Flexible connections for aerated concrete: application features

The main disadvantage of aerated concrete block material is its unattractive appearance, which is why objects built from it are often faced with brick. It is not recommended to use fasteners made of ordinary material to connect main walls and decorative rows. The bottom line is that the aerated concrete blocks located behind the finishing layer are not affected by changes in temperature conditions, their dimensional parameters remain constant. But the facing row is influenced by precipitation, wind and sun, reacting to this with expansion or contraction. To minimize the displacement of the constructed walls, flexible connections for aerated concrete are installed.

Features of flexible connections

These products have this name due to their characteristics. The internal walls of the building have a more constant temperature. This is due to the fact that they are not subject to regular external temperature fluctuations. However, the outer facing wall is subject to reverse influences. This layer can heat up to +70 °C in summer, and freezes to -40 °C in winter. Significant temperature changes lead to the fact that the inner wall remains motionless, and the outer one changes its geometric size.

It is worth noting that flexible connections for brickwork and aerated concrete bend well. Thanks to this, they are able to maintain the integrity of the structure. The products are not subject to corrosion. They do not break as a result of frequent bending, and also do not create insufficient heat transfer. The high strength and durability of flexible connections are greater than those of traditional connections. Therefore, the building as a whole will be more reliable.

What it is?

The flexible connection for aerated concrete is represented by a round bendable rod with a sand coating, made from basalt raw materials or fiberglass.

In terms of their ability to resist oxidation, the effects of acidic compounds and alkalis, fiberglass flexible connections are superior even to their stainless steel counterparts.

According to their characteristics, flexible connections for aerated concrete walls are divided into several types:

- At each tip of the rod, for ease of screwing into the gas-block material, there are screw thickenings covered with a sand layer. With their help, reliable fastening of the flexible connection in aerated concrete or mortar is ensured. During screwing, the thickenings open, securely holding the cladding layer;

- at one end there is a plastic dowel for attaching a flexible connection, at the other there is an anchor with a special coating;

- There is a flexible connection option for aerated concrete and insulation, one of the ends of which has a clamping clamp.

The fittings, with their flexibility, provide additional functions.

Installing flexible connections allows you to:

- create ventilation areas between brick and aerated concrete blocks;

- in the case when an insulating layer is installed, the material is tightly pressed against the wall surface with anchors so that it does not move.

For partitions that are located perpendicular to the load-bearing surfaces, experts advise using connections for aerated concrete made of stainless steel or metal coated with zinc. The reliability of the connection is guaranteed by a wavy or ninety-degree bent tip.

What is flexible communication?

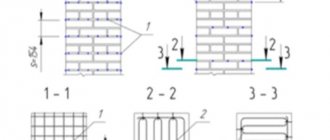

This is a type of reinforcing element that is used to strengthen a structure or its individual parts. In this case we are talking about brickwork. Most often, this method of reinforcement is recommended for three-layer walls, which have an internal heat insulator in their niche and themselves act as a connecting link for the load-bearing technical and facing layers.

In terms of the device, the connection is an elastic rod with a circular cross-section. To eliminate rusting processes, flexible galvanized connections for brickwork are used, as well as basalt models, which in principle are not susceptible to corrosion. An important technical and structural feature of all types of connections is the presence of thickenings at the ends and protruding ribs. These additions increase the adhesive function of the element and give it the characteristics of a real anchor. Sand spraying at the end of the connection gives an even greater coupling effect - it organically enters into the structure of the solution, increasing the strength of the seam.

«>

Advantages of ties made of plastic material

Fiberglass flexible connections have a number of advantages:

- they do not create “cold bridges”;

- a design with such reinforcement elements is considered completely sealed and creates good opportunities for energy saving at minimal cost. The reason for this is the low thermal conductivity of the material;

- flexible connections and the aerated concrete anchors on them are lightweight and do not create load effects;

- plastic does not corrode and resists negative manifestations;

- connections for facing bricks and aerated concrete have a long service life.

Making connections

Installation of flexible connections for aerated concrete is easier than metal analogues. All you need is the desire to work and the appropriate tool.

Places for holes for anchors are marked on the gas-block wall. As a rule, they are located in increments of fifty centimeters in each direction.

The rows are placed parallel to the masonry seam of the facing material.

Using a drill with a diameter of 1 cm, holes are drilled according to the marks, the depth of which reaches ten centimeters. Then the remaining dust is blown out of them with a special blower that comes with a set of flexible connecting elements.

The connection is inserted along the entire length of the anchor sleeve and screwed until it stops with a special key. If there is a need for this, then an insulating material is attached to them, which is pressed and snapped into place with a plastic fastener. After this, each hole is sealed with a solution of sand and cement; work continues after its hardening is complete, so that the rods do not become loose.

Additional anchors are placed at intervals of thirty centimeters at the corners of the building, along the entire perimeter of the opening areas, at expansion joints and near parapet areas.

Now several rows of facing bricks should be brought out (to the height of the lower mark), after which the free ends of the ties, treated with a layer of sand, are gradually inserted and walled up into the seams of the facing row.

The connection of aerated concrete and brick is made using flexible connections based on the latter independently, but experts recommend installing at least five elements on each square of the aerated block surface.

All cladding work should be carried out at a temperature not lower than zero degrees.

Installation of flexible connections

When using flexible connections for brickwork for cladding, the technology must be followed. Their number and location are determined at the first stage of work - when drawing up design and estimate documentation.

Most often, four products should be used for each square meter of load-bearing wall. If the walls are insulated using mineral wool slabs, the spacing of flexible connections should be 50 cm both horizontally and vertically. Polyurethane foam and polystyrene foam can also be used in the insulation process. In this case, the horizontal step of the products is 25 cm, but not less than four pieces per square meter. Vertically, you should adhere to an indicator not exceeding 100 cm.

It is worth noting that flexible connections for brickwork must be additionally arranged around the perimeter of the openings. They also need to be installed in each corner of the building in increments of 30 cm near the parapet and at expansion joints. During installation, the minimum required depth of penetration into the load-bearing wall and the facing layer is observed, which is 9 cm.

A situation may occur when the horizontal seams of the outer and inner layers do not match. It is necessary to install ties for the load-bearing wall in a vertical joint using cement-sand mortar to perform a thorough seal.

When following the technology for installing flexible connections, you need to ensure that they do not become loose. Initially, a layer of thermal insulation is installed, after which a flexible connection for the brickwork can be installed. To do this, you need to pierce the insulation board and install it on it. If the insulation is attached to an old product, you should wait for the mortar to set in the seams where the connections are installed.

Rules for choosing a suitable rod

Flexible connections are elements that require smart selection. The size of the composite rod is determined taking into account the specific installation option of the facing material.

There are four ways:

- tightly to the load-bearing wall so as not to leave a ventilation gap;

- using heat-insulating material installed close to each layer;

- at a minimum distance from aerated concrete so that an air gap remains;

- with a gap between the insulating material and the facing brickwork.

If you plan to use insulating material with a gap section, then the longest rods will be required. The appropriate size can be determined using a special formula:

in which: 90 is the parameter for the depth of screwing into the block material (this size can be smaller and depends on the fastening); T – size of the thickness of the insulating layer; 40 – width of the gap area for ventilation; 90 – depth of embedding in brick rows.

Today in building materials stores there are composite rods, the length of which ranges from 15 to 45 centimeters. The diameter is 4 – 6 mm. If buildings with a height of more than twelve meters are to be faced, it is recommended to use thicker connections.

