If you have built a concrete well on your plot of land, it would be a good idea to think about protecting it. After all, the constant presence of water inside, as well as groundwater, can adversely affect the strength of the walls of an underground tank. How is a concrete well waterproofed? What materials are used for this? The answers will be found in this article.

Why do you need to protect wells from water?

There are several reasons for this, and they depend on the purpose of the well. Drinking wells must be treated with waterproofing materials. After all, these are sources of water that they drink and cook food from. Therefore, the water there should be crystal clear.

But groundwater washing the outer walls of wells is destructive. Cracks appear in the concrete rings of the reservoir, and everything that flows along with the groundwater - clay, feces, herbicides settled in the soil, nitrates, organic decomposition, salts, oil products - gets inside and pollutes the source of drinking. Such water cannot be saved either by filtration or boiling.

Using water contaminated with hazardous substances is strictly prohibited.

If the container is built for technical purposes, there should be no moisture in it at all. After all, there are taps, pipe branches, and other communications. Dampness and moisture in such wells will lead to the development of corrosion, rot, and, as a result, to the destruction of the walls of the structure. Therefore, technical concrete wells must be waterproofed.

If the well is built for sewerage, waterproofing is used to prevent waste from escaping through the walls of the sewer mini-pool and to protect the water from contamination.

Return to contents

Types of compositions

- "Penetron". The mixture is applied directly to the surface of the structure from the inside. A protective layer is formed that prevents moisture from penetrating into the concrete.

Penetron - 5 kg bucket

Price: 1750 rub.

Order Product Description

Penetron - 25 kg bucket

Price: 7875 rub.

Order Product Description

Penetron - 10 kg bucket

Price: 3500 rub.

Order Product Description

- "Penecritus." The material is used to waterproof wells at joints, cracks, seams, junctions, and utility lines. The composition is characterized by plasticity, shrinkage, and water resistance. The mixture has high adhesion to concrete, stone, brick and metal substrates.

Penecrit - 5 kg bucket

Price: 1500 rub.

Order Product Description

Penecrit - 25 kg bucket

Price: 6375 rub.

Order Product Description

Penecrit - 10 kg bucket

Price: 3000 rub.

Order Product Description

- "Penebar". The waterproofing is a bentonite strand of rectangular cross-section. When processing concrete structures it is used as a gasket.

Penebar 5 meters

Price: 1500 rub.

Order Product Description

Penebar 30 meters

Price: 9000 rub.

Order Product Description

Application area

Waterproofing of sewer wells and drinking decks is possible due to the characteristics of waterproofing compounds. The mixtures are certified and can come into contact with water intended for drinking. After treatment, concrete structures become resistant to the aggressive effects of alkalis, acids, wastewater and groundwater.

Waterproofing wells from outside

For external protection of wells, roll insulators, bitumen mastics, cement mortars, and impregnating materials are used. Let's look at some of them in more detail.

Return to contentReturn to content

Carrying out work

Waterproofing wells from the outside.

External waterproofing is carried out in multilayers with the additional use of polyester fibers and non-woven reinforcing mesh. It is better to carry out waterproofing during the construction of the well in order to avoid additional labor costs for digging the ground and cleaning the walls of the mini-pool from contamination. But it is possible to protect a functioning well from further destruction. To do this, the earth is dug to the entire depth of the structure so that there is access to its walls from all sides.

The loose part of the concrete coating is beaten with a hammer. If the fittings become visible, they also need to be cleaned of corrosion and coated with an anti-corrosion agent. All well rings are washed and cleared of moss, mold, and other contaminants. Chisels, metal brushes, spatulas, and drill bits are useful for this. After the structure has dried, clean the walls again. Then begin the waterproofing process.

Return to contents

Application of roll waterproofing

First, go over each ring with primer. This will provide excellent adhesion between the waterproofing materials and the walls of the well. When the primer has dried, examine the walls for damage, cracks, or chips. If any are present, cover them with a thick cement-sand mortar with the addition of PVA glue. This mortar sets faster than a simple cement mortar. Using the solution, bring the surface of the mini-pool to a perfectly smooth state. After the cement layer has dried, go over it again with a primer.

Next, apply tar or bitumen mastic to the walls. Some craftsmen prefer the first option, arguing that the bitumen mixture may crack. Glue roofing felt or other waterproofing material on top of the mastic in several layers. The joints between strips of material are also coated with mastic.

