Equipment and materials

We prepare everything necessary for constructing a well in this way.

List of tools and equipment:

- excavator;

- truck crane;

- shovels;

- Bulgarian;

- roulette;

- bubble level;

- concrete mixer;

- boards;

- wood hacksaw;

- hammer;

- rule;

- concrete trowel;

- roller;

- burner;

- spatulas;

- hammer drill with crown.

List of materials:

- sand;

- crushed stone;

- cement;

- reinforcing mesh;

- nails;

- knitting wire;

- rings of wells with a diameter of 1 or 1.5 m;

- well floor slab;

- well cover with shell;

- bitumen roll waterproofing;

- primer;

- bitumen mastic;

- waterproofing mixture;

- penetration for concrete;

- sheet polystyrene.

Excavation

It is better to time the arrangement to coincide with the season of low groundwater, when the soil is dry and dense. This is especially true for installations with a concrete pit.

Concrete structures provide poorer tightness compared to welded metal or plastic factory caissons. They are not very suitable for installation in places where the groundwater level remains high for a long time. But with a serious approach to waterproofing, this design turns out to be more durable.

A pit is dug manually or with an excavator. To be able to perform high-quality waterproofing, the diameter of the pit should be 1.5-2 m larger than the diameter of the rings. If there is confidence that groundwater in this area always remains below the bottom of the future pit, waterproofing can be carried out according to a simplified scheme. Then a gap of 20 cm per side is enough to install the rings. It is necessary to remove the soil so that the wellbore is in the center of the future pit, this is more stable.

The depth is generally 2 m.

This allows you to go below the freezing level and provides sufficient height in the pit for a person to be in it.

The bottom of the pit is carefully leveled by hand. You only need to leave the rear sight, and lift all the loosened soil to the surface with a container tied to a rope. If there is nowhere to distribute the soil on the site, the volume occupied by the well will have to be removed. To avoid paying separately for loading, it is better to hire an excavator together with a dump truck.

Making a well ring with your own hands

Work can begin only after assessing the reasons for the disappearance of water.

Each of the methods for reviving an excavation is used in a specific case, depending on the condition of the soil and the flow rate of the aquifer. This method is applicable in a shaft of up to 10 links, operating for no more than a year, if there are new rings in it.

Settlement of a concrete source shaft that has been in operation for more than two years, with old reinforced concrete products and compacted soil around the column, can lead to deformation of the structure.

Procedure:

- We prepare for work: shovels, buckets, cable, block on a tripod device; rope ladder, safety belt with rope; canvas clothes, rubber boots and a helmet with an LED flashlight. To pump out water we use a deep pump;

- We remove the protective house, gate (device for raising water). We clear the bottom of silt, crushed stone and sand, check the barrel for displacement of the rings, the presence of cracks and wear on the inner surface;

- the work of removing soil from the bottom is carried out by two workers with practical experience and knowledgeable about safety precautions. The worker below is wearing a safety belt with a rope. We remove the earth from the bottom by digging under the lower ring, using buckets, a cable and a block on a tripod;

- Having removed the soil under the shaft to the height of the reinforced concrete element, use a load and an excavator to press on the upper link, and lower the structure into the shaft to the excavated depth;

- We repeat the process, immersing ourselves to a new layer of water, but no more than three meters. We place new rings on top of the column, securing them to the trunk with plates with anchor bolts and brackets. We insulate the joints between reinforced concrete products with a solution of cement and liquid glass;

- Having lowered the structure to the required depth, we leave the last ring above the surface of the earth. We lower a layer of filter crushed stone into the shaft and pump out the cloudy liquid until it appears clear. We install a protective house.

The advantages of the method of settling a concrete shaft when deepening the source include the integrity of the column (without violating verticality) and maintaining the tightness of the seams between the rings.

Disadvantages - the risk of damage to the trunk links when the structure is pressed in due to the density of their contact with the ground, the limited depth of use of the method. The need to waterproof all connecting seams between the crowns after the column is settled.

To increase the flow rate, this method is used.

Preparatory work and removal of soil from the mine are similar to the previous method, with the exception of digging under the lower link of the shaft.

- We increase the output flush with the inner wall of the column. We carry out the work until signs of collapse of the walls of the funnel appear;

- a worker rises from the excavation and the ladder is removed. A ring with an outer diameter smaller than the inner one in the column by 4-6 cm is suspended from the winch cable and smoothly lowered;

- When it reaches the bottom, the descending worker installs it in the center, vertically to the trunk of the source. Then the next link is lowered and connected to the previous one with plates and anchors;

- the rings are lowered until the top link appears in the old mine shaft. As soon as the result is obtained, we stop installing the crowns. If there are no keys, it is necessary to further deepen the well, digging under the lower concrete circle of the new trunk;

- Having installed the column, we waterproof the seams and fill the space between the links of the old and new trunk with a solution of cement and sand.

The positive thing about this option is the use of standard products in dense soil conditions.

Disadvantages include the large weight of the structures, labor-intensive work, and the need to seal seams.

Filter

This method is used if it is enough to increase production by a meter to increase the flow rate of the source.

For the filter we use a perforated plastic pipe. The procedure is the same as when installing crowns of smaller diameter, but instead of concrete links, a one and a half meter PVC pipe is used. Its diameter is 4-6 cm less than that of the column links.

- We make holes in it (20 mm) for perforation over the entire area. We cover the pipe with a stainless steel mesh with a fine mesh. The created filter protects against sand ingress;

- To deepen the excavation with the diameter of the rings in the column less than 800 mm, we use a bailer. We remove soil from the bottom of the well by a meter until there is an active influx of water;

- We install a plastic pipe with a mesh on the bottom, sealing the space between the barrel and the link. To prevent it from floating up, we fix it to the concrete column with anchors at the junction.

The filter is convenient when installed at a shallow depth of an aquifer and prevents siltation of the well.

