What are supplements for?

To increase the strength of highly loaded and special concrete structures, special additives are used, which are added directly to the prepared cement-sand or concrete mortar.

After setting and complete hardening, the mixtures to which strengthening additives have been added acquire additional performance properties: water resistance, corrosion resistance, frost resistance and significantly greater compressive and bending strength.

Considering the relatively high cost of concrete and cement mortar with additives, their use is economically feasible in the following cases:

- Increased requirements for frost resistance and water resistance of concrete structures;

- Use of non-standard materials as filler. For example, very fine sand;

- Production of highly loaded concrete products. For example, the production of paving slabs, foundation blocks, etc.;

- Preparation of fine-grained concrete;

- Construction of monolithic buildings and structures that use expanding additives.

Types of strengthening additives for cement

Plasticizer . At this point in time, the best additive to cement for strength, increasing the strength of the structure by an average of 125-140%. In this case, the main task of the plasticizer is to increase the mobility of the solution.

Also, the use of this type of additive makes it possible to increase the frost resistance of concrete by 1.5 grades, water resistance to 4 grades and reduce binder consumption by 25%. A popular “folk” plasticizer is ordinary liquid soap or washing powder.

Strength gain accelerator . The purpose of this type of additive is to increase the rate of setting and hardening of concrete and, accordingly, increase its grade strength in bending and compression.

The most popular and inexpensive strength gain accelerator is regular calcium chloride. Used in the production of: paving slabs, foam concrete blocks, wall and foundation blocks, polystyrene concrete, etc. Thanks to the use of hardening accelerators, the time of its exposure in the mold is significantly reduced. Accordingly, productivity increases, yield increases, and the strength of concrete products increases by several percent.

Antifreeze additives . In accordance with the name, the purpose of the antifreeze additive is to enable concrete work to be carried out in low temperature conditions (down to minus 25 degrees Celsius).

In parallel with this, there is an increase in the strength of concrete, an increase in water resistance, a decrease in the delamination of ready-made concrete during transportation, as well as an improvement in workability. The most popular antifreeze additive is neutralized resin mixed with the water repellent Sofexil-gel or Tiprom-S.

Complex additives . They accelerate hardening, increase strength, significantly reduce dust separation, and increase frost resistance. In particular, through the use of a complex additive, it is possible to achieve: an increase in the strength of concrete by 70-110%, with the same mobility, a reduction in shrinkage by 60-70% and a two to threefold increase in water permeability. One of the most popular types of domestic complex additive for concrete is the “Elastoconcrete” additive: A, B or C (depending on the purpose of the reinforced concrete goods or structure).

Additive for intensifying cement grinding

697433 Union of Soviet Socialist Republics o-3 acceptance of application C 04 In the 7th Committee of the USSR for inventions and discoveries of the State 3) Priority Published on 53. 1.79.

Belletv that publication description 181179(54) ADDITIVE FOR INTENSIFICATION OF REMOLATED CEMENT oya saltaldehyde components, 2.5 soluble and salicylic R at the following and weight. e: Soap aft 8-1 Water-soluble polymer of sodium salt of salicylic acid with formaldehyde 1.5-2. Water The rest, The specified composition is introduced in an amount of 1-2 2 by weight of cement, The additive for intensifying cement is obtained by the above-mentioned ingredients of this additive by Spraying it into cement (clinker) at any stage of grinding, an additive to intensify the grinding of cement is introduced at the second hundred. - grind in a ball mill. The test results are shown in the table. With optimal introduction of the additive, the specific surface area of crushed cement increases by 600 cm g, mill productivity by 25-3 In addition, the properties of cement prepared with the intensifier cecamredsanitation are induced by pumping and mixing. grinding and water. The invention relates to adding a binder clinker substance intended to accelerate the grinding process, and can be used in the production of construction materials; in particular, cements. An additive is known to intensify the grinding of cements used in grinding clinkers and cements based on them, including soap naft 10-30 and the rest water, introduced in an amount of 0.3-0.5 by weight of cement calculated on a dry matter basis (11 The main disadvantage of the known additive is insufficient increasing the productivity of mills, a relatively large amount of introduced additive without significantly improving the properties of the finished product (cement). Indicated to the closest to the achieved invention, the purpose of the invention is to increase the productivity of mills. This goal is achieved by an additive for cement intensification, including soap, which additionally contains 2 ( 53) UDC 666942.2b 9 7433 ment,. are improved; strength, cement density decreases, which increases the improvement stone by 15%, normal frost resistance. Contained surface cm / g it t 10.3000 10.2500 87.8 2900, 0.0 90.24 formula of the invention 8imirium Dmea for intensification, including soap naphtha, thus increasing it produces an additionally soluble polymer of sodium cylic acid with the following ratios, weight. odSource accepted in the external Higeoovictional communication. Lyzhova Tehred. Alien Proofreader M. Demchi EditOrder b 540/4 TsNIIPI Gpo del1 30 35, Mos Circulation 7state invention, J, Rauw Sub-Committee of the USSR and Otkrytiysnaya embankment d4 / lial PPP Patent, Uzhgorod, Proektnaya st., addition nta, l and ch elyu, p nits, rdstv sali house n ponent grind and water, which, in fact, contains the evaporation Soap aft Borodisolpolymer salts salic acids smaldehyde water 1 5 Osta Formats with e et al ITsemen See

Subtleties of application

All types of concrete additives should be diluted or dissolved in warm water. If the additive is mixed with cement-sand mortar in a liquid aggregate state, it begins to work immediately after addition.