Return to contents

Materials

A variety of materials are used to waterproof wells.

Polyurea

Polyurea is an excellent waterproofing agent, but it is applicable exclusively for the outer surface of the well.

This substance belongs to a group of organic polymers that are obtained from polyester amine and isocyanate resins. The result is a substance very similar to hard rubber or plastic. This composition is highly resistant to moisture , so it effectively protects concrete from the penetration of groundwater. According to SNiP requirements, water wells can be waterproofed with polyurea only from the outside . Spraying of this composition is carried out using special equipment that ensures proper mixing of the components and the required pressure.

Liquid glass

At the construction stage, external waterproofing of a well from concrete rings with liquid glass is quite often carried out. The use of this material allows you to create a protective layer that is very resistant to aggressive environments and mechanical damage . In some cases, liquid glass is used in its pure form for waterproofing, but more often it is added to the cement mortar that covers the surface of the rings. This type of plaster must be applied in a single layer, since a large number of joints can greatly deteriorate the quality of the coating.

Roll materials

This type of waterproofing materials is also used only to protect the outer surfaces of concrete rings. The use of this waterproofing allows you to provide high-quality results for a fairly long period.

This category includes:

- glass ruberoid . This material is also called stekloizol or steklomast. It is obtained by applying bitumen impregnations to fiberglass canvas. The service life of glass roofing felt is approximately 25-30 years;

- hydrosol _ This type of insulation is obtained by impregnating the asbestos base with petroleum bitumen. The top of the roll is covered with protective polymer films, which melt when heated during the laying process. The result is a waterproof waterproofing material with high tensile and tear strength. Such waterproofing can last up to 15 years;

- foilbitep . The basis of this roll material is corrugated aluminum foil, impregnated on both sides with a polymer-bitumen composition. Foilbitep is glued onto the concrete base using the fusing method. Its service life is approximately 20 years.

Rolled waterproofing materials for external use are extremely difficult to install after loading concrete rings into the pit

Polymer-cement compositions

This group of materials is characterized by ease of application and fast curing. Polymer-cement compounds form a very strong moisture-proof barrier on concrete surfaces, so they are mainly used for sealing joints. service life (from 30 years) compared to organic waterproofing materials .

For modern waterproofing they use:

- film polymer-cement compositions. Vinyl acetate or synthetic resins are used as the basis for these materials;

- penetrating polymer-cement compositions. To make these materials, cement, sand and a number of chemically active additives and substances are used, such as latex, synthetic resins, polyurethane and epoxy emulsions, polyester, glass and basalt fiber. Penetrating waterproofing protects the concrete base from weathering and other weather-related damage, and also prevents oxidation of the reinforcement. Most often, a penetrating solution such as Penetron is used to treat the surface of concrete rings.

Coating waterproofing

This category includes various types of waterproofing compounds. Each of them is prepared according to the manufacturer’s instructions, and then applied to the surface with a spatula or any other similar tool. The composition of isolants varies depending on the purpose and brand of the product , but they are all made from safe components that do not pose a threat to the environment or human health. This insulation dries quickly and provides a very high level of protection against moisture.

The most popular coating material is Aquastop waterproofing. It is available in powder or mastic form. When interacting with water, the powder forms a dense waterproof film. The mastic has a thick consistency and can be applied to the concrete surface using a spatula. It can be diluted with water to cover the first (primer) layer. Aquastop mastic, diluted with water, is applied with a roller or brush . After complete hardening, waterproofing becomes like rubber and has many advantages over other materials.

Impregnation of walls

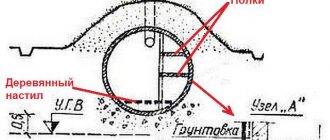

External waterproofing scheme.

Here, after cleaning, the walls are not primed. They need to be moistened, soaked in a deep penetration waterproofing liquid, treated with the same product again, and left for four days. You can prevent the liquid from spreading during drying by constantly moistening the impregnated surface. And also make sure that there is no mechanical damage to the impregnation.

External waterproofing is carried out along the entire height to the upper edge of the wells. When filling a hole, a sand and gravel mixture is used, mixed with soil, which is thoroughly compacted during the process.

