What is a classic dowel?

The first requirement for fasteners is workmanship. The classic version of the part consists of a plastic bushing with notches. They are necessary to prevent the fasteners from turning. The main element is a specially formed rod. It guarantees the strength of the fastening, since after it is inserted into the sleeve, the latter expands, pressing the body and notches into the concrete. This fastening option is available for dismantling - the rod has notches that allow it to be unscrewed with a screwdriver.

What types of dowels for concrete are there?

Figure 1. Concrete dowels

A standard concrete dowel is inserted inside the drilled holes. Such products are used everywhere, they are used almost everywhere, although the maximum effect is achieved when installing doors and windows in concrete walls. Thanks to the possibility of simple dismantling, it is possible to maintain the original appearance of the removed structure.

Metal dowels for concrete are classified into two types:

- anchor hardware that allows you to securely fasten structures to layered or multi-hollow concrete surfaces;

- expansion products for monolithic concrete.

Universal mount

The new system is intended for use in industry and everyday life. It has become widespread due to its distinctive technical properties, high manufacturability and ease of use.

Hilti chemical anchor is used for rod-bearing parts for various purposes. The composite material, created from synthetic durable resins, provides sufficient strength. Among the distinctive characteristics, it is worth noting a significant increase in the level of quality of elements under tension and fracture. Chemical properties improve the installation quality of steel products and are superior to standard options. Such results can be achieved by excellent adhesion of the rod part and the base, with a hardened synthetic resin composition.

The Hilti chemical two-element anchor allows you to fasten elements with a large weight on any concrete and stone surfaces. The high level of sealing is an additional advantage. This plays a special role when operating in conditions of high humidity. Some types of bases do not allow the formation of high-quality fastening of metal products using steel or plastic dowels. This applies to loose building materials, including natural stone, hollow brick and aerated concrete.

Dowels intended for heavy loads are made of metal alloys and equipped with threaded elements (bolts and studs). They are suitable for the installation of lifting hoists, garage doors and sun awnings. In accordance with safety precautions, metal options should be used to secure the suspended ceiling, since in the event of a fire the plastic can melt and there is a threat of the ceiling falling.

Elements for porous material can be mounted without drilling holes. The dowel for concrete and brick easily fits into the wall using a standard screwdriver due to the large thread on the outside and the tip, which is similar to a feather drill.

Features of fasteners for concrete walls

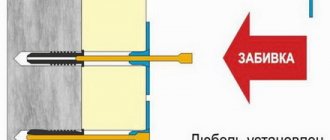

Figure 2. Dowel fastening for concrete

To connect parts and concrete, it is not necessary to hire craftsmen, since all actions are available for independent use. All you need is the dowel itself, a sharp nail, an electric drill equipped with a Pobedit drill, insulating tape, and a hammer.

The stages of fastening the structure are as follows:

- The location of the fastener is marked with a sharp nail after careful measurement.

- At this point a slight indentation is made.

- Select a suitable drill. The dowel must fit into the finished hole using some force - then it will be securely fastened. On the drill, a mark of the required hole depth is made in advance with insulating tape. The drill is positioned strictly perpendicular to the concrete surface and a hole is drilled.

- After this procedure, you need to remove dust from the hole with a vacuum cleaner.

- Then the fasteners are carefully inserted into it, hammering until it stops. Having placed the part to be fixed, screw or drive a screw into the dowel.

Drilling dust will tell you what the wall is made of.

In an old house, people often don’t know what building material is hidden under the wallpaper or plaster. Dust from a borehole will provide an explanation. If the drilling dust is like fine flour and free-flowing, it is probably concrete. The dust will be white to light gray in color. Porous concrete is also white, but coarse and somewhat sticky. It provides a bit of resistance to the drill. Contrasted with concrete: this requires the use of a hammer drill.

Clay bricks and hollow bricks produce red or yellowish drill dust. Calcareous sandstones break down into white borer flour, which has a sandy feel. Gypsum board has a fine white flour that clumps together in the channels on the drill bit. With gypsum fiber boards it is light gray. Depending on the material, special dowels are also needed to hold the screw.

Choosing a dowel for concrete

The main problem for the home craftsman is to choose which dowel is best suited for concrete. When choosing, you need to take into account what the operating conditions of the fixed part will be, expected loads, fastener features and type of material:

- for heavy structures, dowels for concrete are suitable, providing an attachment depth of more than 85 mm;

- with horizontal fixation, a mounting depth of 30 mm and a hardware diameter of 7–11 mm are sufficient;

- in order to mount lighting fixtures or suspended ceilings, in which the main load is assumed to be from below, you need to purchase fasteners equipped with transverse notches, having antennae of different lengths;

- when selecting fasteners, it is important to ensure that its diameter matches the size of the hole;

- for weak walls, the fasteners become a softening pad so that the load is evenly distributed over the product;

- in case of increased load, it is necessary to select reinforced fastening elements - it is recommended to select their exact parameters using special tables;

- For old concrete, it is recommended to use universal fasteners, since there may be voids in the material.

Types of dowels and their use according to the method of fixation

The design features of the fastener are related to the characteristics of the material into which the sleeve is driven.