The dry additive will begin to “work” only after complete dissolution and thorough mixing. The dosage of additives depends on the specific material, specific tasks and the requirements of the manufacturer’s instructions. In general, the amount of additives should not exceed 1% by weight of the binder (cement).

Additives for cement mortar - a complete builder's guide with photos and videos

Please note: this material is dedicated specifically to the types and properties of additives for cement, not for concrete. What is the difference?

- Concrete is made by mixing 4 components: water, cement, large and small aggregates (crushed stone / gravel, pebbles).

- The mortar (cement and sand mixture) includes 3 components: sand, cement and water.

It is the presence of large fractions in concrete and sand in mortar that is the main difference between the materials. This difference accordingly affects the scope of their use: concrete is used for the construction of large / medium-sized structural elements and foundations; cement-sand mortar - for plastering surfaces, filling joints, constructing screeds for floor coverings.

Types of additives for cement: features, dosage, use

In order to choose the right product for the implementation of your tasks, it is important to know the characteristics of each substance. According to GOST 24640-91, additives for cement are divided into the following types: plasticizing, air entrainers, mixture set accelerators, set retarders, compactors, corrosion inhibitors, antifreeze, polymer, coloring.

Let's take a closer look at each type:

Plasticizing

Advantages

A plasticizer is a special product in the form of a powder, liquid or ready-to-use solution, which, when added to a cement mixture:

- increases the degree of elasticity and fluidity;

- increases the hardness and strength of a monolithic structure up to 125-140%;

- reduces the concentration of water in the solution by 5-15%;

- increases resistance to temperature fluctuations;

- reduces the percentage of material shrinkage after hardening;

- increases adhesion between the components of the cement mortar and with metal products;

- prevents the occurrence of corrosion formations on fittings and other elements;

- reduces the amount of cement used in mortar by up to 15%;

- reduces the likelihood of air voids;

- increases the total coverage area by reducing the thickness of the solution poured;

- improves workability and saves labor resources.

In addition, plasticizing additives make cement more homogeneous, holistic and durable. Thanks to this, the material does not delaminate, does not become covered with a “network” of cracks, and is stored longer before use.

Important! When carrying out construction work at low temperatures (-10°C and below), it is not recommended to greatly reduce the amount of cement in the solution.

Types and areas of use

Depending on the effect they have, plasticizing additives for cement are divided into 4 groups:

- Super strong - capable of increasing mobility by 3-4 times and the plasticity of the solution by several levels (for example, from P1 to P6) without reducing the strength and density of the material. The product is made on the basis of sulfuric acid, 30% formaldehyde, naphthalene and sodium sulfate. Super-strong plasticizing additive for cement is suitable for any construction work: pouring, screeding, plastering.

- Strong - a substance made on the basis of acrylic polymers, inorganic salts, lignosulfonate. Strong plasticizers increase the workability of the cement mixture, increase thixotropy and plasticity by 3-4 levels (from P1 to P3). Recommended for use in molding various structures, screeds and plaster.

- Medium – an additive that increases the waterproofing properties of cement; improves resistance to sulfates and chlorides; increases the mobility of the material from P1 to P3. Medium plasticizers are traditionally used for building foundations and laying plinths.

- Weak - a product created from sodium, fluorine and potassium methyl siliconate increases the plasticity of cement by only 1 level, but at the same time significantly improves its waterproofing characteristics. It is advised to choose weak additives if you need to build small cement structures.

Additives that regulate the properties of cement

3.1. Additives that regulate the properties of cement are divided into:

1) regulating the basic construction and technical properties of cement;

2) regulating the special properties of cements.

3.2. Additives that regulate the basic construction and technical properties of cement are divided into:

1) regulators of setting time (accelerators and retarders of the onset of cement setting);

2) hardening accelerators - increasing the initial strength of cement;

3) increasing strength - increasing the activity of cement at the age established by product standards for brand strength;

4) plasticizers - reducing the water demand of cement.

3.3. Additives that regulate the special properties of cement are divided into:

1) water-retaining - increasing the sedimentation resistance of cement paste, reducing water separation;

2) hydrophobizing - increasing the resistance of cement to air moisture;

3) regulating volumetric (linear) deformations of cement stone (expansion or shrinkage of cement);

4) regulating heat release - reducing or increasing the heat of hydration for a specified period;

5) improving the decorative properties of cements - increasing whiteness, as well as imparting or improving color;

6) regulating the density of cement paste - making it heavier and lighter;

7) regulating the backfilling and technical properties of cement.

What additives need to be added to cement and their characteristics

Cement additives are used everywhere in construction today: special substances make it possible to improve various characteristics and properties, and increase the mechanical properties of concrete mortar for various purposes. Polymer and plasticizing, modifying compositions can make the concrete mixture more plastic and practical to work with, resistant to water or frost, increase strength, etc.

Most cement additives greatly facilitate the process of laying the mortar and its compaction, thus reducing labor and financial costs. Can be used in the production of concrete structures, mortars, elements of any strength level. The most popular additives for cement today are: concrete set retarders/accelerators, anti-frost, for waterproofing, air-entraining, stabilizing, etc.

Types of additives for cement

Additives to cement are classified in accordance with the regulatory document - GOST 24640-91. "Additives for cements." In this case, each individual type of additive is used to change or improve certain properties of the building material.

