Reinforcement of a pile-grillage foundation for a private house and the pile foundation itself are used when constructing a building in non-standard conditions. This may be a large amount of groundwater, strong changes in elevation, or weak soil that is not able to properly withstand the pressure of the building. This type is also used for construction in permafrost zones. Under such conditions, it is impossible or too expensive to use a monolithic or strip foundation.

At the design stage, and further throughout the work, SNIP and GOST standards are used to determine the materials used and construction technology.

Other types of foundations are solid, monolithic structures, and thanks to this, the weight of the building is evenly distributed without the use of additional devices. The pile structure is divided into parts, each of which is subjected to different pressure, as a result of which some piles can sink more than others, thereby posing a threat to the integrity of the building. In order to combine individual piles into a strong and integral structure, regardless of their type, a grillage slab is used. With such a foundation arrangement, the main pressure falls on the grillage, which redistributes the load and transfers it to the piles.

The pile-grillage foundation is reinforced, then the slab is formed from concrete. For a private house, reinforcement is a mandatory element. The fact is that concrete itself is a very durable material and can withstand compressive loads well. But when stretched or bent, it tends to crack and deform, since it is not flexible enough. In order to prevent this, the entire structure is reinforced with a reinforcing frame consisting of individual metal rods. The plasticity of the metal gives the foundation the necessary properties and makes it more durable and reliable.

Types of grillage

There are two main types of grillage:

- A strip grillage is formed in the same way as a strip foundation - a narrow concrete strip connects the piles to each other and does not cover the entire area of the house. This type of grillage requires much less materials than a monolithic one, and it will cost you less. A strip foundation is formed along the perimeter of the building, which ensures the reliability of the load-bearing walls.

- Monolithic. Covers the entire area of the house. To pour a monolithic foundation, a very large amount of concrete and reinforcement is required, so it is not used as often as a strip foundation. However, in some cases this choice is quite justified.

Selection of fittings

The lower part of the grillage most often bears the heaviest loads, so the lower layer of the reinforcing frame is assembled from thick corrugated rods, their diameter must be at least 2 cm. The upper part of the reinforcement of a pile-grillage foundation for a private house mainly performs the function of redistributing pressure, so reinforcement up to 1 cm thick is sufficient to form it. Various types of reinforcement are used to perform reinforcing work:

- A1 – reinforcement with a smooth surface and a relatively small diameter. Such rods can be used in places of the frame where heavy loads are not expected, as well as to create the foundation of the structure.

- A3 – reinforcement with an uneven surface. These are rods with a diameter of 1 cm. They have increased strength characteristics and a diameter of 1 cm. There are 2 main types of corrugated reinforcement: with a ring-shaped profile - for increased adhesion to concrete and with a crescent-shaped profile - to counteract tensile deformation. There may also be mixed options that offer the benefits of both types.

In order to reinforce a pile-grillage foundation for a private house, two types of connections are used - welding and wire knitting. Thus, when choosing metal rods, pay attention to how they will be attached to others. Only fittings marked “C” are suitable for welding.

Welding unsuitable reinforcement can lead to a loss of strength and elasticity in the material and an increased tendency to corrosion, which will negatively affect the condition of the entire foundation.

APPLICATION AREA

1.1. The technological map has been developed for the installation of four-pile grillages of grade R-4 under standardized steel supports.

1.2. The map serves as a guide for the construction of power lines, as well as a guide for designing work.

1.3. The works covered by the map include:

— alignment of immersed piles to the level with installation of linings;

— slinging and installation of grillages;

— fixing grillages on piles with installation welding;

— checking the correctness of the marks and installation dimensions for the support.

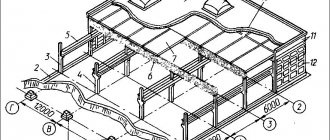

Reinforcement scheme for pile foundation grillage

When reinforcing the grillage of a pile foundation, a drawing must be drawn up before the start of construction work. When creating a drawing, it should be taken into account that in places where the grillage is connected to the piles, there are increased loads; such places require additional reinforcement by increasing the frequency of laying horizontal reinforcement by 2 times. The process of laying the reinforcement will differ depending on the type of grillage.

- For a strip-type grillage, creating a drawing for the reinforcement of a pile foundation grillage is quite easy. To perform this, you should take into account the width and height of the tape. The standard distance between horizontal rods is 8-10 cm. They are laid in two layers - upper and lower, which are connected to each other by sparser vertical rods.

- For a monolithic grillage, high-strength reinforcement is used. To do this, reinforcement with a diameter of 20-25 mm is laid across the entire area of the house. The laying step is from 10 to 15 cm, depending on the type of construction. In addition to standard vertical and horizontal elements, the design of such a frame for additional reinforcement also contains cross-laid rods designed to maximize the strength of the pile foundation grillage reinforcement.

The drawing allows for the presence of only a lower layer of the reinforcing frame, since it is this layer, as in the case of a strip grillage, that takes on all the loads. The upper mesh is often absent completely or remains only in the form of thin additional rods.

To obtain the most accurate calculations, it is necessary to take into account not only the weight of the future structure, but also the weight of the roof, concrete floors and additional loads that will appear in the future. Furniture, equipment, precipitation and the number of people who will be in the building at the same time.

