Bookmarked: 0

How to make money in the production of concrete products

The business of producing reinforced concrete rings can generate good and stable income for a long time, or rather, for a lifetime. Construction is gaining momentum, both basic and private. What are well rings for? The construction of wells, laying sewers and pipelines is impossible without this part.

Reinforced concrete products are widely used in construction and repair work for various purposes. Therefore, such a business will be in demand and profitable.

It is necessary to start the production of concrete products by drawing up a business plan. It should provide for the specifics of future activities, including the range of products that the enterprise will produce. Most businessmen start their company by manufacturing reinforced concrete rings or piles, which are in great demand today.

As a rule, special technical conditions are not required for the production of reinforced concrete products. So, it is enough to have any production premises of sufficient size with water supply and sewerage, electricity and ventilation.

Such a workshop must be equipped with the following equipment:

- forms, the varieties of which will depend on the chosen specifics of the products being manufactured;

- rails along which the trolley with forms moves;

- concrete mixer;

- overhead cranes;

- vibrating table;

- bins for sifting raw materials;

- drying chamber.

As in any other production, qualified employees are required to create reinforced concrete products. Depending on the scale of production, there may be 2-3 such workers per shift. In general, at first you will need at least 6 such employees. You will also need a manager to find buyers for finished products.

Of all the possible options for selling products, the most common and profitable are the following:

- wholesale sale of finished products to construction companies;

- searching for buyers using advertisements in the media and the Internet;

- retail sales directly at the production site.

For advertising purposes, you can advertise in the media or on the Internet. But it will be more profitable and convenient for a novice entrepreneur to establish long-term contacts with large buyers who will provide stable and sufficient income regardless of the season.

With proper business organization and accurate planning, the costs of organizing a business and initial investments pay off within the first year of operation. Thus, the approximate net profit that can be obtained from one ring of reinforced concrete products, taking into account depreciation costs and tax deductions, is 1000 rubles. Thus, by organizing constant production and establishing sales, you can achieve good results.

For greater profits, you can offer clients a service such as installation of ready-made concrete products. In this case, you will have to acquire a car to deliver the products, as well as hire installation specialists.

Having decided on the type of products that the mini-factory will produce, it is necessary to calculate all the necessary costs for creating the enterprise. If the own funds of the future owners of the enterprise are not enough, you can contact investors or a bank to obtain a loan. For many types of business activities, there are special government programs that provide favorable loans and even gratuitous assistance for certain areas of business.

Creating the company’s own website will contribute to a faster development of a client base, which will ultimately have a positive impact on the organization’s profitability and its relevance.

Main characteristics of concrete rings

The use of prefabricated reinforced concrete structures in construction can significantly reduce the time required to complete work, while increasing productivity. It is the rings that are considered the product most often used in construction processes.

Application area

The scope of use of such products can be very different:

- Construction of drinking wells;

- Arrangement of inspection wells necessary to monitor the condition of communication systems;

- Construction of septic tanks;

- Arrangement of storm drainage, etc.

Advantages and disadvantages

The advantages of structures of this kind include:

- High level of strength;

- Durability;

- Frost resistance;

- Easy installation;

- Ease of operation;

- Small price.

But there is one significant drawback, which lies in the heavy weight. So, for example, the answer to the question of how much a concrete ring with a diameter of 1 meter weighs is 600 kg. This means that transporting such a product to the construction site is impossible without special equipment.

Sizes of structures

Overall dimensions and weight of concrete rings are two parameters directly related to each other. Both the weight and the overall dimensions of such products may vary, depending on the type of product being created and the purpose of its use.

Today there are rings of the following sizes:

- KTs-10. The height of such a product is 0.9 m, the outer diameter is 1.16 m, and the weight of a concrete ring with 1 meter of inner diameter is 0.6 tons;

- KTs-15. Such a ring is called medium and has the following parameters: height - 0.9 m, internal diameter - 1.5 m, external diameter - 1.6 m, product weight - 1 ton;

- KTs-20. The ring is 0.9 m tall, weighs 1.5 tons, and has external and internal diameters of 2 m and 2.2 m, respectively.

