Owners of country houses are installing an autonomous sewage system to remove sewage and sewage. The most common option for constructing a treatment plant is a septic tank made of concrete rings, the installation of which can be done by yourself. Whether the septic tank can handle large volumes of waste and prevent soil contamination depends on how competently the concrete rings are installed.

Installation from reinforced concrete is possible if the groundwater level is below the level of the septic tank.

Design and principle of operation

A septic tank is a structure designed to clean sewage that is formed as a result of using a bathtub, washing machine, dishwasher and, of course, toilet. It is a structure made of several tanks connected by pipes at a certain height so that water entering the septic tank can flow from one chamber to another. Typically this structure has two or three chambers - their number often depends on the volume of drainage. In this case, as a rule, one of the sections of the septic tank is a filtration well, where an additional cleaning process takes place and the liquid is discharged into the environment.

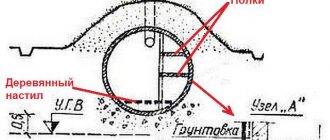

Diagram of a septic tank made of concrete rings

The principle of operation of a three-chamber septic tank is as follows: wastewater, flowing through the drainage sewer pipe, enters the first chamber, where the primary stage of purification occurs - large inclusions, according to the laws of gravity, begin to settle to the bottom of the tank. Further, as the chamber is filled, partially purified water passes through a pipe located at a certain level (but located lower than the inlet pipe) into the next chamber - the secondary settling tank. There it settles further, and some of the lighter particles also have time to settle to the bottom.

On a note! Additionally, anaerobic bacteria can work to purify the water in the second purification chamber, which process pollutants. For them, this is their favorite “delicacy.”

Anaerobic bacteria

The third chamber is a filtration well, which, unlike the previous two, has a bottom that is not sealed, but through, but covered with sand and crushed stone. The liquid begins to seep and go into the ground, further purifying itself in this layer. Such a septic tank, one might say, does not need pumping, since the water goes into the soil layers on its own. But still, every few years it is necessary to remove sediment deposited at the bottom from it. Vacuum trucks are called for this purpose.

A septic tank consisting of two compartments works on the same principle, only the water after the first chamber immediately enters the drainage well and goes into the ground. By the way, soil purification can also be carried out on filtration fields or using biofilters, and not only in filter wells.

Scheme of a two-chamber septic tank made of concrete rings

What are the benefits of septic tanks made from concrete rings?

One of the most common and inexpensive ways to build a septic tank with your own hands is to make it from concrete rings. Such rings come in different sizes, and can also have additional parameters - a certain thickness, the presence of holes in the walls, etc. In addition to these products, round bottoms and covers are also produced, in which a hole is provided for installing a hatch.

Concrete rings have many advantages

Table. Types of concrete rings.

| View | Characteristic |

| Auxiliary | Such rings are also called additional rings. They are used only in situations where standard parameter rings are not suitable. Such designs are made to order. |

| Reinforced concrete | Ideal for use when installing wells and other various communications. For example, they make excellent drainage wells, water canals, gas pipelines and others. |

| Wall | A neck can be formed from such rings during the construction of a septic tank. They are used for the manufacture of the upper part of any types of communications and wells. |

| Other types | Prefabricated, closed with a bottom, with ceilings, with a lock, etc. |

Types and sizes of concrete rings

A septic tank made of concrete rings is a time-tested design. But during installation you will have to work hard. Most likely, to install the rings in the pit prepared for the septic tank, you will have to call in special equipment - a truck crane. It is very difficult to move such structures on your own - they have considerable weight. There are, of course, options for installing and digging reinforced concrete rings into the ground without the use of machinery, but the problem is that the ring itself is, nevertheless, quite fragile. If such an element is dropped even from a small height, it can easily break.

The ring is lowered using special equipment

The disadvantage of using concrete rings as the basis for a septic tank is the need for a large space. In a small area, it is unlikely that such a design will be implemented in compliance with all rules and regulations. Also, when building a septic tank from concrete rings, great attention should be paid to sealing seams and joints. “You can see how to pour a concrete septic tank with your own hands in our article.” The advantages of a septic tank made of reinforced concrete rings are as follows:

- these structures are not afraid of exposure to aggressive chemicals that enter the drain. And the waste water itself is far from having the most harmless composition;

- such a septic tank will not be afraid of temperature changes;

- the structure will cope perfectly with the unexpected influx of large volumes of water.