Reviews from experts

Experienced craftsmen recommend using flexible Galen ties for aerated concrete. We have already found out how to use this type of fastener. But there are a couple of ways that should be discussed separately:

- Parallel - this method of knitting horizontal masonry joints involves placing a metal mesh pre-cut into strips. One side of the reinforcing sheet is inserted into the seams of the aerated concrete row, and the other into the cladding. The flexible connection is fixed to the mesh with knitting wire, the free areas are sealed into seams located horizontally.

- With offset - when performing this method, the plastic connection is bent along the axis, placed in a vertical seam, and fixed to the block ends with nails. This option makes it possible to knit at different heights and create step-by-step reinforcement of masonry from brick material. Everything else is done the same as in the first option.

It should be noted that reviews of flexible communications are predominantly positive.

Flexible connections for brick, concrete and aerated concrete: assortment, selection, installation

When constructing multilayer walls with insulation or an air gap, problems arise in maintaining the integrity of the entire structure during changes in ambient temperature, subsidence and seasonal soil movements. Specialized reinforcing products come to the rescue - composite flexible connections (CF), made of polymer materials.

Flexible connections for masonry made of polymer materials are responsible for solving several problems:

Mechanical connection of the load-bearing layer with the facing layer in the presence of an air gap or heat-insulating material;

Compensation for displacements of the main wall and cladding relative to each other during temperature changes, soil movements, etc.;

Main types and markings of flexible connections

Flexible connections may vary by type of use:

- For perpendicularly adjacent internal walls. They have the form of a perforated strip, attached in a bent state to the load-bearing wall and laid in the inter-row spaces of the masonry of the adjacent wall. They are made primarily of stainless steel, since the specific nature of internal operation does not threaten the formation of cold bridges.

- For three-layer walls with insulation and an outer cladding layer. These are the anchor rods in question made of polymer materials with a sand-coated coating.

Marking of flexible connections fully reflects the parameters of the rod:

BPA - 300-6-2P

- where BPA is basalt-sand reinforcement.

- 300 is the length of the anchor rod.

- 6 - diameter.

- 2P - 2 sand anchors.

Sometimes the marking directly indicates the type of material of the load-bearing walls for which the anchor is intended, for example:

SPA -250-6-aerated concrete.

- SPA - fiberglass fittings.

- 250 is the length of the rod.

- 6 - diameter.

- Aerated concrete is a load-bearing wall material. The indication of the material usually indicates the presence of a plastic sleeve at one end, installed like a dowel into a load-bearing wall. Aerated concrete is a rather soft material, and conventional installation methods are not suitable for it.

Advantages and features of GS

First of all, you need to answer the question: why is it more profitable to use flexible connections made of composite materials than steel ones? Composite products have several advantages:

A combination of high mechanical strength and elasticity sufficient to compensate for movements;

High chemical strength (bending, tensile and torsion) and resistance to negative influences - water, alkaline and acidic environments, high and low temperatures;

Low weight, when laying the connections they do not weigh down the walls;

Low thermal conductivity, which prevents the formation of “cold bridges”;

High adhesion to masonry mortar;

One of the key advantages that flexible ties for aerated concrete and brick have is their resistance to corrosion and aggressive environments: these products work reliably in a wide range of pH values of concrete and masonry mortar, and withstand the effects of water and aggressive environments. In situations where steel reinforcement or mesh is subject to corrosion (especially in colored solutions or when the pH changes towards acidity) and gives characteristic traces of rust, composite products remain passive and do not manifest themselves in any way.

Benefits of using flexible links

In addition to ensuring the stability and integrity of the entire building, the correct use of flexible connections provides the following advantages:

- “Cold bridges” are completely absent. Thanks to this, the building remains completely sealed and indirect heat loss is eliminated.

- Basalt and plastic bonds exhibit excellent resistance to the alkaline environment of masonry mortars.

- Anchor products made of plastic are durable and do not deform for decades of service.

- Light-weight flexible connections do not weigh down the structure. In addition, it is convenient for builders to work with them.

Design, classification and characteristics of flexible connections

Structurally, the HS is made in the form of a round rod made of one or another composite material (glass composite, basalt composite, carbon composite or a combination thereof) with a length of 150 to 650 mm, at both ends of which anchor parts are formed. Depending on the design of the anchor part, flexible connections for facing bricks are divided into four main types:

With uncoated thickenings at both ends;

With one pointed and one thickened anchor part without coating;

With sand-coated bulges on both parts;

With one pointed and one thickened anchor part with a layer of sand.

The thickened anchor parts are intended for embedding into brick or aerated concrete masonry; to increase adhesion with the masonry mortar, this part can be covered with sand (with an epoxy binder). The pointed parts are intended for embedding into a special dowel, with the help of which the flexible connection is mounted into the body of aerated concrete blocks, a monolithic aerated concrete or concrete base

HS are produced with constant and variable nominal diameters - 3, 4, 6, 8, 5.5x7.5, 7.5x10.5 mm.

The main characteristics of GS on the territory of the Russian Federation are regulated by the GOST R 54923-2012 standard.

Other materials can be used in conjunction with flexible connections - flexible basalt construction mesh and spacer washers. The mesh can act as a flexible connection, and it is also designed to increase the strength of brickwork and aerated concrete blocks. Washers are used to press a layer of thermal insulation material against a load-bearing wall in order to create an air gap between it and the cladding.

HS marking

Today, several systems for marking flexible connections are used.

The main system is in accordance with GOST R 54923-2012, in accordance with it the marking is as follows: KGS (type) – material of manufacture – dimensions – number of anchor sections (adhesive strength in MPa), where KGS means “composite flexible connection”. For example, the marking KGS (R) – BK(E) – 300/5 – 2A(5) means that this is a GS spacer (installed horizontally in vertical masonry) made of basalt composite (BC) with an epoxy binder (E) 300 m long and with a diameter of 5 mm with two thickened anchor parts, having an adhesive strength of 5 MPa

However, simpler markings are more common, referring to the fact that flexible connections are made from composite reinforcement based on basalt fiber (BPA - basalt-plastic reinforcement). The marking looks like: BPA – length of the product – diameter of the product – number of anchor parts with sand. For example, the above type of product in this system is marked BPA - 300 - 5 - 2P.

It is easy to notice that any marking indicates the main parameters of a flexible connection for aerated concrete, concrete or brick - length, diameter and number of anchor parts, which is enough for the successful selection of products.

Selection and calculation of HS

The selection of GS should be done based on the following factors:

Supporting base material – brick, aerated concrete or concrete;

Type and thickness of the heat-insulating layer;

The presence of door and window openings, and other elements in the wall.

If you need to build cladding on a brick wall, you should choose flexible masonry ties with two widened sand-coated anchor parts. For work on walls made of aerated concrete blocks, it may be necessary to use products with both widened anchor parts and pointed ones - products of the second type are suitable for situations where the place where the connection is installed falls not on the seam, but on the body of the block. For work on monolithic concrete or aerated concrete blocks, only connections with a pointed dowel are suitable.

Calculation of the length of the horizontal line for facing bricks is carried out using a simple formula: L = (60...150) + T + d + 90 Where L is the total length of the horizontal line, 60...150 is the penetration of the product into the base, T is the thickness of the insulation (regardless of its material) , d – air gap, 90 – penetration of the product into the cladding. If the wall structure does not provide insulation or an air gap, then the corresponding values in the formula are equal to zero. It is not recommended to go beyond the boundaries of deepening the horizontal structure into the load-bearing base and cladding, as this violates the strength and characteristics of the entire wall.

As for the diameter of the connections, it is directly proportional to the thickness of the supporting base and the facing layer. In general, the rule here is true: the heavier the walls and heat insulation, the thicker the products should be.

The number of joints is calculated from the consumption of products per square meter of wall: for brickwork and concrete structures - an average of 4 connections per square meter. m., for walls made of aerated concrete - an average of 5 connections per square meter. m. However, at expansion joints, window and door openings, parapets, as well as at wall corners, the number of products should be approximately doubled.