Note! The product marking consists of the letters KC or KS and an indication of the size of the internal diameter of the product in decimeters.

Modern manufacturers offer rings with a diameter from 0.72 to 2 meters and a standard height of 90 cm.

In addition to such standardized products, there are also non-standard ones, which are called additional ones.

Such products may differ from standard ones in the following parameters:

- The shape of the structure itself;

- Wall thickness, which varies from 65 mm to 115 mm;

- The presence of locks on the surface, which simplify the process of assembling the structure;

- Height;

- Diameter.

So, for example, you can purchase large-diameter concrete rings (more than 2 m) or even square products.

Advice. The advantages of using square-shaped reinforced concrete structures include the possibility of installing them on a concrete slab. This eliminates the need for construction, and besides, it is easier to dig a square hole than a round one.

Types of rings

Based on the type of construction, this kind of construction is divided into two main types:

- Direct

. The connection of such rings is made using metal staples and cement mortar; - With a lock

- such products are equipped with an annular protrusion at the top and a recess at the bottom. Installing similar elements on top of each other allows you to create strong connections, which eliminates the possibility of displacement.

Photos and videos from the production of reinforced concrete rings Kolodets-PRO

Only the sequential implementation of the above necessary operations ensures the selection of the required level of strength of reinforced concrete rings. Finished products acquire their final operating parameters at positive ambient temperatures.

Manufacturing technology

The serious load on products of this kind during their operation necessitates the need to give them high strength indicators. That is why in the production process only high-quality solution with fine grain is used. Typically this is concrete of grades from M200 to M500.

The manufacturing process is divided into the following stages:

- The mold is prepared for filling;

- A reinforcement cage is placed into the mold;

- The finished concrete solution is poured;

- Voids are removed using vibration.

Now the product just needs to dry in the appropriate microclimatic conditions.

Making rings at home

If you decide to make reinforced concrete rings with your own hands, you should definitely know:

- To obtain a high-quality product, it is necessary to use cement grade M400 and higher;

- Washed quartz sand should serve as a fine filler;

- The coarse filler is low-graded gravel.

Instructions for making products of this kind at home are as follows:

- Arrangement of formwork. You will need to build 2 cylinders, 1 for the inner diameter and 1 for the outer.

Advice. The materials used for making formwork can be boards, plywood, roofing sheets, etc.

- Select a flat area and install the inner and outer cylinders on it, so that the walls of the products are equidistant around the entire circumference;

- Along the perimeter of the formwork, place 10-12 metal reinforcing bars with a diameter of 8-10 mm at equal distances;

- The resulting frame must be secured with wedges, which will move upward as the mold is filled with solution;

- In order to easily separate the finished product, lubricate the walls of the mold with used machine oil;

- Pour about 10 cm of concrete into the mold and compact it using a metal pin using the piercing method. Thus, fill out the entire form;

- Cover the poured formwork with thick fabric to protect it from the sun;

- After 3-5 days, the formwork can be removed and the product can be left to dry for another 7-14 days, covering it from the sun and moisturizing it several times a day.

Sewerage installation from reinforced concrete rings

The sewerage installation technology involves the process of concreting the bottom of the well in order to prevent wastewater from penetrating into the soil.

In addition to the fact that it is necessary to insulate the bottom of the well, it is also necessary to waterproof the joints between the rings.

The following building materials can be used for this purpose:

- Plaster mixtures;

- Liquid glass;

- Rubber seals.

We should also not forget that as the soil freezes, it shifts, which leads to some movement of concrete structures. In order to solve this problem, specialized plastic inserts made of polyethylene, 0.8 cm thick, are used. Today, such inserts are produced in a large assortment, with different diameters and heights.