All types of dowel clamps according to this criterion are divided as follows:

- products for materials with increased density. Most fasteners with a spacer operating principle are suitable for solid concrete walls, brick foundations and heavy concrete. The products differ in the configuration of the protrusions, the number of cuts and sizes. Reliability of fastening is ensured due to the friction force, as well as the increased density of the array;

- fasteners for cellular and hollow materials. Porous substrates are characterized by low strength, so it is important to choose the correct hole diameter to ensure effective contact with the fastening unit. Nylon dowels, as well as liquid dowels, have proven themselves to be good for cellular bases;

- fasteners for drywall and thin boards. Sheet building materials are mounted to special profiles. As a result, a cavity is formed where the heat insulator is laid. The dowel clamp for such structures is called a butterfly. It has elongated slots. When screwing in the self-tapping screw, the sleeve takes on an umbrella shape.

When choosing a fastener to perform specific tasks, take into account the characteristics of the building material and select the correct fasteners, taking into account the method of fixation.

Rules for installing dowels for brickwork

The stages of fastening the product, if necessary, to connect something to a brick wall, look like this:

- First, drill a mounting hole in the wall. It is convenient to carry out the work with an electric drill. The diameter of the drill is selected the same as that of the dowel.

- Then the hole is thoroughly cleaned, removing construction dust. After this, the fasteners must fit inside without obstacles.

- Next, use dry tile adhesive, which is diluted with water. After receiving the adhesive mass, it is pushed into the hole. It is convenient to carry out the procedure with a rubber spatula; to push the adhesive mass through, use a regular pencil. Once the hole is filled, the dowel is inserted into it until it stops. Then allow the glue to harden, pausing for a day.

- The next stage is screwing the screw into the product. When performing the procedure, be sure to control that the process occurs with a certain effort. When it is present, it means that the dowel is really securely held inside the brickwork.

- By scrupulously following the action plan, you obtain fasteners that are characterized by excellent reliability, guaranteed to withstand even very significant weight loads.

Figure 3. Installation of a dowel for concrete

The described technique can also be used for situations where it is necessary to ensure reliable fastening of the dowel inside any other porous material. These are aerated concrete, foam concrete, certain types of porous brick, and cinder block. Taking into account the high popularity of these building materials on the market, the selection of fasteners for them that can guarantee reliable fastening of any objects to surfaces is quite an urgent task.

Synthetic resin helps in problematic cases

Some walls made of modern building materials, as well as an old stone wall, are not strong enough to support, for example, a countertop with a sink. In such cases, the so-called Injections system will help. A quickly hardening synthetic resin mortar is injected into the hole and a screw or dowel with an external thread is inserted. The mortar seals it into the stone wall.

Removing fasteners

Figure 4. Dismantling a dowel for concrete

When purchasing various options for dowels, you should always think about how you will have to dismantle fasteners that will lose their relevance. Life is changeable - there is always a situation when the completed fastening will need to be disassembled in order to move it to another place. It is advisable to think about this even at the stage of installing the dowel. To quickly remove it, you will need different tools, but all of them are usually present in the home craftsman's pantry. It is worth understanding that certain fastenings (such as chemical ones) cannot be dismantled in principle.

How to disassemble the mount:

- To remove a plastic product, it is quite enough to use a self-tapping screw of the appropriate diameter. It is screwed in approximately 2/3 of the depth, then the head of the hardware is clamped with pliers, removing the fastener simultaneously with the dowel. Sometimes it is enough to use an ordinary corkscrew for the procedure.

- If the self-tapping screw is screwed into the dowel, its head can be pryed off using a nail puller. However, you need to make sure that the hardware fits tightly in the hole.

- If the dowel is wooden, it is removed in parts. To do this, a piece of wood is crushed along the grain with a chisel and hammer. Then the remains are pryed with an awl or nail, removing them from the hole.

- When the product sits firmly in concrete, it is easier not to dismantle it at all, but to cut it flush with the wall, covering the recess with plaster.

- When part of the screw remains inside the fastener, a heated soldering iron will help. With its help, the plastic base is melted, then the fragment is pryed with round pliers and removed.

- A metal dowel, embedded in concrete using a construction gun, is treated with powerful and frequent blows of a sledgehammer, acting on the protruding elements of the product from all sides. Typically, this procedure leads to loosening of the anchor, after which it can be simply removed. If the event fails, make a hole near the fastener with a drill. Thanks to the presence of a circular funnel, the area of contact between the dowel and the wall is reduced, after which it can be removed without problems.

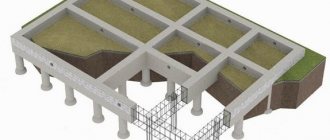

We secure a heavy load in walls with a void

For heavier installations on walls with voids, special dowels were developed. Such a dowel spreads out into a star-shaped cavity and is therefore securely fixed in the wall. To open such dowels, there is a special tool that can be found in a construction supply store.

The soft structure of porous concrete sometimes creates problems for the worker. But here, too, special dowels help, with which you can strengthen almost everything in this material. Here, manufacturers offer various methods. These are the external threads that cut into the concrete to secure them in place, as well as the three-part body of the dowel.