If you plan to install a heat insulator with an air gap in the structure, then when purchasing flexible connections you should also take care of spacer washers in the appropriate quantity.

Recommendations for installation of flexible connections

The installation procedure for the HS depends on the material of the walls and the method of their construction.

If a load-bearing wall is first erected (made of brick, aerated concrete or concrete), and after some time it is lined (which often happens in private housing construction), then the order of work is as follows:

Places for installing flexible connections are marked on the supporting base; the fasteners do not necessarily have to go into the seams of the wall, but it is desirable that they go into the seams of the facing layer;

Holes for connections are drilled and dust is blown out;

If there is a heat insulator, it is pinned to the connection;

A facing wall is being erected with connections sealed in the mortar.

Another order of work is also possible: flexible connections are mounted into the load-bearing base as the facing layer is being erected. If insulation is used, then in this case the hole for the flexible connection is drilled through the heat-insulating layer.

In both cases, it is recommended to pre-treat the load-bearing wall with impregnation to protect it from destruction. And flexible connections for aerated concrete are sealed using special glue.

Basalt flexible ties for brickwork

What is composite flexible link?

This is a rod with a round cross-section and thickened at the ends: these zones allow you to securely fix the reinforcement in the masonry, ensure good adhesion to the masonry mortar and protect the reinforcement from corrosion. The air gap is provided by a plastic retainer with a latch.

How to choose the right composite flexible connection?

The length of the product, designated L, is selected taking into account the presence/absence of an air gap. In the first case, the calculation is made according to the formula: L = 90mm+T+40mm+90(150)mm (designation T is the thickness of the insulating layer, 40mm is the air gap indicator, 90/150mm is the minimum and maximum depth to which basalt connections are embedded in wall). If a ventilated gap is not provided, the length is L=90mm+T+90(150)mm.

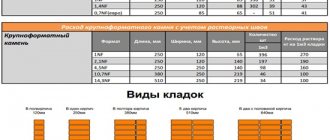

Prices for basalt connections of BPA reinforcement for brickwork

Name of product

| Price including VAT RUB/pcs | ||

| Retail | ||

| BPA- 250-6-2P | 9,12 | |

| BPA- 300-6-2P | 10,80 | |

| BPA- 350-6-2P | 12,60 | |

| BPA- 400-6-2P | 14,28 | |

| Retainer | 2,90 | |

Flexible connections for masonry differ

- have an extremely low thermal conductivity coefficient (in contrast to highly thermally conductive metal);

- characterized by significantly lower mass;

- are not subject to corrosive effects and are resistant to alkaline environments;

- are produced with a high level of quality, confirmed by a full set of technical documentation and relevant certificates.

Flexible basalt connections: technical characteristics

- Certificate of Conformity of the Gosstroy of Russia No. ROSS RU.SL55.N00042

- Fire safety certificate SSPB.RU.UP001.N00259, issued by “POZHTEST” FGU VNIIPO EMERCOM of Russia

- Sanitary and epidemiological conclusion No. 21.01.04.571.P.000141.06.02.

- Recommended for use by the State Construction Committee of Russia

DEAR BUYERS, PAY ATTENTION! FLEXIBLE BRACES FOR BRICK MASONRY : BPA 250-6-2P

, BPA 300-6-2P , BPA 320-6-2P , BPA 350-6-2P

are included in the warehouse program and are sold individually from our warehouse.

All other products are sold in multiples of 1000 pieces! BPA 250-6-2P BPA 260-6-2P BPA 270-6-2P BPA 280-6-2P BPA 290-6-2P BPA 300-6-2P BPA 310-6-2P BPA 320-6-2P BPA 330 -6-2P BPA 340-6-2P BPA 350-6-2P BPA 360-6-2P BPA 370-6-2P BPA 380-6-2P BPA 390-6-2P BPA 400-6-2P BPA 410-6 -2P BPA 420-6-2P BPA 430-6-2P BPA 440-6-2P BPA 450-6-2P BPA 460-6-2P BPA 500-6-2P BPA 550-6-2P BPA 560-6-2P BPA 600-6-2P BPA 650-6-2P

| Name | Pack/piece | Price/piece, rub. | |

| 1000 | 9,9 | — + | Buy |

| 1000 | 10,3 | — + | Buy |

| 1000 | 10,7 | — + | Buy |

| 1000 | 11 | — + | Buy |

| 1000 | 11,5 | — + | Buy |

| 1000 | 11,8 | — + | Buy |

| 1000 | 12,2 | — + | Buy |

| 1000 | 12,5 | — + | Buy |

| 1000 | 12,9 | — + | Buy |

| 1000 | 13,4 | — + | Buy |

| 1000 | 13,7 | — + | Buy |

| 1000 | 14 | — + | Buy |

| 1000 | 14,4 | — + | Buy |

| 1000 | 14,8 | — + | Buy |

| 1000 | 15,2 | — + | Buy |

| 1000 | 15,6 | — + | Buy |

| 1000 | 15,9 | — + | Buy |

| 1000 | 16,4 | — + | Buy |

| 1000 | 16,7 | — + | Buy |

| 1000 | 17,1 | — + | Buy |

| 1000 | 17,5 | — + | Buy |

| 1000 | 17,8 | — + | Buy |

| 900 | 19,3 | — + | Buy |

| 900 | 21,3 | — + | Buy |

| 900 | 21,6 | — + | Buy |

| 700 | 23 | — + | Buy |

| 500 | 25 | — + | Buy |

Flexible connections are designed to connect the internal, thermal insulation and facing layers of brickwork. They can be used to attach a facing layer of small-piece material and insulation to a base made of a large-format ceramic block.

Using flexible ties for brickwork

Basalt-plastic flexible ties for galen brickwork with sand anchors are optimally suited for reliably and quickly connecting the load-bearing layer and the cladding - for example, for three-layer brick walls insulated from the inside. The employees provided the possibility of creating a ventilated gap by specially equipping the durable composite rods with plastic clips.

How to choose a brand of flexible ties for brickwork.

First you need to find and decipher the markings. As a rule, it looks like this - “BPA-300-6-2P”. In this particular case, the abbreviation “BPA” means “basalt-plastic reinforcement”, the number 300 indicates the length of the connection, the number 6 indicates the diameter of the rod, and “2P” means that the flexible connection for galen brickwork is equipped with two sand anchors.

The required grade of flexible connection is calculated using the simple formula “L = 90 mm + T + 40 mm + 90(150) mm”, where

- L is the length of the product for a wall with an air gap,

- T is the thickness of the insulating layer,

- air gap is 40 mm,

- the minimum depth of penetration of the rod into the cladding layer is 90 mm,

- the depth of penetration of the rod into the load-bearing wall is min 90 mm and max 150 mm.

If it is not intended to make a ventilated gap in the wall, then the formula is as follows: “L = 90 mm + T + 90(150) mm” with similar notations.

Technical characteristics

of flexible connections for brickwork.

Diameter of round cross-section flexible galen connections

is 6 mm, and the minimum anchoring depth is at least 90 mm. The modulus of elasticity in tension reaches 51,000 MPa, in compression - up to 30,000 MPa. The breaking stress during bending and tension is 1000 MPa; in order to tear out a flexible connection for galen brickwork from concrete mortar grade M100, a significant force of 4000 N should be applied. The relative deformation of basalt plastic rods at break is only 30%, and the thermal conductivity coefficient reaches 0.46 W/m*ºС .

Installation of flexible connections for brickwork.