The disadvantage is that the steel mesh may become clogged with sand, limiting the flow of water.

Plastic pipe

This type of recess is made according to the option with concrete rings of smaller diameter.

- into the dug recess we lower to the bottom a plastic circle of two walls, the outer one of which is corrugated. We prevent the walls of the dug funnel from collapsing and continue to dig in;

- Having reached the layer with rapidly rising water, we settle the pipe to the bottom. Between the column and the plastic ring we pour a mixture of cement with small pebbles and sand, spill it with water;

- We lower the next ring into the shaft and, using the threads at the ends of the pipe, connect it to the installed link. To prevent the pipe from being pushed out by accumulating water, we pour a mixture of cement and sand into the space between the columns;

- repeat to the top. The low weight allows the links to be lowered without using a winch.

The plastic design allows you to protect the mine from quicksand, reaching the aquifer. By covering a concrete column from the inside, we prevent its destruction, increase its strength, and extend its service life.

Disadvantage: it is impossible to remove the plastic structure if damaged.

The method of deepening a well by drilling a well is used in sources with a concrete crown diameter of less than 800 mm:

- We drill from the bottom of the mine to the aquifer. We insert a plastic casing pipe into the drilled well, and a deep-well pump into it;

- a submersible pump supplies clean water to the well without additional filtration.

The method allows you to add water to the source at minimal cost, bypassing complex soil layers.

The disadvantage of this option is the need to constantly use a submersible pump.

When this occurs, especially under pressure, there is a danger in excavation work. Quicksand can reach a thickness of 10-12 meters, be mobile and false.

If under the well there is the first option, a layer of silt, sand and water, work must be stopped and a location for a new source must be determined.

- If a quicksand with a layer thickness of up to one and a half meters is false, in which buoyancy ceases when pressure is created on it, it can be passed using concrete rings of smaller diameter column links;

- When the quicksand is more than two meters thick, the Abyssinian well method is used. Through a layer of weak soil, using a vibrator, we drive a thick-walled pipe with a diameter of 25 mm to a depth of 20 meters, until clean water flows into the well.

Increasing production by feeding pipes through quicksand allows you to get a positive result with minimal costs.

To reduce the risk of getting caught in quicksand and make the right decision on deepening the well, before starting work, it is advisable to conduct an assessment of the soil by drilling a well.

We suggest you familiarize yourself with How to feed tomato seedlings so that they are plump, after picking, at home

If the water level in the well rises above the freezing level of the soil, it may freeze in the winter. Insulating a well helps prevent freezing of the source and destruction of the well shaft. To protect the structure, various types of heat insulators and insulation methods are used, which prevent deformation of the seams between the reinforced concrete rings of the source, as well as their depressurization.

Thermal insulation is a reliable way to protect a well structure from destruction

Thermal insulation is a reliable way to protect a well structure from destruction. In winter, the air temperature can drop to sub-zero levels, at which water begins to freeze. During the freezing process, water expands greatly, which creates considerable pressure on the walls of the well shaft. This leads to its destruction and depressurization of the structure.

What are the possible consequences of freezing a source?

- Break in the power cable of the submersible pump;

- Icing of the pipeline approaching the source;

- Impossibility of drawing water from a well;

- Displacement of well shaft rings;

- Rupture of seams between reinforced concrete rings of the structure.

All of the above factors create an emergency situation in which the source can no longer be used. Over time, soil may be filled into the well, which will block the flow of groundwater into the well shaft. To prevent such consequences, the structure is not only possible, but must be thermally insulated.

However, it is worth noting that not all types of wells require additional thermal insulation

It doesn’t matter whether the source is connected to the water supply system or not, it must be insulated. However, it is worth noting that not all types of wells require additional thermal insulation:

- Wooden structures do not need to be insulated, since wood has low thermal conductivity. Due to this, the temperature in the well shaft does not drop below zero;

- There is no need to do insulation if the water level is significantly below the soil freezing level. Even with severe frosts, the water in such a source will not be covered with ice.

What types of structures will still need to be insulated?

- concrete;

- brick;

- reinforced concrete.

All of the above materials have fairly high thermal conductivity, this is especially true for concrete. It freezes to the same depth as the soil. And if the water level is slightly above its freezing level, at sub-zero temperatures the water in such a mine will certainly be covered with ice.

Insulating the lid. Wells in the country are often left without covers or hatches. The construction of a heat-insulating cover in this situation will help to avoid freezing of the water at the source

Concrete and installation works

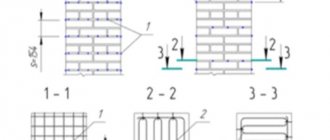

A concrete layer of 80-120 mm is laid on a dense, leveled base. For it, lean concrete grade 100 is used. It is prepared from the following calculation: 105 liters of crushed stone, 75 liters of sand and 20 liters of water are laid per 25 kg of cement. Volume fractions are measured with a 10-liter bucket. The accuracy of the concentration is not very important here.

We place the formwork from the board around the perimeter so that the base extends beyond the rings by 15-20 cm, its upper edge should be located at the height of pouring into the level. If there is no board of the required height, you can simply hammer nails at the required height around the perimeter inside the formwork, which will mark the height of the pour.

We prepare and pour concrete. The fill is carefully leveled into a plane. When pouring along the edges of the formwork, you can simply run a rule or a suitable board along the upper ends of the formwork, as if using a template. The concrete base is left to harden for 7 days.

Using a grinder, we cut the well bore so that it protrudes 50 cm above the concrete and plug it with polystyrene foam. Rolled waterproofing is spread over the base, its overlaps are fused using a torch. A hole is cut carefully around the barrel, without unnecessary gaps. The waterproofing must extend beyond the footing.

The waterproofing mixture is prepared according to the manufacturer’s recommendations.

Before mounting the rings, their mating surfaces are thoroughly cleaned, dust-free and wetted.