GOST 24640-91 identifies the following types of additives:

- Plasticizing. By introducing a material of this type into concrete or mortar, you can significantly increase the workability and plasticity of concrete without adding additional portions of the sealer (to optimize the “water-cement” ratio as much as possible). In addition, plasticizers increase the strength and frost resistance of structures, and also allow saving up to 15% of cement. Popular plasticizing additives for cement: Polypast SP-1 (S-3), “Lignopan B-2”, “Fort UP-4”, as well as liquid soap and detergent “Fairy”, widely known in our everyday life.

- Air entrainers. By adding air-entraining additives to the concrete solution, the porosity of the concrete structure is achieved, which in turn increases the frost resistance of the structure. The anti-frost effect is achieved as follows - air pores allow freezing water to expand into the pore space, and not into the thickness of the concrete. Since an overdose of this additive leads to a significant decrease in the strength of the structure, the air entrainer should be used strictly according to the attached instructions. Types of air-entraining additives used by Russian builders: “Micro Air 125”, “Micropor 1”, “TECHNONICOL Aero S”, “Aero 200”.

- Mixture setting accelerators. They are used in two cases - during concrete work in conditions of low air temperature and to compensate for the harmful effects of other additives that inhibit setting. The use of hardening accelerators allows for layer-by-layer pouring and reduces pouring time. Popular hardening accelerators: Relamix M2, Energy Admix, Hard Plast, Bisil FS.

- Retarders. They are used by concrete plants and builders to increase the time interval of “survival” of ready-made concrete or mortar. Building material with the addition of retarders can be transported over long distances, and can also be poured in stages in accordance with some types of construction technologies. Popular brands of retarders: Linamix P-120, Potash, Bisil Retarder, tartaric acid, Neolas-P(1).

- Sealing additives. These are effective additives to cement for waterproofing concrete structures operating in conditions of high humidity: water storage tanks, subway tunnels, foundations, cellars, basements and hydraulic structures. In addition, seals increase the strength and waterproofness of structures. Popular cement additives for waterproofing and compacting concrete mortars: “D-5”, “SIKAPAVER AE-1”, “Microsilica MK-85”, “Kalmatron”.

- Corrosion inhibitors. They are used to effectively protect steel reinforcement from corrosion and subsequent destruction. The technical meaning of the additive is the formation of a protective oxide film on the surface of the reinforcing bars. Corrosion inhibitor brands: MasterProtect 8000 Cl, Sika® FerroGard®-901, calcium nitrate.

- Antifreeze additives. In accordance with the name, they allow concrete work to be carried out in winter, at ambient temperatures up to 15-20 degrees Celsius. The essence of the action of the antifreeze additive is to accelerate the removal of the sealer from the thickness of the material. Popular antifreeze additives: ArmMix NORDPLAST M, sodium formate, Ultralit, Frieze, Irbis-PrM.

- Polymer additives. Cement with polymer additives is used to prepare concrete with increased density, water resistance, frost resistance and bending strength. The mechanism of action of polymer additives is the formation of a thin polymer film on the surface of the component particles (cement, crushed stone and sand), which in turn contributes to the strong “gluing” of the particles into a monolithic conglomerate. Among the polymer additives used: DEG-1 and TEG-1 resin, S-89 polyamine resin, Mowilith Pulver, water-soluble methylcellulose, Tylose.

- Coloring additives in cement. In accordance with their name, they are used in the production of colored concrete solutions used in the production of: decorative structures, paving slabs, sculptural compositions, vases, flowerpots, etc. Brands: “Technical carbon P-803”, “Titanium dioxide DuPont R-706”, “ KZhO-50", "FEPREN Y-710", "BROWN 686".

Additives for cement mortar and concrete

Most often, special additives are used in construction to increase the strength of highly loaded concrete structures. Hydrophobic compounds that improve frost resistance are popular. Basically, they are added directly to the mixed concrete mortar, which is used immediately after preparation.

After the setting and hardening processes are completed, solutions with additives demonstrate additional performance characteristics - resistance to corrosion, sub-zero temperatures, water, increased bending/compressive strength, etc. The use of additives is advisable in certain situations, taking into account the high price of concrete and mortar with additives mixed into it.

The use of cement additives is relevant:

- In the production of highly loaded reinforced concrete products, these can be foundation blocks, for example

- If concrete has increased requirements for resistance to water/frost

- When materials of non-standard fractions are chosen as a filler - fine sand, for example

- If there is a need to mix fine-grained concrete mortar

- In the construction of monolithic structures and buildings where expanding additives are used

Types of additives

When thinking about what to add to cement for strength, it is necessary to carefully consider all existing types of additives, study their properties, determine the feasibility of using certain compositions, calculate the expected loads and other key points.

Strength accelerators

Additives of this type increase the speed of setting and hardening of the concrete mixture and, accordingly, significantly increase the compressive and bending strength in comparison with brand indicators. The most popular and affordable strength gain accelerator is ordinary calcium chloride. It is used in the production of foam concrete blocks, various types of blocks for foundations and walls, polystyrene concrete, etc.

Plasticizers

These cement additives are considered the best, as they can increase the strength of a structure or monolith by 125-140% on average, which is a very good result. The main task of plasticizers is to increase the mobility of the concrete mixture.

This additive to cement mortar for strength also demonstrates excellent properties in terms of frost resistance and improves other characteristics: on average, the frost resistance of a concrete mortar increases by 1.5 grades, moisture impermeability by 4 grades, and binder consumption is reduced by about a quarter. The most popular homemade plasticizers are ordinary washing powder and ordinary liquid soap.

