There are many tools and devices for joining parts in the world. It all started with primitive pegs - holes were made in the products into which stakes were driven. This is how the parts were fastened together. Later there was a transition to primitive nails made from bones and plant thorns. In Ancient Egypt, they came up with the idea of using metal (bronze) to make nails.

Modern self-tapping screws appeared only in the late 19th and early 20th centuries. They were invented by a Latvian emigrant to the USA. Having received a patent, this man soon became rich, and the world learned about the self-tapping screw. They became very popular - their reliability and durability amazed many. But people really began to use it only after the appearance of a standardized screw in the 70s of the 20th century.

For better fastening, you can use a spacer element called a dowel. It can be used to cover walls made of concrete, timber, stone and brick. Each material has its own plastic dowel with a screw.

How to remove a dowel nail?

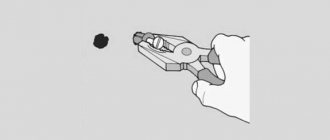

If the dowel sticks out of the wall along with the nail, removing it will be quite simple. You will need to take a small hammer and tap the dowel nail on both sides as well as the top and bottom to loosen it in the hole. After which you will need to take pliers and sharply pull it out of the wall.

Before pulling a dowel nail out of a concrete wall, check whether such an operation will damage the top layer of plaster, which you may need in the future. As a last resort, you can simply drive the dowel and nail more tightly into the wall using a piece of metal or wood comparable in diameter to the dowel and a hammer. As a rule, the depth of the hole for the dowel is initially made slightly larger than its length. Therefore, such an operation should not cause much difficulty. To level the surface of the wall above the dowel nail, use mastic or gypsum plaster.

Return to content

Types of fastening

Plastic dowels are classified according to many characteristics. Sometimes it is easier and faster to select fasteners according to their intended purpose - for thermal insulation, roofing, frame, sometimes you need to know the design features in order to take into account all the features of the material.

In general, the design of the dowel is as follows.

- The non-expanding part is that part of the sleeve that does not change when the screw is tightened. Its purpose is to hold the dowel in the exact position during installation. It also prevents contact of the nail with the wall material. The non-expanding part passes through the attached material, where it plays the role of a regular nail, so its length is determined by the thickness of this material. With through installation, the length of the fragment is greater, since it includes the thickness of the heat-insulating layer, for example, or the air gap.

- The spacer part is the working part; when the screw is screwed in, it expands, twists, folds, that is, it is deformed in a certain way. The spacer part may include teeth, spikes, ailerons, protrusions, and must have slots, thanks to which the sleeve can change shape without ruptures or damage.

Depending on the number of slots, the fastener can have several thrust directions. Double-spacer, for example, is the simplest and cheapest, but creates uneven pressure. The four-spacer holds better and does not turn when screwing in the screw.

The design and proportions of the spacer and non-spacer parts are the basis of the classification.

According to the structure of the spacer part

Since the design of the dowel is determined by its purpose - a sort of ratio between the characteristics of the wall material and the characteristics of the attached material, this classification can be considered the most universal. Based on the type of dowel, it is easy to understand what purposes it is intended for.

- K – studded. The simplest and most common option. The sleeve is wedged almost along its entire length, the non-expanding part is small, the largest expansion is in the front part of the sleeve. There are spikes on the surface of the sleeve, which ensure tight contact with the wall material.

- S – universal fastener for concrete and solid brick. The sleeve is equipped with teeth that are denser and higher: when compressed, they significantly increase the friction force. In addition, there are locking tabs that prevent the dowel from turning during installation.

- U is a truly universal dowel, since it can be mounted on both solid and hollow bases. The sleeve has 3 petals, which, when in contact with concrete, for example, increase the friction force when wedging the dowel. In a hollow brick the picture is different: the sleeve is deformed when a screw is screwed in, literally screwing onto it, and forms a three-dimensional thrust unit.

Type U fasteners are used for fixing to any brick, concrete, plasterboard and any other panel bases.

- T – three-leaf dowel for brick and concrete. When the screw is screwed in, the sleeve expands along its entire length, the petals are pressed tightly against the walls of the hole. The fastener can be installed with a screwdriver, since it does not rotate in the hole.

- N – four-spread dowel, ensures uniform distribution of pressure on the walls of the hole. It is made only from nylon and has a high load-bearing capacity. It is used for fastening to solid and hollow bricks, as well as concrete.

- Butterfly - designed for fastening to sheet material: drywall, plasterboard, panels, that is, material with a thickness of no more than 10–12 mm. The dowel passes through the thin base and folds, pressing tightly against the back of the sheet. This design makes it possible, for example, to hang chandeliers from a plasterboard ceiling.