Final stages

Next, you can seal the joints using concrete mortar. If in your area the groundwater is as close to the surface as possible, then the septic tank should be made as airtight as possible. To do this, approximately 10-20 centimeters of coarse river sand is placed at the bottom of the well, which is carefully compacted. The layer is lightly sprinkled with water, after which another seven to eight centimeters of crushed stone is laid.

All. Fill the resulting “sandwich” with concrete. After a couple of weeks, you can go down into the well and treat it from the inside with bitumen in two layers. As soon as it completely dries, you can start using the sewer.

Rings for cesspool: general information

Reinforced concrete rings are widely used for the construction of sewer systems - inspection wells or cesspools. The use of rings is considered the simplest and most convenient way to arrange a sewerage system.

The rings are made of reinforcement and concrete, they are very durable and are used primarily for durable work.

A sewer system equipped with reinforced concrete rings is reliably protected from various weather conditions and protects groundwater from sewage leakage.

There are two types of rings - Euro rings with a lock and ordinary reinforced concrete rings. The second type of rings is connected to each other with cement mortar and iron staples.

Advantages of using reinforced concrete rings:

- Long product life;

- Do not allow moisture to pass through;

- Easy installation and operation;

- Low cost;

- Can be used to equip sewerage systems, small tunnels, power lines and heating networks;

- Protect from groundwater.

The disadvantages include purely technical aspects - the heavy weight of reinforced concrete rings requires transportation in a large car, and their installation is only possible using special equipment.

Production technology

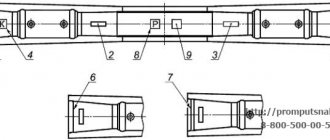

The mold used to produce concrete rings consists of 2 elements:

- External part. It is equipped with a vibration mechanism and reinforced with stiffening ribs.

- Inner core. It is cone-shaped with a loop in the center.

The form is placed on a pallet. Reinforcement is inserted into it and concrete is poured, then the product is subjected to vibration compaction. This is carried out by vibrators, thanks to which the necessary strength is achieved. In addition, the outer part of the structure is leveled. After two days, the formwork is removed, but the rings themselves are not touched for 6 days, the strength of the concrete by this moment reaches 80%.

Reinforced concrete rings are manufactured in stages:

- The industrial structure is placed on a metal platform, reinforcement is placed inside and filled with a mixture of concrete. At this stage, metal loops are also placed, they are firmly connected to the reinforcement using a knitting wire. These loops are necessary for loading and unloading processes and installation of the structure in the designated location.

- The technology begins with compacting and leveling the solution to the shape of a ring using a vibrator.

- The frame is not touched until the structure becomes strong enough. Typically, two days pass from the moment of low tide until the product is ready for use.

- The formwork is removed, but the reinforced concrete remains in place. The duration of this stage is 6 days. During this time, the strength of concrete will increase to 80%.

Classification and volume of reinforced concrete rings

These rings are made of heavy concrete B25, frost resistance of which is F-100, water permeability of W4. Reinforced concrete rings are marked, according to which the classification of the ring can be determined.

Reinforced concrete rings are divided into prefabricated, additional, with a lid, with a lock and with a bottom.

First, the marking indicates the type of structure: KS - wall ring, KSD - wall ring with a bottom. After the type, the size of the ring is written, the first group of numbers indicates the diameter of the ring, after the hyphen - the height of the product. For example, KS-15 designates a wall ring with a diameter of 1500 cm.

When installing a cesspool on a site, first of all, the size of future sewage is taken into account. Depending on the depth of the sewage pit, the required number of reinforced concrete rings and their types are calculated.

The standard height of the rings is 90 cm, but if necessary, the design can be supplemented with rings of other sizes. Depending on the needs, the diameter is selected - from 70 to 200 cm. The thickness of the concrete wall is 7-14 cm.

The strength of the structure largely depends on the bottom well ring - experts recommend installing a ring with a bottom. Next come the wall rings and the cesspool is closed with a lid with a hatch. The diameter of the septic tank elements must be the same everywhere, otherwise the structure will be unstable and sewage may leak into the ground.

How to organize the production of reinforced concrete rings?