The lower ring is placed directly onto the waterproofing using a truck crane. On the inside, the inaccurate joints are filled with a waterproofing mixture. A layer of the mixture is applied to the upper end of the ring and the next one is installed. The mixture is again applied along the second ring and the floor slab is mounted. The truck crane can be released.

All excess mixture must be carefully removed with a spatula and a smooth surface should be formed without transition between the rings. It is important to do this on the outside of the well to perform vertical waterproofing.

Reinforcing mesh is laid along the bottom of the well. The bottom of the well is filled with concrete grade 400. To prepare it, for every 10 liters of cement, 11 liters of sand and 24 liters of crushed stone are added. The pouring thickness should be 120 mm.

The same concrete is used to fill the shell on the well slab. It is concreted along the height of the cast iron rim with a slope from the hatch to the edge of the slab. To protect the concrete on the surface from cracking, it is also better to reinforce it.

Vertical waterproofing and installation of equipment

Areas of horizontal waterproofing extending beyond the rings are cut off. The outer surface of the well is primed with a primer. The walls are covered from the outside using the fusing method in a circle from bottom to top. The joint between horizontal and vertical waterproofing is carefully coated with mastic. For soils with low surface water levels, external surfaces are not covered.

At a level below the freezing depth, a hole is drilled using a hammer drill with a crown for the passage of the water supply. A pipe is inserted into it, which must be laid without joints from the point of consumption to the pit itself. The outlet is sealed using factory penetration. This can be a flange collar or a sealed bushing. The sealing element is located on the side of the support, that is, on the outside.

The arrangement ends with the installation and connection of equipment, including a sealed well head, pump, check valve, hydraulic tank, pressure regulator, pressure gauge. The wiring is usually done with plastic pipes, and the devices are connected through a five-piece. The power cable is inserted into the caisson through a hole in the top plate.

After testing the system, backfilling with compaction is carried out. After the soil settles, a blind area 80 cm wide with an outward slope is made along the perimeter of the caisson. The well, equipped with concrete rings, is ready for long-term year-round operation.

At the initial stages of building his own house, its owner thinks about where he will get water. After all, even to fill the foundation of a building, you need a lot of it. The first thought that comes to mind is to drill a well. Along with this, you will need to install a pump, pipes and a concrete caisson to get a working pipeline. Attention should also be paid to the arrangement of the water source - the wellhead. The distribution of pipes along pipeline sections should be below the depth at which the soil freezes. If this condition is not met, the water will freeze at zero temperature and the pipes will burst. Accordingly, the pump will also break down and the system will become inoperable. To avoid this, you will need to install a caisson made of concrete rings.

A caisson is an impenetrable tank 2 meters deep that serves as an additional room for a well. The caisson can be made of plastic, steel, metal, brick or concrete. The shape can also be different: round, square and rectangular. It is installed on the casing pipe of the water source, and has a hatch on top for full access to the well. The caisson must be insulated with waterproofing to prevent water freezing. Equipment installed inside the caisson:

Pump; Shut-off valves that block the flow of the medium; Instruments for measuring water pressure - pressure gauges; Filters; Automation - a pump that turns off when the pressure drops below normal; Hydraulic accumulator tank.

Gardeners install an additional piece of pipe in the caisson, which is used for irrigating the soil.

Advice!

You can do without a caisson if the well is located next to a warm room. In this case, you will be able to see all the components of the water supply system, but the noise from their operation may disturb you.

Selecting material for the well head

And when faced with a problem and freezing of water in a well in winter, its owner is fully aware of his mistake. Thus, the answer to the question of insulating a well can be divided into two specific guidelines. The first will tell you how to insulate a well made of concrete rings immediately during construction.

We suggest you read How to care for indoor hibiscus

The second is about what can be done after the fact.

The use of modern materials greatly facilitates the construction process. This is speed, durability, and economic feasibility. But the “old-fashioned” methods, proven over centuries, have a right to exist. Previously, wells in Rus' were built mainly from special types of wood.

The excellent characteristics of such a well made it possible to use it for many years, and the low thermal conductivity of the wood prevented the water from freezing even in the most severe frosts. But now such technologies are a thing of the past, and most often ready-made concrete circles are used for construction. Using the digging method, they are gradually immersed in the ground, reaching the desired depth.

To prevent the water inside the well from becoming ice, its level should not reach the level of soil freezing in winter. If this condition is met, then problems arise extremely rarely. But no one is protected from force majeure and natural disasters.

In any case, it won’t hurt to play it safe in advance, because it doesn’t require much additional effort, and the money spent on insulation is not so large as to risk it.

Ignoring insulation can cause not only inconvenience in the form of a lack of drinking water for some time. If a pumping station is installed in the well, and water pipes go from it to the house, then freezing of the water will lead to failure of all equipment.

Repairing it is a very expensive procedure; in addition, the matter is complicated by the fact that the ground freezes thoroughly in winter, and if the water in the pipes also freezes, this can cause them to burst. Restoration work will need to be done in difficult conditions or even postponed until spring.

To avoid such a problem, you need to immediately learn how to insulate a well from concrete rings and do all the work correctly.

When work is being done during construction, the insulation needs to be laid around the well gradually, as it is buried. The depth of insulation laying depends on the climate in the region.

It happens that even very deep wells, the depth of which exceeds 15-20 meters, freeze. Most often, it will be enough to lay the insulation to a depth of no more than one and a half to two meters. The technology for this process is simple; the main thing is to follow the instructions on how to insulate a well.

Methods for insulating a well largely depend on the type of winter in the region.

If the frosts are not very severe and the ground does not freeze deeply and for a long time, then you can protect the well from above by installing a wooden frame with a tightly closing lid over it. Such a house cannot simply be placed on the ground around the well. It is necessary to build a foundation for it.

