The foundation on bored piles has a high load-bearing capacity and can be used on difficult soils where it is not possible to install a strip foundation. The professional specialists of our company will install a bored foundation with a turnkey grillage within a clearly defined time frame. We strictly control every stage of the technological process and guarantee quality.

Quick cost calculation

Guarantee

We provide assistance in the selection of materials and delivery to the site

Site visit is free!

Due to its ability to withstand significant loads, a bored foundation is popular when constructing houses made of brick, blocks and other heavy materials.

Areas of use

A foundation of bored piles with a grillage is installed in the following cases:

- in urban construction conditions, when other methods of driving pile supports can create dynamic impacts on buildings located in the immediate vicinity of the construction site;

- in wetlands or other types of weak soils, where incompressible layers are located at great depths;

- if the facility is being built on a steep terrain area;

- during the construction of heavy industrial structures;

- in cases where it is not economically profitable to build a monolithic foundation for buildings made of wood material or light frame-type houses.

Advantages and disadvantages

To begin with, we propose to consider all the pros and cons of such a foundation used for the construction of buildings made of stone, wood, brick material, aerated concrete blocks, etc. The pile foundation will ensure the strength of the entire structure and prevent unwanted deformation processes.

The construction of such a foundation is permitted on any soil and is completed within one day.

The foundation on bored piles with a monolithic grillage makes it possible...

- carry out construction work in complex geological areas;

- carry out construction near other objects without causing damage to them;

- minimize construction costs;

- tired

- pour compact reinforced concrete elements next to utility lines.

The foundation is characterized by high load-bearing capabilities and simplicity of construction; delivery of large parts is not required; there is no need to rent special equipment for work.

As a negative point, experienced builders note the fact that it is impossible to perform accurate calculations to find out at what level the required incompressible soil layer is located that can withstand pile pressure. To avoid mistakes, the well is drilled to a depth of one and a half to two meters in order to reach the freezing point of the soil, which has a compacted structure in such places.

More about the technique

Before starting work on the construction of the foundation, calculations should be made and markings should be carried out. At the same time, the future boundaries of the house and the location of the main nodes are determined. The distance between the piles will depend on the type of building. This parameter can vary from 1.5 to 2.5 m.

To build a house on bored piles with a grillage, you should prepare:

- Boer;

- formwork for piles;

- sand;

- cement;

- concrete mixer;

- ribbed metal rods for reinforcement.

Formwork is inserted into the drilled holes. Today, cardboard tubes are available for sale for this purpose. Before installation, metal formwork is protected from rust using reinforced tape or bitumen. If the work is carried out on loose soil, then before installing the formwork it is necessary to form a cushion of sand and gravel, the thickness of which will be 15 cm.

Calculation of a bored foundation with a grillage

During the development of the design assignment, calculations are performed to determine the exact number of support piles and their placement. Piles are placed in rows in accordance with the markings of the object, on its corner sections, at the points of intersection of walls and between these places.

The distance between the supports is determined by the total mass of the object being built: the heavier it is, the more pillars will be required, and the installation distance will be shorter.

The minimum permitted distances should be taken into account - at least three pile diameters. The reason is that the load-bearing capacity of supports that are placed too often is reduced.

When installing piles on your own, it is recommended to check the level of the heads, which should rise above the surface at the same height.

Let's consider how to calculate the bearing capacity of a bored foundation with a grillage.

To determine the required number of support elements, you will need two initial indicators - the mass of the object and the load-bearing capabilities of the individual element. Determining the strength of one pile depends on the brand of concrete mixture used. If M100 is used, the support will withstand up to one hundred kilograms per square centimeter. A pile cross section of 200 by 200 mm creates a support area of 400 cm2. This means that the support pillar will withstand a load of forty tons.

Consequently, the bearing capacity of the soil is significantly lower than that of piles. It turns out that determining the need for piles and their load-bearing characteristics will be unreliable if the strength of the soil composition is not taken into account.

The grillage unites the entire structure and increases the stability of the base. If a bored foundation is installed without a grillage, calculations should be made to ensure that all supports are installed to the required depth, ensuring that the structure will not sag or be “squeezed out” by frost heaving.

Foundation on bored piles

Take the survey and get a special offer!

Take the survey

Bored piles: technology and price

A reliable foundation in 3 days!

Call us and we will help you choose a pile foundation project for your home!

Stroitelnaya suggests paying attention to bored piles, the installation technology of which has proven itself to be one of the most reliable in Nizhny Novgorod and the region.

A bored foundation has a lot of advantages:

- excellent load-bearing capacity;

- versatility;

- Possibility of use on difficult and problematic soils.

