Size module

The fineness modulus is determined by the percentage of total residue on the sieves and directly depends on the grain composition of the material. This is an important property for fine sand. It is most often used in finishing work, and the smaller its components, the more homogeneous the mixture will be.

To clearly demonstrate what we are talking about, look at the photo below:

On the left is coarse material, and on the right is fine sand. If you look closely at their grains of sand, you will notice that in a sample with a fine fraction, the grains lie closer to each other, forming a material of almost uniform consistency. For some construction work this is very important.

According to GOST, regarding the value of the particle size modulus, fine sand is divided into the following groups:

- Small (1.5-2)

- Very fine (1.0-1.5)

- Thin (0.7-1.0)

- Very thin (less than 0.7)

The value of the particle size modulus for each group is indicated in parentheses.

In our region, material is mined with a particle size modulus from 1.17 to 2.3.

What does sand fineness modulus mean?

The use of sand as a filler in concrete mixtures is mandatory. The viscosity of the solution and the consumption of cement depend on this. The particle size module allows you to select the material necessary to obtain the fluidity of the composition required by the standard.

Size indicator

Sand is an inorganic substance of natural or artificial origin, divided into particles with a size <5 mm. Characteristics depend on its composition, as well as technical features.

1. The fractional appearance is of natural origin and is divided by grain size.

2. An enriched version is obtained using special equipment. It is different:

- improved grain composition;

- content of dust and clay elements within limits not exceeding standard values.

The fineness module is used only to estimate the size of a grain of sand, being a conditionally generalizing parameter. This is a variable value that is obtained by dividing by 100 the total sum of all residues obtained on standard sieves with aperture diameters of 2.5-0.16 mm.

1. The maximum fixed limit for calculating the value is <0.1mm.

2. After measurement, the material is divided into several groups depending on the size of the fractions.

3. Sand has the following parameters:

Despite the heterogeneity of origin, the sand fineness module is set in strict accordance with the data of state standards, as well as the technical specifications of the manufacturer.

Effect of grain size

The volume of liquid used in preparing the solution depends on the grain composition. Coarseness has a major influence on the amount of binder used in concrete.

| View | Sand size, mm | Application Description |

| Alluvial, small | <0,7 | Construction work with increased quality requirements (fine mixtures), as well as glass production |

| Occurred as a result of rock destruction | <0,7-5 | Construction of foundations and walls of buildings; tile production; road installation and other works |

| Large and medium size | 2,0-3,0 | Production of reinforced concrete structures, concrete, sidewalk curbs, tiles |

| Very small and medium | 1,0-2,5 | Brick, cement mixtures |

1. Determining the unit of measurement of grain composition allows you to determine what size it belongs to in order to use it in accordance with technological characteristics.

2. Bulk material when preparing solutions must contain grains:

- less than 20% of the total weight passing through No. 0.14;

- < 2.5 mm - for ground plasters;

- on average 1.2 - for finishing mixtures.

3. Sand is part of concrete. The more of this component is introduced into the solution, the higher its viscosity. However, overdoing it can cause loss of strength properties.

The coarseness of river sand causes the formation of intergranular voids and an increase in the consumption of binder to fill them. An increased content of cement paste is required to cover the total surface of small grains, as well as to enhance their mobility.

Module Definition

The separation of the sand composition is affected by its grain size, as well as the content of dust and clay particles. The sand fineness modulus is calculated as follows:

1. A sample weighing 2000 g is dried to a constant % humidity.

2. Gerbils are sifted manually or mechanically through sieves with a cross-section of 10 and 15 mm:

- in 1 minute no more than 1 g or 0.1% of the total mass of the sample should be passed through;

- from the composition remaining on the sieves, the fractions of gravel present in it are calculated;

- the grain size should be >10.5 and <0.16 mm.

3. 1 kg of the sample obtained by sowing is passed through sieves with sizes ranging from 2.5 to 0.14 mm:

- the smallest value corresponds to the sieve diameter with a residue ≥ 95%;

- the largest - the sieve section with a residue ≥ 10%.