- Fasteners for foam concrete - longitudinal ribs on the sleeve change direction. When screwed in, the sleeve expands, and the ribs form almost one whole with the porous material.

- Spacer - a classic version of the dowel, where the spacer part can have a different number of petals, necessarily includes teeth and protrusions, and in the tail part, as a rule, there is a hole, which makes tightening the screw easier. In fact, most types of dowels are a modification of spacer ones.

- Dowel-nail - the spacer part of a plastic product is designed in the simplest way: as a rule, it is a double-spacer sleeve with small teeth. But during installation, the nail is simply driven into the sleeve, and not twisted. This method significantly speeds up installation, and therefore is used when it is necessary to fix a large number of structures and materials.

- Piranha - designed for installation in chipboard, wood, brickwork, thick panel bases. The sleeve has reverse-directed teeth: such fasteners have good tear resistance even in soft material, such as chipboard.

Plastic dowels with screws 8x60 mm

According to the structure of the non-expanding part

This fragment of the dowel is conditionally considered non-working. In fact, its design is also of considerable importance.

One of its main characteristics is length. On this basis they distinguish:

- conventional fasteners - that is, designed for the traditional installation method: pre-drilling a hole and immersing the dowel into it for the entire length. This option has restrictions on the thickness of the attached material, which is indicated in the manufacturer’s catalogue;

- elongated - in this case, the non-spacer part can be the same length or even longer than the length of the spacer. The model is designed for through installation. This category includes, for example, a facade dowel: the fastener must pass through the facing material, a layer of thermal insulation or a ventilation gap, and then end up in the wall material.

The frame dowel has the same structure: the plastic structure is not pressed tightly against the wall, this gap later foams. In addition, frame fasteners can be used in slotted materials: the non-spacer part ends up in a void, and the spacer part ends up in a dense area.

The structure of the upper part of the dowel is mainly important for the material being attached. There are such product groups.

- Dowel without a shoulder - used when installing in dense material, where the possibility of twisting or misdirection is minimal.

- Option with a collar - if there is such a danger, the collar will fix the dowel on the surface of the base and will not allow it to rotate when screwing in the screw. This same device prevents the fasteners from falling into the hollow material.

- Disc-shaped dowel - for thermal insulation. The fastener has a very wide head - from 40 to 90 mm in diameter and is designed to hold soft and loose material: basalt wool, mineral wool, as well as hydro- and vapor barriers.

Fastening material

Of all the possible plastics, 3 are used for the production of fasteners - polyethylene, polypropylene and polyamide. This is due both to the quality of the material and its availability.

Polyethylene

Polyethylene is a thermoplastic polymer, lightweight, colorless, chemically inert - resistant to most acids, bases, oil and gasoline. It is a dielectric, that is, it does not conduct electricity, it is resistant to cold - it does not change its properties down to -40 C. It is less resistant to heating: already at 80–120 C it softens and deforms.

Polyethylene is an excellent shock absorber, so it is very resistant to impacts and mechanical damage. For a dowel, this means ease of deformation and preservation of properties in a new form - elasticity, ductility and impact resistance.

The disadvantage is flammability. Even self-extinguishing plastic will burn in the presence of a fire source and will in any case deform as the temperature rises.

Polypropylene

Polypropylene is a thermoplastic propene polymer. It has a lower density compared to polyethylene, but is harder and abrasion resistant. In addition, polypropylene can withstand heating up to +140 C, and only then begins to melt. The material is not subject to cracking, but is sensitive to ultraviolet radiation. The latter can be solved through additives.

Polypropylene is chemically inert and is only affected by very strong acids and appropriate organic solvents. It is resistant to water, so polypropylene dowels can be used for external fastening and for installation in damp rooms.

Only stabilized polypropylene is used for the manufacture of fasteners: these components prevent aging of the material.

Polyamide

Polyamide - or nylon. This is a group of crystalline thermoplastics characterized by high strength, toughness and rigidity. Its important characteristic is vibration resistance, which allows the use of nylon products in literally any construction work.

Polyamide dowels are most often used in outdoor work, since the products are little sensitive to weather factors, and among aggressive substances, only very strong oxidizing agents such as ozone or sulfuric acid act on nylon. However, installation must be done in relatively dry and warm weather: polyamide, due to its crystalline structure, absorbs moisture and changes volume.

Manufacturers consider polyamide to be the best solution, despite the high cost of the polymer and its hygroscopicity.

Read below about which GOST regulates the dimensions and other characteristics of plastic dowels.

Plastic dowel 6x40

How to remove a plastic dowel?