One of the pleasant additions to all the advantages of this type of foundation is that the price for bored piles is much more affordable than other products. Without any fear, they can be used in the construction of structures in Nizhny Novgorod and the Nizhny Novgorod region.

The installation of bored piles is the most suitable option in terms of price/quality ratio.

Features of this type of foundation

TISE piles are characterized by increased load-bearing capacity. Thanks to the expansion at the base, they can carry high loads and are not affected by weather conditions, which ensures unsurpassed reliability of the foundation of the house under construction.

The peculiarity of constructing a foundation on bored piles is that the wells for the future foundation of the structure must lie deeper than the soil layer that freezes at low winter temperatures. These conditions will protect the future foundation of a house or bathhouse on bored piles from damage during soil heaving or shifting due to quicksand.

Installation technology and areas of use of bored piles

The bored foundation is universal and unpretentious to soil types, and is also affordable, so it can be used for any suburban construction project. So, it will take very little time and money to build a house on bored piles.

This base design is ideal for buildings on slopes and in areas with heaving soils. Even in Nizhny Novgorod and the region, a rather inconvenient and costly environment for construction, a bored foundation continues to be one of the most affordable.

The technology for constructing bored piles was developed at the very beginning of the twentieth century. It was very successfully used in construction activities for the construction of military facilities. True, its distribution for many years was limited precisely to the military framework.

Today, bored piles are available to everyone. Considering that the main material used for the manufacture of load-bearing supports is concrete, concrete piles must be equipped with a metal frame. The role of formwork is performed by the casing pipe. During the process of hardening of the concrete mixture, such formwork will retain the required shape of the TISE pile. This is especially true if the foundation is laid on problematic and heaving soils.

Thanks to this, many individual developers choose bored piles as the basis for the foundation, the construction technology of which involves their creation directly on the future construction site.

Construction of a bored foundation

The foundation is laid in an accessible way, even for buildings with difficult access to them. There is no need to use large special equipment when arranging a bored foundation.

Stages of work:

- First, construction specialists mark the location of future wells;

- The amount of foundation for installing concrete bored piles is based on the structure of the soil. But there should be no depths less than 1.5 meters. For Nizhny Novgorod and the region, a depth of about 1.6 m is acceptable, because The level of soil freezing in our region is about 1.4 m.

- To increase the strength parameters of a bored pile foundation made of concrete, the bottom of the excavation is filled with it, maintaining a diameter of 30 cm.

- Next, work is carried out on the installation of the frame and asbestos-cement formwork.

- Then the pipes are aligned to the height required by the customer and filled with concrete.

One of the advantages of this type of foundation device is that further construction of a house or bathhouse can begin in just a few days.

The price for bored piles depends on their length and additional services. Standard specimens have a cross-sectional size of 15 cm, and the cross-sectional size of the base is 30 cm. The price indicated on the website includes on-site services for test drilling, materials and the work of professional builders.

The technology of bored piles is such that it is possible to build a strong foundation for a house in two days. Construction specialists will be happy to answer all your questions and carry out installation in Nizhny Novgorod and the region at reasonable prices.

Do you have any questions?

Request a call back or call us at +7

Choosing a location for installing piles

Before installing a foundation with bored piles and a grillage, geological research should be carried out and a project drawn up. A full-fledged geological exploration can be ordered, but it will cost a decent amount. In private construction, you can determine the condition of the soil yourself - dig a hole or drill a well. The soil composition is developed to a depth of half a meter lower than where the piles are supposed to be poured. By specifying the type of soil and its characteristics, you can determine the distance between the piles and the reinforcement of the structure.

In the process of studying the soil composition, it is necessary to clarify:

- soil type;

- depth of groundwater;

- moisture saturation of the earth.

The type of waterproofing layer depends on these data.

Installation stages

Let's figure out how to build a bored foundation with a grillage with your own hands.

Preparation

All calculations have been completed and the project has been drawn up. Once all the parameters are determined, you can proceed to work. First of all, a layer of fertile soil should be removed at the construction site.

Construction begins with the location of the support piles being taken to the site - markings are made. So that it does not interfere with excavation work, cast-off boards are prepared. Elements are placed around the perimeter of the object at certain distances so as not to interfere with drilling. Nails are driven into the boards and a cord is pulled to indicate the axes of the object. During the installation of wear, it is necessary to control the parallelism and perpendicularity of the axes.

Drilling

We continue to consider the technology of constructing a bored foundation. It is necessary to drill wells to the depth established by the design specifications, here the question arises: what is used to drill the soil under the grillage foundation? For this work, a hand drill is used, which during the digging process does not bring soil to the surface, but compacts it along the walls of the well.

When drilling a well, you should control the location of the drill - it should enter the ground at a right angle, without deviation.