The exact number and location of flexible galley connections with a diameter of 6 mm are determined at the stage of developing design estimates: on average, there are 4 composite products per 1 m 2 of a blank multilayer brick wall, provided that a ventilated gap is created. If insulation is planned with a mineral wool slab, then an adequate “step” of flexible connections is galen

made of basalt plastic equals 500 mm - both vertically and horizontally; insulation with polystyrene foam (polyurethane foam) requires that the vertical “step” be equal to the height of the slab, but not exceed 1000 mm, and horizontally be 250 mm, but not less than the “step” at the rate of 4 products per m2.

Often, the horizontal seams of the inner and outer layers of masonry where the rods are installed do not match. In this case, it is necessary to install flexible galen connections in the vertical seams of the inner layer, and then carefully seal the seam with cement-sand mortar.

To avoid loosening, you should first install a layer of thermal insulation, and then lay flexible galley connections on top or stitch them through the slab. If you plan to attach the heat-insulating layer to previously installed flexible galen connections, then you need to wait until the mortar in the joints of the brickwork completely “sets.”

The difficult climatic conditions of our region, characterized by low temperatures and high humidity, as well as strong winds and sudden temperature changes, significantly complicate the construction of buildings (structures), especially residential ones. At the stage of erecting brick walls, which is one of the main ones, measures are also taken to insulate them, for which a variety of materials are used - from mineral wool to polyurethane foam (expanded polystyrene) slabs. In order to reliably and firmly attach a layer of cladding with thermal insulation to the load-bearing wall of a building (structure), today so-called flexible connections for brickwork are increasingly used - the most popular among the mass buyer in the significant North-West market of construction and finishing materials are used by domestic products (Republic of Chuvashia).

Durable flexible connections for galen brickwork, buy inexpensively and quickly in St. Petersburg and the Leningrad region, are part of a wide range of products made from new generation composite materials, including basalt plastic and fiberglass, which are also in demand in the countries of the former CIS and in Europe - Today, up to 20% of production is exported. Therefore, in 2012, an additional enterprise was organized in Belarus (Mogilev), and the main high-tech production is located in our country (Cheboksary); The dealer network in Russia and the countries of the former CIS includes more than 40 branches, and a separate sales division was created in England, the fruitful activity of which has brought the standards - both Russian and European - of the construction industry to new heights. Composite materials and products, founded in 2011 by engineer, inventor, businessman and leader V.N. Nikolaev, has ISO 9001-2000 and ISO 9001-2008 certificates, as well as the British BBA (British Board of Agreement), has implemented a Quality Management System in accordance with international standards and in 2010 won the prize of the International competition “Pultruder of the Year” (USA, Baltimore), and a year later received the status of a design company from RUSNANO.

High-quality flexible ties for galen brickwork, the price of which is very affordable, are basalt-plastic rods of round cross-section (diameter 6 mm) with sand anchors made by spraying at the ends. This design solution provides both optimal adhesion to the concrete mortar and excellent protection against moisture and corrosion caused by the aggressive alkaline environment of the cement-sand mixture, which can significantly extend the service life of both the fixing elements themselves and

building structures. Relatively light in density and weight, flexible connections for galen brickwork reduce the load on the foundation of the building (structure); simple installation reduces labor costs, reduces the cost of estimates and shortens the construction time of building structures. Interestingly, basalt-plastic rods can be either laid on top of the insulation layer or passed through it. A fairly high degree of fire resistance - domestic flexible galen connections are capable of withstanding temperatures up to 700°C for a considerable time - additionally provide reliable protection against fire; the low coefficient of thermal conductivity (no more than 0.46 W/m°C) of high-strength flexible connections for galen brickwork once and for all solves the problem of the formation of “cold bridges”, which any metal fastener inevitably becomes, which contributes to the tightness of the insulating layer and increases the energy saving of the building ( buildings) in general. Excellent results are shown by the use of domestically produced flexible basalt-plastic rods with a diameter of 6 mm for reinforcing various types of structures intended for operation in unfavorable conditions - for example, chemically aggressive environments. If a specific project involves creating a ventilated gap, then experts advise purchasing special snap-on galen fasteners made of polypropylene, frost-resistant and impact-resistant.

Basalt plastic consists of an organic binder (the so-called matrix) and reinforcing basalt fibers, therefore it is environmentally friendly: during the production of galenic products, up to 40 times less carbon dioxide is released into the atmosphere compared to the production of traditional metal reinforcement. This stable composite is characterized by high strength and rigidity, so Russian flexible ties for galen brickwork cope “excellently” with operational loads and pressure that arises due to the inevitable mutual movements of the layers that make up multi-layer brickwork.

The scope of application of modern material with such high efficiency as basalt plastic (as well as fiberglass and carbon fiber), of course, is not limited to residential, civil or industrial construction; aerospace engineering and mechanical engineering, energy and shipbuilding are some areas of activity where products made from composites, including those produced by Russian manufacturers, are successfully used.

Detailed descriptions, calculation formulas and photos - with the help of this information you can independently select strong and durable flexible connections for galen brickwork, and also, using the contacts posted on the pages of the online store, place an order and delivery in St. Petersburg and the Leningrad region. If necessary, you can get prompt advice from the specialists on duty, including on the entire range of innovative domestic products. Success in Russia and abroad clearly shows that composites are the future!

The Continent company offers flexible basalt connections from the Galen plant. You can get acquainted with the prices for basalt connections in the price list

in the ceramic blocks section “related products for laying ceramic blocks”.

The Galen company is the leader in the domestic market for basalt-plastic building materials, which occupies more than 50% of the composite market in Russia and the CIS. The plant is a successful manufacturer of flexible connections, facade dowels, reinforcement and mesh. Flexible basalt connections

are a necessary element when performing masonry work, providing a strong connection between brick walls - load-bearing and facade.

Flexible basalt ties must have high strength and anchoring ability, and also be resistant to the alkaline environment of cement mortars and concrete, without reducing the thermal resistance of the wall and without disturbing the uniformity of its temperature field. The latter practically eliminates the use of metal flexible connections and construction meshes, because due to the high thermal conductivity of metals, they become “cold bridges”, which reduce the thermal resistance of the wall by about 10%. In addition, to ensure the alkali resistance of such bonds, they should be made of expensive alloy steel. This is primarily due to the appearance on the building materials market of flexible connections made of oriented (uniaxially reinforced) polymer composites, the thermal conductivity of which is, as a rule, 100 times lower than that of metals, and the level of deformation and strength indicators is even slightly higher than that of steel. Flexible basalt ties for laying facing bricks

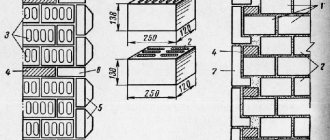

are rods that are molded from a bundle of basalt fiber impregnated with an alkali-resistant epoxy binder and have a corrugated surface. Basalt fiber was selected as having the highest resistance in an alkaline cement environment. Below are the values of the level of strength retention of a 2 mm thick sample made of basalt fiber. Calculation of the predicted degree of damage to basalt-plastic in the alkaline environment of concrete using experimentally established values of the coefficients of diffusion and sorption of alkali in the named composite showed that even after 50 years of operation in moisture-saturated concrete, the thickness of the surface layer of the flexible basalt-plastic bond damaged by alkali will not exceed 11 microns, i.e. . the strength and rigidity of the connection will remain virtually unchanged.

Flexible Galen ties made of basalt plastic for brickwork (TU 5714 - 006 - 13101102 - 2009) with a diameter of 6 mm are produced according to TS 2352 - 08 in lengths: 250 mm, 300 mm, 350 mm, 400 mm, 450 mm, 500 mm, 550 mm and 600 mm. Typically used in three-layer brick walls

with internal insulation and connect the load-bearing and facing layers.