On a note! When choosing rings for a septic tank, it is best to choose those that have fittings inside. Such rings are much stronger than ordinary concrete ones and will last as long as possible.

Installation of a septic tank from reinforced concrete rings

Main types of reinforced concrete rings for sewerage, sizes, prices

Manufacturers produce different types of rings. Each type of product has its own parameters and specific purpose.

Buyers can buy reinforced concrete rings for sewerage of the following types:

- elements without a lock;

- filtration parts;

- elements with a solid bottom;

- components with a locking connection or with a quarter.

Dimensions of reinforced concrete rings for sewerage

How much do concrete rings for wall-type sewerage without a lock cost?

Wall rings for septic structures without a lock are considered the working part of the storage system. This section of the sewer system is formed from three elements, including wall, support and additional type products. The dimensional parameters of the rings, as well as their number, are selected in accordance with the design data. Manufacturers mark products of this type with a combination of the letters “KS”.

Sales price of concrete rings for wall-type sewerage without a lock:

| Product name KS | Diameter, mm | Height, mm | price, rub. |

| 7-3 | 700 | 290 | 675 |

| 7-6 | 700 | 590 | 1050 |

| 7-9 | 700 | 890 | 1275 |

| 10-8 | 1000 | 800 | 1520 |

| 10-9 | 1000 | 900 | 1650 |

| 15-9 | 1500 | 900 | 2570 |

Straight rings without a lock are installed one on top of the other. The joints are treated with cement mortar, which fixes these elements. It is allowed to use special brackets to secure these rings.

Buying sewer rings: how much do products with locking joints cost?

Quarter or locking rings greatly simplify the well assembly process. The result is a tight and reliable connection of parts without additional treatment of the seams using sealant. In addition, the special structure of these elements allows for compact storage of products on the construction site.

Special recesses are formed in the lower part of these parts. There are protrusions at the top of the rings. This specific structure allows the elements to be placed on top of each other during installation. As a result, the rings are securely fixed using a locking connection, eliminating the possibility of the septic tank structure moving or shifting. After installation, the elements will maintain their original position throughout their entire service life.

Cost of concrete rings for sewerage: prices for products and a quarter:

| Product name KS h | Diameter, mm | Height, mm | price, rub. |

| 7-3 | 700 | 300 | 530 |

| 7-5 | 700 | 500 | 710 |

| 7-6 | 700 | 600 | 755 |

| 7-10 | 700 | 1000 | 1130 |

| 8-3 | 800 | 300 | 700 |

| 8-5 | 800 | 500 | 1125 |

| 8-10 | 800 | 1000 | 1370 |

| 10-3 | 1000 | 300 | 715 |

| 10-5 | 1000 | 500 | 955 |

| 10-6 | 1000 | 600 | 980 |

| 10-9 | 1000 | 900 | 1375 |

Important! High-quality installation of rings with recesses is only possible if the dimensions of the products exactly match. To avoid such difficulties, it is recommended to purchase products from a manufacturer that adheres to regulations.

Assortment of reinforced concrete rings for sewerage: prices for filtration products

Filtration rings for the construction of septic tanks are concrete elements covered with perforations. In other words, the surface of the product is covered with many holes of the same size. They are evenly distributed around the perimeter of the ring at an equal distance from each other. Through these holes, water purified in the septic tank enters the soil. Based on these elements, filtration wells for sewage are constructed.

To fix the drainage rings, special H-shaped fasteners are used. They are made of metal and reliably fix structural elements in case of soil movement. To secure a pair of rings together you will need about 3-4 fixing elements.

Average price of reinforced concrete rings with perforation:

| Product name KS | Diameter, mm | Height, mm | price, rub. |

| 7-9 | 700 | 890 | 2410 |

| 10-9 | 1000 | 890 | 2520 |

| 15-6 | 1500 | 590 | 3255 |

| 15-9 | 1500 | 890 | 3730 |

| 20-6 | 2000 | 510 | 5180 |

| 20-9 | 2000 | 890 | 6250 |

At what cost can you buy reinforced concrete rings for sewerage: prices of products with a solid bottom

Well elements with a solid bottom in the form of rings are used for the construction of sedimentation tank structures. In this part of the sewer system, sludge gradually accumulates during operation, which can be removed using a fecal pump for sewage in a private house or special equipment equipped with equipment with similar functionality.

