The overall design of a large house is difficult to imagine without some small architectural forms. Concrete balusters, inscribed in elegant flights of stairs, are striking representatives of design creativity. They provide a certain charm and style to the entire structure.

Balusters are shaped posts that are designed to support railings.

Concrete balusters are offered ready-made in a very wide range. You can choose designs to suit every taste and for a variety of purposes, or you can do it yourself. Their appearance attracts the eye and provides the first impression.

Features of balusters

In general, balusters are vertical column-type structures used as supports for railings of fencing systems. They are mainly installed for fencing stairs, balconies, terraces, roofs and other structures. In addition to the fact that they must provide a reliable basis for the railing, their task is to prevent a person from falling from a height (safety functions) and decorative functions. Based on the purpose of balusters, we can distinguish the following properties:

Arrangement of balusters.

- sufficient stability;

- mechanical strength;

- resistance to external factors (precipitation, temperature, etc.);

- decorative appeal (shape, color, surface quality).

In the design of a baluster, three elements can be distinguished: the base, the central (decorative) section and the railing support. The base, or lower part of the column, is intended for attachment to the main structure (steps, platform, etc.), usually through an intermediate element - sub-balusters. This element should ensure the stability of the post and the reliability of the fastening. The central section is the largest element, providing decoration and security functions. The railing (handrail) support, or upper part, is intended for fastening the railing of the fence.

The size of the balusters depends on the purpose of the fence. As a rule, handrails are installed on them, and their height should be comfortable for the placement of hands, about 80-100 cm. The distance between the posts is normalized based on safety requirements, no more than 15 cm. The shape and thickness of the central part is determined mainly by the design project. The most widespread is the round cross-section of the pillar, and along its length it can have the most bizarre shape.

Balusters

Balusters are architectural and decorative elements of staircases, balconies, fences indoors or outdoors. These are shaped posts supporting the railing, made in the form of round or polygonal objects in cross-section. They are designed not only to ensure the stability of the railings and the safety of movement along the stairs, but also to serve as a decoration element that transforms even the simplest design of a flight of stairs, the facade of a house, balconies, terraces and gazebos.

Prices

| Name of product | Price |

| Balustrade (7 balusters, 2 posts, total length 230 cm) | from 8,500 to 15,000 rubles. |

A variety of materials are used to make balusters. It can be wood, cast iron, bronze, steel, brass, stone, concrete, marble. They are made from the same material as the steps, but can also contrast with it in combination, for example, wood and metal, metal and stone. The surface of the racks is also decorated in accordance with the general style of the staircase: with figured carvings, painting or spraying, decorative stucco.

Photos of our products

It is extremely important to give the balusters a certain shape. It should not only fit harmoniously into the overall architectural ensemble, but also emphasize the empty silhouette formed by the beautiful shape of the figured racks. The composition of the balustrade made of railings and balusters gives the architectural structure lightness and dynamism in space.

Balusters convey the general style of the building, adding some aristocracy and solidity to the building. Most of all, this is conveyed by figured racks made of modern concrete using the vibratory casting method. While adding some sculptural quality, concrete balusters add classic architectural features to buildings. Products made from cast concrete do not require glossing after stripping, since the molds used to cast the products create a very smooth surface. Painting in a special way allows you to create an imitation of any natural stone.

Our company produces balusters from architectural concrete, which is particularly durable and decorative. Concrete structures allow you to design the product in any style and direction. The vibratory casting method promotes high speed of production of products, a large selection of models, as well as ease of assembly and installation without chips or damage. In addition, we ourselves make molds for balusters, both for mass production and for individual orders. Thus, we can qualitatively fulfill any wish of our clients.

Dear Clients! We manufacture and sell forms for all concrete products.

Features of concrete balusters

Balusters can be made from a variety of materials (marble, granite, gypsum, wood, etc.), but quite often they are made of concrete. Despite the apparent lack of solidity of concrete balusters, their appearance can acquire a very rich, sophisticated look. This is due to the use of decorated concrete, in particular concrete marble or granite.

Concrete balusters are highly durable and durable.

In general, a concrete baluster has a number of advantages:

- high strength;

- manufacturability;

- frost resistance;

- waterproof;

- weather resistance;

- low cost;

- possibility of making it yourself.

An important property is the ability to produce identical figures of a sufficient degree of complexity in the manufacture of the desired mold. The main disadvantages are low impact strength, insufficient smoothness (lack of gloss) of the surface, lower durability compared to marble or granite.