The production of reinforced concrete rings begins with the choice of location. In this case, difficulties should not arise. It can be produced not even indoors, but outdoors.

You will need a flat area of 20 square meters. Well, if an entrepreneur decides to carry out this work in a building, then you need to pay attention to the height of the ceilings.

It must be at least five meters. The next stage is equipment.

Buy or rent the following:

- different shapes for rings, lids and bottoms,

- vibrator, concrete mixer, trowel,

- zinc buckets and shovels.

As for the forms, you can make them yourself or order them from the factory. The number of forms depends on the production volume.

To move and load finished products, you will need a lifting device. To start production, you will need consumables: concrete, road mesh with cells, fittings for hooks, lubricant and polyethylene film.

And another important detail for organizing the production of well rings is the workers. First you need to hire three specialists. They will be able to produce about 20 products in a day. As a rule, payment for their work is piecework.

The volume of a concrete ring is 1 meter: the nuances of building septic tanks

A single-chamber septic tank made of reinforced concrete rings must have a bottom and a lid. Such a cesspool is considered ineffective; it is most often installed in the country.

A drainage pit is installed at a distance of no more than 20 m from a residential building. The further away the septic tank is, the more pipes will have to be laid from the reinforced concrete septic tank. In this case, the minimum distance to residential buildings is 5 m. The number of people who will use the sewer system should be taken into account. On average, a person uses approximately 200 liters of water per day for sewage.

When choosing rings made of reinforced concrete, it is important to know how many liters of waste water this structure can accommodate. It is believed that the minimum volume of a septic tank made of rings is 6 cubic meters. To calculate the volume of a reinforced concrete ring, you need to multiply the number of residents by 200 liters, and multiply the resulting amount by 3 (the period of time during which the wastewater is processed in the pit). To obtain the volume of the ring, divide the final amount by 1000. Based on the tables on the Internet, select a reinforced concrete ring with a suitable diameter. One standard ring 90 x 150 cm holds approximately .59 liters of water or waste.

When installing a septic tank from rings, you need to remember that the surface on which the rings are placed must be strictly horizontal.

If it is not possible to install a lower ring with a bottom, you can fill it with a dense layer of crushed stone and fill it with cement mortar. The top of the septic tank is covered with a ring with a hermetically sealed cast-iron sewer hatch.

Expert advice

It is useful to take advantage of professional experience if you decide to do part of the process of installing well rings for a septic tank on your own. How - shown in the video. The stages of sewer construction are as follows:

- The necessary calculations are carried out before purchasing the required size of concrete rings. A place is selected for installing a septic tank, with the condition that it is located at a distance of at least 5 m from the house. To reservoirs, including drinking water - 25 m. The well sewage system is located 3 m from the garden and at least 5 m from the highway. In the case of sandy or gravel soil, all specified distance parameters from the well increase by 4–5 times. And, in addition, you should choose the least weight, since the soil can sink under the sewer.

- A pit is dug according to the purchased concrete rings for the well + the length of the inlet and outlet pipes + the necessary insulation for the sewerage system. If it is planned to install a multi-chamber septic tank, then the sump tank of the first is installed higher than the second and subsequent wells. The distance between them is no more than 0.5 m. The soil bottom of the well is carefully leveled while checking the level. The excavated soil is not removed - it will be needed to fill voids after installing a septic tank made of concrete rings.

- Next, the foundation pit for the future sewerage system is compacted with a sand-crushed stone cushion for future depreciation - well rings are heavy and the weight will affect the soil bottom, sinking lower. The finished layers are again checked for compliance with the level. The layers used to protect against subsidence of concrete rings and prevent the aggression of wastewater when interacting with concrete must be at least 20 cm each. Only then is there no threat to the well sewer system.

- Having prepared the pillow, lower the bottom, which is larger than the outer diameter, or immediately a combined concrete ring for the well. How the first element of the sewer system is installed will determine its further operation and the entire structure as a whole - an uneven load on the well structure cannot be allowed, as this is fraught with destruction of the lower “crowns”.