Thus, when performing the reinforcement-grillage of a pile foundation, the drawing gives you all the necessary information about the amount of materials needed for the work and the type of reinforcement.

ORGANIZATION AND TECHNOLOGY OF THE CONSTRUCTION PROCESS

2.1. Before installing grillages, the work provided for in clause 0.2 of the general part must be completed.

2.2. The grillages are installed using a TK-53 assembly crane, the technical characteristics of which are given in the general part.

2.3. Technical sequence of work:

a) align the sunken four piles of the bush for installing a grillage (height marks - with a level, distance in plan - with a tape measure);

b) check the compliance of the grillages with the working drawings and the actual position of the loaded piles;

c) run the threads of the anchor bolts of the pile;

d) install metal pads to level the four piles of the bush at the same level;

e) rig the grillage according to Fig. 0-7 and drag it with a crane to the installation site;

f) install with a crane the two lower beams of the grillage in series, fixed on the piles, and temporarily secure them by screwing in the nuts of the anchor bolts;

g) install with a crane the upper beam of the grillage, fixed to the lower beams;

i) check the installed grillages in accordance with the tolerances given in clause 0.5 of the general part, in the following order:

for free-standing supports (racks) - after installing all four grillages,

for portal supports with guys - after installing two grillages under the posts,

for grillages for guys - after installing each of them;

j) weld the lower beams of the grillage to the support pads, and the upper beams to the lower ones;

k) finally secure the lower beams on the piles with anchor bolts.

2.4. Orient the grillages under the guys by tilting the frame towards the center of the support.

2.5. For safety instructions, see general section.

2.6. Labor Costing

| Justification (ENiR, etc.) | Name of works | Unit change | Scope of work | Standard time per unit Meas., person-hour | Labor costs for the entire volume of work, man-days |

| EniR § 3-3-4 |

Reinforcement of a pile-grillage foundation

Rods released from the piles are used to connect the reinforcing grillage of the frame and the pile structure. All elements are fastened together by welding. When forming the frame, you should strictly follow the drawn up drawing of the pile foundation grillage and ensure compliance with the standards. The reinforcement is laid in two layers, which must be fastened together with vertical rods. They may not be too thick and have a smooth surface, since they are practically not subject to load and are intended solely to create the base and shape of the frame.

Reinforcement of a pile-grillage foundation for a private house occurs in several stages:

- Construction of trenches between piles. Sand and fine crushed stone should be sequentially poured and compacted into these trenches. This is done so that the grillage pressure is subsequently transferred not directly to the ground, but to the supporting cushion.

- Formwork assembly. Carefully ensure that there are no cracks or crevices on the surface of the formwork, this will lead to leakage of the solution.

- Reinforcement of the lower part of a pile-grillage foundation for a private house. This part must be especially strong, since the main loads fall on the bottom of the grillage.

- Installation of vertical rods and additional supporting elements.

- Assembling the upper part of the frame.

- Fastening all individual parts of the frame with wire and, if necessary, welding.

- Pouring the structure with concrete.

N 1, 2

k=1.1 for welding

Installation of one grillage, consisting of 3 beams (under the rack of a single-post support on guys) 1 grillage 1 3(2.4+0.8)1.1=9.9 1.21 The same, two grillages (under the racks or guys of the portal supports) » 2 » 2.42 The same, three grillages (for the guys of a single-post support) » 3 » 3.63 The same, four grillages (for the legs of a single-post free-standing support, as well as for supports with guys) » 4 » 4.84 The same, twelve grillages (for a three-post free-standing support) » 12 » 14.52Pouring concrete

After completing the formation of the reinforcement frame, you can begin pouring the slab with concrete. Concrete, when forming the concrete base of the grillage, must be of a grade no less than M250 or M300. Such concrete has sufficient strength and is used for pouring foundations, stairs, columns and other structures that require maximum reliability. The required amount of concrete mixture for construction work must be calculated taking into account the percentage of concrete shrinkage after hardening.

When performing reinforcement of a pile-grillage foundation for a private house, it is extremely important to perform all calculations with maximum accuracy. A lack of materials necessary to continue the work can lead to an interruption of the construction process. Subsequently, this will negatively affect the strength characteristics of the foundation, since unevenly hardened concrete is prone to cracks and deformation. In turn, excess concrete is wasted money.

Concrete gains the necessary strength after 28 days, but you can walk on it after just a week. It is worth noting that a month after pouring, concrete sharply loses its hardening rate, but gradually becomes stronger over many years.

TECHNICAL AND ECONOMIC INDICATORS

| Index | Number of grillages per support | ||||

| 1 | 2 | 3 | 4 | 12 | |

| Labor intensity, person-days | 1,21 | 2,42 | 3,63 | 4,84 | 14,52 |

| Number of units, people. | 4 | 4 | 4 | 4 | 4 |

| Duration of installation of grillages under one support, shifts | 0,3 | 0,6 | 0,91 | 1,21 | 3,63 |

| Unit productivity per shift, supports | 3,3 | 1,67 | 1,1 | 0,83 | 0,28 |