Structurally, a concrete baluster contains a reinforcing element around which a hardened concrete mass is located. The fittings have exits at the top and bottom for mounting to the base and fastening the railings. All 3 parts of the pillar are usually made simultaneously by pouring concrete mortar into the mold.

Types of balusters

Depending on their appearance, all balusters can be divided into four types.

Turned balusters

They are made in the form of bodies of revolution. This type is the easiest to produce, and its price is appropriate. But, meanwhile, such balusters have an elegant appearance.

Milled balusters

This type of balusters has different types of cutting. Most often, longitudinal and transverse cutting is performed.

Carved balusters

Such wood products are complex; most often, they have a variety of small carving elements. To produce such balusters, it is necessary to use precise and complex equipment. Therefore, such balusters have the highest cost.

Forged balusters

Forged balusters are often used with wooden stairs and wooden railings. As you know, forged products have been used for many centuries in the design of interiors and exteriors; they are excellent for both exterior and interior decoration. Such balusters enliven the room, creating an atmosphere of grace and sophistication.

Concrete for balusters

Scheme for preparing a concrete mixture.

The simplest concrete balusters can be made from cement-sand mortar filled with pebbles of various sizes. Such elements are coated with a primer and painted with paint of the desired color. This is the cheapest option for concrete balusters.

Colored concrete involves the introduction of special coloring pigments for concrete mixtures. Currently, more than 20 different color shades of such dyes are sold, which makes it possible to prepare a solution of the desired color. Standard pigments are supplied with a special hardener that provides the protective properties of colored concrete. These ingredients are made from metal oxides. For example, malachite color is provided by chromium oxide, reddish shades are provided by iron oxide, and manganese oxide is responsible for indigo color. Sufficiently durable concrete marble is obtained by introducing the oxide in a concentration of up to 1% by weight.

Decorative concrete can be obtained by grinding the surface onto which large grains of multi-colored aggregate emerge. For these purposes, crushed particles of marble, granite, limestone, basalt and other natural stones and minerals are used. Such surface manifestations of the aggregate can be made corrugated or ground into a smooth surface. Particularly impressive concrete surfaces are created when using aggregates in red, pink and gray colors.

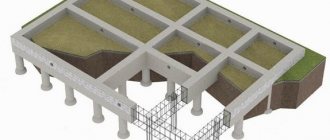

Elements of a concrete stair railing

Stair railings consist of several basic elements:

- handrails;

- balusters;

- support posts;

- decorative elements.

Staircase elements.

All of them will be needed both for the porch and for arranging the balcony. Each element of the staircase railing can be made with your own hands. To accomplish this task, special forms will be required. This is a basic, but fairly easily overcome difficulty. To make the mold, you will need plaster and a blank baluster or support, which can be made from any material. It's even easier to find a ready-made sample.

Instead of pouring molds, you can use a self-assembled machine, which is based on a manually rotating metal or wooden rod. Under it there is a tray with concrete, on the side of it there is a baluster template, which is its horizontal projection, cut lengthwise from the top to the bottom point vertically.

When the rod rotates, concrete is fed onto it, the excess of which is cut off by the edge of a mold template installed on the side. The resulting blank is left to dry. Then it is treated with cement-sand mortar so as to close possible pores and cavities.

Decorative concrete fencing.

When making supports and balusters yourself, you need to take into account that inside each product there must be a reinforcing element: a reinforcement bar with a cross-section of 7-10 mm (the choice of diameter depends on the size of the part). Therefore, when pouring forms with concrete or when making fencing parts on a machine, a metal rod is placed in the central part of each product.

Its length should be such that the upper part protrudes beyond the baluster (support) by 5-7 cm, and the lower part by 10 cm. These protrusions will be needed when installing structural elements on steps and platforms. If the balusters will be installed on an inclined surface, their upper and lower platforms must be beveled at an angle corresponding to the slope.

To give concrete products a more impressive appearance, they are coated with nitro varnish. It will also provide significant assistance in protecting against moisture.

Making a mold for pouring

Scheme of the form for filling balusters.

A concrete baluster is made by pouring concrete mortar into a mold that completely replicates the appearance of the future baluster. This form can be made of wood, clay, gypsum, foam plastic and other material in which the desired cavity can be easily formed. The most widely used form is a plaster mold, which is made by hand in the following order.