- In the case of the first option, the bottom goes separately, before installing the concrete ring, it is checked for level and, if the result is satisfactory, a layer of prepared mortar is placed on the edges. It is best to prefer a ready-made composition; it only needs to be brought to a consistency with water. If you add a little detergent to it, the solution will become plastic and will not set instantly, which will allow the well sewer to fall into place correctly.

- Next, the concrete ring is lowered. Excess cement mass should be removed immediately, otherwise it will peel off with constant contact with moisture and can clog the outlet hole. It is necessary to clean all caulked seams with a stiff brush to eliminate even small concrete crumbs.

- Concrete rings of a future sewer or septic tank installed on top of each other are waterproofed with molten bitumen on both sides at the seams - thus, reliability increases many times over. If desired, the surface can even be plastered and then whitewashed. Not for beauty purposes, of course, just because the concrete ring will also receive a chemical disinfectant - the smell will be much less.

- You will need to drill two holes for the pipes in the concrete ring for the well. They are located opposite each other, but the drain must be installed a size higher than the outlet and both have vertical outlets so that volley discharges inside the sewer do not disrupt the stratification process.

This way, the masses will not mix and clog the outlet pipe. Sewer pipes with a diameter of 100 are inserted and the holes in the concrete rings are sealed. Frost-resistant compounds should be used for the solution - well structures are cold and can contribute to cracking of the seams.

- It is important to insulate concrete rings for a septic tank, since the freezing depth in some regions of Russia reaches a large value. The sewage system should not suffer from the climate, because the usual rhythm of life will immediately be disrupted. For this, polystyrene plates with a thickness of 50 mm and glue are used. After lining the well structure, the voids in the pit are slowly filled with the excavated soil, each time compacting the backfilled layer.

- All that remains is to install the lid with the hatch on the concrete rings for the septic tank and remove the ventilation. To do this, drill a hole on the opposite side of the cover from the edge of the hatch. It should not be large, a size of 2.5–5 cm is enough. A tube is inserted into it, rising 15–20 cm above the surface of the covered concrete sewer ring cover.

A visual video helps to significantly facilitate the process of installing concrete rings for a well.

High-quality design is the key to longevity of the sewer system

In order for the well sewer system to serve the owners long and productively, it is important to understand the rules before starting construction. So:

- Advance calculations and design of the entire sewerage structure made of concrete rings will allow the work to be done quickly and soon you will begin to enjoy the benefits of civilization even in areas without main networks.

- Important - if any point in the instructions for installing concrete rings for a well pit seems complicated, it is better to contact professionals. Handicraft work will reduce the service life of the septic tank by 50%.

- Well sewerage that is ready and put into operation should be cleaned in advance. The check is carried out by visual inspection or using a special beacon. You can choose a method for cleaning concrete rings immediately by finding out the cost of the service from local professionals.

- Owners should be alerted to the unpleasant odor in the area from concrete rings, even with all the measures taken and the lid closed. This could be due to many reasons, but mainly due to overcrowding of the sewer system, where the wastewater has already reached the vents. If this is not the problem, then it is worth reconsidering the cleaning methods - perhaps biological septic tanks will cope with bacteria on the walls of concrete rings better than manual labor.

- If a defect is detected in the well concrete rings, the process of replacing the sewer system should immediately begin. Otherwise, the destruction of the entire structure will not take long to occur. The ecology of the site will be disrupted, the foundation of the house will be flooded and other troubles will occur.

If all requirements are met, the shelf life of concrete septic tank rings is tens of years. It is important to remember that if damaged, the structure cannot be repaired - only complete replacement.

Cesspool made of concrete rings without a bottom: do-it-yourself installation

Before you start laying the rings, you need to prepare a pit 3 meters deep for the cesspool. Its width should be slightly larger than the diameter of the reinforced concrete rings selected for the septic tank.

You can dig a hole for a foundation pit yourself using shovels, or you can hire special equipment to get the job done faster.