To avoid distortion and subsidence, the foundation must be built according to all the rules, to a sufficient depth (no less than the average freezing level of the ground) with a width of one meter. Before the concrete solution is poured, a cushion is created at the bottom from layers of sand, crushed stone and soil, which will act as a drainage system.

The pillow must be thoroughly compacted and then the solution must be poured. After installing the wooden frame, insulation should be placed in the gaps formed between it and the walls of the well. For this purpose, you can use mineral wool, foam sheets, expanded clay or penoizol.

Residents of the southern regions respond well to this method, but those who live further north are dissatisfied with the results.

How to insulate a well made of concrete rings underground is a slightly more complex question. This work is carried out in several stages.

- The well rings must first be treated with special means to prevent groundwater from penetrating inside. But when choosing, it is important to take into account environmental friendliness and the possibility of using the product specifically in working with wells.

- The next layer is the insulation layer itself. How to insulate a well made of concrete rings, let's look a little further.

- The insulation must be wrapped with a hydro- and vapor barrier layer. Most often, film is used for these purposes. This measure will help avoid contact of the insulation with the ground and condensation settling on it.

- To fix the entire structure, wooden formwork is installed around the rings; it holds all the layers together.

- Finally, the trench must be covered with earth. For this process, experts advise not to use soil from the trench itself. It would be correct to alternate layers of two materials with different calibers. It can be sand and gravel or clay with expanded clay. Layers with a fine fraction are usually laid up to 15 cm thick, and others - 20 cm. This measure will help create a high-quality drainage system, this will reduce the risk of water contamination in the well and reduce the pressure on its walls.

This is a classic, time-tested method, and the reviews about it are the most positive.

How to insulate a well made of concrete rings for the winter if it has already been built? The technology itself is the same as in the previous case, but you will have to dig a trench. This work must be done manually with a shovel.

The use of specialized equipment can lead to displacement of the soil and rings, violating the integrity of the soil layers. The rest of the work is carried out according to the given technology. Separately, it is worth noting that it is very important to take care of a good cover for the well.

Heat loss due to its absence or poor fit to the edges will also cause water to freeze. When a wooden frame or other structure is installed above a well, its cover is made in the form of a multilayer panel, in the middle of which there is a layer of foam plastic or mineral wool.

The well, which is not formalized on the outside, is closed with a concrete hatch and a plastic plug. Those who live in areas with warm winters characterize this method as quite cheap and practical.

To find out how to properly insulate a well from concrete rings, you need to know how to do it. There are quite a lot of options. Among the newest ones is foam insulation. Applying such material to the walls of the well eliminates seams, penoizol completely covers the entire space, eliminating leaks of cold air or water.

This technology involves the use of special equipment; this cannot be done manually. And the cost of the service is not cheap, so it is not yet very widespread in our country. In warm regions, mineral wool on foil insulation is sometimes used. The advantage of this option is the ability to wrap the insulation around the well as tightly as possible.

But some experts warn that this material crumbles easily and over time can break down into individual fibers and end up in the well water.

Insulating a well made of concrete rings with polystyrene foam is the most successful option, experts say. The properties of this material are truly unique. It is an excellent barrier to cold air, and is also very durable and inexpensive. For these purposes, sheet material is most often used, which is not always convenient, because it is problematic to get around the rounded shapes of the rings with sheets.

Manufacturers have found a way out of the situation and offer consumers ready-made insulation parts that have a semicircular shape. Standard sizes are available to suit the most common diameters of well rings.

In addition, you can use bulk granulated polystyrene foam. In this case, to create a frame, you need to use wooden slats to attach a layer of roofing material to the ground around the walls of the well and pour granules into the resulting opening.

We invite you to familiarize yourself with Decorative well 3 options, master class, photo || How to make a toy well with your own hands

In this way, you can insulate a well not only with foam balls, but also with other bulk insulation materials.

This is an effective method, and well owners who have chosen it confirm the reliability of such thermal insulation.

The modern approach makes it possible to make the structure of the well invisible by placing all the components in a caisson underground, but such an advantageous element of the landscape should not be missed by those who like to decorate the site.

Stone. It looks solid and powerful. In turn, stone heads can be divided into two types:

- Stone. Laid out “from scratch” around the well.

- Imitation. The top ring serves as the basis for decorative cladding.

Tree. Looks great against the background of a chopped wooden house. Divided into:

- Log (lumber). Created in the same way as the walls of the house.

- Sheathed. A frame is attached to the base, onto which panels, blockhouse, siding or board are sewn.

Whatever the finishing material of the head, there are a number of requirements that apply to this type of water intake structures:

- Reliable walls. The finish should be strong; ideally, run an armored belt or screed along the upper contour of the base and finish in the form of a table top or support platform. It will protect the finish from water and allow you to place a bucket.

- Lid. Will prevent accidents with children and animals and keep the water clean from debris. There should be a hole or hatch for the hose.

- Insulation. In areas with an average winter temperature below -18 °C, you will have to make insulation or select a heat-insulating material. In mild winters (above -18 °C), insulation is not required.

- Lifting mechanism (for a bucket of water). Usually this is a frame and a knob. They must be included in the design from the very beginning.

Next, we will look at the nuances and features of all traditional types of construction and finishing of the above-ground part of the well.

To ensure an increase in the mine, certain materials will be required for each of the options used:

- for settling the structure - concrete rings, cement, sand, liquid glass, metal plates with anchor bolts;

- arrangement of the excavated recess with reinforced concrete rings - concrete links with a smaller diameter than the internal ones at the crowns of the column, by 4-6 cm;

- increasing the depth with a plastic pipe and filter - PVC pipe is 4-6 cm smaller than the inner diameter of the concrete column, fine-mesh stainless steel mesh, sealant, anchor bolts, fastening clamps;

- deepening with a well and increasing flow rate through quicksand - casing plastic and metal pipe with a diameter of 25 mm, a tip with perforation;

- deep well pump for continuous operation.