The diameter of the well is set to be five to seven centimeters larger than the same parameter of the piles, the bottom is carefully compacted, and a cushion of sand and gravel is arranged with a height of ten to thirty centimeters.

Installation of casing pipes

With their help, an obstacle is created for the soil, which can fall from the walls of the well, and the safety of the work is ensured. According to the technology of constructing a pile-rammed foundation with a grillage, such pipes are not allowed to be installed in compacted clay areas and loamy soils, but if you work on your own, then such elements will not be superfluous. The frame base for reinforcement is easier to install in pipes, making the process of concreting and compacting the concrete mass easier. Casing pipes can be made of plastic or metal material; asbestos-cement sections of suitable diameter are used for the same purpose. If you have enough money, it is recommended to purchase real casing pipes with prepared joints and convenient connections. The pipes are installed in the wells strictly vertically, the gaps between them and the walls of the wells are filled with sand and compacted.

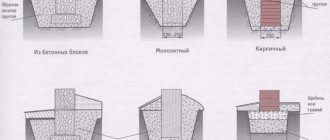

What it is? Design features

Bored foundation

Structurally, a bored foundation is a set of piles made by drilling wells with their reinforcement and subsequent pouring of concrete mixture (how to properly pour a foundation for a house).

The diameter of the wells is determined by calculation. Experience shows that this parameter varies in the range of 150-400 mm. Depending on the purpose of the building and its type, the prepared piles are tied together with a grillage or walls are erected directly on them.

Diagram of a bored foundation:

Design advantages:

- increased resistance to vibration;

- possibility of construction under unfavorable geological conditions;

- ease of installation;

- lack of large volumes of earthworks;

- relatively low cost.

It is possible to make a bored foundation with a monolithic grillage without the involvement of specialists and professional equipment.

- danger of uneven settlement of supports;

- impossibility of constructing a ground floor and basement.

Calculation of a bored foundation with a grillage

When making calculations, it is necessary to be guided by data on the characteristics of soils and materials specified in SNiP 2.03.01-84, 11-23-81, 11-25-80, 2.05.03-84 and 2.06.06-85. A total of three settlement operations are carried out:

Calculation of bored piles

During the calculation, the length of the piles (depth), their cross-section, number and arrangement are determined. The diameter of a bored pile for the construction of a cottage ranges from 15 to 40 cm. Most often, this parameter is taken equal to 20 cm. In order not to carry out complex calculations using cumbersome formulas, we suggest using a ready-made table that indicates the bearing capacity of supports of various diameters, as well as the approximate consumption concrete and reinforcement:

Knowing the load-bearing capacity of one support, you can use a simple formula to calculate the distance between the elements:

l is the distance between piles;

P - bearing capacity of 1 pile;

Q - load per 1 running meter of the foundation (weight of the house divided by the length of the grillage).

Calculation example: For a house weighing 50 tons, built on clay soils on piles with a diameter of 20 cm, 27 supports will be required (50,000 kg/1884 kg = 26.53...).

The pitch of bored piles in a strip grillage is easier to calculate based on the rule: the distance between the supports should be no more than three of their diameters. For piles with a diameter of 20 cm, the step will be 0.6 m. For dense soils, this figure can be increased by 25%, which means that the distance between the piles in our case will be 0.8 m.

If desired, you can more accurately calculate the pitch of bored piles using the formula: l = P/Q, where l is the distance between the piles; P - bearing capacity of 1 pile; Q is the load per 1 linear meter of the foundation (weight of the house/length of the grillage).

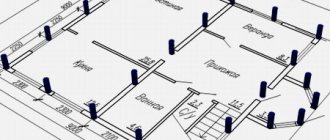

The layout of bored piles is drawn up taking into account SNiP, the supports are located:

- in the corners of the house;

- along load-bearing walls with a selected step;

- under the entrance group.

Additionally, bored piles must be installed under heavy elements, such as a fireplace, stove, boiler room. The depth of the piles depends on the depth at which load-bearing soils will be found if the foundation is being built on weak soils or on the level of soil freezing in the region. As a rule, the drilling depth for supports is 1.5-3 m.

Calculation of a monolithic grillage

The calculation of the grillage consists of determining its width and height. To calculate the width you can use the formula:

B is the width of the grillage tape;

L is the length of the grillage;

R is the bearing capacity of the top layer of soil.

This formula is applicable both for a grillage of zero height and a shallow one. The hanging grillage is calculated using a fundamentally different technology, which is extremely complex. If you are planning to build a house with a hanging grillage, then the calculation must be ordered from the design organization.

