September 23, 2018

8873

Reading time: 3 min

Thanks to its design and installation, ceiling anchors of various types, which are in demand when fastening suspended structures, have become easier to buy today, and the price is attractive for buyers. The cost of this type of fastening depends on the type - wedge anchor or ceiling hook anchor, type of connection (fastening pendant lamps or structures).

The article discusses the features of its design and scope of application. Ceiling anchors are widely used in both industrial and private construction.

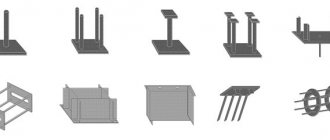

Wedge (expansion) anchor

It consists of a steel rod with a thread and a cone at the end, a movable bushing-belt and a nut. The anchor is designed for attaching heavy suspended structures to the base. A hole is made in the construction material and in the base, into which the anchor is subsequently inserted. The nut is tightened, as a result of which the wedge-shaped end of the rod expands the sleeve-belt in the hole, fixing it to the walls of the hole. The connection is considered very reliable, capable of supporting significant weight of the structure.

Wedge anchor, Fischer FAZ II

Ceiling tiles

Armstrong produces slabs in two sizes:

- 610x610 millimeters;

- 610x1219 mm.

Square panels are the most popular. The following materials are used for their manufacture:

- plastic;

- wood;

- glass;

- mirrors;

- metal solid or perforated sheets.

Soft panels are made from mineral or organic materials of natural origin. Mineral wool-based slabs have recently been practically not used, since they release small particles of material into the air that enter the human respiratory system.

Installation of Armstrong suspended ceiling and installation cost

To produce organic panels, recycled cellulose raw materials are used. These slabs are easy to install due to their low weight, are easy to process and are environmentally friendly.

Advice! If necessary, ceiling panels can be made independently. For this purpose, fiberboard, wooden elements, plywood or MDF are used.

Screw anchor

In its design, it is almost no different from its wedge counterpart. The only difference is that the screw anchor has a Phillips head screw instead of a nut. Tightening the screw allows you to hide its head in the material of the structure, which is sometimes very important in terms of aesthetics.

Screw anchor, Molly Sormat

Wall profiles

Essentially, this is a plinth for a suspended ceiling. In cross-section, the product resembles a corner and is attached to the wall surface around the perimeter of the room. Unlike a wall profile for a suspended ceiling, it does not have a harpoon clamp or other fixation mechanism. The slabs are simply laid with one side on the element. The length of the product is 3000 millimeters. If necessary, the profiles are spliced. To install it in the corner part of the room, the shelf of the product is cut and the vertical side is bent to the shape of the corner.

Important! Wall elements are fixed in a strictly horizontal position using a level.

As you can see, each element of the Armstrong suspension system performs specific functions and is of great importance. The strength and reliability of the entire structure is ensured by the use of high-quality components and compliance with installation technology.

Drive-in anchor

Consists of two metal elements - a bolt and a bushing. A special feature of the bushing is the presence of holes that allow the bushing to expand as the bolt enters it. The anchor is inserted into a hole drilled in the base and structure being fixed, after which the bolt is struck with a hammer. The expanded bushing is firmly adjacent to the walls of the hole. This is how many rigid materials are attached.

Drive-in anchor, Sormat LA

Cross profile

These parts also have a T-shape in cross-section, which allows ceiling tiles to be laid on the shelves on both sides. They come in metal-plastic and metal. The latter are painted using powder paints. The shelf width is 24 and 15 mm. Elements with a short flange are suitable for laying lightweight slabs made of organic materials. Elements with a wide shelf can cope with loads from lighting fixtures, metal panels, glass, and mirror plates.

Prices in the estimate and cost of dismantling the Armstrong suspended ceiling

The length of this necessary element of the system is 600 mm, which is equal to the standard dimensions of one of the sides of Armstrong ceiling panels. All supporting and longitudinal slats have holes for snapping the locks of the transverse elements into them.