The flexible connection is a round rod with sand thickenings at the ends, which act as an anchor when fixed in the mortar joints of the masonry. The sand coating ensures adhesion to the mortar. Technical characteristics:

Breaking tensile stress - not less than 1000 MPa;

Breaking stress during bending - not less than 1000 MPa; Tensile modulus of elasticity - 51000 MPa; The pullout force from the M100 solution is no less than 4000 N; Thermal conductivity - 0.46 W/M 0 C. Marking -

BPA-300-6-2P: BPA - basalt-plastic reinforcement; 300 — connection length (mm); 6 — rod diameter (mm); 2P - 2 sand anchors.

The length of the flexible connection (L) for a wall with an air gap is selected as follows: L=90 mm+T+40 mm+90(150)mm where T is the thickness of the insulation layer, 40 mm is the size of the air gap, 90 mm is the minimum embedment depth flexible connection into the facing layer, 90 mm is the minimum and 150 mm maximum depth for embedding flexible connection into the load-bearing wall. For a wall without a ventilated gap: L=90 mm+T+90(150)mm. Installation of flexible connections:

The number and location of flexible connections in multi-layer walls are determined at the stage of design and estimate documentation. Installation of flexible connections with a diameter of 6 mm with the creation of a ventilated gap usually requires 4 products per 1 square meter of a blank wall. When insulating walls with mineral wool slabs, the pitch of basalt-plastic flexible ties both vertically and horizontally is 500 mm. When insulating walls with polystyrene foam or polyurethane foam, the vertical spacing of the ties is equal to the height of the slab, but not more than 1000 mm, the horizontal spacing is 250 mm, but not less than the spacing at the rate of 4 pcs/sq.m. Additionally, flexible connections are installed along the perimeter of the openings, at expansion joints, at the parapet in increments of 30 cm and in the corners of the building. The minimum recommended depth for embedding the flexible Galen connection into the facing layer and into the load-bearing wall is 90 mm. If the horizontal seams of the outer and inner layers in which the connections are mounted do not coincide, then in the inner layer the connections are placed in a vertical seam with careful sealing of the seam with cement-sand mortar. The technology for installing flexible connections should exclude the possibility of their loosening. It is recommended to first install the thermal insulation layer and only then install flexible connections by laying them on the insulation board or piercing it through it. In the case of attaching insulation to previously installed flexible connections, before installing it, it is necessary to wait until the mortar sets in the masonry joints in which the connections are installed.

Difficult climatic conditions often require additional insulation of building structures and structures. When constructing brick buildings, multilayer systems are widely used.

To firmly and reliably fix the layers together, flexible brickwork ties are used. What is it, what materials are used for their manufacture and the specifics of using these elements - let’s look at them in more detail.

Features of fastening facing bricks to aerated concrete

Cladding a house made of aerated concrete with brick is the best finishing option, guaranteeing protection of aerated concrete from moisture and climatic factors. A cottage lined with ceramic bricks will last for decades without requiring investment in facade repairs. It is not difficult to cladding a house made of aerated concrete with bricks: the laying is done using the standard “spoon-poke” method. The difficulty arises when connecting an aerated concrete wall with a brick finish. Such a connection must be required, otherwise the cladding will simply be a free-standing wall erected near the aerated concrete masonry. In order for the structure to perform all the functions assigned to it, flexible but reliable connections are needed.

Advantages of facing aerated concrete blocks with bricks

Why do owners of private aerated block houses in Moscow and the Moscow region prefer ceramic bricks for cladding? This type of finishing has many advantages:

- attractive appearance and aesthetics;

- durability - lasts at least 50 years;

- effective protection of aerated concrete from moisture;

- additional heat and sound insulation;

- mechanical strength, absence of chips, cracks;

- maintainability, ease of maintenance of the facade;

Another plus is ease of installation. Unlike plaster, aerated concrete blocks covered with bricks do not require preliminary leveling, puttying, or priming. A layer of insulation can be laid between the aerated block wall and the brickwork, if this is feasible and provided for by the project. In the absence of insulation, the space is filled with air, which itself has good thermal conductivity.

Purpose of brick cladding for aerated concrete

Facing bricks in combination with aerated blocks perform two main functions that provide a comfortable microclimate in the house:

The thermal conductivity of aerated concrete D500 at a humidity of 5% is 0.112 W/m°C, ceramic brick - from 0.36 to 0.42 W/m°C. Facing aerated concrete with bricks helps retain heat inside the house and guarantees:

- absence of high humidity in the premises;

- absence of fungus and mold on the walls;

- long service life of interior decoration;

- no freezing of gypsum concrete even at extremely low temperatures.

Vapor barrier

Vapor barrier is the protection of aerated concrete blocks from steam penetration both from the inside and from the outside. Why is steam dangerous for aerated concrete? At certain temperatures, steam condenses into water, which is instantly absorbed by aerated blocks. Condensation occurs at the “dew point”. Ceramic lining allows you to “move” the dew point away from the aerated block, thus protecting it from getting wet. Ceramic brick has excellent vapor barrier properties. As a result of its use:

- aerated concrete walls are always dry;

- the house is warm and comfortable;

- heat is well retained and does not leave the house;

- heating costs are reduced.

In order for brick cladding to fully fulfill its functions, a stable connection between aerated concrete and brick is needed, which can be done in different ways.

Flexible connection methods for facing bricks and aerated concrete

The purpose of the flexible connection between brick and aerated concrete is to prevent destruction or deformation of the structure. To bind materials you can use:

- special drive-in anchors;

- flat “L”-shaped anchors;

- cup-washer type foundation anchors;

- reinforcement or ordinary nails.

Embedded anchors are installed at the stage of construction of the gas-block “box”. If they are not installed, then other fastening methods are used. Currently, few people use nails, reinforcement or foundation anchors. The simplest and most practical way to attach facing bricks to aerated concrete walls is using drive-in anchors.

Drive-in anchors for flexible connection between brick and aerated concrete

The anchor for a flexible ligament is a round rod 150-650 mm long with anchor parts at both ends. Products are manufactured in accordance with GOST R 54923-2012.

The advantages of such fasteners:

- mechanical strength combined with flexibility;

- excellent compensation and shock-absorbing properties;

- resistance to corrosion, aggressive environments, temperature changes;

- ease of installation and durability - lasts up to 100 years;

- low weight - does not weigh down the cladding and aerated concrete walls;

- prevent the appearance of cold bridges in the masonry.

Types of drive-in anchors - flexible connections

Manufacturers offer several types of rods:

Steel. They are made of stainless or carbon steel followed by galvanization. They have anti-corrosion properties and increased strength.

Basalt. They are characterized by high flexibility and thermal conductivity. They are used primarily in low-rise construction, because do not load the walls.

Fiberglass. Not subject to corrosion, durable. They are characterized by little flexibility and are only suitable for buildings on dense soils.

Size and number of anchors

Any of these flexible connections are suitable for cladding a house made of aerated concrete. The required size (length) of anchors can be calculated using the formula:

L = (60…150) + T + d + 90

where: L is the length of the anchor, 60...150 is the penetration of the product into the base, T is the thickness of the insulation (if any), d is the thickness of the air gap, 90 is the penetration into the cladding.

The number of anchors is calculated based on the consumption per 1 sq. meter of facing masonry. On average, 1 m⊃ requires 3-5 ties, plus additional ties at window and door openings, in the corners of walls.

Fastening brick cladding to aerated concrete blocks

The technology for creating flexible connections for facing bricks and aerated concrete depends on when the cladding is performed. There are two options:

The aerated block box is ready, the walls will be covered after some time. In this case, the order of operation will be as follows:

- On the load-bearing aerated concrete wall, the places where the rods will connect the blocks with the cladding are marked.

- Holes for the rods are drilled in the aerated concrete at the marked points.