Reinforcement calculation

Bored piles must be reinforced. The diameter of the reinforcement depends on the mass of the structure. The best option for a private home is 12 mm ribbed reinforcement. The dependence of the reinforcement size on the diameter of the piles can be seen in Table 1. The reinforcement is connected only with special metal wire; welding cannot be used for the foundation!

Load Definition

When calculating the number of piles, you must take into account the load-bearing capacity of each support, as well as the strength of the underlying soil layer. When calculating a foundation on bored piles with a grillage, you must determine the permissible load of the support, which will be subject to compressive longitudinal load. This parameter is calculated by the formula: P = k * R * F + U * N * Fn * L. Here, the soil homogeneity indicator is k. The resistance of the soil to the support pressure is R, while the size of the bottom of the pile is F.

The perimeter of the bottom of the pile is U. The standard soil pressure on the side supports is Fn, but the coefficient that determines the working factors is N. The layer of soil that will press on the side surface of the piles is L. When determining the distance between the supports, it should be taken into account that the maximum step is 2 m. Between the supports there should not be less than three double diameters of the supports.

Installation of a bored foundation with a grillage

The implementation technology is described in SNiP 2.02.03-85 (formerly SNiP II-17-77). According to the documents, bored piles according to installation technology are:

- solid section - are universal, suitable for any soil;

- hollow section with a multi-section core - a complex option not used in private construction;

- with a compacted face - used for houses weighing more than 500 tons;

- fifthly, the technology includes blasting.

As can be seen from the classification, the only possible option for building a cottage is to build a foundation on solid-section bored piles, which have a simple design and L-shape.

To install a foundation with your own hands, you will need the following materials and tools:

- hand drill;

- casing;

- corrugated fittings 12 mm;

- concrete mixture;

- wire for tying reinforcement with a cross-section of 1.2-1.4 mm;

- waterproofing;

- insulation for grillage;

- boards for formwork.

In addition, you will need a standard set of tools: a tape measure, a laser or regular construction level, vibrating equipment for compacting concrete, etc. Concrete for filling wells can be mixed yourself or ordered from a concrete plant.

Construction of bored piles: work order

Bored piles

In favorable areas during the construction of small buildings - country houses, outbuildings, etc., you can build bored piles manually: the technology for installing supports in this case is not replete with particularly complex operations, so, having a set of manual drilling and a couple of strong assistants, you can take on work.

The manual drilling method has a number of significant disadvantages:

- This is a very labor-intensive process, so while you save money, you will lose in ore and time costs;

- Manually drilling wells in hard soils is very difficult;

- Experts recommend drilling down to clay (which foundation is better on clay soil). If it lies deep, you may not be able to reach it with a hand drill.

The use of a gasoline drill makes the task somewhat easier. With its help you can drill several wells in a day.

But the best solution would still be to use special equipment that allows you to complete the full scope of drilling work within one day.

However, in this case, the high speed of completing further work is extremely important: if it suddenly waits, all the previous work will go down the drain - the walls of the finished wells will collapse, and you will have to start all over again. Repeated rental of equipment will negatively affect the final cost of the foundation.

Stages of work

So, you have decided to build a bored foundation with your own hands.

Step-by-step instructions for performing the relevant work will look like this:

- First of all, the pile field is marked (how to mark the foundation for a house with your own hands).

- After all the axes of the foundation have been removed to the area, you can begin drilling wells. The diameter of the drill is selected according to the corresponding size of the casing pipe, taking into account an allowance of 10 cm per size. That is, if you plan to use a two-hundred-millimeter pipe, you need to drill a hole for it with a 300-mm drill.

Drilling of the wells

- into the prepared well and checked for verticality. After the product has taken the desired position, it must be fixed - with stops made of boards or pads inserted between the walls of the pipe and the well.

- are installed in the pipe . The rods should not come into contact with the walls of the pipe - the distance between them should be at least 50 mm.

- The pipe is filled with concrete. Its consistency should be more liquid than, for example, when pouring a strip foundation (about what brand of concrete is needed for a strip foundation). But the amount of cement in the mixture should be greater—about twice as much.

- Due to the small diameter of the pipe, the likelihood of an air lock being formed is high. Therefore, during the pouring process it is necessary to periodically compact the mixture. This is best done with a construction vibrator. If it is not there, you will have to use a regular “pusher”.

- Upon completion of filling the casing with concrete mixture, a control check of its verticality is carried out, and then backfilling is carried out. Fill the gap between the pipe and the well wall layer by layer. The soil must be thoroughly compacted every 20 cm.

Grillage arrangement

A reinforced concrete strip grillage is made for the foundation of a private house. Lightweight structures, such as bathhouses and log country houses, allow the use of a wooden grillage. The simplest and least labor-intensive option is a low grillage, which rises 0.2-0.3 m above ground level. A high grillage up to 0.5-0.6 m can be used on wet soils to maximize the house’s elevation from the surface.