4. The resulting module means:

- large > 2.5;

- average 2.5-2;

- fine 2-1.5;

- very fine < 1.5.

5. Based on the measurements taken, calculations are carried out, where:

- m is the sample passed through the sieves;

- mi is the mass remaining on the sample sieve;

- ai = mi/m *100% - residue on a certain sieve;

- A is the total residue on the sieve.

6. The final result is compared with standard data, after which the class is determined in accordance with GOST 8736-93.

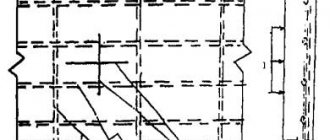

7. Based on the results, a sand sifting graph is constructed, the curve of which should be inside the shaded plane of the diagram.

The particle size module allows you to determine the suitability of a material for a certain type of work. If necessary, sand is enriched to reduce the content of excess fractions.

Author: Valentin Tokarev

| Related articles: | |

| Minimum thickness for sand concrete screed made of M-300 Application of Axton sand concrete Composition and ratio of components of sand concrete grade M300 | |

Grain composition

The particle size modulus and sand class depend on this indicator.

The grain composition is examined according to two criteria:

- Complete residues on sieves

- Content of grains of a certain size

Total residues on sieves are determined by sifting a sample of raw materials on sieves with cells with a diameter of:

- 2.5 mm

- 1.25 mm

- 0.63 mm

- 0.315 mm

- 0.16 mm

- Less than 0.16mm

For fine sand, the total residue on the sieve is set to 0.63 mm, which is 10-30%. In our region it varies from 27.7 to 30%. The sum of the percentage of total residues on each of the sieves, divided by 100, gives the value of the particle size modulus.

The content of grains larger than 10 mm, larger than 5 mm, and smaller than 0.16 mm affects the determination of the sand class. GOST establishes the proportion of grain content from 5 to 20%. In the Sverdlovsk region there is no sand containing grains larger than 10 mm.

Other indicators vary within the following values:

- More than 5 mm – 4.4-0.32%

- Less than 0.16 mm – 8.9-2.8%

Based on these data, we can conclude that all fine sand sold in our region belongs to the first class.

Technical requirements

4.1 Sand must be manufactured in accordance with the requirements of this standard according to technological documentation approved by the manufacturer.

4.2 Sand, depending on the values of standardized quality indicators (grain composition, content of dust and clay particles), is divided into two classes.

4.3 Main parameters and dimensions

4.3.1 Depending on the grain composition, sand is divided into groups according to size:

- Class I - very coarse (sand from crushing screenings), increased coarseness, coarse, medium and fine;

- Class II - very coarse (sand from crushing screenings), increased coarseness, coarse, medium, fine, very fine, fine and very fine.

4.3.2 Each sand group is characterized by the particle size modulus value indicated in Table 1.

Table 1

| Sand group | Size module Mk |

| Very large | St. 3.5 |

| Increased size | » 3.0 to 3.5 |

| Large | » 2,5 » 3,0 |

| Average | » 2,0 » 2,5 |

| Small | » 1,5 » 2,0 |

| Very small | » 1,0 » 1,5 |

| Thin | » 0,7 » 1,0 |

| Very thin | Up to 0.7 |

4.3.3 The total sand remaining on the sieve with mesh No. 063 must correspond to the values specified in Table 2.

table 2

| Sand group | Full residue on sieve No. 063 |

| Very large | St. 75 |

| Increased size | » 65 to 75 |

| Large | » 45 » 65 |

| Average | » 30 » 45 |

| Small | » 10 » 30 |

| Very small | To 10 |

| Thin | Not standardized |

| Very thin | » » |

| Note - By agreement between the manufacturer and the consumer, in class II sand, the total residue on sieve No. 063 is allowed to deviate from the above, but not more than ±5%. | |

