A country estate occupies a special place in the life of a modern person. Here you can take a break from the daily hustle and bustle and constant stress. Most of us often ask the question: “How to build a bathhouse in the country?” Modern tools and materials help to cope with the task.

Our material provides detailed instructions for a turnkey bathhouse. All the nuances of the work process are taken into account here. Recommendations from experienced specialists will help you choose the right materials and components for the ideal construction.

The initial stage of any construction is:

- detailed design of the structure;

- choice of terrain;

- purchase of construction materials;

- construction of a bathhouse;

- interior decoration and communication connections.

How to choose the location of the bathhouse?

Before starting construction work, you need to decide on the location where the bathhouse will be located.

Experienced specialists recommend taking into account a number of criteria that play an important role in the construction of this facility:

- It is best to choose elevated areas. There will be no problems with drainage of wastewater;

- for aesthetic purposes, it is recommended to choose a place where there is a river or pond nearby;

- To save land, an extension is being made to the house. Proper hydro and vapor barrier will prevent the appearance of mold.

Preparation for construction: project drawings

Creating a drawing requires certain skills. If they are not there, then it is better to entrust this work to a specialist or use a ready-made drawing.

Before drawing up a diagram, it is important to decide on the following points:

- Location of the building on the site. It is important to consider sewer and water drainage. Quite often, the main factor when choosing a location is the laying of communications.

When choosing a place for a bathhouse, it is important to consider the location of communications - Soil at the construction site. If you plan to make a swimming pool in a bathhouse, then groundwater should not be located near the surface of the territory. The type of foundation to be built will also depend on the type of soil.

- Bathhouse construction plan and number of floors. If you plan to make a two-story building, it is important to take into account the additional load on the frame structure and foundation. At this stage, you should think in advance about the placement of the stove and what material it will be made of. This will allow you to understand where and which chimney to install, as well as the ventilation passages in the room.

- Laying communications. It is important to take care of ventilation, electrical wiring, vapor barrier and thermal insulation. It is worth considering the features of water drainage.

- An important element of any building is the roof. The service life of the structure will depend on it. You should take into account the material of manufacture, as well as its shape. This will allow you to calculate the power of the floors.

You need to include all the information received in the drawing, as well as supplement the project with the necessary details. The more detailed the diagram, the easier it is to build a bathhouse.

The more detailed the project, the easier it is to make a frame bathhouse yourself

It is recommended to draw up a separate plan for communications. If you have little experience, you should not create a complex project. You can use a ready-made diagram, slightly supplementing it based on your own needs.

A standard bath includes a corridor, a dressing room, a washing room and a steam room.

A standard frame bath consists of a dressing room, steam room, shower and rest room

Quite often a separate room for recreation is provided. It is recommended to mark the installation location of the stove on the diagram. If this is a steam room, then it is best to place the stove in the corner closest to the door. The stove can be stone or brick.

It is recommended to determine in advance the dimensions of each room and indicate them in the drawing. The standard dimensions of the steam room are 200x240 cm. The optimal ceiling height is 220 cm. This design can accommodate 2-3 people at the same time.

In the drawing you can see a bathhouse for a suburban area with a balcony measuring 1.5x4 m. The overall dimensions of the building are 4x6 m. The project is suitable for organizing gatherings in an open area in the summer.

A frame bath can be equipped with a terrace for gatherings in the warm season

This bathhouse consists of 3 rooms:

- steam room;

- washing and shower;

- rest room.

The corridor is shown separately in the diagram. There is no room for a locker room. There is a small changing area in the washing room. The terrace connects to the living room.

The optimal wall thickness of a frame structure is 100 mm or more. The wood that is used in the process of making a bath must be treated with an antiseptic. It is recommended to use dried, calibrated lumber.

It is mandatory to perform a vapor barrier of the insulating material on the internal base. In the steam room you need to use foil vapor barrier. The reflective layer can increase the temperature inside the steam room.

Walls and ceilings in the stove area should be made using non-flammable materials. For example, the frame is made of a rack-mount metal profile, which is coated with zinc. Cuttings can be made from asbestos cord. In these places, a basalt slab can be used as an insulation material.

Supply and exhaust ventilation is required in all rooms. Floors in the sink should be made with a slight slope or along a screed. The top and bottom floors need to be insulated in the same way as the walls.

The minimum size of a frame bath is 3x4 m.

The minimum size of a bathhouse for a comfortable stay of several people is 3x4 m

The budget version of the frame is made in this way: the racks are sheathed on the inside and outside with boards up to 25 mm, basalt insulation or ecowool is laid inside the frame structure.

If you plan to use ecowool inside the walls, it should be carefully compacted and horizontal platforms for unloading should be installed. The frame must be sheathed inside and outside. To do this you will need to make a sheathing. On the outside, the insulation material is covered with a membrane to protect it from the wind. In the horizontal plane, the use of ecowool is a more economical option compared to basalt insulation.