Stages of construction of a monolithic grillage:

Construction of the base and formwork

For low grillages, a gravel-sand cushion of 10-20 cm is used, on top of which a footing is laid - a 5 cm layer of lean concrete and waterproofing. Roofing material or waterproofing material is used as a waterproofing layer. The formwork is assembled from boards along the entire length of the grillage.

Reinforcement

The technology of tape grillage reinforcement involves the longitudinal laying of reinforcement bars, which are connected both to each other and to the reinforcement of bored piles. Proper reinforcement ensures a rigid connection between the bored support and the grillage. In stretched areas, 4 reinforcement bars of 20 mm are laid, in corners - 12-15 mm. To fasten the reinforcement into a single frame, vertical rods of 5-8 mm are used, the distance between them is 25-30 cm. The connection between the reinforcement frame and the grillage will look like this:

Pouring concrete

Concrete of class B12.5...B15 is poured into the formwork and compacted using vibration equipment. At an air temperature of +25 C, concrete must be periodically moistened. To ensure gradual hardening, the grillage must be covered with polyethylene. The final pile-grillage foundation on piles will be ready in 20-25 days.

Insulation of a bored foundation with a grillage

To create a favorable microclimate in the house, it is recommended to insulate the foundation. Piles buried in the ground do not need to be insulated; thermal insulation is necessary for that part of the grillage that is located above the zero level. Insulation and waterproofing of the base with a recessed grillage is carried out in the horizontal and vertical plane.

Thermal insulation is performed with foam boards or other foam insulation. It is impossible to use thermal insulators based on mineral wool, because... they intensively absorb moisture from the soil and quickly become unusable. The algorithm for creating hydro- and thermal insulation of a grillage is simple:

- Waterproofing is carried out: a layer of bitumen or rolled roofing felt. The top and sides of the grillage are waterproofed.

- The insulation boards are glued with glue and secured with dowel nails.

- Sealing of joints and corners is done using polyurethane foam or liquid polyurethane foam.

- The side walls of the grillage are finished with plaster or other decorative material.

Simultaneously with thermal insulation, a blind area is made, which also helps to conserve heat and remove moisture from the foundation.

A properly executed pile-grillage foundation on bored piles will last at least 100 years. The design does not require maintenance and is affordable.

A bored foundation with a grillage is a special design for the base of a building, which involves the presence of separately located supports connected by a single frame. The piles are laid to the required depth, which depends on the design features of the buildings and the geological conditions of the site.

Thanks to drilling wells to great depths, it is possible to significantly increase the area of contact between the supports of the structure and the soil, increase friction, making the foundation capable of withstanding considerable loads.

Typically, a foundation on bored piles with a monolithic grillage is installed below the soil freezing level and wrapped in two layers of roofing material to protect the structure from soil heaving, excessive pressure, and moisture.

When arranging pile foundations, a concrete grillage plays a very important role - it unites individual supports and eliminates the risk of uneven settlement. Thanks to the grillage reinforcement, it is possible to increase the structure’s resistance to bending loads and create a single, reliable monolith.

Overview of the characteristics of bored piles with grillage

A foundation made of bored piles with a grillage is one of the most popular at present, as it can withstand buildings on almost any soil. In addition, it has good load-bearing capacity and is affordable. At least piles have a lower cost compared to strip foundations. You can read the instructions on how to make a foundation with a plinth here.

The photo shows bored piles with a grillage

Specifications

A foundation made of bored piles with a grillage has a number of advantages compared to other types of foundations:

- installation of piles is carried out below the freezing level of the soil;

- a pile foundation is perfect for terrain where there are slopes, as well as for any type of soil;

- when installing this foundation, there is no harm to the landscape surrounding the area;

- there is no impact on nearby buildings and structures in the area located next to the construction of this foundation;

- on such a foundation it is possible to erect a building even next to a reservoir, which is impossible with other types of foundations;

- a foundation made of bored piles with a grillage can support any building, be it a frame house, log or brick;

- the cost of installing such a foundation is significantly lower than that of a strip foundation or a foundation with a monolithic grillage;

- The construction of a pile foundation is carried out quite quickly, in comparison with other foundations, it can be laid in a maximum of a week.

When installing a foundation on bored piles, the following technical characteristics should be taken into account:

- The minimum distance between bored piles in a grillage should be at least 100 centimeters. If the distance is reduced, then deformation of the piles is possible in the future. An exception to this rule is the installation of a pile foundation in rocky soil. In this case, the minimum distance should not be less than 30 centimeters. Read the guide to calculating and designing a pile foundation on this page.

- The pitch of bored piles in a strip grillage can be calculated by knowing what the load on the foundation will be.