- Anchors are installed in the holes.

- The cladding is laid and the anchors are sealed with mortar.

It is advisable, but not necessary, to install the rods so that the anchor fits into the joints of the brickwork.

Aerated concrete walls and cladding are erected simultaneously. In this case, the binding of materials is performed in this way:

- The gas-block and facing walls are erected to the same level.

- Flexible rods are laid on top of the walls at a selected pitch.

- The next row of blocks and bricks is laid on top of the ties.

To ensure that the anchors are attached as tightly as possible and do not move, you can use a reinforcing mesh. In both cases, before tying the aerated concrete wall to the cladding, it must be treated with impregnating waterproofing.

Creating a flexible connection between aerated concrete and brickwork is a process that requires care and precision. Only in this case will the cladding perform its intended functions and last for many years.

Metal flexible connections

Metal parts are widely used for reliable connection of load-bearing structures of walls with perpendicular partitions. They are made of stainless or galvanized steel wire.

The strength of the installation in the seams of the brickwork is ensured by the special shape of the elements: an L-shaped or wavy tip of a flexible connection, which is welded to a perforated plate.

Installation Features

If a load-bearing and facing wall is being built at the same time, the plate is installed in the masonry joint of the brick structure. In the case of cladding of an erected building, dowels are additionally used.

Holes are drilled in the load-bearing wall for them, then dowels are installed, and flexible connections for facing bricks are screwed inside.

Steel parts with dowels - photo

The manufacturer's instructions allow you to calculate the required number of elements at the design stage. It depends on the loads that the structure will experience.

In places that require special reinforcement: wall corners, window and door openings, the number of parts must be increased by 1.5-2 times compared to conventional masonry.

The selection of a flexible connection is made based on several points:

- Total thickness of the multilayer structure.

- Presence and width of the air gap.

- Type of thermal insulation material and its thickness.

In addition, to ensure a stable size of the ventilation gap, it is necessary to use special clamps that will reliably hold the thermal insulation layer.

Flexible connections for bricklaying are currently very diverse. The load-bearing wall can be made of wood, aerated concrete or brick. Depending on this, you should select exactly those fasteners that are intended for a given base. You can find out more information on the topic from the video in this article.

Previous articleDietary meat: product ratings and recipes

Next articleFeatures of nutrition according to blood type

Julia

Application area

Basalt-plastic anchors (flexible connections) with a diameter of 6 mm are intended for connecting the facing layer of brick to an internal wall made of porous material (aerated concrete). The main areas of application of basalt-plastic anchors are:

- two-layer structures (aerated concrete, brickwork);

- three-layer structures (aerated concrete, insulation, brickwork).

Advantages of basalt-plastic flexible ties

- High strength

- Long service life

- High energy efficiency of the building, deprivation of “cold bridges”

- Stabilization of heat and humidity operating conditions

- Ease of installation

- Reliability of connection of elements enclosing the structure

- Cost reduction

Analogs of flexible connections "Galen" are on sale

Installation diagram of flexible connection for aerated concrete

for flexible connection on hardened aerated concrete walls. Note: After installing the flexible connection into the aerated concrete block, its sand-coated end must be in the soluble seam of the facing layer!

drill diameter - 10 mm, hole depth - 100 mm

with an anchor in the finished opening

The anchor sleeve must be completely immersed in the aerated concrete block

attach insulation if necessary

Recommended embedment depth of flexible connection "Armplast":

- into a load-bearing wall - 90 mm;

- in the facing layer - 90 mm.

The number of connections depends on the project. Minimum number of products per 1 sq. m walls - 5 pcs.

Advantages of basalt-plastic fastenings for gas blocks

Advantages:

- No cold bridges. The structure with composite reinforcement is 100% sealed, providing a high level of energy savings with a minimum of costs. This is due to the low level of thermal conductivity of basalt plastic.

- Fastenings of this type are lightweight, which makes the entire structure lighter. Their use reduces the load on the foundation and eliminates problems during installation and operation.

- Basalt plastic is resistant to any negative influences, including chemically aggressive substances, and is not subject to corrosion.

- Long service life due to high strength.

Sizing

The length of the composite reinforcement rods is selected depending on the chosen method of installation of the cladding. There are four of them:

- close to the load-bearing wall (without a ventilation gap);

- at a short distance from aerated concrete walls (with a ventilated gap);

- using a heat insulator, which is mounted close to both layers;

- with a ventilation gap between the insulation and the brick.

If you plan to use insulation with gaps, you will need the longest rods. The appropriate size is calculated using the formula: 90 + T + 40 + 90, where:

- 90 - depth of screwing into the gas block, this size may be less, depending on the type of fastening;

- T is the thickness of the insulation;

- 40 - width of the ventilation gap between the insulation and the cladding;

- 90 is the depth of laying in the seam between bricks.

On sale you can find anchors made of composite reinforcement with a length of 150 to 450 mm. The diameter of the rods is 4 or 6 mm, thicker ones are chosen for cladding walls with a height of 12 m or more.

Marking

Anchors made of flexible composite reinforcement, intended for fastening bricks to aerated concrete, are marked as follows: BPA 250-6-P. Explanation:

- BPA - the material from which the connections are made - basalt-plastic reinforcement;

- 250 — length in mm;

- 6 - diameter in mm;

- P - sand coating.

End design options:

- 1P - plastic dowel sleeve on one side, sand on the other;

- 2P - two screw anchors with sand coating on both ends.

Installation

Work on creating cladding on top of aerated concrete blocks is carried out at an air temperature of at least 0C. The mounting kit includes a mounting key, a blower for cleaning holes, and plastic clamps for insulation. Installation procedure:

1. Mark the walls for drilling in increments of 500 mm in height and width. The rows are positioned strictly parallel to the future seams of the brickwork. Additional connections are installed at the corners, in the area of expansion joints, and along the perimeter of the openings. There must be at least 4 anchors per 1 m2 of wall.

2. Using a drill with a drill with a diameter of 10 mm, drill holes in the gas blocks. Their depth should be 10-15 mm greater than the length of the rod.

3. Use a blower to blow out dust from the drillings.

4. Insert the anchor to the full depth of the hole. If you select a type with a dowel sleeve on one side, then this is what is inserted into the aerated concrete.

5. Using a wrench, screw in the connections until they stop.

6. If installation of insulation is planned, then it is attached to the installed anchors and pressed with special plastic clamps.

7. Seal all cracks with sand-cement mortar.

8. You can start laying bricks only after the cement has dried, otherwise loosening is possible.

9. The free ends are laid in masonry joints. Minimum depth - 9 cm.

Installation of steel rods has some features. Perforated metal plates are placed in the masonry joints of the load-bearing and front walls, and the rods are welded to them. This method is used for parallel laying of aerated blocks and bricks. If an already constructed building is being clad, then holes for fasteners are drilled and dowels are inserted into them, then the ties are screwed in.

Prices

The cost of flexible ties for facing bricks depends on the manufacturer, material, type, length and diameter. They are sold in packs of 1000 pieces.

Approximate cost of a basalt-plastic anchor, rub/piece:

| Marking | Price |

| BPA-200-4-P | 4 |

| BPA-250-4-P | 5 |

| BPA-300-4-P | 6 |

| BPA-350-4-P | 7 |

| BPA-400-4-P | 8 |

| BPA-450-4-P | 9 |

| BPA-150-6-1P | 7 |

| BPA-200-6-1P | 9 |

| BPA-250-6-1P | 11 |

| BPA-300-6-1P | 13 |

| BPA-350-6-1P | 15 |

| BPA-400-6-1P | 16 |

| BPA-450-6-1P | 19 |

| BPA-200-6-2P | 11 |

| BPA-250-6-2P | 12 |

| BPA-280-6-2P | 14 |

| BPA-300-6-2P | 15 |

| BPA-330-6-2P | 16 |

| BPA-350-6-2P | 17 |

| BPA-400-6-2P | 18 |

Metal rods cost from 9 rubles/piece. You can buy fasteners for insulation separately at a price of 4 rubles.