This type of product is considered by experts as the most optimal option for the construction of an autonomous and overflow sewer system for wastewater treatment.

Average cost of concrete rings for sewers with a solid bottom:

| Product name KCD | Diameter, mm | Height, mm | price, rub. |

| 7-3 | 700 | 300 | 1075 |

| 7-5 | 700 | 500 | 1115 |

| 7-6 | 700 | 600 | 1195 |

| 7-9 | 700 | 900 | 1289 |

| 7-10 | 700 | 1000 | 1289 |

| 8-6 | 800 | 600 | 1215 |

| 8-9 | 800 | 900 | 1289 |

| 8-10 | 800 | 1000 | 1420 |

| 10-3 | 1000 | 300 | 1200 |

| 10-5 | 1000 | 500 | 1289 |

| 10-6 | 1000 | 600 | 1545 |

| 10-9 | 1000 | 900 | 1610 |

| 10-10 | 1000 | 1000 | 1740 |

Note! Markings on concrete products reflect their characteristics. For example, KS 20-9 means that the element belongs to the category of concrete wall rings, its diameter is 2000 mm and its height is 900 mm.

We calculate the sizes

Calculating the dimensions of the future structure is an important point in the design of a structure. The parameters of the space occupied, as well as the amount of materials needed, will directly depend on this. The first step is to calculate the volume of the septic tank, which depends on the volume of wastewater, which, in turn, depends on water consumption. On average, a person uses about 200 liters of water during the day. This means that a family of three will spend 600 liters per day. However, according to the standards, the septic tank must be three times larger in volume. This means it must contain at least 1800 m3 of liquid.

Now we need to calculate the internal volume of one concrete ring. It is easier to figure it out using the formula for the volume of a cylinder. This is V = 3.14*D3*H/4 , where H is the height of the structure, D is its internal diameter, and V is the volume required for further calculations. Let's say the ring has a diameter of 1 m. Then its volume will be equal to 0.79 m3. In this case, the height of the ring does not need to be measured - this is a standard value and is equal to 1 m. Although sometimes there are rings with a height of 0.9 m on sale. Additional rings can have very small dimensions.

Two-chamber septic tank, connected to the toilet

Attention! When making calculations, it is important to remember that the last, upper ring should never be filled entirely with liquid, but only 1/3. Thus, the working volume of the upper ring is 0.79/3 = 0.26.

Based on the calculations described above, you can deduce the number of rings that need to be purchased. Thus, one section of the septic tank will need 3 rings. To build a structure of three chambers, 9 reinforced concrete rings will be required.

The rings that are sold in stores usually have standard sizes and can be of different diameters - 70, 100, 120, 150, 200 cm. If the sewer system will be built for a house where many people live, then it is better to use structures with a diameter of at least 100 cm For small families, you can purchase 70 cm rings. The larger the ring, the heavier it is, and therefore, to install a septic tank from products 100 cm or more in diameter, you will definitely have to call a truck crane, since the weight of these rings varies between 700-900 kg.

An example of arranging a concrete septic tank with your own hands

Advice! When making calculations, it is worth remembering that the upper ring should protrude above the ground by about 20-30 cm.

Septic tank volume calculator

Choosing a place

Before you begin building a septic tank, you will need to choose the right location for the treatment structure. It is imperative to take into account the distances to important objects on the site. For example, a septic tank cannot be located closer than 5 m from a residential building. It must be separated from the neighbors' fence by at least 2 m, and the nearest water intake (for example, a well where clean drinking water is obtained) cannot be closer than 30 m.

Attention! It is also necessary to take into account such a point as the distance from the septic tank to the place where the vacuum truck can stop. Even a structure without pumping must be periodically cleared of the sludge accumulated at the bottom. If the car cannot get close enough, then there will be no way to clean the septic tank.

Septic tank made of concrete rings

For a septic tank that requires the presence of a soil treatment system, it is important to take into account the proximity of groundwater. If the aquifers are close to the surface of the earth, then it is impossible to discharge wastewater into the environment - it will be necessary to equip a tank to collect it. Fortunately, water that has been treated in a septic tank can be used to water your garden.

For the construction of a septic tank, a place is selected in the lowlands of the site, which must be lower in level than the residential building in order to maintain the required slope of the sewer pipes (on average, 2 cm per 1 linear meter). It is also taken into account that the septic tank wells are not placed close to each other - there should be a distance of at least 20-25 cm between them.