Main functions of the caisson

So what is a caisson for?

1. It is an additional place for the location of water supply system devices. 2. Protects water from freezing. 3. Prevents the ingress of groundwater and sediments, which may contain pesticides and fertilizers. 4. Protects the well from the penetration of insects, small rodents and amphibians.

Caissons made of brick and concrete rings are the cheapest. Such material will also require high-quality waterproofing. In addition, reinforced concrete caissons are difficult to install, and their tightness is compromised over time. So, let's start installing concrete rings.

Insulation methods

The main requirement when carrying out construction work is to preserve

ecology of the internal environment and water composition.

All materials used for insulation must not compromise the quality

water. In addition, materials are divided according to functional tasks.

What is used outside

, is not necessarily suitable for

internal

processing.

Cover insulation

The lid can be made from various

materials:

- wood;

- reinforced concrete;

- plastic.

Wood is a unique material; it does not require

additional insulating layer.

The wooden lid can be made double

: inside the concrete ring and outside

Internal

will moderate temperature changes.

The outer one

will protect against dirt, snow, and debris.

The second material (reinforced concrete) differs in its service

, strength and reliability.

Plastic covering is installed inside

concrete frame, approximately at the level of the top layer of soil.

Method for manufacturing an insulating structure

closing:

- Two panels are cut out, the material is

moisture-resistant plywood - One is treated with a waterproof

mixture, wrapped in film, cellophane or other material to protect against moisture penetration. - Metal rods

are fastened inside the rings , on which the first shield is laid. - Insulation

is spread ; any building material except mineral wool will do. - A second shield

, also treated with insulation. - All layers are fastened together and wrapped in waterproof

fabric or cellophane.

The lid made in this way is complemented by a handle

, it is needed for ease of lowering and raising.

Insulation of well walls

Options

There are quite a lot of insulating materials offered by trade organizations.

The choice remains with the developers. To insulate the walls, a trench

.

Its depth depends on the level of

soil freezing.

There are few types of insulation that are popular:

There are many advantages of the material:

- not subject to rotting;

- does not deform under mechanical influence;

- withstands the statement coming from the soil;

- easy;

- easy to install;

- wear-resistant;

- difficult to burn.

The last stage of work, after selecting the material and insulating the concrete structure with it, is digging a trench

Now the well will not be afraid of severe winter cold.

For the safety of the manufactured log house, when getting water with buckets or through hoses, they try to prevent water from getting on the surface of the walls

.

Ice

will damage the concrete and reduce its service life.

External insulation

houses are built on the outside for insulation

. Their shape depends on the wishes of the developers.

Nadkolodezny

the wooden frame will serve both as a design for the concrete structure and as insulation.

Tree

retains heat and is easy to work with. Any design can be made from wood; it lends itself to painting and other design details.

Such houses become decorative decorations

the entire plot of land.

Concrete rings

are round in shape,

wooden log houses

have corners.

space between the rings and the tree

.

Craftsmen advise filling it with expanded clay

; it will complement the insulating functions of the external log house.

Any heat insulator

, properly used for insulation, will protect against frost and temperature changes.

The instructions describing the stages of construction activities provide a list of necessary tools

.

You can get ready, experiment in small areas, then proceed to the main work. Insulation is considered complete

after insulating the lid, walls and outer surfaces.

All work is simple in technology and can be independently

. The water will be protected from severe frosts and will remain clean and healthy at any time of the year.

The coolness of the water will delight users and lovers of clean water from the depths of the earth.

Uninsulated

The concrete frame structure will require urgent major

repairs

. The cost of the work will correspond to the installation of a new one.

Pumping

equipment is better stored and works when

insulation

.

A well is an ancient structure that has served humanity from time immemorial. Proper operation, timely cleaning and various procedures for maintaining a drinking source in proper condition can extend its service life for a longer period. And first of all, you need to take care of effectively protecting water from freezing during the cold season.

Earth work

It is necessary to install a reinforced concrete caisson during the dry season, because the groundwater is deep and the ground itself is dry. If you have an area where groundwater persists for a long time, then give up concrete rings. Of all the materials, this one has the poorest airtightness. Choose plastic or steel. If you choose concrete, then seriously consider waterproofing it. Since the diameter of the rings is 1.5-2 meters, the pit in the ground is needed 2 times larger. The reserve will be needed to protect the structure with insulation. You can dig it out by hand or with an excavator. If there is little water in the ground, then you can reduce the pit and leave a gap of 20 cm. Dig so that the casing pipe is in the center of the hole. You also need to go 1.5-2 meters into the ground. Then the level of soil freezing will be higher, and a full-length person will fit into the caisson. All loose soil must be removed from the bottom of the hole to create a perfectly flat surface.

How to prevent a well from freezing?

If you live in a village, you have a well and in winter you don’t want to be left without water, you need to think about insulation already when the well is being built. There are many ways to insulate this structure. You can choose any one to suit your taste and depending on the cost of materials.

If water is used only in the warm season, then there is no need to insulate the well using the above methods. It is important to clean it before leaving to prevent mold from forming. Also, the water must be completely pumped out and covered with a regular lid.

Return to contents

Works with concrete

The bottom of the pit should be filled with grade 100 concrete. The layer thickness is 8-12 cm. To prepare such concrete, mix cement - 25 kg, crushed stone - 105 liters, sand - 75 liters and water - 20 liters. Measure proportions with a 10-liter bucket. Place the formwork. We make it from boards and place them at a distance of 20 cm from future rings. The top edge of the board should be flush with the concrete pouring. If there are no suitable boards, then hammer small nails around the perimeter of the proposed filling. Pour concrete into the pit and level it. Leave for a week to harden. We cut the pipe from the well so that it protrudes 50 cm above the surface. We seal it with foam plastic. We lay waterproofing on the concrete so that it extends beyond its edge and connect it with a torch. We cut the insulation around the pipe so that it fits snugly.

