Waterproofing concrete joints in a well is a technologically complex process. The seams expand over time, which leads to significant water losses and even complete drying of the well. The reason for the formation of cracks and holes is salts, tectonic movements of the soil and poor-quality sealing between the rings.

Treatment of well joints

Popular sealing methods

There are several ways to cover up joints and holes:

- Cement + PVA glue;

- Clay castle (waterproofing on the outside);

- Special solutions, for example, “Panetron”;

- Hydraulic seal for wells;

Scheme for sealing a well from reinforced concrete rings.

Note that any of the methods can be used to waterproof concrete joints. Let's move on to a further description of each technology.

Order waterproofing from professionals

Do you want the well on the site entrusted to you to be reliably protected? Contact . We will achieve sealing of joints, ensure protection of concrete from erosion, and maximize the service life of the structure. The company’s employees will select environmentally friendly, safe formulations with which they can achieve excellent results.

Call us by phone or fill out a request for work online - we will agree on the details of the project with you. You will be satisfied with how the waterproofing of a well made of concrete rings will be carried out through the efforts of our employees. Order the service by phone: +7 (495) 150-52-07.

Method one – cement + PVA glue

Buy a bag of M 300 cement and a bucket of PVA M “Universal” glue. The ingredients are mixed in a ratio of 4:1 (4 buckets of cement to 1 bucket of glue). Cement and glue are mixed to a very thick consistency, such that it does not slip off the spatula.

Work order. First of all, we drain the well, clean out the dirt from the concrete seams and soak out the remaining water. Let the empty well sit for a few days and air out. Then we go down inside and begin to cover the seams with the prepared solution. Try to drive each hole as tightly as possible, smoothing the cement evenly along the sides.

Before using the mixture for treatment, clean the well and leave it to air

Completion of work. We collect the remains of the working mixture and get out of the well. The cement mixture dries within 4–7 days. It is recommended to pump water after a week only after checking the quality of sealing.

The second method is a clay castle

Clay castle is well-compacted clay or loam. Note that this method will allow you to cover only the upper joints (no more than 2-3 meters deep). To create a high-quality seal between the ground and the well, you will need clay that contains no more than 15% sand.

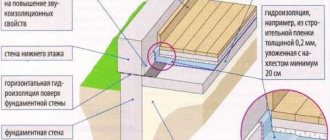

Scheme of a clay well castle

Work order. Dig up the well, then get rid of most of the soil (you won't need it). You can dilute the clay yourself or order it. How to dilute it yourself? You will need a large metal or plastic container. Pour half a bucket of water into it and add clay. The solution is mixed until the consistency of the clay begins to resemble melted butter.

Fill a bucket with clay and go down to the bottom of the trench. First, the concrete joints are sealed, then the space between the well and the ground is completely filled with clay. Practice has shown that it is better to fill the clay within one day, since hardened clay practically does not adhere to diluted clay.

Completion of work. Fill the top of the clay castle with soil and wait 10 days until it hardens completely. Sealing with clay does not guarantee 100% protection of the well from tectonic movements, as a result of which the rings can move, compromising the integrity of the structure.

Method three - sealing with Penetron

A special mixture consists of quartz sand and chemical additives. With this mixture you can cover even the largest holes and seams between the rings.

Sequence of work:

Treating the well with Penetron will eliminate the leak

- Cleaning concrete seams using a brush with metal bristles from dirt, dust, plaster layer, paint and other materials that interfere with adhesion between chemical components and concrete;

- Removing loose concrete with a jackhammer;

- Installation of a “U”-shaped groove along the entire length of joints, seams and junctions. Cleaning with a brush with metal bristles;

- Moistening the groove with water;

- Application of Penetron waterproofing material to seams, joints and junctions.

Completion of work. Treated seams should be protected from mechanical damage and freezing temperatures for 3–5 days. Also make sure that the joints and junctions coated with Penetron do not dry out. Spray the dried surface with a spray every 5-7 hours.

BOSTIK well sealing in action

Increasing the density of the well surface

Mechanical cleaning of seams from outside

If it is necessary to seal small gaps or cracks in the well, then it is better to do this from any one surface of the assembled parts of the well.

The external or internal side is treated with a special waterproof mixture.

Before applying it, it is important to clean all weak spots in the gaps where concrete elements are joined and in defective areas.

Advice! In order not to miss a significant flaw or crack during a well inspection, they need to be widened, since sometimes they are difficult to notice immediately.

If upon inspection it is discovered that a significant hole has formed somewhere, then it is necessary to clean the damaged surface on both sides. After such treatment, they begin to seal the crack first from the outside and then from the inside of the well.