Installation work

Installation work on arranging a septic tank is quite complex; you may need the help of special equipment to lay the rings in the pit.

All other work will be reduced to a minimum of time and effort:

- After completing the excavation work, you must install a 30 cm cushion of sand at the bottom of the future septic tank. Then make a 20 cm screed. This is necessary in order to eliminate the risk of harmful elements getting into the soil;

- Using the technique, lower the rings into the prepared hole. Seal the resulting joints with cement.

All joints are covered with mortar

Advice! It is better to seal the place where the pipes will enter with liquid rubber or some other insulating materials. This is necessary so that during shrinkage of the pipe structure the pipes do not become rigidly fixed and crack.

Grouting joints

Tips for arranging a septic tank made of concrete rings:

- To save money, before purchasing rings, prepare a hole for installing a septic tank. After all, to unload them you will still need a crane, but this way you can unload them directly into the pit;

- When covering wells, use slabs with hatches. This will help you track the percentage of filling of the septic tank, and will also give you the opportunity to add special bacterial mixtures to the chambers, which are designed to speed up the process of decomposition of particles and suppress unpleasant odors;

All that remains is to lay the hatch and bury the structure

- If possible, install vent pipes on each ring separately;

- Insulate the septic tank to prevent it from freezing in winter;

- To enhance the reliability of the structure, it is advisable to connect the concrete rings with metal brackets.

We build a septic tank from concrete rings

How to build a septic tank from concrete rings yourself? The instructions will tell you about this.

Step 1. First of all, a fairly large pit is dug in the selected area. It is formed immediately for all septic tanks, whether there are two or three – it doesn’t matter. The work can be done manually or using special equipment. Soil from the bottom can be lifted with a winch, placing it in buckets and placing them on a board to which ropes are tied. All walls of the pit are immediately leveled.

Digging a pit

Step 2. The bottom of the pit is leveled. Then the bottom of the first well is lowered from above.

Bottom of the first well

Step 3. Along the edge, the bottom is coated with cement mortar to adhere to the ring - it is on this that the first ring will be placed.

Along the edge the bottom is coated with cement mortar

Step 4. The first ring is lowered into the pit and carefully installed on the round bottom. Where the cement mortar has not settled tightly, a small amount of it is added.

The first ring is down

Step 5. The upper edge of the side of the installed ring is also coated with a layer of cement. A second ring is installed on top. The seams are carefully sealed with cement mortar.

Second septic tank ring

Step 6. A floor slab is installed on top of the second ring, also on a layer of cement, which immediately has a hole for the hatch.

Installation of the stove

Step 7. The second compartment of the septic tank is installed - the filtration well. There is no concrete slab placed on the bottom here. The concrete ring is simply lowered onto a flat surface.

Installation of the second compartment of the septic tank

Step 8. The bottom of the filtration well is filled with crushed stone, which is then leveled.

The bottom of the well is filled with crushed stone

Step 9. The upper side of the ring is coated with concrete mortar, the second ring is lowered. The seams are coated with additional solution. The well is also covered from above with a floor slab.

Second ring

Step 10. The pipes are connected. The tee seats are lubricated with grease so that the pipes fit neatly.

Using Lubricant

Connecting a tee to a pipe

Step 11. The septic tank and filtration well are connected to each other by pipes through special holes. The gaps between them and the walls of the concrete rings are coated with a solution.

Connection of the first chamber with the filtration well

Step 12. Rings of smaller diameter are installed on the ceilings. All joints are coated with cement mortar.

Rings of smaller diameter are installed on the ceilings

Step 13. Well covers are installed on rings of smaller diameter.

Well covers

Step 14. The sewer pipe is installed from the house to the septic tank. It is placed in a trench on a sand bed.

Laying a sewer pipe

Step 15. The pit is filled with soil.

Backfilling the septic tank

Prices for concrete rings

concrete rings for well

Video - Septic tank made of concrete rings

Calculation, assembly and complete installation of a septic tank

So, if you are planning to make a septic tank for a private house from concrete rings with your own hands, then you should consider how often someone will use it. But we will consider a filtration device, which is most often installed in the private sector, where people live not seasonally, but permanently.