The bottom of the pit must be leveled with sand, on top of which a concrete ring with a bottom or an ordinary wall ring is installed.

How to install a septic tank from reinforced concrete rings:

- Install the first ring. Check that it does not lean to the side.

- Having installed the next wall ring, fill the space between the septic tank and the pit.

- Gradually build a septic tank, not forgetting to check the level of installed reinforced concrete rings.

- Seal the joints between the rings with a solution of cement and sand.

- Using a hammer drill or grinder, make holes for the sewer pipes. The drain pipe from the house is installed at a slight angle.

- If the sewerage system consists of several septic tanks, in addition to the drainage pipe, you need to lay a pipe connecting the septic tanks. This pipe is located 20-30 cm below the waste pipe.

- To prevent runoff from getting into the ground, it is important to choose the right waterproofing. For this, bitumen or polymer mastic is used.

- The final stage is installing covers on the septic tank. After the joints have dried, you can begin using the cesspool.

A septic tank made of reinforced concrete rings does not require special operating rules, but it is important to clean it on time and use special bacteria to better process wastewater.

Making a crushed stone pillow

In most cases, it is not necessary to resort to such drastic measures. You can make a much simpler sewer system from concrete rings. In this case, its installation scheme does not provide for complete tightness.

First, a hole is dug, the diameter of which is approximately one and a half times larger than the same size for the ring itself. The depth depends on the required volume of your future septic tank. A cushion made of a layer of sand (at least 30 cm) and crushed stone (approximately 40-60 cm) is laid in advance on the bottom. After this, all the rings are installed, and the progress of work should be constantly monitored, checking the rings with a building level.

The same gravel is poured between the edge of the earth and the resulting well. The result is an almost completely autonomous sewage system. Excess liquid will gradually leave it, filtering through layers of sand, and the solid fraction of waste can be pumped out very rarely.

To improve the degree of wastewater treatment, it is necessary to dig a cascade of septic tanks (at least three wells), going downhill and connected to each other by pipes of sufficient diameter. The drain is made in the form of a collector made of bricks and buried at a depth of approximately 60 cm. In such a sewer, the liquid is completely drained, and the solid fractions need to be pumped out from the first tank no more than once a year.

This is what a sewer system made of concrete rings looks like. There is nothing complicated in its design and installation. Just follow our recommendations!

How to calculate the volume of a ring (video)

The performance of a reinforced concrete septic tank largely depends on the quality of the materials from which it is made. All items must be correctly labeled. By observing all the nuances and installation technologies, the waste pit will last for quite a long time.

Reinforced concrete rings are a construction material that belongs to the finished type and is manufactured in accordance with GOST 8020-90. In the production of the product, various mixtures of concrete grades, fillers such as crushed stone (many fractions), sand and special metal reinforcement are used. The totality of the material used determines the weight of the rings, and the presence of reinforcement determines the name of the structures. Providing strength and reliability of the rings, the metal also reduces the risk of cracking of reinforced concrete rings and provides resistance to stretching of the structure. In turn, the concrete component serves as protection for the reinforcement, eliminating corrosion processes, and also rendering it immune to compression during temperature changes.

Thus, reinforced concrete rings for various types of wells have super-strong characteristics in comparison with concrete structures not reinforced with reinforcement.

Advantages and disadvantages

The advantages of concrete rings for use in construction purposes are the following design properties:

- long service life (more than 10 years);

- affordable price;

- easy installation due to the correct geometric shape;

- high strength and operational reliability.

However, despite having a number of advantages, concrete rings have two significant disadvantages:

- additional costs for delivery and installation - the heavy weight of the structure will not allow you to install it yourself, so the services of special equipment will be required;

- Uneven load on the large mass of the ring can lead to the formation of chips and cracks.

Types of reinforced concrete structures used for various purposes

The following designs are shown for the installation of sewer and drinking wells:

- With ring-type locking connection. On each element, special protrusions are cast in the upper part, and recesses in the lower part. During installation, one element is pushed onto another, tightly enclosed in a lock. This technique ensures the integrity of the structure during operation and the impossibility of movement/displacement to the side.