Ties made of composite reinforcement or steel are necessary for reliable fixation of facing bricks to a load-bearing wall made of gas blocks. Anchors of this type are suitable for creating multi-layer insulation due to the possibility of installing insulating material (expanded polystyrene, mineral wool) and a ventilated gap.

UNIKMA offers BEVER fastening elements:

- For a brick base

- Flexible tie-anchor ZV-Welle

Material:

spacer-connecting element made of stainless steel and polyamide sleeve (included in the kit).

In the edge zones of the building façade (1m from the outer corner in each direction for low-rise construction), we recommend installing an additional 3 anchors per sq.m.Installation:

Drill a hole with a diameter of 10 mm and a depth of 60 mm in the load-bearing brick base. Remove drilling products from the hole. Install the dowel sleeve into the hole. Using a hammer and a special casing tool, drive the spacer-connecting element into the dowel sleeve.In assortment:

vendor code Name Dimensions, mm Gap, mm 13000 ZV-Welle 4.0 x 160 4.0 x 135 up to 25 13010 ZV-Welle 4.0 x 180 4.0 x 155 up to 45 13020 ZV-Welle 4.0 x 210 * 4.0 x 185 up to 75 13030 ZV-Welle 4.0 x 250 4.0 x 225 up to 115 13040 ZV-Welle 4.0 x 275 4.0 x 250 up to 140 13050 ZV-Welle 4.0 x 300 4.0 x 275 up to 165 13060 ZV-Welle 4.0 x 320 4.0 x 295 up to 185 13070 ZV-Welle 4.0 x 350 4.0 x 325 up to 215 13075 ZV-Welle 4.0 x 375 4.0 x 350 up to 240 13080 ZV-Welle 4.0 x 400 4.0 x 375 up to 265 *

- in stockFlexible anchor DA-Welle

Material:

spacer-connecting element made of stainless steel and dowel sleeve 6x50 (not included).

In the edge areas of the building façade, we recommend installing an additional 3 anchors per sq.m.Installation:

Drill a hole with a diameter of 6 mm and a depth of 60 mm in the load-bearing brick base. Remove drilling products from the hole. Install the dowel sleeve into the hole. Using a hammer and a special casing tool, drive the spacer-connecting element into the dowel sleeve.In assortment:

vendor code Name Dimensions, mm Gap, mm 13200 DA-Welle 3 x 160 3.0 x 135 up to 35 13210 DA-Welle 3 x 180 3.0 x 155 up to 55 13220 DA-Welle 3 x 210 3.0 x 185 up to 85 13240 DA-Welle 3 x 250 3.0 x 225 up to 125 13250 DA-Welle 3 x 275 3.0 x 250 up to 150 13260 DA-Welle 3 x 300 3.0 x 275 up to 175 13300 DA-Welle 4 x 160 4.0 x 135 up to 35 13310 DA-Welle 4 x 180 4.0 x 155 up to 55 13320 DA-Welle 4 x 210 4.0 x 185 up to 85 13340 DA-Welle 4 x 250 4.0 x 225 up to 125 13350 DA-Welle 4 x 275 4.0 x 250 up to 150 13360 DA-Welle 4 x 300 4.0 x 275 up to 175 13370 DA-Welle 4 x 350 4.0 x 325 up to 225 13380 DA-Welle 4 x 400 4.0 x 375 up to 275

- For installation in masonry joints

- Flexible Well-L connection

Material:

stainless steel element.

In the edge zones of the building façade (1m from the outer corner in each direction for low-rise construction), we recommend installing an additional 3 anchors per sq.m.Installation:

Placed in the seam during laying of the load-bearing wall, the end is not bent. The depth of laying in the load-bearing and facing masonry is 50 mm.In assortment:

vendor code Name Dimensions, mm Gap, mm 10600 Well-L 3.0 x 225 3.0 x 200 up to 100 10610 Well-L 3.0 x 250 3.0 x 225 up to 125 10620 Well-L 3.0 x 275 3.0 x 250 up to 150 10630 Well-L 3.0 x 300 3.0 x 275 up to 175 10640 Well-L 3.0 x 340 3.0 x 315 up to 215 10650 Well-L 4.0 x 225 4.0 x 200 up to 100 10660 Well-L 4.0 x 250 4.0 x 225 up to 125 10670 Well-L 4.0 x 275 4.0 x 250 up to 150 10680 Well-L 4.0 x 300 4.0 x 275 up to 175 10690 Well-L 4.0 x 340 4.0 x 315 up to 215 Flexible Multi connection

Material:

stainless steel element.

In the edge areas of the building façade, we recommend installing an additional 3 anchors per sq.m.Installation:

Placed in the seam during the laying of the load-bearing wall. The depth of laying in the load-bearing masonry is 90 mm and the facing masonry is 60 mm each.In assortment:

vendor code Name Dimensions, mm Gap, mm 11451 Multi 250* 250 up to 100 11461 Multi 280 280 up to 130 11471 Multi 300 300 up to 150 11481 Multi 320 320 up to 170 *

- in stockFlexible Multi-Plus communication

Material:

stainless steel element.

In the edge areas of the building façade, we recommend installing an additional 4 anchors per sq.m.Installation:

Placed in the seam during the laying of the load-bearing wall. The depth of laying in the load-bearing masonry is 90 mm and the facing masonry is 50 mm each.In assortment:

vendor code Name Dimensions, mm Gap, mm 13490 Multi Plus 280 280 up to 130 13500 Multi Plus 300 300 up to 150 13510 Multi Plus 320 320 up to 170 13520 Multi Plus 340 340 up to 190 13530 Multi Plus 360 360 up to 210 Flexible DUO connection

Material:

the element is made of stainless steel and consists of two parts - a flat perforated tape and a wire with a bend at the end on one side and an S-shape on the other

In the edge areas of the building façade, we recommend installing an additional 3 anchors per sq.m.Installation:

A flat perforated strip is laid into the masonry joint of the aerated concrete masonry.In assortment:

vendor code Name Dimensions, mm Gap, mm 15010 DUO 113 113 up to 60 15020 DUO 133 133 up to 80 15030 DUO 153 153 up to 100 15040 DUO 173 173 up to 120 15050 DUO 193 193 up to 140 15060 DUO 213 213 up to 150

Facing brick is the most durable and reliable finishing material of all used in construction.

At the same time, it cannot be used as the main material, which creates certain difficulties when laying it on an insulated wall with the formation of a ventilation gap.

There is a need for a mechanical connection of the facing layer, otherwise there will simply be a free-standing half-brick wall.

If construction is carried out without external insulation, the outer layer is bandaged with interlocking bricks, periodically laid through a certain number of rows.

The situation with an insulated wall is more complicated.

The layer of material completely cuts off the inner and outer parts of the walls, creating difficulties in bonding.

The design of the bundle in such cases is a rod passing through the insulation into the wall, the other end of which is laid between the rows of cladding.

Previously, either a metal mesh or (most often) anchors made of thin reinforcement were used to connect the facing layer and the wall. This technique had a negative property - since only the outer layer heats up or cools down, its dimensions are subject to constant changes.

This leads to constant movement of the rods, gradually loosening the sockets and reducing the strength of the fastening. Ultimately, the bundle simply lost its mechanical qualities, since the rods did not stay in the wall.