Video: Installing a septic tank using an excavator

How to calculate the required dimensions

To get an idea of your family's estimated water use, use this research-based chart.

| Special purpose | % | Number of l/day |

| Personal hygiene (shower, bath, washbasin, etc.) | 35 | 60 |

| Toilet | 32 | 45 |

| Wash | 12 | 17 |

| Washing dishes | 10 | 14 |

| Drinking consumption and food preparation | 3 | 4 |

| Cleaning the room, watering flowers, etc. | 8 | 11 |

| Total | 100% | 151 l |

Table of average water consumption per person per day

To calculate the number of concrete rings for one tank, you need to compare the amount of water consumed per day with the volume of one tank. For example, if you have a residential building with water supply, sewerage, a bathroom and a solid fuel boiler, then for one person, according to the table above, the consumption is 151 l/day. A family of 4 people will consume 4*151=604 liters per day, and even if we exclude the discharge of water for drinking and cooking into the sewer, 604-4*4=588 liters or 0.588 m3 will remain, that is, a little more than half Cuba.

To calculate the volume of a concrete ring, we need a formula for calculating the volume of a cylinder: V= πr2h, where:

- V – volume of the cylinder (concrete ring);

- π – constant value equal to 3.1415;

- r – radius of the circle of the cylinder (concrete ring);

- h – height of the cylinder (concrete ring).

In this situation, the same rings are used as for wells, and there is a certain standard.

| Marking | Height h, mm | Ø internal D, mm | Ø outer D, mm | Weight, kg |

| KS 7.3 P | 290 | 700 | 840 | 130 |

| KS 7.5 P | 490 | 700 | 840 | 220 |

| KS 7.6 P | 590 | 700 | 840 | 270 |

| KS 7.9 P | 890 | 700 | 840 | 380 |

| KS 10.3 P | 290 | 1000 | 1160 | 200 |

| KS 10.5 P | 490 | 1000 | 1160 | 330 |

| KS 10.6 P | 590 | 1000 | 1160 | 400 |

| KS 10.9 P | 890 | 1000 | 1160 | 600 |

| KS 15.3 P | 290 | 1500 | 1680 | 340 |

| KS 15.5 P | 490 | 1500 | 1680 | 550 |

| KS 15.6 P | 590 | 1500 | 1680 | 660 |

| KS 15.9 P | 890 | 1500 | 1680 | 1000 |

| KS 20.3 P | 290 | 2000 | 2200 | 480 |

| KS 20.9 P | 890 | 2000 | 2200 | 1480 |

| KS 24.6 P | 590 | 2400 | 2600 | 1350 |

| KS 24-12 P | 1190 | 2400 | 2600 | 2700 |

| KS 24-20 P | 1990 | 2400 | 2600 | 4500 |

| KS 30.10-I P | 1000 | 3000 | 3300 | 3900 |

| KS 30.10-III P | 1000 | 3000 | 3300 | 3800 |

Note. For each diameter, a cover is made for the bottom, a cover with a hole for insertion, a hatch cover, but, as a rule, a concrete cover for the passage is not ordered and a plastic one is installed.

Let's move on to calculations using the formula to calculate the required volume of the tank and, for example, take the KC 10.9 P model:

V= πr2h=3.1415*0.4452*1=3.1415*0.198025= 0.6220955375 m3

Therefore, in your situation, you can use one ring with an internal ø0.89 m (r 0.445 m) and h1 m for one tank. The volume in this case will be slightly larger than required, which means you can receive guests for several days with a calm heart.

Standards for the location of a filtration septic tank in relation to other objects

Standards for the location of a filtration septic tank in relation to other objects

Installing a filtration septic tank requires compliance with certain parameters, which depend on the arrangement of the site. That is, tanks must be located from certain objects at a distance of at least:

- own house - 3 m;

- well or borehole - 60 m;

- road on the street - 6 m;

- river -10 m;

- pond or lake – 30 m;

- fruit trees and shrubs 2-4 m.

Warning! If you neglect such norms, you may have disagreements or a quarrel with your neighbors, which may entail administrative penalties in the form of a fine and forced relocation of the sewer system.

What you need for work

Tank configuration (from bottom to top): bottom, ring, cover, PVC hatch

Cover insert

To make a filtration septic tank from concrete rings, you need to stock up on:

- concrete rings, bottoms, covers and liners for them;

- PVC sewer pipes ø110 mm (DN 100 mm) and fittings for them;

- inserts into concrete rings;

- insulation for pipes (mineral basalt wool for winding or shell);

- cement M400 or M500;

- seeded sand, without clay (preferably river);

- crushed granite stone fraction 5×20 mm.