Advice!

Before installing concrete rings on the well pipe, you need to thoroughly clean the joints.

Installation of rings

Only a truck crane can install the rings. We place the first ring on the waterproofing layer. We fill all the joints between the ring and the base with a waterproofing mixture. Generously lubricate the upper cut of the ring with this mixture and place the next one on it. We lubricate the end again, and place the floor slab on the second ring. A truck crane is no longer needed. Remove any mixture that goes beyond the rings with a spatula. The edges of the caisson must be smooth, especially on the outside. We lay a welded mesh of reinforcement at the bottom of the well and fill it with concrete 400. Its composition is: cement - 10 l, sand - 11 l, crushed stone - 24 l. The layer thickness is 12 cm. The prepared concrete is also poured into the rim of the slab. Reinforce the fill at the top of the well to prevent cracking.

Caisson waterproofing

After installing and pouring the concrete rings, you can remove excess waterproofing. Apply primer on top of the well. We cover the outside of the ring walls with insulation, from bottom to top. To do this, melt the joints of the sheets with a burner and glue them together. At the bottom of the caisson, coat the insulation joints with mastic. These actions are necessary for wet soils. We drill a hole in the wall of the well for the pipe to the water supply. The pipe must run straight from the well casing to the place of its consumption, without joints. We seal the hole from the outside. For this we use a sealed sleeve or cuff. After this, we install the equipment in the caisson and route the pipes through the five-piece. We lead the electrical power cable upstairs through the hatch in the stove. We check the operation of the entire system. If everything works properly, then you can fill the well with soil. Your concrete caisson is completely ready for use!

Conclusion

Now you can buy a caisson made of any material, from steel to brick. You can make it with your own hands. But the point is the same: without a high-quality caisson, the well will not be able to function normally.

A well or a well is a vital attribute of any private home. However, their arrangement must be carried out in accordance with certain rules to ensure the durability of these water sources. One of the elements of proper arrangement is the caisson of a water well. We intend to talk about how to equip a concrete caisson in our article.

When installing downhole equipment, it should be taken into account that it will be located in the soil layer that is susceptible to freezing. This fact may well cause physical damage to the equipment due to temperature shifts in soil layers. In addition, water in equipment cavities can also freeze and cause them to rupture.

To eliminate the possibility of such situations, caissons are often installed in wells, which are an insulated container in which downhole equipment is installed. The great advantage of caissons is also that their internal volume provides fairly easy access to the devices located in it.

Why is well insulation required?

Ice not only prevents you from drawing water from the well, it contributes to the formation of cracks and chips

in concrete.

If cables or pipes

, their quality will also deteriorate.

Broken cables and frozen pipes will require repairs

, which will be both complicated and expensive.

It is especially dangerous if an uninsulated log house freezes

and thaws several times during the winter.

The rings are destroyed

and grow old.

The concrete structure itself will not serve

a person as long as he expected.

Types of caissons

Caissons differ from each other both in their shape and in the material used for their manufacture. The main materials used for this purpose are:

- steel;

- concrete rings;

- plastic.

Steel caissons

Many users consider the ability to make them themselves to be a great advantage. For this, steel boxes or sheets with a thickness of 4 mm or more can be used. During the work process, welding is used, and the finished product is treated with anti-corrosion compounds to ensure greater durability. Of course, these containers can be purchased ready-made, but this is much more expensive for users.

Caissons made of reinforced concrete rings

Reinforced concrete rings, which were widely used earlier and are still quite often used to construct caissons, are rather disadvantageous, although they are loved by a large number of users. Their disadvantage is due to the following reasons:

- high price;

- large mass, requiring the use of special equipment and capable of causing soil subsidence and damage to the entire complex of well equipment;

- the susceptibility of concrete to the destructive effects of moisture and the need for careful waterproofing of concrete rings;

- insufficiently high thermal insulation capacity and, therefore, lack of full guarantee of equipment serviceability in extreme cold.

The presence of the above disadvantages has led to the gradual displacement of reinforced concrete caissons by their analogues made of plastic and steel. However, since reinforced concrete rings still retain their wide popularity, we will discuss the procedure for laying them below.

Plastic caissons

Plastic caissons are considered by many to be the best option for constructing water wells. This point of view is due to:

- affordability of products;

- light weight and ease of installation, carried out even without the use of special equipment;

- resistance of products to corrosion and other aggressive influences;

- high thermal insulation properties;

- high level of product tightness.

Having a large number of advantages, plastic caissons also have an important drawback, which is their low strength. This drawback is quite capable of causing damage to downhole equipment, that is, negating all the advantages that we listed just above. That is why many Russians continue to remain faithful to caissons made of reinforced concrete ring-shaped elements, the installation rules of which we intend to devote the main part of our article to.

So, we assemble the reinforced concrete caisson together, based on one specific situation that the author had to experience first-hand.

Caisson dismantling process

The situation was as follows. One craftsman drilled a well and installed a caisson made of reinforced concrete rings, lowered the pump and decided to distribute water to his neighbors for a fee. In the end, they decided that the craftsman needed to return everything and equip the well himself, and reinstall a good quality and sealed concrete caisson.

To do this, we dug up the old caisson with an excavator and took out the rings, which were already pretty saturated with moisture, and transported them to the craftsman. The rings turned out to be of terrible quality, they fell apart, and the last one was completely cracked. I believe that this is precisely due to the abundance of moisture.

What to do if you're already frozen

Having opened the well, it is clear that frost has covered the entire area of the walls of the ring and has tightened the pumping equipment. Perhaps the installation depth of the cover is incorrectly calculated, or the source is not insulated correctly.

If there are signs of freezing, but water is still flowing into the house, nothing needs to be done until the air temperature rises. Then it should be properly insulated.

Frozen equipment can be warmed up with a hair dryer right on the spot, or, after removing it, bring it into a warm place and let it stand for a day.