With anti-frost effect

This type of additive allows you to carry out work on preparing and pouring concrete at low temperatures - down to -25C. Concrete improves its strength characteristics, the level of water resistance increases, the finished concrete delaminates less during transportation, and is much lighter and easier to lay. The simplest version of an anti-frost solution is neutralized resin mixed with a water repellent such as Tiprom-S, for example (you can also take Sofexil-gel).

Modifiers for concrete solutions

When considering different types of additives, you should not stop only at looking for what is added to the cement mortar for strength. There are compounds that work differently, but are no less useful. Thus, modifying additives are introduced to increase the elasticity of the mixture, resistance to deformation, cracks, and increase the adhesion of concrete to various types of non-absorbent bases and reinforcement.

There are substances with anti-corrosion properties - they bind free calcium hydroxide in the concrete solution. Additives that increase density make the mixture more resistant to moisture. You can also increase the hardening time - for example, gypsum has this property. It also increases the strength of the solution, resistance to sulfides, and sub-zero temperatures.

Crushed clinker is added to cements with mineral additives. Such additives are active substances or granulated slag of sedimentary origin. Concrete with additives of this type introduced into the composition demonstrates increased resistance to moisture, frost, and generates heat well.

DIY supplements

What supplements can you prepare yourself:

- A plasticizer from shampoo or liquid soap is added during mixing at the rate of 250 milliliters per 50 kilograms of cement (standard bag). First, mix water and additive, then pour water into a trough, add cement and aggregate, mix and work. The volume of water must be reduced by the volume of the additive, otherwise the concrete will harden 3 hours longer than the standard time.

- Plasticizer from washing powder - first dissolve 100-150 grams (per bag of cement) in warm water, pour water into a trough, add cement, add filler, mix.

- Slaked lime fluff – to increase elasticity and adhesiveness, improve bactericidal properties (resistance to fungi, mold). First, 15-20% of the weight of cement is added to water, then prepared according to the method described above.

- PVA glue - to improve mobility, significantly increase strength and water-resistant properties. It is introduced during the mixing process of concrete in a volume of about 200 grams per bucket of solution.

- Chloride salt - reduces the setting time of the mixture and reduces cement consumption, a good anti-frost additive.

- Introduction of fiber (cut wire, etc.) into the solution - to strengthen the solution.

Construction of houses

69 votes

+

Vote for!

—

Vote against!

In order to improve the quality characteristics of the cement mortar, special substances are added to it. There are several types of cement additives that give it certain properties. Let's look at the features and types of cement additives below.

Table of contents:

- Additives to cement: types and characteristics of cement

- Additives for cement and concrete - operating principle

- Waterproof and polymer additives in cement

- Features of antifreeze additives in cement

- Modifying additives for cement: characteristics

- Types of additives for cement

Additives to cement: types and characteristics of cement

Cement appeared not so long ago, but managed to gain popularity very quickly. To obtain it, clay and lime were combined and fired in a special way. Cement is the main component of most building compounds. In addition, polymer-cement compositions are made on its basis.

Cement also contains substances based on aluminates and silicates, the formation of which uses raw materials exposed to high temperatures. At the same time, after hardening, the cement becomes quite hard and durable.

There are several options for cement, depending on their composition. Each of them has a certain hardness characteristic, which determines the brand and quality of the product. There are several options for cement, the most common grades from two hundred to six hundred. At the same time, the choice of one type of cement or another is directly determined by the scope of its application. We suggest you familiarize yourself with the main types of cement:

1. The use of Portland cement is quite common. This material is also called silicate. It has the form of a hydraulic binder that hardens both in a normal environment, upon contact with air, and by dissolving in water. In appearance, this material is a gray-green powder that requires the addition of water to mix it. When the cement composition sets, it gradually hardens. Portland cement is the main component for almost every type of cement composition.

2. The use of plasticized cement has many advantages. This material allows you to reduce the cost of preparing the solution; the cement mixture becomes not susceptible to frost, moisture, evaporation and other negative environmental factors.

3. There is another type of cement called slag cement. To make it, clinker and blast furnace slag are crushed. Certain substances are added to the resulting mixture, in the form of gypsum or lime. This solution is used in the process of mixing building compositions.

4. The material in the form of aluminous highly active cement is unique. Its setting time is no more than forty-five minutes, and for the composition to gain strength, ten hours is enough. The main advantage of this composition is the ability to set quickly, despite the high humidity of the environment. If you add this version of cement to concrete, it gains additional resistance to moisture, corrosion, and sudden changes in temperature.

5. If you combine sodium fluoride and quartz sand, you get an acid-resistant cement. Plain water is not used to dissolve this composition. For these purposes, sodium-based liquid glass should be used. Among the positive characteristics of this cement, we note the high level of its resistance to mineral and organic acids. However, during operation of this solution in caustic or humid conditions, the duration of its use is significantly reduced.

6. To make colored cement, ordinary Portland cement is used, to which various types of pigments are added. This type of cement is widely used in facade decoration. It is also the basis for the manufacture of concrete roads.

Portland cement, when mixed with water, forms a plastic substance, which after drying takes on a rock-like shape. The widespread use of this substance is explained by its following advantages:

- ability to harden without outside intervention;

- the formation of a stone product, which is characterized by high strength and hardness;

- minimum level of chemical hazard;

- environmental Safety;

- Fire safety;

- affordable price;

- Wide scope of application - versatility.