The outside of the frame structure can be covered with any facing material. The inside of the building is covered with clapboard, plasterboard sheets with tiles or imitation timber.

Wooden building

Such buildings are made from natural solid wood. The surface of the walls and ceiling is treated with a special fire-resistant compound. It protects against fire and has a protective effect against insect attacks.

How to build a bathhouse from timber? For this purpose, dense wood species are used. They retain heat well and have a beautiful appearance. To build a small building you will need more than 150 beams of different lengths.

Tips for choosing material

The frame should be assembled from the following parts:

- bars;

- slats for creating sheathing;

- boards for the floor base.

Instead of plank flooring, the floor base can be covered with tiles. You need to choose based on personal preferences, however, in the case of a steam room, it is recommended to give preference to wood. There will also be materials for protection. Quite often, lining is used for wall cladding.

It is recommended to cover a frame bath with wooden clapboard

To cover the structure from the outside, you can use larch lining. The inside of the building is clad with clapboard made of coniferous trees. Sheathing boards must be mounted vertically.

Excess moisture and elevated temperatures will negatively affect structural elements, so it will not be possible to do without the use of special protective materials. You can use glassine, polyethylene or roofing felt. A vapor barrier should be placed between the insulation and the sheathing. The disadvantage of roofing felt is that during the heating process it will emit an unpleasant odor. Therefore, it is not recommended to use it.

You need to pay attention to the selection of material for thermal insulation. If you choose wisely and install the insulation correctly, it will be possible to significantly reduce heat losses, as well as the cost of heating a bathhouse building.

Mineral wool is used as insulation in most cases.

A good insulation material for a frame bath is mineral wool.

A good option is to use fiberglass. In some cases, the ceiling is insulated with expanded polystyrene, and the floor base with expanded clay.

Arbottle structure

This type of material has good heat and waterproofing. For construction, blocks or monolithic slabs are used.

The finished product is neat and durable. This bathhouse is ideal for a small summer cottage.

Tips for finishing and insulation

The outside of the bathhouse is covered with siding, boards, plaster or ceramic tiles. Waterproofing material should be laid under the sheathing. The resulting gaps can be filled with thermal insulation material. You need to leave a small gap between the clapboard and the foil for ventilation. For this purpose, strips several cm thick should be nailed to the vertical supporting parts. The distance between the elements must be selected taking into account the distance between the supports.

In the diagram you can see the design of the wall cladding

To give rigidity to the walls, they need to be covered with plaster shingles. After the cladding work is completed, the outside of the structure must be plastered.

Guidelines for internal cladding of frame buildings:

- The inside of the building should not be painted, as paints and varnishes will release harmful chemicals when heated.

- To make a rough ceiling, you should use OSB boards. They must be secured to the bottom of the floor beams.

- The walls in the steam room should be covered with foil. The remaining walls can be covered with glassine.

- The minimum ceiling height is 2.2 m. In this case, it will be possible to install lining and additionally insulate the ceiling.

- It is important to pay attention to the joints between the walls and the ceiling structure. The vapor barrier material must protrude at least 15 cm.

The slats can be nailed in using different methods - during the fitting process, a selection is made into a groove or a quarter. The slats must be attached to the joists with the front part.

There is no need to make holes between the foil and the corrugated sheet; the sheets are nailed to the foil. Fixation is done using self-tapping screws with rubber gaskets.

After this, the furnace and boiler are installed. It is important to remember fire safety rules. The wall that will be used for the soaring room and resting place must be made of brick. It is recommended to place the heating boiler in the dressing room. The best option is a brick stove, but if you have no experience in laying a similar structure, it is recommended to entrust this work to a qualified stove-maker.

When working with foil, you need to be careful, as the material is easily damaged. Any gaps will significantly reduce the effectiveness of thermal insulation. The vapor barrier should be fixed with a stapler, and it is important to ensure that there is no sagging of the material. The minimum distance between the wooden paneling and the insulating material is 1 cm.

In the bathhouse, it is best to attach the foil using an ordinary stapler

Frame structures are convenient in terms of finishing. Work can be done both inside and outside. If there is a forced break, you can make partition frames at this time, upholstering them with blockhouse or clapboard. In this case, the time will be spent usefully.

For most regions, the optimal thickness of the walls of a frame building is 10 cm. Insulation can be done either with mineral wool or with expanded polystyrene. A layer of mineral wool 12 cm thick can replace a wall made of bars 50 cm thick.

You can insulate a bathhouse from the inside using mineral wool

For northern regions with cold climates, there are 2 methods of insulating a bath:

- Making a frame from slats 15 cm thick. The insulating material must be of identical thickness.

- Sheathing the walls on the outside with OSB sheets or plywood, followed by installation of expanded polystyrene boards 5–10 cm thick.

For northern regions, it is recommended to cover the outside of the frame with OSB boards

If you plan to use expanded polystyrene, then after installing the sheets you need to make a thin screed using a mesh of reinforcement. Finally, a topcoat should be applied.