Return to contents

Alternative methods for filling holes in a well

Waterproofing seams can be done using:

Well sealing scheme

- Painting. The paint composition is made from gasoline and bitumen in a 50/50 ratio. The composition is applied in 2-3 layers to damaged seams. If it is not possible to get gasoline, then the seams can be sealed with molten bitumen;

- Impregnation for concrete rings – “Eklakor-PU Ground – 2k/50”. The product is applied to a damp surface in several layers at intervals of 5 minutes. Then the impregnation is regularly wetted for 72 hours with an ordinary sprayer;

- QAUAFIX is a substance consisting of cement and active polymers. In common people it is better known as a cheap analogue of “hydraulic plug”. QAUAFIX is designed for waterproofing concrete rings inside and outside the well. Mix the mixture in a ratio of 4 portions of QAUAFIX and 1 portion of water, then cover the hole.

Internal waterproofing

Here we use environmentally friendly two-component cement-polymer products that do not have any harmful chemical effects on drinking water. Therefore they are safe for people. Similar products include the compositions AQUAFIX, MEGACRET-40, AQUAMAT-ELASTIC.

Carrying out work

If we are talking about a functioning well, then first you need to pump water out of it to the very bottom, and until the end of the work, make sure that the water level does not rise. Next, check and eliminate weak points, clean the walls from various contaminants. Clean up damaged concrete. Cut cracks up to 25 mm deep, then clean them with a metal brush.

The seams between the well rings are cut to a depth of 30 mm. If a leak forms during this time, it is immediately sealed with the AQUAFIX “hydraulic plug” mixture. Using the MEGACRET-40 repair mixture, cracks and potholes are filled and the inner surface of the well is completely leveled. Then you need to wait until this layer completely hardens.

Next, the pre-moistened walls inside the well are coated with AQUAMAT-ELASTIC waterproofing solution. This product must be diluted to such a consistency that it can be easily spread with a wide brush. In this case, the brush is directed from bottom to top. This product is applied in two layers. Before applying the second ball, you should wait until the first one dries. Complete hardening of this solution occurs in about two days.

Return to contents

Waterproofing seams

Waterproofing seams.

When waterproofing wells, you should not forget about the joints between the rings. In this case, craftsmen use two-component products designed to seal well rings.

Separately, you need to take care of waterproofing internal seams. Solutions designed for this can be purchased at hardware stores. The product is applied and leveled with a spatula. In sewer and technical pools, the seams between the rings are treated with liquid rubber or liquid glass. These products provide increased waterproofing of the object.

Seams are also protected from the effects of water in wells by applying special cement-polymer mixtures or by applying cement mixed with PVC glue . You need to dilute the cement in the glue gradually, bringing the solution to the consistency of very thick sour cream.

Return to contents

Do-it-yourself internal waterproofing of a well made of concrete rings

It is possible to protect the structure from the penetration of contaminants not only from the outside, but also from the inside.

To work, you will need antiseptic agents for treating the internal walls and means for sealing joints.

Attention : If water from a well is used for food purposes, then it is not worth treating its interior with chemicals.

Process:

- The liquid is pumped out using a pump or manually.

- Give the structure time to dry.

- Carefully check the links for unevenness and other defects.

- If flaws are found, they are repaired using a special solution.

- The seams are treated with liquid glass.

- The coating and joints are treated with an antiseptic substance.

Bottom insulation

During construction, a special slab with a protrusion is placed at the bottom of the concrete well, ensuring accurate alignment of the lower ring. The resulting joint is carefully sealed. This is done in several ways:

- Before installing the first ring, a special waterproofing cord is placed in the place where the well will stand, which swells several times as humidity increases, thereby insulating the bottom of the well.

- Rolled waterproofing materials are also effective here. The bottom of the well is thoroughly cleaned of dirt and debris, filled with bitumen mortar, and covered with roofing felt with a 20-centimeter overlap on the walls. To ensure that the bottom of the well is protected, roofing felt is placed in several layers. Additionally, it is recommended to coat the top layer of roofing felt with mastic and pour a 10-centimeter ball of gravel on top.

- In drinking pools, the seams between the bottom and the first ring are covered with MEGACRET-40 repair mixture. When the first layer is applied, waterproofing tape should be applied to it. Finally, the joint in two layers is treated with AQUAMAT-ELASTIC.