There are often cases when the nail for which the dowel was driven into the wall has long been removed, but the dowel itself remains in the wall. In this case, there are several ways to remove the dowel from the wall.

1. Perhaps the most common way to remove a dowel from a concrete wall is to find a self-tapping screw suitable for the size of the dowel, screw it into the dowel approximately 2/3 of its length, and then pull it out using pliers or any other suitable construction tool.

If you don’t have a self-tapping screw on hand, you can try to pull out the dowel using a simple hand corkscrew. In this case, the dowel is pulled out of the wall, like a cork from a bottle.

2. If the dowel does not unscrew in this way, try making several small holes around the dowel, at a minimum distance from it, and only then try to pull the dowel out of the wall. Please note that in this case you will end up with a much larger hole in diameter.

3. If you cannot remove the mounting dowel or nail from the concrete, you can, by analogy with the method described above, simply leave it in the wall. True, driving a plastic dowel deep into the wall will not be so easy. To simplify the process, use a construction knife to cut off the head of the dowel, and only then drive it deeper into the wall and putty on top.

4. If you have a drill in your house, you can try to drill out the dowel. Select a drill of the same or slightly larger diameter than the size of the dowel and simply drill it out from there. The dowel will come out of the hole as plastic shavings. The hole is then also filled with putty.

Return to content

By place of application

Universal. This type includes those hexagonal and round dowels in which the load-bearing capacity is the main one. The type of material is not important.

Specialized:

- Frame. Used only for fastening window profiles. Here the main role is played by the ratio of the spacer and non-spacer parts.

- Plasterboard. It uses a “butterfly” or “molly” type spacer - it opens only in complete emptiness.

- Dowel clamp. A particularly special dowel, due to its special screw, is used only for fastening cables and pipes.

- Metric. Used in conjunction with a bolt or stud.

What to do if there is a fragment of a nail or screw left in the dowel?

A nail or screw in a dowel sometimes breaks due to too much pressure. In this case, you will not be able to pull it out with pliers. But there is another effective way. You can take a soldering iron or a gas torch and heat the plastic dowel until it becomes soft and pliable. After this, you need to quickly pull out the dowel along with the fragment from the wall until the plastic hardens again. If you can’t pull it out the first time, the dowel can be heated again until the operation is successful.

Dismantling of dowels is required as often as their installation. Installation of cornices, fastening cable ducts, installation of plastic skirting boards - these and other tasks cannot be accomplished without the use of dowels.

Return to content

How to pull a chopstick out of the wall?

Nowadays, plastic dowels are widely used, which are considered stronger, more durable and reliable. However, some people still use wooden dowels instead of plastic dowels the old fashioned way.

The difference in dismantling plastic and wooden dowels is not so great. You can also try screwing a self-tapping screw into it and pulling it out with pliers, a nail puller, or another suitable tool at hand.

Wooden dowels

Another popular way to get rid of a wooden dowel is to break it apart and pull it out piece by piece. Using a chisel and hammer, divide the dowel along the grain into several parts, then pick out the fragments using a knife or screwdriver.

You can also try drilling out the cap using a drill. However, if the chopik was made of hard wood, this process will take quite a long time. Instead of a drill, you can use a hammer drill if you have one. However, do not overdo it, otherwise you will end up with holes in the wall that are much larger in diameter than you would like.

Return to content

How to remove a metal dowel?

Metal dowels are quite rare, because... their installation requires special equipment. Pulling out such a dowel is not an easy task, because you will not be able to destroy it with any tool. The only option is to try to carefully remove it from the wall.

If the dowel protrudes slightly from the wall, try loosening it in the hole with a hammer. As a rule, such dowels sit very firmly in the wall, and they cannot simply be pulled out of the wall.

If the dowel is almost flush with the surface of the wall, all that remains is to make several small holes at a minimum distance around the dowel, and then drag it using a nail puller or pliers. If you don't have a drill, this operation can be performed using a hammer and a punch.

If you don’t want to spoil the wall, but still need to remove the dowel from the concrete wall, then as an alternative you can consider the option presented in the video below.

Return to content

Types of dowels

In stores you can see various types of this popular fastener. Each is only suitable for the specific material of the parts it holds together.

According to the types of connections for dense materials, it is divided into:

- Spacer. It is the most common, classic dowel, regardless of the screw. Each manufacturer makes them differently - but these differences consist only in the shape and number of protrusions and spikes.

- Universal. It exhibits the qualities of the previous one in dense materials, but behaves differently in hollow materials.

- Facade dowel-screw. Despite the fact that it is slotted, it is better to use it in solid walls.

- Gvozdeva. It is not as common, unlike the previous ones, such a dowel-screw can be bought at the Construction Store.