- Straight reinforced concrete rings without locking elements. They require sealing at inter-ring joints using metal staples, cement mortar, and special-purpose sealant.

- Adjusting low rings having an increased thickness along the width of the walls and a reduced diameter. Indicated for adjusting the horizontality of the surface of a structure, adjusting the internal volume when there is a need to narrow the diameter to the required size.

- Additional reinforced concrete products. Used to adjust the height of wells. Usually used to build up a “glass” or to replace a standard reinforced concrete ring due to its large size.

Important! Low additional rings are applicable according to SNiP and are approved for use in a wide variety of situations.

Dimensions of precast concrete products

Markings of rings for the construction of wells: KS, KTs. Each element has its own weight, dimensions, volume and diameter. According to the established GOST 8020-90, the dimensions of reinforced concrete rings (KS - wall rings) are specified by a certain diameter of the outer wall (dн), inner wall (dв). Options:

- Height 2.9 – 11.9 meters;

- Dн – 0.8-2.7 meters;

- Dв – 0.7-2.5 meters.

Standard reinforced concrete well rings are divided into three categories:

- Small. They have parameters of diameter dв - 1 m, height - 0.9 meter (with a wall thickness of 1.6 cm), weight up to 600 kg;

- Average Internal diameter up to 1.5 meters, weight – up to 1000 kg;

- Large ones. Internal diameter from 2.0 meters, weight up to 1500 kg.

A simplified way of dividing reinforced concrete fragments into classes:

- Class A – up to 1 meter in diameter;

- Class B – more than 1 meter in diameter.

Dimensions also determine the name of the elements. In particular, the KS 7.9 series has a height of 0.89 m, an internal volume of 0.84 meters, an external diameter of 0.67 meters, which is different from the KS 10.10 products, the height of which is 1 m and a total diameter of 1.2 m. How much does it weigh? each element is indicated in the appendix to the product.

Important! In product names, the first numerical designation corresponds to the rounded value of the internal volume. Therefore, when choosing reinforced concrete well rings, you need to focus on this indication. The number after the dot is the height value, rounded to a convenient calculation. Therefore, in particular, the design diameter of KS 20.6 will always be larger than products of the KS 7.9 brand.

Characteristics of standard reinforced concrete elements for wells with a bottom:

- Dh 100 cm – height 0.9 m, weight 830 kg;

- Dh 150 cm – height 0.9 m, weight 1400 kg;

- Dh 200 cm – height 0.9 m, weight 2300 kg.

Thanks to the table, you can always calculate the volume of the required well, the number of standard and additional reinforced concrete rings.

Calculation of the volume of concrete for the production of reinforced concrete rings

The product manufacturing procedure complies with GOST standards. Any deviations from the requirements lead to a decrease in product quality, violation of the specified technical characteristics and minimization of service life during operation. For the mixture from which the rings for the reinforced concrete well are cast, the following components are used:

- sandy clean mixture;

- gravel;

- fine crushed stone;

- heavy grade cement M400, M500;

- iron fittings.

It is important to maintain the ratios of all components. In particular, for a 2.4 t concrete batch, the parameters of other components are as follows:

- 150 kg of clean river sand or mixture;

- 300 kg of cement (it is better to take the specified grades so that the concrete base is stronger);

- 1200 kg of crushed stone;

- 150 liters of water.

An important parameter: the ratio of water and cement should not be greater than 0.7 in calculations. Otherwise, the strength and toughness characteristics will be significantly reduced. Only by carefully calculating how many components to take for the manufacture of reinforced concrete rings for wells can you obtain a high-quality product.

First, guess a simple riddle: “It won’t fit on your finger, but it will fit in a well.” What it is?" A person familiar with water supply will answer it without hesitation - a concrete ring!