It is not recommended to use traditional insulation materials made from sawdust and straw.

It is not recommended to use sawdust and clay to insulate the ceiling

During the cooking process, they will be mixed in water with clay, and therefore the insulation will have a lot of weight. In addition, a large amount of liquid often causes wet ceiling parts made of wood. This has a negative impact on the performance characteristics of the bathhouse building.

Frame walls are an excellent bait for rodents who love polystyrene foam. In 2–3 years, solid sheets can turn into dust. Therefore, it is not recommended to use polystyrene foam for insulating rooms inside a frame structure.

Particular attention should be paid to the quality of vapor and waterproofing. Such a bathhouse does not have free supports; each of them will carry the load and hold other parts of the building. If the strength is compromised due to prolonged exposure to moisture with one rack, the sauna may become unstable. In this case, complex repair work will be necessary. It is best to prevent such a situation at the stage of insulating the rooms.

To insulate the insulation, it is best to use aluminum film.

It is best to insulate the insulation with aluminum film

However, the material is not cheap. If you want to save money, you can use plastic film. The material is cheaper, but in terms of steam and water protection parameters it is practically not inferior to foil. It should be remembered that polyethylene can be damaged when exposed to sunlight. For this reason, it is important to cover the frames. This will reliably protect the film from exposure to ultraviolet radiation.

Roof

There are three types of roof for a bathhouse:

- Single-pitch.

- Gable.

- Complex - consisting of four or more slopes.

Usually the first two options are used for a bath. Let's look at the option of a gable roof covered with metal tiles:

The manufacture of the roof begins with the installation of the Mauerlat. In the case of frame walls, the role of the Mauerlat is performed by the upper outline.

- Place the uprights on the bench.

- Connect the posts using purlins and ties.

- Install the rafter legs by attaching them to the mauerlat, purlin and connecting the upper ends together. The distance between the rafters should be 50-60 centimeters.

- Install sheets of metal tiles.

- Cover the gables with wooden slats or sheet metal.

For a more visual understanding of the roof fastening, here is a drawing:

All dimensions of roof elements are given in the list:

Please note that the less you slope the roof, the more snow load it will bear in winter. Also, a small roof slope can lead to poor water drainage and leaks.

Construction

The technology for building a bathhouse in a country house with your own hands is practically the same, regardless of what materials were used. First, the foundation is laid and the walls are erected. When the walls are ready, the rafter system is assembled and the roofing material is fixed. Next, windows and doors are installed, and finishing work begins.

Construction of a country bathhouse (Source: stroidomsait.ru)

Foundation

To build a bathhouse, several types of foundations are used. Depending on the weight of the walls and soil characteristics, the following types of foundations are made:

- Slab foundation.

- Columnar foundation for light walls.

- Pile foundation.

- Concrete strip foundation.

As practice has shown, the most reliable foundation for almost all types of soil is a concrete strip foundation reinforced with reinforcement.

To make a reinforced strip foundation for a bathhouse you will need:

- Cement.

- Sand.

- Gravel.

- Fittings.

- Formwork.

- Ruberoid.

- Wire.

- Shovels.

- Concrete mixer.

- Tourniquet.

- Stakes.

- Tools (pliers, hammer, tape measure and others).

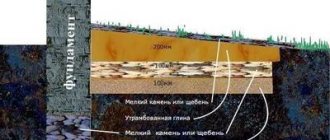

In the location chosen for building the bathhouse, mark a trench for the future foundation. To mark, use a tourniquet stretched between the pegs. The width of the trenches is based on the weight of the wall material. For a one-story bathhouse made of wood or brick, it is enough to make a trench 30-40 centimeters wide. After installing the markup, do the following:

- Using the markings as a guide, dig a trench 50-80 centimeters deep.

- Compact the bottom of the trench and fill it with water to shrink the soil.

- Cover the bottom of the trenches with roofing felt for waterproofing.

- Fill the trench with gravel to a third of its depth.

- Install formwork along the edges of the trench.

- Make a frame reinforcing the foundation from reinforcement bars tied together with wire.

- Install the reinforcement cage into the formwork.

- Using a concrete mixer, make a cement mortar in the proportion: one part cement to one part sand and two parts gravel.

- Pour cement into the formwork, being careful not to allow any air voids.

- After the concrete has dried, remove the formwork.

The foundation for the bathhouse is ready!

What is included in the timber bath project

It is impossible to do without reporting documentation during the construction of a bathhouse. This building requires the presence of the following forms and acts:

- sketches and drawings of the future building;

- expected work schedule and deadlines;

- calculation of estimate documentation;

- special permission from the authorities if the structure is permanent.

If all documentation is provided for the project, then a guarantee is always provided for the finished structure. Having received official registration and all the necessary papers for construction, the developers carry out construction in accordance with the previously announced deadlines. If these indicators are violated, the customer may demand a certain amount of the cost of the work as damages.

Wooden baths can be installed on stone blocks PHOTO: bindom.ru