4.3.4 Content of grains of coarseness. 10, 5 and less than 0.16 mm should not exceed the values specified in Table 3.

Table 3

| Sand class and group | Grain size content | ||

| St. 10 mm | St. 5 mm | Less than 0.15mm | |

| I class | |||

| Extra fine, large and medium | 0,5 | 5 | 5 |

| Small | 0,5 | 5 | 10 |

| II class | |||

| Extra large and extra fine | 5 | 20 | 10 |

| Large and medium | 5 | 15 | 15 |

| Small and very small | 0,5 | 10 | 20 |

| Thin and very thin | Not allowed | Not standardized | |

4.4 Characteristics

4.4.1 The content of dust and clay particles in the sand, as well as clay in lumps, should not exceed the values specified in Table 4.

Table 4

| Sand class and group | Content of dust and clay particles | Clay content in lumps | ||

| in natural sand | in sand from crushing screenings | in natural sand | in sand from crushing screenings | |

| I class | ||||

| Very large | — | 3 | — | 0,35 |

| Extra fine, large and medium | 2 | 3 | 0,25 | 0,35 |

| Small | 3 | 5 | 0,35 | 0,50 |

| II class | ||||

| Very large | — | 10 | — | 2 |

| Extra fine, large and medium | 3 | 10 | 0,5 | 2 |

| Small and very small | 5 | 10 | 0,5 | 2 |

| Thin and very thin | 10 | Not standardized | 1,0 | 0,1* |

| * For sands obtained during the enrichment of ores of ferrous and non-ferrous metals and non-metallic minerals from other industries. Note - In very fine natural sand of class II, in agreement with the consumer, the content of dust and clay particles up to 7% by weight is allowed. | ||||

4.4.2 Sands from crushing screenings are divided into grades depending on the strength of rock and gravel. Igneous and metamorphic rocks must have a compressive strength of at least 60 MPa, sedimentary rocks - at least 40 MPa.

The grade of sand from crushing screenings must correspond in strength to that indicated in Table 5.

Table 5

| Strength grade of sand from crushing screenings | Ultimate compressive strength of rock in a water-saturated state, MPa, not less | Gravel grade according to crushability in the cylinder |

| 1400 | 140 | — |

| 1200 | 120 | — |

| 1000 | 100 | Dr8 |

| 800 | 80 | Dr12 |

| 600 | 60 | Dr16 |

| 400 | 40 | Dr24 |

| Note - It is allowed, by agreement between the manufacturer and the consumer, to supply sand II from sedimentary rocks with a compressive strength of less than 40 MPa, but not less than 20 MPa. | ||

4.4.3 Sand intended for use as a filler for concrete must be resistant to the chemical effects of cement alkalis.

The durability of sand is determined by its mineralogical and petrographic composition and the content of harmful components and impurities. The list of rocks and minerals classified as harmful components and impurities and their maximum permissible contents are given in Appendix A.

4.4.4 Sand from rock crushing screenings, having a true grain density of more than 2.8 g/cm³ or containing grains of rocks and minerals classified as harmful components in an amount exceeding their permissible content, or containing several different harmful components, is released for specific types of construction work according to technical documents developed in accordance with the established procedure and agreed upon with laboratories specialized in the field of corrosion.

4.4.5 It is allowed to supply a mixture of natural sand and sand from crushing screenings with a content of the latter of at least 20% by weight, and the amount of the mixture must meet the requirements of this standard for the quality of sand from crushing screenings.

4.4.6 The manufacturer must inform the consumer of the following characteristics established by geological exploration:

- mineralogical and petrographic composition indicating rocks and minerals classified as harmful components and impurities;

- emptiness;

- content of organic impurities;

- the true density of sand grains.

4.4.7 Natural sand, when treated with a solution of sodium hydroxide (colorimetric test for organic impurities according to GOST 8735), should not give the solution a color that matches or is darker than the color of the standard.