The independent use of Portland cement is rare, since most often it is a component of various kinds of composites, such as dry mixes, building concrete and mortars. To determine the Portland cement of a mixture, it should be compared with three criteria:

- quality of initial powder mixtures;

- cement paste and its characteristics;

- the resulting cement stone.

Additives for cement and concrete - operating principle

Portland cement contains substances in the form of clinker. To obtain this product, raw materials containing calcium aluminates and silicates are fired. In order to make Portland cement, clay, marl and lime are used. By reacting with water, cement is susceptible to crystalline hydrogenation. After this, a substance is formed in the form of a concrete stone, which has special qualities.

In relation to GOST, the following types of cement additives are distinguished:

1. In relation to the main action, they are:

- material components;

- regulators;

- elements that simplify the cement grinding process.

2. Real elements, in turn, are:

- active minerals;

- filling components.

3. Mineral additives in active cement are:

- hydraulic action;

- pozzolanic action.

4. Regulating additives are:

- determining the setting time of the solution;

- hardeners;

- increasing strength characteristics;

- plasticized substances.

With the help of certain types of additives for cement and concrete, it is possible to perform the following functions:

- reduce the release of moisture from the concrete solution, that is, increase its plasticity;

- make the cement mortar more resistant to moisture;

- increase or decrease the level of cement shrinkage;

- adjust heat release;

- improve the decorative qualities of cement mortar;

- adjust the cement paste according to density;

- make the composition of the cement mortar more plastic.

Waterproof and polymer additives in cement

Polymer additives act as surfactants. With their help, it is possible to improve the quality of the concrete composition. With the help of certain compositions it is possible to improve the plasticity of concrete, reduce its moisture absorption, and regulate the release of moisture. Thus, the strength characteristics of concrete are significantly improved. In some cases, additives are used to create materials that contain air.

There is a possibility of polymer additives going into a viscous state. With their help, it is possible to seal concrete pores and increase the adhesion of concrete mortar to aggregates and reinforcement.

Additives for cement help make it moisture-proof, frost-resistant, tensile, and gas-tight. Another type of additive is silicon substances of organic origin. They release gases inside the concrete solution. Therefore, with their help, air is drawn into the solution. It becomes more porous and resistant to frost and moisture.

Some types of additives have a hydrophobic effect. The principle of their action is based on the clogging of capillary plexuses inside concrete. Thus, moisture migration occurs. With the help of moisture-proof additives, it is possible to improve the structure and increase the density of the concrete composition.

Features of antifreeze additives in cement

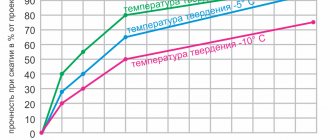

Negative temperature conditions have a bad effect on the performance characteristics of concrete mortar. This is explained by the fact that at low temperatures, the water inside the solution begins to freeze. During warming, it melts and expands, deteriorating the quality of concrete. The effectiveness of resisting increased moisture volume is called the frost resistance of concrete.

The resistance of a concrete solution to frost determines its moisture content. To ensure this characteristic, special additives should be used, most often these are substances with surfactants.

Plasticizers have a positive effect on creating an optimal concrete structure. The structure of the solution is distinguished by a higher level of density, which makes the cement paste sedimentary. Some of the additives are designed to make the solution more water-saturated, so that water, after expansion, fills the pores and does not in any way affect the quality of the concrete.

Please note that in order to achieve a positive effect from introducing the additive, you should choose only high-quality materials from trusted manufacturers. In addition, before using additives, you should read the instructions from the manufacturer and strictly follow all proportions recommended for a particular type of additive.

If you add a small amount of the additive, the concrete will still be susceptible to frost. If the amount of plasticizer is too much, the structure will lose strength.

Modifying additives for cement: characteristics

These compounds are introduced into cement mixtures to improve their elasticity, resistance to cracks, and deformation. In addition, with their help it is possible to increase the adhesion of concrete to reinforcement and any non-absorbent base.

By introducing this type of additive, it is possible to increase their adhesion to the tiles. Most often, these supplements are in liquid form. They make cement materials more elastic, reduce their level of shrinkage, are used both indoors and outdoors, and are completely environmentally safe.

Cement without additives, although it has its own performance characteristics, is, however, rarely used due to its susceptibility to various types of external irritants.

Another option for a cement additive is a substance with an anti-corrosion effect. With the help of these substances it is possible to bind free calcium hydroxide in the concrete composition. In addition, some of the additives improve the density of concrete, making it not only corrosion-resistant, but also moisture-proof.

Adding gypsum to cement increases its hardening time. In addition, with its help it is possible to improve the quality of the finished solution, namely its strength characteristics, frost-resistant qualities and resistance to sulfides.

To produce cements with active mineral additives, crushed clinker is used. Additives are granulated slags or active substances that are of sedimentary origin. Concrete to which these substances have been added is characterized by a high level of moisture resistance, excellent heat release and frost resistance.

Types of additives for cement

1. For dry mix or concrete with special characteristics, a plasticizer is used. With its help, the consumption of cement and water during the preparation of concrete mortar is reduced. Plasticizers make the solution more plastic and mobile. Thus, with its help it is possible to fill all the pores.

2. Water-retaining additives are presented in the form of starch or cellulose. With their help, it is possible to achieve a uniform consistency of concrete. In addition, they help get rid of concrete delamination and such an effect as cement laitance. However, the negative side of using these additives is a decrease in the strength of the base and a decrease in its mobility.

3. The use of redispersible powders is an excellent binder in the process of applying cement to paint the surface. In addition, these substances are the basis for cement glue, as they give the composition high adhesion.

