High chair reinforcement clamp

These products are considered the most popular for reinforcing floors, floors and other surfaces. The latch looks like a cylindrical barrel with four grooves. The jumpers located at the top are unbent.

The usual device has four legs, the reinforced one has five. This type of device is ideal for fittings whose diameter does not exceed 1.4 cm.

Read on to find out more!

Concrete: properties, types and applications

Two of the best concrete mix recipes

Vertical concrete placement technique

Protective layer of concrete for reinforcement

Concrete grade for strip foundation

Cement in bags M500

- 2.55

Rating: 2.5 out of 5 Votes: 177

- 4

Reply

5 years ago

Dmitriy

5 years ago

Quote

Recently, such clamps have appeared on our market. You can't imagine how relieved I felt. Previously, it was necessary to prepare proportionate beacons from bars. Now there are any sizes of clamps. Glory to progress!

Alex

5 years ago

Quote

I did something similar when I poured the slab under the foundation. There were no such clamps then. I cooked it from pieces of pipe and made slits for horizontal fixation. Now of course it's a blessing with today's technology. Saving expensive concrete, time and money.

Novel

5 years ago

Quote

Wonderful thing. How much we toiled when pouring monolithic floors or casting individual elements using a reinforcement frame. Until one of our workers told us about such technology. We are still grateful to this day. If only it were possible to learn about new products in this area earlier! Thank you!

Cube

Thanks to its thick wall, this type of device can withstand heavy loads.

Requirements for reinforcing fasteners

The most important criteria that clamps must have are the following indicators:

- high strength;

- dimensional identity;

- resistance to a variety of liquids, chemical compounds, temperature changes.

Plastic fasteners for reinforcement (protective layer)

Features of the protective layer

Reinforced concrete structures combine the beneficial properties of concrete and metal. The metal frame can withstand high tensile loads, and the hardened solution has high compressive strength. In addition, these materials have similar thermal expansion rates. At the same time, the alkaline environment of concrete prevents the penetration of moisture and oxygen into the reinforced concrete structure and protects the steel from chemical destruction. Such protection is effective when there is a sufficient layer of concrete mass (at least 10 - 40 mm) between the reinforcement and the surface of the reinforced concrete products.

Creation of a protective layer using reinforcement clamps

When pouring a metal frame, there is a possibility of displacement of the reinforcing bars. In this case, the steel rods may be too close to the surface of the reinforced concrete products and the concrete layer will not be thick enough. As a result, the strength properties of concrete structures are lost and their service life is reduced. Therefore, it is so important to ensure reliable fixation. The retainers of the protective layer made of polymer are mostly non-removable; they are installed on the frame rods before pouring concrete. They provide sufficient thickness of the protective layer.

Requirements for the protective layer and frame fasteners

Requirements for concrete, reinforcement and protective layer are specified in the Construction Codes and Rules for Concrete Concrete Products (SNiP 52-01-2003). According to regulatory documents, the selected reinforcement and concrete of a certain grade must be compatible in terms of strength and deformation characteristics. The use of plastic reinforcement fasteners in construction makes it possible to achieve the required indicators, including the thickness of the protective layer of reinforced concrete products. The following standards have been established for the size of the protective coating:

- for internal reinforced concrete products - at least 20 mm at normal humidity and 25 mm at high humidity;

- for external reinforced concrete products without special protection – 25 mm;

- in the ground – 40 mm;

- for foundations without additional protection – 70 mm.

Compliance with these building requirements is mandatory.

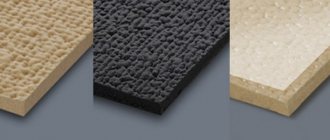

Types of plastic mortgages

The most popular models of fasteners made of polymeric materials for horizontal and vertical reinforcement:

- "Star". They are used to form vertical monolithic concrete structures (walls, columns). They have a locking connection that ensures reliable fastening of steel rods. These embedded parts do not deform under the influence of elevated temperatures and retain the necessary elasticity in frosty conditions. All models are marked in accordance with the size of the protective layer formed (15 - 60 mm), and the maximum permissible diameter of the reinforcing rod is also indicated (4 - 20 mm).

- "Stool". Support clamps are used when pouring horizontal planes (floors, ceilings). Using such parts, you can create a layer with a thickness of 20 to 40 mm; a suitable diameter of reinforcing rods is from 4 to 20 mm. When installing on loose soil, an additional PVC base is taken.

- "High chair." Also used for the construction of horizontal reinforced concrete structures, including foundations. SNiP requirements determine the number of fasteners to be installed per square meter. meter from 6 to 10 pieces. It is prohibited to place such supports on soft surfaces (thermal or waterproofing) without a stand, as they may tear them.

- "Cube". Install on a horizontal plane. These models have different recess depths to form a layer of the required thickness (up to 80 mm).

- Universal multi-storey clamp for horizontal surfaces. The design of this part allows you to increase the height by installing elements on top of each other. There is a hole in the center of the post that prevents the formation of air bubbles when pouring concrete.

- Universal protective layer clamps for vertical and horizontal reinforcement.

- Plugs, cones (for formwork). The plugs are placed on protruding metal rods to prevent them from coming into contact with the panels of the formwork structure. This prevents the strands of the reinforcing structure from coming out onto the concrete surface. Also, plugs are placed on unused technological holes in the formwork to prevent liquid concrete mixture from getting into them during the pouring process. Plastic cones are placed on the end of the limiter tube to protect against solution during monolithic work.