The solution to the problem was flexible connections with some elasticity

. They are capable of changing the direction vector of the rod without destroying the strength of the fill. An anchor-type fastening is made into the wall - when screwed, the rod increases in diameter and is firmly fixed in the socket.

The second end is laid between the rows, connecting the layers. In addition, to seal the insulation material, there is a special plastic washer that presses the insulation to the wall. It does not allow the material to lag behind the wall, eliminating sliding or other deformation.

This type of connection reacts to movements of the outer facing layer with some displacement without weakening the rigidity of the connection with both layers - the main wall and the cladding, which greatly increases the service life and solves the problems of rigid connections.

The material used for the manufacture of flexible connections is stainless steel or a newer development - composite polymer materials:

- Basalt plastic.

- Fiberglass.

Having optimal properties, these materials do not change their properties at all throughout their entire service life and provide high-quality connection of three-layer wall structures. The rods have an external coating of sand with thickenings at the ends, which significantly enhances adhesion to the sand-cement mixture.

Polymer materials do not create cold bridges, promoting more efficient heat conservation and increasing the service life of wall materials.

All the secrets of the correct choice of flexible connections for facing bricks

Flexible connections for facing bricks are a necessary part in construction. What they serve for and in what cases they are used, as well as find out the types and technical characteristics of the material, choose the ideal option for a particular design, you can carefully study the article, which describes in as much detail and clearly as possible all the information about the modern method of fastening the cladding.

What are flexible connections: application

Flexible connections for facing bricks and aerated concrete are an important stage in construction and finishing; thanks to them, the facing structure is mounted and sound and noise insulation is secured. Their use increases the service life and quality.

Currently, flexible connections are made from basalt plastic using innovative structuring, which includes basalt, and a substance of organic origin acts as a connection. The product is 100% environmentally friendly and does not require large and irreversible costs of a valuable resource. Due to the use of this particular material, the design has a high resistance to temperature changes.

The diameter of such structures reaches 6 mm. Due to the use of modern technologies, the material guarantees the strength and reliability of fastening small elements.

Domestic manufacturers make ties for facing bricks in the form of long rods with a round cross-section; for fastening they are equipped with a screw anchor and are also covered with sand, thanks to this, manufacturers have achieved maximum adaptability to all types of composition for laying bricks.

Flexible connections for facing bricks are usually referred to as BPA-300-6. For those who rarely come across construction terms, here is a transcript:

- BPA – basalt-plastic reinforcement;

- 300 is an indicator of the length of a certain anchor;

- 6 – indicates the diameter of a specific rod.

The last two indicators may be different, it all depends on the flexible connection model.

Marking and types of basalt plastic rods

Before purchasing connections, you need to decide whether the cladding will be with or without insulation (their length depends on this), and pay attention to the designations.

For example, BPA 200-6 Aerated concrete; BPA 20-6-2P.

- BPA – basalt-plastic reinforcement;

- 200 – rod length;

- 6 – its diameter;

- Aerated concrete – designed for installation in aerated concrete structures.

- 2P – two sand anchors.

In the first case, the marking indicates that the connection has a plastic anchor sleeve, and in the second, that instead of a sleeve, sand coating is used on both sides. Rods with anchors are more popular.

You can select the required length of bonds (L) using the following calculation:

L=90 mm+T+40 mm+90 mm.

The first 90 is the depth of the hole in the wall made of aerated blocks, usually this is the length of the anchor sleeve at the end of the pin, which is completely immersed in the block.

T is the thickness of the insulation used.

40 is the width of the air gap; it is left for natural ventilation to avoid condensation settling on the insulation, which contributes to its freezing and deterioration of the thermal insulation properties.

Types and technical characteristics

The following types of flexible connections are found on construction sites:

- Basalt rods. The material is characterized by relatively low weight, but at the same time has a predisposition to high loads. In construction stores you can find both foreign and domestic manufacturers.

- Steel connections. Thanks to modern technologies, manufacturers have managed to create rods from hydrocarbon steel; the material differs from its predecessors in its high level of endurance and protection against corrosion, to which most metals are susceptible. Products produced by the German company Bever are popular. To prevent rust, the material is pre-treated with a specialized zinc solution.

- Fiberglass rods. It has characteristics similar to basalt bonds, but is somewhat inferior to them. Positive properties include rod stretching and corrosion protection, but manufacturers had to sacrifice elasticity.

- Metal. Made from stainless steel. They are in no way inferior to their competitors on the market. Due to the composition they have good protection against corrosion.

Unlike other materials, metal rods have the ability to form freezing areas, which brings a lot of inconvenience, so such connections are used exclusively in tandem with insulation.

The technical characteristics of aerated concrete directly affect the installed connection. So for concrete with a density of 400, 500 and 600, a connection with the following characteristics is necessary:

- Pullout strength – 2500 N, 3000 N, 400 N;

- Bending stress – 1000 MPa, 1000 MPa, 1000 MPa;

- Tensile stress leading to failure – 1000 MPa, 1000 MPa, 1000 MPa.

Types of flexible connections

Basic elements of flexible connections.

Today the following varieties of these elements are known:

- Basalt plastic rods. The most common type at present. The problem of “cold bridges” is completely eliminated by an important characteristic - a low thermal conductivity coefficient (0.46 W/m°C). A high degree of fire safety (withstands heating up to +700° C), high bending strength (1000 MPa) and a pull-out force of 12,000 N - all this makes flexible connections of this type indispensable for high-quality bricklaying.

- Stainless steel rods. They have less flexibility than basalt-plastic analogues - no more than 550 MPa. Sufficiently elastic (200 GPa). Disadvantages include a high degree of thermal conductivity and electrical conductivity. Often used when installing thermal insulation and ventilation ducts in monolithic building structures.

- Carbon steel rods. They are characterized by a tensile strength of 550 MPa and an elasticity of 200 GPa. Since the material from which such rods are made is classified as ferromagnetic, the presence of carbon flexible bonds can cause the occurrence of magnetic fields. To prevent corrosion, elements of this type must be coated with a special anti-corrosion compound.

- Fiberglass rods. Very tensile strength (1000 MPa). Thanks to the use of composite components, flexible connections of this category guarantee the absence of magnetic fields and stray currents harmful to humans in the walls and around them. Fiberglass anchor rods have low thermal conductivity, which generally improves the thermal insulation performance of the entire house.

How to choose flexible connections for facing bricks and aerated concrete

Fastening rods have gained popularity due to their long service life, as well as the relatively low cost that distinguishes products from domestic manufacturers.

Construction professionals have developed a special formula thanks to which even beginners will be able to accurately select a flexible connection with a ventilated gap and the necessary characteristics important for a particular finishing material.

To do this, you need to know 4 main indicators:

- Rod length. Experts recommend using 90 mm in almost all cases;

- The thickness of the insulating layer is calculated individually and depends on the selected material;

- The size of the air gap. Most often - 40 mm;

- Embedment depth. According to professionals, it is better to take an anchor - 90 mm.

If ventilation is not included in the design plan, then this item is discarded in the formula.

Fasteners for aerated concrete walls. Methods of fastening the cladding. Flexible connections

Today, three types of fasteners are common in the field of low-rise construction: nail pair, Fischer dowel FTP, Sarmat KBT and Fischer dowel GB.

A nail pair consists of two 120 mm nails, which are driven into aerated concrete directly through a block or through a 40 mm thick support bar. The angle between the nails should be approximately 45-50 degrees. Such fasteners can withstand pull-out forces of over 100 kg.

Fischer dowels are installed in a pre-drilled hole: the FTP is screwed in, and the GB is simply driven in with a hammer. The fastener is reliable even when using aerated concrete D300 B1.5 and is 60 kg per tear.

All of the listed types of fasteners are common in stores and have widely proven themselves in practice.