4. The second or third filler is polymer fiber fiber. It makes the base resistant to cracks; in addition, the resulting composition is characterized by high mobility and self-leveling.

To increase water resistance, substances in the form of hydrophysers are used. With the help of accelerators or retarders of hardening it is possible to regulate this process. The combination of several additives helps to give the cement the characteristics necessary for a given type of environment.

Some characteristics of the use of additives in cement mortar

Compositions that are added to concrete for strength, frost resistance, ductility, workability, and water resistance require careful adherence to the instructions. You can purchase ready-made ones in Moscow and the region, other regions, or make them yourself.

All compositions are diluted/dissolved only in warm water. When a liquid additive is mixed with a ready-made cement-sand mortar, it begins to act instantly. Therefore, you need to calculate in advance the required volumes of concrete solution and the optimal portions that will need to be prepared and immediately used in work. Dry additives begin to act only after complete dissolution in water and mixing with the solution.

The dosages of factory additives are indicated in the instructions, as well as the technology for preparing the mixture. Depending on the material, desired properties and requirements, the volume may vary, but usually does not exceed 1% of the weight of the cement (binder).

It is very important to use the mortar with additives for its intended purpose - you cannot use the masonry mixture to fill the foundation, for example (and vice versa). This can lead to structural failure, deformation, and reduced performance. You also need to take into account that additives have different effects on the viability of the solution, differ in the “power” of the effect, etc.

When properly selected and used according to technology, cement additives can greatly improve the properties of concrete and make it possible to complete the most complex work easily and quickly. First you need to decide on the requirements, then carefully study the composition and properties of the additives, prepare the concrete mixture according to the rules - in this case you will be able to achieve the best result.

Application

As a rule, additives to concrete, which are needed to increase its strength, are not always used. The use of such materials is permissible in the following cases:

- the presence of high requirements for concrete or reinforced concrete structures for water resistance or frost resistance;

- use of non-standard fillers such as fine sand in the solution;

- production of concrete products that will be subject to high loads (for example, paving stones made of heavy or fine-grained concrete);

- construction of monolithic structures that use mineral expansion additives.

Classification and characteristics of additives

Strengthening mixtures and concrete additives are specially prepared chemical products. They are added to the structure or product during preparation and harden along with the base materials.

The main advantage of the additives is the complete protection of the entire volume of concrete. A disadvantage is the inability to strengthen an already created structure (this function is performed by strengthening impregnations intended for concrete).

Plasticizers

The task of plasticizers included in concrete solutions is to increase their mobility. In this case, it is possible to both increase the strength of the resulting concrete by 120-140 percent, and give it the following properties:

- frost resistance increased by 1.5 marks;

- water resistance is 3–4 grades higher.

Also, the use of plasticizers reduces cement consumption by up to 25 percent, which allows saving on construction work.

Strength accelerators

Strengthening accelerators are characterized by an increase in the rate of hardening of concrete, as well as an increase in its grade strength. One of these substances is granulated calcium chloride, used in the manufacture of foam concrete, paving slabs, wall stones and polystyrene concrete.

With its help, the production process is accelerated due to less downtime of the product in a special mold, and the number of products produced accordingly increases. In this case, concrete strengthening by several percent is observed. And the number of chips on products that worsens their presentation is reduced.

Additives with antifreeze effect

The useful qualities that a concrete hardener with an anti-frost effect adds to the material include not only an increase in strength, but also the elimination of the influence of low (down to minus 25 degrees) temperatures on the hardening process.

One of the most popular substances of this type is neutralized resin, used in conjunction with water repellents (for example, Sofexil-gel and Tiprom-S).

Another advantage of the additive is that it increases the ease of processing the mixture.

In addition, the resulting product becomes waterproof (and thus does not require waterproofing). And when transporting the solution, its delamination noticeably decreases.

Modifiers for concrete solutions

Modifiers are additives to concrete to increase strength, which also increases frost resistance and workability of the composition. There are modifiers that can improve the anti-corrosion properties of concrete.

Complex Supplements

Complex additives to increase the strength of concrete provide additional positive effects. For example, some substances increase the workability of concrete, its construction and technical characteristics (water resistance and frost resistance), reduce the amount of water spent on preparation, and reduce cement consumption. At the same time, all components of the additive interact perfectly with each other.

Information data

1. DEVELOPED AND INTRODUCED by the State Association “Soyuzstroymaterialov” DEVELOPERS Z.B.

Entin, Candidate of Technical Sciences (topic leader); N.V. Fartunina, Candidate of Technical Sciences; A.B. Morozov 2. APPROVED AND ENTERED INTO EFFECT by Resolution of the State Construction Committee of the USSR dated March 11, 1991 N 6

3. The standard fully complies with ST SEV 6824-89

4. INSTEAD GOST 24640-81 5. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | In which place |

| GOST 310.2-76 | Application |

| GOST 310.3-76 | » |

| GOST 310.4-81 | » |

| GOST 310.5-88 | » |

| GOST 310.6-85 | » |

| GOST 965-89 | » |

| GOST 15825-80 | » |

| GOST 23464-85 | » |

| GOST 26798.1-85 | » |

| ST SEV 4772-84 | Introductory part |

This standard applies to all types of additives used in the manufacture of cement and establishes their classification.

Definitions of terms used in this standard are according to ST SEV 4772.