Installation of concrete caisson

By the time we were getting the rings, new rings arrived to us. After the old ones were taken out, it was necessary to deepen the pit and make a smooth sand cushion. Once the pillow was ready, it was time to build the concrete caisson. Before installation, it was necessary to drill a hole in the bottom slab for the well pipe. After which the bottom was lowered to the bottom and the rings were installed on top one after another. Our caisson was made of 1.5 m reinforced concrete rings. Previously, I personally coated each ring with bitumen mastic (grade 24, they say it seals better) in two layers after the previous one had dried. Despite the rain that fell all day, the mastic dried well.

Bituminous mastic is designed to seal concrete rings and to prevent surface water from entering our concrete caisson.

If you do not coat the rings with mastic, there is a high probability that the concrete ring will become saturated with moisture and become fragile, as well as moisture and groundwater will get into the caisson, fill up and fall into the well.

We decided to foam the joints between the rings, we decided to try this for the first time, let's see what the effect will be.

Why foam? Because any solution on which rings are placed usually falls apart when the earth moves and becomes meaningless. The foam should hold. Let's see.

Concrete caisson for well

As a result, we have a finished caisson made of concrete rings, with maximum sealing techniques.

You can install a well piping in such a concrete caisson and not be afraid that it will be flooded with water and all the equipment will not fail.

Private houses are mostly equipped with a non-centralized water supply, so the construction of a well is most often required. The installation of a caisson is necessary to protect the hydraulic structure. The design will protect the water intake in winter, protect it from groundwater and limit unwanted access of any entities. In addition, the caisson provides additional strength to the water supply system. Installing a caisson with your own hands is quite a feasible task.

Types of caissons

Concrete.

Durable and anti-corrosion structures.

They can be made from ready-made rings or by pouring concrete mixture into prepared formwork. Metal.

Strength is also high.

Installation is simple, but the design requires protection against corrosion, even if stainless steel is used. Plastic.

Lightweight, installation is very simple. The price of the caisson itself is high.

Plastic caisson

Installing plastic caissons is the most affordable method. Such a caisson is a chamber with a diameter of up to 1.5 meters and a height of up to 2.5 meters. Available with or without a lid. Advantages of a plastic caisson:

Lightness of design. Tightness. No risk of corrosion. Possibility of installation alone due to the light weight of the equipment. Made from safe polymer. Service life is about 50 years. Ease of installation and maintenance.

Flaws:

High risk of deformation due to seasonal compression of soil.

Installation for shallow well depth. High price. Installation of plastic caissons is carried out as follows:

1. Prepare a pit around the casing pipe, taking into account that its width should be 30-50 centimeters larger than the container. 2. The bottom of the hole must be covered with a layer of sand and compacted well. 3. The casing pipe is cut to the height of the pit. 4. The caisson is lowered onto the pipe.

5. Provide a lid for tightness. 6. Check the vertical installation of the caisson. 7. The outside of the caisson is foamed. Polyurethane foam secures the caisson to the base and serves as thermal insulation. 8. Compact the pit with a mixture of sand and cement.

Important! When groundwater is close to the ground, sand compaction is not enough. The bottom of the pit must be reinforced with a concrete slab or made using pouring. When water flows into the pit, the concrete will protect the soil under the caisson from erosion.

Concrete caisson

Installing a concrete caisson for a well is one of the most common options for installing a well caisson. Advantages of concrete caissons:

Strength.

Simplicity of design. Wear resistance. No corrosion. Any installation depth. The design has a number of disadvantages:

The weight of the structure complicates the installation of the caisson if you take ready-made concrete rings. Requires special equipment for installation. You will need a tap to feed the rings into the pit. The need for additional sealing work. Installing a concrete caisson in a well with your own hands is quite possible if you use pouring.

Thermal insulation of the cover

This happens in several stages.

First stage

. To make a pie, you will need two panels of plywood or moisture-resistant chipboard and a piece of polystyrene foam or polystyrene foam. A round washer is cut out of plywood to match the inner diameter of the well ring. If the chamber is square, then cut out a square according to the internal markings of the caisson. A piece equal to the rest is also formed from the foam.

Stage two

.

Using wood glue, the pie is held together, leaving foam between the panels.

To further secure these layers, you can screw in screws. A handle is installed on the top of the washer, making it easier to remove and put the lid back on. Third stage

.

Insulation of a well in a summer cottage is complicated by rare inspection of the inside of the collector. Not all owners audit the source. Therefore, the installation of the insulated cover must be securely fastened. To prevent the washer from falling into the water or onto pumping equipment, but to remain at ground level, it must be secured. Four holes are drilled crosswise in the shaft wall at a depth of 50–60 centimeters from the lid, and a small piece of reinforcement is driven into them. 2-3 centimeters should stick out inside the ring. The insulated pie will rest on these ledges.

Important:

if the ground freezes below 2 meters, you should make two such washers and install them 15 centimeters apart. This will create an additional air curtain.

Which caisson is better?

Which caisson is better can be determined based on the availability of equipment and skills in working with concrete and welding. Installation cost, well depth and maximum winter temperatures also matter.

- The simplest, but also the most expensive method is to install a plastic caisson. The cost of the container starts from 20 thousand rubles. The advantage is the speed of work.

- Installation of a metal caisson for a well is more labor-intensive, but quite affordable for craftsmen who know welding. It will cost much less.

- Installing a concrete caisson for a well will require significant time investment and experience in constructing formwork and pouring. The cost of this installation is approximately equal to the previous method.

- For shallow wells, the best choice would be to install a plastic caisson. For greater depth, concrete and metal options are suitable. For temperatures in winter of more than 30 degrees, a plastic caisson is not suitable; it can be deformed by soil movement. In addition, when exposed to low temperatures, it can crack. Metal and concrete caissons will withstand any weather changes.