Polymer bases are used as additional components to create a monolithic frame on a soft horizontal surface. These stands have 4 holes for attaching stool or high chair type clamps. Mortgages with a round base are designed for installation on loose soil, as well as for hydro- and thermal insulation. In this case, the use of an additional stand is not required.

Advantages of PVC fasteners

The advantages of embedded parts made of polymer materials are the following features:

- Low cost.

- Creation of a high-quality protective layer to protect reinforcement from moisture and corrosion. The use of such consumables ensures the placement of metal rods at the required depth in the concrete mass.

- Durability and unlimited shelf life of mortgages.

- Resistance to extreme temperatures. They are used in any climatic conditions.

- Compliance with design standards. It is always possible to select suitable fastenings taking into account the characteristics and features of reinforced concrete products.

- Versatility. There is a large selection of embedded parts for reinforcement of a certain cross-section. The required models in the required assortment are quickly selected.

In addition, plastic retainers of the protective layer are quickly installed and ensure the solidity of the reinforcing structure when pouring concrete. The displacement of steel rods during preparatory work and when laying the mortar is eliminated.

Selection of polymer fasteners and cost of fasteners

The number of embedded parts in the production of reinforced concrete structures is regulated by building codes. On average, 3 – 10 mortgages per 1 m2 are required. Also, when manufacturing reinforced concrete products, the following is taken into account:

- Design thickness of the concrete protective layer. This indicator is indicated on the parts labeling.

- Diameter of reinforcing bars.

- The material on which it is installed. If the base is soft, then it is necessary to additionally use a flat stand or take plastic products specifically for loose soil.

- Surface type (horizontal or vertical).

In addition to these factors, when choosing components you need to pay attention to the material from which the supporting elements are made. The plastic should not break when bent, but only bend. It is important to have certificates confirming the quality of the polymer.

The use of such embedded elements simplifies installation work and speeds up the pace of monolithic construction. The depth of the clamps is controlled using magnetic sensors.

The price of one product depends on the size of the protective layer it forms. For example, the “stars” FZ-15 forms a layer of concrete of 15 mm and the fasteners cost 5 times less than the similar FZ-50 (layer size 50 mm). Such consumables can be sold in packs of hundreds of pieces, and discounts are offered when purchasing large quantities.

All products have the necessary certificates, passports and permits. The warranty applies for the entire period stated by the manufacturer. After-sales service is carried out in the service centers of our partners and workshops of manufacturers.

Do you want to buy a product at a special price? Are you interested in current promotions and discounts? If you have found an error in the description or have questions about the products presented on our website https://www.Komplektacya.ru, please contact us by contact e-mail: , by multi-channel phone 8 (812) 380-12-34 or with the help of an online consultant located in the lower right corner of the page.

What are fasteners made of?

These products are made of durable plastic. Their use makes it possible to maintain stability of shape and size. Thanks to their versatility, fasteners can be easily selected for fittings of any type and size, with various fastening variations.

Similar plastic stands are also used during concreting of structures made from composite raw materials. In addition, the fixing products are interchangeable.

It is also important to remember that plastic retainers are consumables that remain in the “fill.” Although there are also reusable stands, for example, a cone, which is dismantled for further filling of the resulting cavity with solution.

Plastic clips

The main advantages of plastic fasteners are increasing the reliability and strength of the building structure, increasing the quality of construction work performed, facilitating and speeding up the execution of monolithic work. From us you can purchase a plastic star fastener, which prevents the walls from coming into contact with the formwork panels. This type of fastener fits onto the reinforcement and helps maintain an equal distance from the rod on all sides. A plastic star fastener will maintain the thickness of the protective layer and is suitable for fittings.

The protective layer of reinforcement is the distance between the edges of the concrete structure and the surface of the reinforcement. Compliance with the thickness of the protective layer will keep the reinforcement in a fixed position, in order to ensure the joint work of concrete and reinforcement, preserve the reinforcement from environmental influences, fire safety and fire resistance of buildings and prevent the appearance of reinforcement on the surface of structures. The latch makes construction work several times easier and faster.

Advantages

The multi-level reinforcement clamp ensures uniform protection of the layer at each level of the horizontal surface. It is enough to set the layer thickness and perform reinforcement in two and/or more levels.

Classification of fasteners

At the moment, the fixer is most widespread in monolithic housing construction. Here we subdivide 2 main groups of retainers and a 3rd auxiliary group. The group of wall reinforcement fasteners includes a fastener called an asterisk marked FZ. The star fastener provides a protective layer of fifteen to fifty millimeters, and is used with reinforcement up to twenty millimeters.

It is very simple to use this type of clamp; they are easily placed on vertical and horizontal reinforcement and thus prevent the reinforcement from touching the vertical formwork. In the group of reinforcement clamps for slabs and floors, there are 2 subgroups. Some fasteners can be installed on any surface, while others can only be installed on a hard surface, for example, on concrete footings and insulation.

In this case, this will primarily affect the cost of the retainer, since the universal option is more expensive. Functionally, different manufacturers produce quite diverse forms of the retainer, which is where a huge number of names arose. For example, the chair reinforcement clamp, as the most common one, has more than one type of design, and it includes clamps 25x50, 25x30, herringbone FU, and ceiling support. However, in reality, it does not matter what the fastener looks like, the main thing is that it fulfills the assigned tasks (provides the necessary protective layer and fits the reinforcement used).