Other methods of strengthening concrete

Strengthening materials include not only those materials that are added to concrete during its creation to increase strength. When the structure is already ready and cannot be replaced, other substances and other techniques are used. The most popular method in construction and repair work is strengthening concrete using liquid and solid hardeners. They are generally best suited for floors and other horizontal surfaces.

Strengthening impregnations

Liquid hardeners or impregnations contain water-soluble inorganic compounds. They are capable of penetrating into ordinary concrete (which was not previously treated with water repellents) to a depth of 3–5 mm. Inside the material, the liquid reacts with it, forming insoluble compounds that act as hardeners.

This strengthening impregnation for concrete is applied both to old structures and to new ones, the increase in strength of which was not provided for during the manufacturing process. The disadvantage of impregnations is the impossibility of application in aggressive environments. The advantage is that it gives concrete the ability to withstand stronger loads.

Dry hardeners

To strengthen concrete, you can also use a dry hardener that contains cement. A structure whose strength has been increased in this way can withstand up to 70 MPa. In addition, the low tensile strength of concrete and its wear resistance increases.

The process of applying dry hardener is not affected by the aggressiveness of the environment. However, it is applied (diluted with water) only to a smooth and dust-free surface. At the same time, the service life of the structure increases by at least 10–15 years.

Complex additive to cement

Union SovetskikSocialistResublmk OP INVENTED IJAK AUTHOR'S CERTIFICATE and, 897741oo about the affairs of neo-theories and discoveries of slowing down the setting, I in that the keel has achieved a complex of rice, sodernozem and com- mon additive in cemelite, sulfite-trembles additionally graphite with the following components , wt.

%;CryoliteSulfite-yeast mash Amorphous NT, including yeast mash morphic gsham ratio 1540-4 The invention relates to the production of building materials, namely to the compositions of complex additives, reducing -. water separation and slow down the setting time of cement, and can be used in large-block hydraulic engineering and in the construction of similar general purpose facilities. It is known to use additives to slow down the setting time of cement - various salts of lignosulfonic acids 11 The closest to the proposed complex additive of sodium fluoride salt (0.01 -0.5% by weight of cement) in a composition with surfactant organic compounds or organic acids. Various salts of lignosulfonic acids such as SDB and SSB are used as surfactant organic substances, i.e. sulfite-yeast mash and sulfite-alcohol stillage, introduced in an amount of 0.001-0.5% of the mass of cement 21. The remainder of the known additives is that, slowing down the time period (beginning and end), they sometimes increase water acquisition - reducing the water separation of cement while maintaining alumina 6-8 Graphite 30 32 The proposed complex additive is obtained by mixing the components leads to it when grinding cement in quantities of 897741 4 known additives, as well as those containing the proposed additive in an amount of 0.4% by weight of cement. 0.3-0.55% of its mass. In addition, SDB can be introduced separately into the mixing water of cement or concrete in an amount of 0.20-0.25% by weight of cement; in this case, a mixture of the remaining components in the ratio, wt.%: Cryolite 25-42 Amorphous alumina 8 h 5 Graphite 50- is introduced when grinding cement in an amount of 0.1-0.3% of its mass. In the table. 1 shows examples of the manufacture of complex additives. Table. Table 2 shows the results of testing cements without additives, containing 2 9-05 11-25 1 26.0 38 1 720 complex,6. 5 5-00 38 11 38 11 680 650 2 8 3 8 0.3 6 Continued table 7.7 6 5.7 49.5 Р5.9 50.3 6.5 48.8 47 660 4 10 71.3 4 Without additive, sf%; SDB 64.0 -р.91: 1,650,752 b The proposed complex additive makes it possible to increase the durability of concrete by reducing water release and heat generation. The complex additive can be used in the production of cements with slow setting times and reduced water release and heat generation, which can be used in large-block hydraulic engineering15 construction, as well as in the construction of similar general purpose facilities. Table 1 6 24 75 6-30 10-00 4 5 2475 8 20 12 40 4Amorphous alumina Graphite 5-830-32 Source nnformatzn; taken into account prn expertnze1. Vavrzhnn f, Influence of chemical additives on cement hardening processes International Congress on Cement Chemistry; M., Stroyizdat, 1974, p. 6-13,.2. US Patent No. 3317327, cl. 106-90, op02,05,67. 5 897741 formula of invention: Complex additive to cement, including sulphite-yeast mixture, etc. The main thing is that, in order to reduce the water separation of cement while maintaining a slowdown in setting time, it additionally contains amorphous alumina and graphite in the following ratio of components, wt.%; eCryolite 15-25 Sulphate-yeast mash 40-45 Compiled by G. Koroleva Editor L. Veselovskaya Technical editor M. Raves Corrector S. Shomak Order 11857/3 1 . Circulation 639 Subscribed VNIIPI of the USSR State Committee for Inventions and Discoveries 113035, Moscow, Zh., Raushskaya embankment, no. 4/5 branch of PPP “Patent”, Uzhgorod, st. Proyektnaya, 4 View

Additives for cement mortar - a complete builder's guide with photos and videos

Please note: this material is dedicated specifically to the types and properties of additives for cement, not for concrete. What is the difference?

- Concrete is made by mixing 4 components: water, cement, large and small aggregates (crushed stone / gravel, pebbles).

- The mortar (cement and sand mixture) includes 3 components: sand, cement and water.

It is the presence of large fractions in concrete and sand in mortar that is the main difference between the materials. This difference accordingly affects the scope of their use: concrete is used for the construction of large / medium-sized structural elements and foundations; cement-sand mortar - for plastering surfaces, filling joints, constructing screeds for floor coverings.