Chemical anchor

This is not exactly an anchor in its purest sense. A hole of the required length and required diameter is drilled at the base, into which the composite composition is poured. In some cases, this may be a finished briquette. The composition is tightly compacted into the hole, after which the fastening element is inserted into it. This could be a rod, bolt or hook. The chemical composition interacts with the base material. This creates a strong connection in which the metal fastener is fixed. This fastening is used in places where it is not possible to use conventional anchors. For example, when installing elements in aerated concrete or foam concrete, or if the base material is loose or soft.

Chemical anchor, Fisher

By choosing the right type of anchor correctly and using it correctly during installation, you will receive a very reliable and durable fastening element.

Operating principles

A ceiling anchor of any type considered is held in the base due to a combination of frictional forces and direct contact. The bushing is wedged under the influence of gravity of the suspended product, which gives stability to the resulting connection. The type of spacer connection in question firmly holds the object being secured.

A solid foundation into which the ceiling anchor is installed is important: a solid foundation creates an anchorage that is resistant to mechanical stress.

Selection of fasteners

The ceiling mount is selected depending on the following parameters:

- type of fastening element;

- type of ceiling covering;

- weight of the fixed structure.

We will analyze different types of fasteners and the possibility of installing them in certain conditions. The main types of ceiling fasteners are:

Rules for choosing self-tapping screws

The easiest way to fasten structures is to use self-tapping screws.

Self-tapping screws are divided into two types according to their purpose:

- wood screws;

- screws for metal.

Self-tapping screws intended for wood are used exclusively for fixing light-weight elements to wooden ceilings (for example, in country houses). There are three types of fasteners:

- standard with different thread pitches. If the screws are black, then the metal from which they are made is hardened (more durable). Self-tapping screws in yellow and gray colors are less durable, since the material has not been hardened;

Standard fastening element for wooden surfaces

- equipped with a press washer. Such self-tapping screws are smaller in size, but due to an increase in the fixation area they are able to withstand a stronger load;

Wood fasteners for heavier products

- equipped with a hexagonal head. Self-tapping screws with a head are tightened with a wrench. They are more durable, but require drilling before installation.

Hex Head Wood Fasteners

If it is necessary to attach to a metal surface of the ceiling, then metal self-tapping screws are used. Fasteners for metal surfaces are:

- standard with a frequent pitch of the threaded tip. Used for fixation to metal whose thickness does not exceed 0.7 mm;

Standard fastenings to metal surfaces

- equipped with a special tip that allows you to secure the product without pre-drilling. Products can be used on any surface.

No-drill fastener

If the ceiling to which you want to fasten any device is made of concrete or brick, then self-tapping screws supplemented with dowels are used, since it will not be possible to screw a fastening element into a brick (concrete) without a dowel.

Installation of anchor fastening - step-by-step description

The technology for using anchor fasteners does not differ significantly from its predecessors - plastic dowels, but requires a more serious approach to the process. To work, you will need a good drill equipped with a hammer drill, as well as a wrench that matches the dimensional characteristics of the nut.

We begin the work by carefully marking the installation locations of the anchor bolts. Remember that once the nut is installed and tightened, the anchor cannot always be removed! If you don't know the diameter of your fastener, it's not difficult to measure it using a familiar caliper.

Having installed a drill of equal diameter, we drill holes at the marking points. Their depth should only be a few millimeters greater than the length of the hollow tube. It is very important to carefully clear the resulting holes from any remaining concrete dust that invariably forms during perforation. For this purpose, you can use a small brush - a brush or a household vacuum cleaner.

Carefully insert a bolt with a partially screwed (attached) nut and the attached product into the thoroughly cleaned hole, and install the fastener into the hole with gentle blows. When performing a large number of fastenings, for example during construction work, it is possible to use a hammer drill equipped with a special attachment to install anchors.

Next, use a wrench to tighten it by rotating the nut (blot head) clockwise. It is not recommended to apply too much force, which could lead to thread breakage, especially of small diameters. Recommendations for tightening force should be checked with the manufacturer or reference literature.

We recommend other articles on the topic