For this calculation, information on the load-bearing capacity of piles of different sizes should be used. For example, if you plan to build a house weighing 50 tons, in this case, you will need 50 piles with a diameter of 15 centimeters, or 17 piles with a diameter of 25 centimeters. The permissible minimum step between piles in a strip foundation is two meters. A guide to constructing pile foundations is here: https://fundamentgid.ru/vidy-fundamenta/svajnyj/rukovodstvo-po-ustrojstvu-svajnyx-fundamentov.html.

- When installing a foundation of bored piles with a monolithic grillage, it will be sufficient to use a pile with a diameter of 300 mm, since the bearing capacity of one such pile is 1600-1700 kg. An average building will require about 70 of these piles.

Kinds

The main types of foundations on bored piles with a grillage are:

- the foundation is on bored piles with a hanging grillage, that is, there is a small distance between the soil and the grillage, approximately 80 - 100 millimeters. It seems that the building seems to be hanging above the ground. This is where the name came from. Such a design is necessary to protect the foundation of the house from swelling of the soil, as well as in areas at risk of flooding and in swampy areas;

- a foundation on bored piles with a monolithic grillage is most often installed as the basis for houses made of brick, aerated concrete or thermal blocks. A monolithic grillage is a concrete strip that creates a single structure by combining piles. The piles of such a foundation are installed at a depth below the soil freezing level. Read an overview of the characteristics of pile foundations.

The diagram shows a recessed grillage on piles

Calculation and device

Calculation of the foundation on bored piles with a grillage is necessary to create a reliable foundation for future construction. One of the main characteristics of such a foundation is the load-bearing capacity of the piles; it must be calculated first. The bearing capacity is directly proportional to the size of the pile; the larger its size, the higher the bearing capacity. If a pole with a diameter of 30 centimeters can withstand a load of up to 1,700 kg, then a pole with a diameter of 50 centimeters can already withstand a load of 5,000 kg. Here you can see that the size has not increased by much, but the load-bearing capacity has increased several times. Based on this, it follows that the strength and reliability of the foundation of the house will depend on the correct calculation of this value. Also, the number of required piles and materials for their manufacture depends on the load-bearing capacity. Together with the number of piles, the optimal distance between the installation of pillars is calculated. The load-bearing capacity of piles is affected not only by the size of the pillar, but also by the material from which it is made, or rather its quality. Besides. It is also necessary to take into account the bearing capacity of the underlying soils. It depends on this whether the pile will not go down, even if it can withstand heavy loads. If the underlying soil is strong enough, then the number of supports can be reduced. Read the instructions for building a pile foundation.

Technology

The technology for installing bored piles with a grillage is quite simple and straightforward:

- Using a manual or mechanical drill, a well is created below the soil freezing level, as already described above. The soil is not removed from the well, but is compacted, compacting the base.

- A rolled-up roofing material is placed into the well for waterproofing.

- And inside the roofing felt pipe a frame made of reinforcement is installed.

- Next, the roofing felt pipe with reinforcement must be filled with a mixture of the selected brand of concrete.

- After the concrete has completely hardened, the support pillars are ready, all that remains is to tie them together with a grillage and a solid foundation for the house is ready.

The photo shows the installation of a bored foundation

Cost of bored piles with grillage

The cost of a foundation on bored piles is influenced by the material from which the piles are made, the number of pillars and the amount of work, plus the delivery of these same materials to the construction site. On average, the cost of installing this foundation will cost from 2000 to 3000 rubles per square meter. Included in the price:

- — marking;

- - drilling of the wells;

- — reinforcement;

- — concreting;

- — installation of grillage.

Where to buy bored piles with a grillage?

Where to buy in Moscow:

- , l. Quarry, 2a building 1, office 101, tel.;

- , st. Ivovaya, 1. k1., tel.: 8 (499) 750-21-15;

- , Moscow region, Orekhovo-Zuevsky district, Likino-Dulevo, lane. Leninsky, 70, tel.: 8.

Where to buy in St. Petersburg:

- Company Funda.ru, st. Novolitovskaya, 15, tel.: 8 (812) 680-18-61;

- Alfa-Stroy LLC, Izmailovsky pr., 9/2, office 16, tel.: 8 (812) 424-15-60;

- , Prosveshcheniya Ave., 53, building 4, office. 103, tel..

Video

Watch the video for information about bored piles with a grillage:

Installing a foundation on bored piles with a grillage is quite simple, it can be done with your own hands, and is also much more profitable compared to other types of foundations. As a result, you have a strong and secure foundation for the future and home and a saved budget.