- Installation of a caisson on an Abyssinian well is done in the same way as on others, the difference is in the size of the caisson. The Abyssinian well is very narrow, so the dimensions of the caisson must correspond to it. Therefore, the obvious solution would be to install a metal caisson; it can be welded to any diameter. Other types will not work in this case.

The lack of a centralized water supply in many residential villages, as well as in some private sector areas near cities, forces the construction of wells or boreholes. Building a well is a very expensive pleasure today, and therefore in most cases preference is given to organizing a well. This is cheaper, and water is supplied to the house automatically through pumping equipment. But it should be borne in mind that pumping equipment needs protection. Therefore, our company recommends purchasing a caisson made of concrete rings for a well in order to protect the equipment inside from ground and rain water, as well as from freezing.

Insulation with polystyrene foam

The most profitable option is polystyrene foam insulation. Penoplex made in Russia is identical in quality and properties to imported ones, but has a lower price. Available in the form of tiles. A diameter of at least 30 cm is required to evenly place the shell for the rings. For insulation, you can use waterproof clay.

Insulation of a well with polystyrene foam is similar to insulation with polystyrene foam:

- Prepare the walls - clean them of dirt and degrease.

- Install the shell for the concrete rings using construction adhesive.

- If necessary, secure the penoplex with dowel nails.

- Do waterproofing.

- Cover the seams between the plates with foam.

Additionally, you can wrap the rings with water-repellent material. Secure the penoplex on the outside with special metal brackets.

How to insulate a pipe in a well if it is not possible to place it below the freezing level of the ground? The best option is the same penoplex. The width of the sheets should be sufficient for the entire length of the water pipe, covering it on the sides. But is an insulated pipe necessary if it is laid deep? The deeper the pipe is, the less insulation is required. The thickness of the outside insulation for a pipe at a depth of 1 meter is 50 mm. If the pipeline goes to the surface, then more than 100 mm will be needed.

Internal insulation is also important. The best protection against freezing is a wooden or three-layer lid made by yourself. The insulation of the well cover occurs as follows: foam plastic is placed between two plywood and fixed there. The wood is then treated with a waterproof compound to prevent swelling. Holes are drilled inside: one for ventilation (a plastic pipe is inserted into it), two for fastening with wire. The finished structure is lowered inside to ground level.

How to build a house over a well

A house built over a mine is a costly but effective way to protect a water source. For construction you will need logs, cement, expanded clay, mineral wool, and tiles. In order to build a house, you need:

- Build blind areas from cement. Can be covered with tiles or expanded clay.

- Make a log house on the blind area.

- Insulate the gaps between the house and the ring with cotton wool.

- Install a gable roof.

- Treat with moisture-resistant impregnation, then close the hatch.

Wells need to be insulated. The cost of the work will pay off in the near future, because you will not need to spend money on repairs and ordering water while the restoration is underway. The range of insulation materials is wide, so among them it is easy to find one that is suitable for you in terms of composition, installation method and price.

Freezing of a well is a very unpleasant event for residents of country houses who use well water for water supply all year round. It’s quite simple to avoid this - insulate the well yourself. And for a positive result, you need to know the specifics of performing thermal insulation and understand the materials. Do you agree?

We will tell you how to choose the right insulation for thermal insulation of a well shaft. Here you will learn everything about the methods and nuances of carrying out work. Taking into account our recommendations, you can ideally protect your water source from low temperatures.

Will the well freeze in winter? This can be predicted with a high degree of probability.

Firstly, if natural wood was used to construct the well, then it will not freeze even with prolonged exposure to sub-zero temperatures. Our ancestors took advantage of this property by constructing wells from wood.

Modern wells are built using reinforced concrete rings, and given that this material has high thermal conductivity, the well will freeze in the same way as the surrounding soil.

Secondly, you need to pay attention to the water level: if it does not exceed 1.1-2.2 m, then the risk of freezing is very high. If the well is deep and the water in it is below the freezing level of the soil, then the water does not freeze.

The third factor that must be taken into account is the depth of soil freezing in the region. In the southern regions, the freezing depth rarely exceeds 0.5 m, in temperate regions - 1-1.5 m, in the northern regions - below 1.5 m.

Thus, the question of how to properly insulate a well for the winter faces owners of reinforced concrete wells located in temperate and northern climates. For residents of the southern regions it is less relevant. There are enough minimal measures - the construction of an insulated cover, and the well itself does not need thermal insulation.

Freezing of a well made of reinforced concrete rings can be prevented by making high-quality insulation, allowing uninterrupted use of water from it all year round

Construction of a concrete caisson

This product is a well approximately two meters deep, built from concrete rings. The latter are manufactured in the factory and delivered to the site by our company. A caisson is built from concrete rings in this way:

- digging a pit more than 2 meters deep

- a bed of crushed stone and gravel is poured and compacted

- the lower concrete slab is being laid, acting as a base

- Concrete rings are stacked on top of each other

- the resulting well is covered with a round concrete floor slab with a hole for organizing an inspection hatch.

Between all concrete elements, the seams are sealed with a solution containing water-repellent components. This makes the resulting structure waterproof, which provides good protection against moisture. A caisson is built from reinforced concrete rings so that the upper ring is approximately 10-25 centimeters above ground level.

How to insulate a mine made of concrete rings for the winter

This question torments all summer residents and owners of country houses. There is no need to insulate the entire well. It is enough just to cover the topmost concrete ring.

Polystyrene foam or expanded polystyrene are similar in shape and installation method. These materials are produced in rectangular slabs.

For a tight fit, they will have to be sawn lengthwise into smaller strips. Having previously been lubricated with foam or special glue, they are pressed against the walls of the reinforced concrete rings from the outside.

We coat all cracks and joints with foam from a balloon. It is advisable to protect the foam from exposure to soil and moisture.

A layer of roofing material or waterproofing material is applied on top of the slab. Afterwards you can bury it.