You will also need a number of tools:

- shovels (bayonet, shovel), but you can order an excavator;

- hammer drill with a set of drills, chisel and cutter ø120 mm;

- small grinder with a 125 mm cutting disc for metal;

- construction long level;

- pencil, tape measure.

Digging trenches and pits

You can make a separate hole for each ring

As a rule, a common pit is dug for two or three tanks filtering sewage, but if desired, you can make a separate hole for each ring, as shown in the top photo. It is important to sink the ring deeper, if not below the freezing point of the soil, then at least half a meter from the surface (then it can be insulated). For example, for a ring a meter high, you will need a hole at least 1.7-1.8 m deep so that you can pour a crushed stone cushion 20-30 cm high from below (this significantly reduces soil heaving, since water drains through the crushed stone layer).

The depth of the trench is usually determined not by the level of soil freezing, but by the depth of the first septic tank. If the sewer line is in a freezing zone, the pipe is insulated. At home, the diameter of PVC pipes for drainage is usually 100 mm, which means that its slope should be from 15 to 20 mm per linear meter. This means that the trench should be dug immediately with a slope and a reserve for a sand cushion (the height of the backfill is at least 5 cm).

Installation and connection of a septic tank

This is how large holes are drilled in concrete rings.

Holes in concrete rings for pipes can be made on the ground, or already in the pit, if, of course, space allows - you will decide this issue yourself. I just want to focus your attention on the hole itself. Drilling it is not so easy, since the walls here are reinforced with steel wire with a cross-section of 6 mm, therefore, the cutter will not pass through them, and the pobedit teeth will break.

To successfully create a passage at the desired location (entrance and exit), draw a circle of the appropriate diameter and drill it around the perimeter, as shown in the photo above. But it’s even more convenient to use a core cutter, albeit partially - they simply go no more than 5 mm along the distant edges (at the top and bottom it will go in a little deeper - 7-8 mm). The groove obtained in this way will prevent the drill from jumping to the side, and it will be possible to make holes exactly around the circumference. Then the center is knocked out with a chisel, and the reinforcement is trimmed with a grinder.

Installation of concrete rings. The tap is working

Lowering the rings into the pit without any equipment (crane or winch) is extremely difficult, and sometimes even impossible. The KC 10.9 P model weighs 600 kg and you can’t do without a winch or equipment, although you can use lightweight options, where the smallest weight is 130 kg (see table).

At this stage of installation, a lot depends on the components that you purchased along with the rings. That is, if you bought concrete bottoms, then only a sand and crushed stone cushion 20-30 cm high is poured onto the bottom of the pit, leveled horizontally, compacted, and then the tank is assembled in the sequence: bottom-rings-lid-hatch insert. But if there is no concrete bottom available, then a concrete mixture 7-10 cm high is poured onto the cushion and a ring is immediately placed on this layer.

Two tanks assembled

The rings are lowered into a pit onto a concrete mortar or a finished bottom with mortar around the perimeter and tanks are mounted from them, as in the top photo. The installation process occurs in the following order:

- the following ring is placed on the ring hermetically sealed at the bottom (as needed), fastening the joint with cement mortar or universal tile adhesive;

- Cement mortar is applied to the edge of the ring and a lid is put on;

- a liner (insert) is installed in the hole of the lid so that it is 7-10 cm above ground level;

- a 100-mm pipe for ventilation is cut into the first tank (preferably the lid) and raised above the overhangs of the roof of the house;

- the tanks are connected to each other by overflow pipes according to the principle specified in the section “Filtration devices”;

- Gaps at the entry and exit points of pipes are sealed with tile adhesive.

It is advisable to put the corner on the outlet pipe with the hole down.

It is advisable to put the corner on the outlet pipe with the hole downward - this way oils and surfactants will rise higher, remaining in the coarse cleaning compartment. That is, overflow here is possible only when the water rises to the horizontal level of the pipe.

Drainage system design

The reservoir with drainage is buried about a meter below the adjacent filter, but it is placed on drainage, which consists of:

- geotextiles with a roll on the walls;

- crushed stone layer – 50 cm;

- layer of sand – 30 cm;

- priming.

In the case when perforation is made at the bottom of the third tank, crushed stone of a fraction of 5 × 20 mm is also poured on the sides. This allows water to flow down the sides of the container and down to the main drain.

Video: Installation of a septic tank from concrete rings