Design advantages

A foundation with bored piles and a monolithic grillage is the best option for combining two technologies (concrete reinforced belt and pile foundation), which in tandem provide the best performance characteristics. Before equipping a foundation of this type, it is necessary to study its features.

The main advantages of a pile foundation with a grillage:

- High load-bearing capacity - the structure can withstand the loads of a building made of any material, and the installed waterproofing makes the structure virtually invulnerable to external negative factors.

- There is no destructive impact of the construction process on neighboring buildings - you can build a house even next to other structures.

- The ability to build a reliable, durable house in difficult geological conditions - in swampy areas, in places with high groundwater, in heaving soil.

- Simplicity of technology, minimal amount of excavation work.

- There is no need to involve qualified specialists (subject to the ability to perform calculations and think through everything), heavy equipment - all work is carried out directly at the construction site.

- Strength is ensured by the fact that the piles are driven deep, below the freezing depth of the soil.

- The ability to build a foundation on bored piles with a grillage in difficult areas - where there are slopes, when you don’t want to spoil the surrounding terrain.

- The choice of any material for the construction of a building - even the most massive one.

- Low cost in comparison with other types of foundations with similar properties and parameters.

- High speed of construction - the foundation is built in 4-7 days.

grillage

Plus, if you install bored piles with a grillage, the foundation will require almost no reinforcement, since initially their stability and strength, as well as their load-bearing capacity, will increase. But on the other hand, you will have to make additional calculations, taking into account the density of the soil, the depth of its freezing, climatic conditions and many other factors that can be omitted when installing conventional piles. However, it's definitely worth it.

Typically, piles are buried below the level where the soil finally freezes - and just in case, it is covered with additional roofing felt protection in order to maximize the load-bearing capacity. Also, such protection plays the role of waterproofing and reduces external pressure, which in winter can reach such limits that it pushes part of the pile out of the soil.

There are two types of grillage:

- hanging;

- recessed.

In the first case, a distance of about 1 cm is left directly between the grillage and the soil, because of which the foundation turns out to be slightly higher than the ground level, in a suspended state - and this protects the building itself from the cold of the ground, moisture, and also from possible soil deformation due to any weather phenomena or climatic features.

If we take the second case for consideration, then the grillage simply goes 2 cm deep into the ground.

It is also important not to forget about reinforcement. In the vertical version, the rods are brought out minus a couple of centimeters by the length of the grillage - and this outlet turns out to be higher than the pile itself. If the soil is too heaving, then the grillage is placed somewhere 15 cm above the soil surface.

Installation

A pile foundation with a concrete grillage can vary in configuration, design features, and materials used.

- Solid - a universal option for all types of soil.

- Hollow with a multi-section core - for private construction in difficult conditions.

- Piles with a compacted face - for houses weighing more than 500 tons.

- Fifthly, with blasting operations.

Typically, in the construction of private houses, solid-section supports of simple design are used.

Bored pile installation technology: step-by-step instructions

Before starting work, the soils are carefully studied, all important calculations are performed, material is purchased, all stages are thought through, and only after that they begin to construct a bored foundation with a concrete grillage.

Preparing the area and marking the future foundation

First, you need to clear the area of debris and anything unnecessary, remove the fertile layer of soil, and carry out cast-offs so that the markings do not interfere with the excavation work. The cast-off is made of wood, installed with posts and lintels around the perimeter of the structure at a certain distance so that wells can be drilled freely.

Nails are attached to the cast-off boards, and a cord is tied to them, which marks the axes of the future building. All lines must be strictly parallel and perpendicular; evenness is checked with a level.

Well drilling

Wells are drilled according to markings to a depth calculated using the formula. The diameter of the well corresponds to the diameter of the supports. When the drill reaches the required depth, it is pulled out, loose soil is removed from the well, the supporting part is compacted, and a sand cushion is covered with a layer of 30-50 centimeters.

Installation of casing pipes

Casing pipes do not allow the walls of the well to crumble and guarantee the safety of work. On loams and dense clay soils you can do without pipes, but if the work is carried out in swampy areas or all stages are carried out with your own hands, it is better to install pipes. It is easier to create reinforcement inside them, which is determined by the load-bearing capacity of the pile.

Reinforcement

To create a reinforcement frame, corrugated rods of the required diameter are used. The technology is simple: 4-6 rods are installed inside the support around a circumference 3-5 centimeters smaller than the pipe. The rods are knitted with wire and secured with clamps. The finished reinforced frame is mounted in a well inside the pipe and buried in the soil (for this, the length of the rods should be 30 centimeters greater than the length of the pipes).

Pouring concrete mixture

For pouring, use concrete with a minimum strength of class B12.5, optimally B15. For filling, a funnel is installed at the wellhead, which helps prevent the appearance of voids. The mixture is poured slowly, in layers 50 centimeters thick, compacting for 10 minutes. After 5-7 days, you can begin installing the grillage.