Types of additives for cement: features, dosage, use

In order to choose the right product for the implementation of your tasks, it is important to know the characteristics of each substance. According to GOST 24640-91, additives for cement are divided into the following types: plasticizing, air entrainers, mixture set accelerators, set retarders, compactors, corrosion inhibitors, antifreeze, polymer, coloring.

Let's take a closer look at each type:

Plasticizing

Advantages

A plasticizer is a special product in the form of a powder, liquid or ready-to-use solution, which, when added to a cement mixture:

- increases the degree of elasticity and fluidity;

- increases the hardness and strength of a monolithic structure up to 125-140%;

- reduces the concentration of water in the solution by 5-15%;

- increases resistance to temperature fluctuations;

- reduces the percentage of material shrinkage after hardening;

- increases adhesion between the components of the cement mortar and with metal products;

- prevents the occurrence of corrosion formations on fittings and other elements;

- reduces the amount of cement used in mortar by up to 15%;

- reduces the likelihood of air voids;

- increases the total coverage area by reducing the thickness of the solution poured;

- improves workability and saves labor resources.

In addition, plasticizing additives make cement more homogeneous, holistic and durable. Thanks to this, the material does not delaminate, does not become covered with a “network” of cracks, and is stored longer before use.

Important! When carrying out construction work at low temperatures (-10°C and below), it is not recommended to greatly reduce the amount of cement in the solution.

Types and areas of use

Depending on the effect they have, plasticizing additives for cement are divided into 4 groups:

- Super strong - capable of increasing mobility by 3-4 times and the plasticity of the solution by several levels (for example, from P1 to P6) without reducing the strength and density of the material. The product is made on the basis of sulfuric acid, 30% formaldehyde, naphthalene and sodium sulfate. Super-strong plasticizing additive for cement is suitable for any construction work: pouring, screeding, plastering.

- Strong - a substance made on the basis of acrylic polymers, inorganic salts, lignosulfonate. Strong plasticizers increase the workability of the cement mixture, increase thixotropy and plasticity by 3-4 levels (from P1 to P3). Recommended for use in molding various structures, screeds and plaster.

- Medium – an additive that increases the waterproofing properties of cement; improves resistance to sulfates and chlorides; increases the mobility of the material from P1 to P3. Medium plasticizers are traditionally used for building foundations and laying plinths.

- Weak - a product created from sodium, fluorine and potassium methyl siliconate increases the plasticity of cement by only 1 level, but at the same time significantly improves its waterproofing characteristics. It is advised to choose weak additives if you need to build small cement structures.

All classes of plasticizing additives increase the density of cement, due to which it conducts heat better (especially important when used for screed under heated floors).

Additive dosage per 100 grams of cement

The dosage of the product depends on its concentration - it is different for each manufacturer. As a rule, this is 0.5-1% of the substance from the total mass of cement - that is, 0.5-1 g of additive is needed per 100 grams of solution. Plasticizers are diluted with water in a ratio of 1:2 (t - up to 30 degrees), and then added to the cement mixture during the mixing process (dry - at the beginning, liquid - in the middle).

Let's look at an example:

when using 0.5% additive by weight of cement - it is necessary to add 100 g of plasticizer for every 10 liters of water

Important! The plasticizer contains substances that are “afraid” of water, so the product should be stored in a dry place at any temperature.

Video: CemThermo complex additive for pouring floors and screeds

Additive for intensifying cement grinding Soviet patent 1979 according to IPC C04B7/54

The invention relates to additives to the clinker binder, intended to accelerate the grinding process, and can find application in the production of building materials, in particular cements. A known additive for intensifying the grinding of cements is used for grinding clinkers and cements based on them, including soap naft 10-30 and the rest water, introduced in an amount of 0.3-0.5% of the weight of cement based on dry matter 1. The main disadvantage of the known additives is an insufficient increase in mill productivity, a relatively large amount of Lobavka introduced without significantly improving the properties of the finished product (cement). This additive is closest in technical essence and achieved effect to the described invention. The purpose of the invention is to increase the productivity of mills. This goal is achieved by the fact that the additive for intensifying the grinding of cement, including soap naft and water, additionally contains a water-soluble polymer of sodium salt of salicylic acid with formaldehyde in the following ratio of components, wt.%: Soap naft 8-12.5 Water-soluble polymer of sodium salt of salicylic acid with formaldehyde 1.5 -2 WaterRest. The specified composition is introduced in an amount of 1-2 f2% by weight of cement. An additive for intensifying the flow of cement is obtained by mixing the above ingredients. The introduction of this additive is carried out by spraying it into the cement (clinker) at any stage of grinding. An additive to intensify the grinding of cement is introduced at the second stage of grinding into a ball mill. The test results are shown in the table. With optimal introduction of the additive, the specific surface area of crushed cement increases by 600 cm /g, and mill productivity by 25-30%. In addition, the properties of cement prepared with a cement intensifier are improved: the strength of cement stone increases by 15%, normal Formula of invention

An additive for intensifying pomo:aa cement, including soap naft and water, characterized in that, in order to increase the productivity of mills, it additionally contains a water-soluble polymer of sodium salt of salicylic acid with formaldehyde in the following ratio of components, wt.%:

Mylonaft8-5

Odorless polymer of sodium salt of salicylic acid with formaldehyde1.5-2

Rest and information sources,

taken into account during the examination 1, Khigeoovich M, I. and others.Informa-. tion message YaIICement, No. 10,195 density is reduced, which improves frost resistance.