4.4.8 The sand must be given a radiation-hygienic assessment, based on the results of which the scope of its application is determined. Sand depending on the specific effective activity of natural radionuclides A

eff is used:

- at A

eff up to 370 Bq/kg - in newly constructed residential and public buildings; - at A

eff St. 370 to 740 Bq/kg - for road construction within the territory of settlements and areas of prospective development, as well as during the construction of industrial buildings and structures; - at A

eff St. 740 to 1500 Bq/kg - in road construction and stumps of populated areas.

If necessary, in national standards in force on the territory of the state, the value of the specific effective activity of natural radionuclides can be changed within the limits specified above.

(Changed edition, Amendment No. 1, 2).

4.4.9 Sand should not contain foreign contaminants.

Content of dust and clay particles

This indicator also influences the determination of the sand class: the fewer impurities it contains, the better its production performance. Small pieces of dust and clay negatively affect the adhesion of the material, which can lead to a decrease in the quality of the cement mortar and finishing mixture.

GOST establishes that fine sand should contain no more than 5% dust and clay particles. In the raw materials of our region, the figure reaches 2%, which, again, allows us to classify it as first class.

Application range of medium-grained sand

Sand with medium-sized particles is an indispensable component when creating solutions and mixtures of various compositions. The relatively fine structure of the sand grains allows it to be compacted without any difficulty. Therefore, medium-sized sand is often used as bedding. The breadth of its use is limited only by the increased percentage of impurities in it. The fewer foreign inclusions in the sand, the greater the quantity it is used at almost every stage of construction work, starting from the installation of an underlying cushion under the foundation and ending with its use in the process of finishing work. Medium-grained sand in accordance with GOST 8736 of 2014 is most in demand in the following types of work:

- construction of buildings and structures;

- installation of foundations;

- road construction;

- laying paving slabs;

- creation of drainage systems.

Sand class

As mentioned above, this indicator, according to GOST, is influenced by three factors: the percentage of grains with a particle size of 0.16-10 mm, dust and clay particles, as well as clay in lumps.

In our region, sand of both first and second classes is mined. The material of the first class is used in the production of high-strength structures, the second - as an element of concrete mortar and for the cushion of highways.

Indicators for first class sand:

- The percentage of fractions up to 10 mm in size is 0.5-10%

- Dust and clay particles – 3%

- Clay in lumps – 0.35%

Indicators for fine sand of the second class:

- The percentage of fractions up to 0.16-10 mm in size is 0.5-20%

- Dust and clay particles – 5%

- Clay in lumps – 0.5%

Difference from other species

River sand is a pure material. It contains no impurities, clay, pebbles or other foreign particles.

The material is characterized by fractional homogeneity. Due to this, it is used in the production of dry mixtures for construction work. It is also used as a filler for floor screeds and in the process of producing asphalt concrete mixtures.

River sand is an excellent natural filter that removes various impurities from water. The material is used as an element of the treatment system and drainages are equipped with it.

In home gardens, river material is added to the soil to make it loose.

Difference from sea

There are no significant differences between these types. Marine, like river, is of high quality, without foreign impurities; during extraction, it undergoes a two-stage enrichment. It is used in the manufacture of concrete solutions and mixtures.

Difference from career

It is difficult to unequivocally answer which of these types is better - it all depends on the further scope of the material. Quarry is a mixture obtained by crushing rocks with special devices, as well as in quarries.

Quarry sand contains admixtures of clay and stone particles. Often, building materials behave unpredictably, reacting with other chemical elements in the solution. It cannot be used as a filter in a treatment system—washed quarry sand is more suitable for making concrete.

Bulk density

The bulk density value is the ratio of the volume and mass of fine sand. The higher the density, the greater its weight. This indicator is important to take into account when calculating the need for building materials.

Bulk density depends on several indicators:

- Humidity

- Porosity

- Presence of impurities

In our region, the indicator of this property for fine sand varies from 1,412 to 1,420 kg/m3.

Read more about this characteristic on the page Bulk density of bulk materials. Bulk density indicators for different types of sand can be found on our page Bulk density of sand (comparative characteristics).