Device technology

When installing bored piles with your own hands, you should keep in mind that the manufacturing process depends on the conditions of the soil at the construction site.

Arrangement of piles in dry soils

If the site is characterized by dry or low-moisture soils, the order of work will be as follows:

- Using a drilling unit equipped with an auger column or a drilling bucket, a well is drilled. Its depth and diameter must correspond to the design.

- To avoid collapse, the wellhead is lined with a metal pipe.

- In the lower part of the wells, a cavity is drilled using an expander.

- Then the reinforcing frame is lowered inside. Its dimensions should be such that a protective layer 6 cm thick is formed between the walls of the pile shaft and the metal when pouring.

- After installing the reinforcement, a concrete pipe with a receiving funnel is lowered into the well.

- The pile is filled with concrete mixture with a gradual rise of the concrete pipe. As the well is filled, the concrete is compacted using vibrators mounted on a concrete pipe.

- Upon completion of the pouring, the pile head is formed in a special inventory jig.

Diagram of a drill device for a bored foundation:

Diagram of a drilled foundation well on dry soil:

Technology for installing bored piles in flooded soils

When working on unstable water-logged soils, the following technology is used:

- The well is drilled using percussive or rotary equipment. If a rock layer gets in the way of the working tool, it is dealt with using a grab or a chisel.

- During the drilling process, a clay solution is injected, the purpose of which is to prevent the collapse of the well walls. The working solution penetrating into the soil forms a clay crust.

- All subsequent actions do not differ from the previous technology.

To prepare the clay solution, clay mixers, mud pumps and settling tanks for the working solution are used.

Grillage arrangement

In private construction, strip reinforced concrete grillage is most often used, which is suitable for buildings made of different materials. The width and height of the grillage are calculated in advance.

Stages of construction of a monolithic grillage:

- Installation of the base and formwork - a low grillage involves the use of a sand and gravel cushion 10-20 centimeters thick, on top of which 5 centimeters of lean concrete and a layer of waterproofing (waterproofing or roofing felt) are laid. The formwork is made from wooden panels around the entire perimeter of the grillage.

- Reinforcement – the grillage reinforcement is steel rods fastened in several layers. They communicate with each other and with the supports.

- Filling with concrete - the same as for wells. After filling the tape is finished, the layer is compacted, periodically moistened, and covered with polyethylene. The grillage will be ready in 28 days.

That's the very foundation

The wells are completed, the supports are made, and you can begin to install the foundation structures (more precisely, their main part). The first step in the construction of the foundation is the arrangement of the bottom of the formwork. It can be of two types - a sand cushion around the entire perimeter of the grillage (protected from water, of course), or shields placed on top of the logs. This choice is not arbitrary, as it might seem. Sand is used for low grillages (maximum forty centimeters above zero), the gap is filled with sand, and above that is waterproofing.

On the other hand, if a grillage of half a meter or higher is made, then it will be extremely difficult to do without shields that transfer the load to the support system. Sand may simply not be able to achieve such a function, and may not hold bored piles with a grillage. When the bottom is ready, one way or another, it’s time for the formwork sides. It can be removable or a frame made of boards. In the case of frame grillages, the side goes along the line of the beams, and in a monolithic scheme, the border will be the perimeter. After completing the construction of the sides, a reinforcing grillage frame is made. This frame is formed by horizontal rods attached to the vertical frame of the supports.

Once the formwork is done, concrete must be poured. The solution is poured into the underground part of the formwork using gutters, filling the grillage with it in portions similar to those used to create the piles. After the last portion has gone inside, we cover the monolith on top with plastic film and wait a couple of weeks, sometimes three, lifting the protection only to soak the top layer. When everything hardens, you need to disassemble the formwork. That's it, the time has come to build the walls of the house.

Insulation of foundation with grillage

Piles are not insulated, but it is advisable to insulate the grillage where it is located above the zero level. Work is performed in vertical and horizontal planes. For thermal insulation, foam boards or any other material of this group are usually used. It is prohibited to use mineral wool, as it quickly absorbs moisture and collapses.

Making a layer of thermal insulation for the grillage:

- Laying a layer of waterproofing (rolled roofing felt or bitumen) to protect the side and top parts of the grillage.

- Laying insulation boards with dowels, nails or glue.

- Sealing corners and joints with liquid polyurethane or polyurethane foam.

- Finishing the side walls of the grillage with plaster (or another method).

Provided the correct calculations are made, quality materials are selected and technology is followed, a building or structure on a bored foundation with a monolithic grillage can last about 100 years. At the same time, the foundation will not require additional costs for maintenance or repairs.