfully combined.

Chip-sawn paving stones Source atex-m.ru

Clinker paving stones began to be produced in Germany in the 19th century. Bars of the same shape and size were made from natural slate clay, which were subsequently fired in industrial kilns at high temperatures. The viability of such production led to an increase in its volumes. 150-year operation for this type of paving stones is not the limit.

Cofigcaption belt production allows us to produce an alternative type of paving stones - concrete. True, calling such material that way is not entirely correct. In addition to concrete, its composition includes numerous polymer additives that provide it with:

Source decorator.shop

- Wear resistance

- Immunity to aggressive external environment

- Possibility of painting in almost any color

Such paving stones create enormous opportunities for the flight of designer imagination. The ability to produce paving stones of any shape provides the master with the opportunity to easily round off paths, transitions and curved areas. In this case, labor-intensive pruning is not required.

Option for beautiful laying of paving stones Source plitkalobnya.ru

Advantages

Many people prefer paving stones due to its obvious advantages such as:

- Reliability and strength - these indicators far exceed the properties of concrete or asphalt

- Longevity - the area paved with paving stones will look great even after 300 years

- The presence of a sand cushion - drainage does not allow water to linger on the surface

- Withstands intense loads

- Excellent aesthetic properties

Flaws

The disadvantages of paving stones include:

- High cost

- The need for careful adherence to installation technology

- Noise from the coating

- Inconvenience of movement for owners of stiletto heels

- Wet paving stones are very slippery

The main differences between paving stones and paving slabs

When choosing a material, it is necessary to determine not only the differences between paving stones and paving slabs, but also to understand them thoroughly. Most versions of produced paving stones are different in appearance and have certain nuances of operational parameters. You definitely need to pay attention to how the chosen material was produced: sawn paving stones have a smoother surface, they are beautiful, and are perfect for laying on garden paths, although they are slippery. When choosing crushed paving stones, you should understand that they are more durable, the product can be recommended for laying on any site (even those with increased loads). This coating will last for decades.

The main difference between paving stones and tiles is the guaranteed strength of the former, which determines wear resistance and long-term operation. The stone roads, which were laid out half a century ago, have been perfectly preserved to this day. But for paving slabs, use of at least two decades can be considered a success, even with its maximum thickness.

Areas of application of paving slabs

Due to the fact that frost-resistant outdoor tiles are increasingly being produced, the scope of use of this material has expanded significantly.

This outdoor coating is used for paving sidewalks, roads and playgrounds. Thanks to frost resistance, high strength and resistance to temperature changes, tiles successfully replace concrete and asphalt. This universal coating has a wide range of applications:

- Sidewalk coverings are especially loved by owners of country houses. They use it to pave garden paths and sidewalks. Since there are tiles on sale in different sizes, colors and textures, you can create beautiful coverings with patterns and ornaments.

- Thanks to its special non-slip texture, this product is simply irreplaceable in pedestrian areas.

- The production of ultra-strong and durable tiles has expanded the range of its use. Now they even pave parking lots with it.

- Products containing rubber fillers are used as coverings on children's playgrounds and sports grounds, near swimming pools.

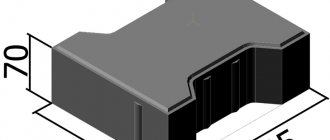

Dimensions of paving stones

The popularity of paving stones (tiles) is only increasing every year, so not every owner will agree to install an asphalt road surface on their own plot of land. Paving slabs have a high class of environmental friendliness, they are durable, easy to use, and easy to install even by an inexperienced specialist. This type of coating has a modern look and creates an atmosphere of home comfort.

Which paving stones to choose

Today, manufacturers supply paving stones of various sizes and shapes to the construction market. Their surface can be made in black, yellow, grey, brown, red and even green. Natural material is made from large stones by cutting them into products of the required shape.

Paving slabs from cement and other components are produced by vibration casting or vibrocompression. This technology uses a small amount of water to produce durable products with high performance characteristics. In the case of vibration casting, plasticizers are introduced into the initial raw material composition, the presence of which prolongs the operational period and increases reliability.

An important point when installing paving stones is counting the number of products. To carry out the necessary calculations, you need to know the dimensions of the materials or their quantity per square meter. It should be noted that the large size of the paving stones allows you to finish the work faster, but when using multi-colored tiles of small sizes, you can pave interesting patterns of complex shapes. Experienced specialists pay attention to the fact that where the paving stones meet the curb, the material will have to be cut, so when purchasing, increase the volume by 10% relative to the calculated one.

Main Dimensions

As we have already said, paving slabs come in many shapes and shades. Now let's get acquainted with the most popular of them, pay attention to the overall dimensions of the products, indicated in centimeters:

- the most common type of paving stones is pavement: 21×14×8, 14×14×8 or 14×7×8;

- brick paving slabs: 20×10×8, 20×10×6;

- well: 30×30×3;

- turtle with anti-slip coating: 30×30×3;

- one of the largest tile sizes is square: 50×50×7;

- eight: 40×40×5;

- checkers: 30×30×3;

- old town: 12x18x6, 12x9x6 or 12x12x6.

Pay attention to the fact that tiles 3 centimeters thick are used for paving walkways. Thicker paving stones are used in places where there are increased loads on the pavement.