In this case, it is recommended to additionally apply a water-repellent mixture on the outside. This layer can prevent further destruction of the gap and seams.

Of course, in order to deal with a serious hole in the well, it is necessary to dig a ditch around the structure to the depth of the hole. Once the leak has been eliminated, the ditch is covered with earth, and the top is thoroughly compacted or a blind area is made.

Hydroseal - modern technology for sealing holes

A quickly hardening substance is called a hydroseal. A hydraulic seal is used for wells mainly in emergency cases when urgent and effective intervention is required. Where to get a hydraulic seal and how to prepare it? To seal concrete joints, it is recommended to use “Waterplug” and “Peneplug” together with “Penekrit” and “Penetron”, respectively. The mixture allows you to cover up fairly large holes, up to a hole with a diameter of 10–13 cm.

Hydraulic seal for well treatment

How to prepare a hydraulic seal for use (using the example of “Waterplag” and “Peneplag”)? Take 1 kg of hydroseal and mix it with 150 grams of water. If it is not possible to measure grams, then you can follow the proportions: 1 part water to 5 parts mixture. Kneading is done quickly and only in warm water (17–23 degrees).

Tip: Do not try to fill all the holes at once by mixing a large amount of mixture. The hydroseal sets so quickly that upon returning to the container with the mixture, you will find one frozen lump.

Sealing seams between rings - detailed instructions:

Well treated with Hydroseal

- Preparation of the working surface. We knock down the exfoliated concrete with a hammer drill or jackhammer, slightly expanding the damaged area;

- Mix the hydroseal in a metal or plastic container in a small amount. Form a lump with your hands and press with a sharp movement into the seam between the rings. Hold the filling for 2-3 minutes.

Sealing concrete joints with a hydraulic seal allows you to instantly get rid of leaks. The only drawback of this mixture is its cost - 3 kg will cost 800–1000 rubles.

Popular materials for sealing joints in a well

Today, sealing seams in a well is a fairly common occurrence, which is why there is a huge selection of different materials. Each material is effective in a variety of situations:

- Prepared dry compounds. These materials for sealing the seam in a well are based on cement mixed with chemically active additives. This helps improve the waterproof properties. The main advantage is that these compounds adhere perfectly to concrete surfaces. Waterproofing can be done using substances such as Penetron and Waterplug. Thanks to them, an almost solid surface is created that does not collapse for several decades. You can buy these connections at hardware stores.

- A solution of bitumen and gasoline. You can make a similar solution for sealing seams with your own hands. It is enough just to stock up on bitumen and gasoline, the latter should be at least 3. Cracks in the well are sealed in three layers using this solution. The first is a primer, the solution is made in a ratio of 1:3. The remaining two times the solution is created in a 1:1 ratio. The resulting mixture must be applied using special equipment that must supply liquid for building materials, this can be a cement gun. This solution is flammable, therefore, in the process of connecting grooves, it is necessary to comply with all fire safety rules.

- A hydraulic seal for a well is a material that hardens and expands quite quickly. One of the most popular seals is “Hydrostop”. It is characterized by complete waterproofness, resistance to temperature changes, and perfectly tolerates any aggressive influences, including thawing salts. Among the disadvantages is the excessively high cost. Three kilograms of foot on average cost from 800 to 1000 rubles.

- Insulating tapes. This material is used only in cases where it is necessary to immediately eliminate the leakage of the well, and there are no other means at hand that can be used to seal the grooves. They are used using the caulking method. It is worth noting that this material can only be used if the grooves of the well do not exceed 70 millimeters. It is important to understand that insulating tapes are not designed for long-term use, so if you are faced with the question of how to seal the seams, it is better to give preference to another material.

Hydroseal is an effective method of waterproofing

Alternative methods for filling holes in a well

Waterproofing seams can be done using:

Well sealing scheme

- Painting. The paint composition is made from gasoline and bitumen in a 50/50 ratio. The composition is applied in 2-3 layers to damaged seams. If it is not possible to get gasoline, then the seams can be sealed with molten bitumen;

- Impregnation for concrete rings – “Eklakor-PU Ground – 2k/50”. The product is applied to a damp surface in several layers at intervals of 5 minutes. Then the impregnation is regularly wetted for 72 hours with an ordinary sprayer;

- QAUAFIX is a substance consisting of cement and active polymers. In common people it is better known as a cheap analogue of “hydraulic plug”. QAUAFIX is designed for waterproofing concrete rings inside and outside the well. Mix the mixture in a ratio of 4 portions of QAUAFIX and 1 portion of water, then cover the hole.