This is a common type of prefabricated structure used in engineering and construction work. Most often, reinforced concrete rings are used when digging mine wells. They are no less popular among developers as strong and durable containers for septic tanks (cesspools). In this case, they are supplemented with a concrete cover with a hole.

Another area of application for concrete rings is inspection wells and drainage pipelines. They house shut-off valves, gate valves, sand traps, and are also used for laying heat and cable mains.

It is useful to know about concrete rings (varieties, geometric sizes and costs) for anyone planning the construction or reconstruction of engineering structures. Therefore, we will try to answer in detail questions related to the “ring” topic.

Types and markings of concrete rings

A separate GOST 8020-90 is devoted to concrete (reinforced concrete) rings

. It specifies the purpose, dimensions and marking of these structures. The strength of the concrete from which the rings are made is standardized by GOST 10180. The frost resistance of the material is determined by state standard 10060, and water resistance is regulated by GOST 12730.

There are several varieties of these designs on the market:

- well rings with a flat end;

- well rings with a locking end;

- additional;

- repair;

- supporting

Standard marking of concrete rings consists of a letter designation (indicates the area of application) and a digital designation (indicates overall dimensions).

The letter marking is deciphered as follows:

- KS - wall ring of the working chamber or well neck;

- KSD - wall with a solid bottom;

- KO - support ring;

- KFK - for working chambers of fecal (domestic) sewerage wells;

- KLK - for storm drainage;

- KLV - water intakes (for storm sewers);

- KVG - water and gas networks.

It is clear from the list that there is no special marking for well rings, since the standard classifies them as wall rings (WW). You won't find repair rings in the standard either. This is what installers call ordinary wall rings of smaller diameter. They are inserted into the well shaft to deepen it.

Digital marking of a concrete ring contains information about its dimensions (in decimeters). The first number indicates the internal diameter, and the second indicates the height. For example, about the design of KS 6-10 we can say that this is a concrete wall ring. Its internal diameter is 60 cm (6 decimeters), and its height is 100 cm (10 decimeters).

Rings with a diameter from 70 to 200 cm and a height from 10 cm to 2 meters are produced in series. Wall thickness from 7 to 20 cm.

For the manufacture of rings, concrete grades from 200 to 500 are used. As a rule, reinforcement is not used in wall well rings. Concrete works well in compression and withstands lateral soil pressure well. To strengthen ring structures operating in difficult soil conditions, reinforcement up to 10 mm thick and steel mesh (0.6-1 mm) are used. It prevents the formation and opening of cracks.

Standard sizes

Considering that builders widely use them in their work, the sizes of concrete rings for sewerage have long been standardized. Let's look at the most common types.

Most often, KTs-10 (KS-10) rings are used in household work. Their internal diameter is equal to one meter, and the height is 90 cm. The KTs-20 (KS-20) model, as is easy to imagine, already has a diameter of two meters, but the height of the ring remains exactly the same. These are the dimensions of concrete rings for sewerage that we will use for the installation of our structure.

Of course, some factories can produce materials with other standard sizes to order. In particular, if you have your own heavy equipment, you can order rings of greater height: this will increase the speed of installation of the structure.

Concrete rings with lock

A very popular type of well rings is a design with a lock. It is made in the form of a recess at the end of the ring and prevents shifting under the influence of groundwater. The second, no less important function of the lock is to increase the tightness of the joint.

A ring with a flat end is less resistant to ground movements. It can move to the side and block up to 50% of the diameter of the well shaft or septic tank. This happens when there is powerful quicksand in the well area (weak clay, silt or sandy soil that liquefies under the influence of water).

Advantages

So that you better understand why you need to use this particular material for sewer construction, we will reveal a list of all its advantages:

- Highest mounting speed.

- The cost is quite acceptable for most buyers.

- Almost complete absence of gaps between components.

- Very simple work on waterproofing the structure, which is extremely important in regions with high groundwater levels.

- Durability and extremely long service life.

Thus, concrete rings for sewerage, the price of which varies between one thousand and five thousand rubles, are ideal for creating a septic tank in your homestead.