First of all, you need one exact copy of the posts that are scheduled for installation. You can purchase it in a store in one copy or make it yourself from wood, polystyrene foam, plastic, carving it in full accordance with the baluster drawing. A body is then formed around this sample in the form of two identical plaster halves. For casting, prepare the following solution: gypsum (4 parts), slaked lime (1 part), a little citric acid. To strengthen, the gypsum blanks are covered on top with a reinforcing mesh, which is also filled with gypsum.

Carrying out calculations

Any construction begins with preliminary calculations. Balusters are no exception in this matter. Calculating the number of elements needed for a staircase or veranda is very easy, especially if they are already installed.

There is one baluster for each step of the staircase. The distance between the elements on the platforms should be 15-20 cm. When calculating the height, you need to take into account that railings will also be installed on the elements.

However, “dry numbers” may not always turn out to be correct. When making calculations, it is necessary to take into account the design of the structure and its harmony with the overall architectural ensemble.

Element installation requirements:

- the distance between the balusters should not be less than 15 cm;

- the railings must be at least 95 cm high;

- the number of attachment points must be at least two (top and bottom);

- the railings should be comfortable.

Making balusters

Scheme for filling balusters.

To make concrete balusters, plaster molds are joined and secured. The inner surface of the cavity is first thoroughly lubricated with oil. A reinforcing steel wire with a diameter of 4-6 mm is passed through the internal cavity so that its extension on both sides of the mold is at least 10 cm. The bottom of the cavity must be plugged. The concrete solution is poured from above into a vertically positioned gypsum mold with constant compaction of the mass. The consistency of the solution should be sufficiently liquid to fill the mold cavity more completely and densely.

The second method of making a baluster post involves molding it from a semi-dry concrete mixture. In this case, a thick concrete mass is fed into the mold in parts, so that at one time the height of the concrete column is about 5-10 cm. After each portion of the mass fed into the mold, the solution is carefully compacted with rods; then the next portion is poured in. In this way, the entire form is gradually filled, after which it is lowered horizontally several times and raised again. The mold is removed after drying the mass for two hours. The simplest and most reliable way to manufacture elements is to purchase a standard form, which are sold in a wide range.

Preparatory stage

To organize a successful enterprise, an entrepreneur should familiarize himself with all the nuances of the process, draw up a plan for opening and calculate possible costs and investments.

Before making concrete balusters with your own hands, you need to consider the following aspects in detail:

- Calculate the number of balusters. If this is a staircase, then 1 baluster is prepared for each step. When installing fences, posts are placed every 15-20 cm, depending on the shape and diameter.

- Calculate the height of the products taking into account the railings.

- The column design is created at the request of the customer. It is advisable to take into account the general style of the interior.

As for the thickness of the column, it does not matter, and the cross section in the center can vary from 3 to 8 cm. After specifying the type and size of the balusters, you can begin preparing tools and material.

Installation of balusters

Baluster installation diagram.

Balusters are supplied for installation in the form of a hardened concrete shaped column, with the ends of steel reinforcement coming out from below and above. Installation begins by drilling a hole in the base of the railing (staircase) for the reinforcement. The ends of the reinforcement extending from the base of the baluster are placed in the drilled hole and filled with concrete. The pillar is positioned strictly vertically along a plumb line. After the concrete has hardened, a similar operation is carried out with the railings, which are placed on the reinforcement extending from the top of the column. The horizontality of the structure is controlled by a level.

Installation of elements with equal heights is carried out using a pre-tensioned control cord.

A few recommendations for beginners

Only high-quality materials should be used in the production process. It is necessary to follow the algorithm for performing actions. The posts can be installed only after they have completely hardened.

It is better to make concrete railings and balusters to order according to a sketch developed together with the client. Several columns can be made for display.

Before you start making items for sale, you should try making a few pieces for personal use.

The price of concrete balusters depends on the complexity of execution and the size of the products. Medium-sized columns cost from 300-800 rubles on the market. with their cost about 150-300 rubles.

Necessary tool

When manufacturing and installing concrete balusters, you will need the following tools:

- perforator;

- electric drill;

- construction mixer;

- pallet type container;

- scales;

- measuring bucket;

- putty knife;

- Master OK;

- paint brush;

- metal ruler;

- roulette;

- level;

- plumb line;

- Bulgarian;

- chisel;

- hammer;

- knife;

- hacksaw for metal and wood;

- Grinder;

- file;

- construction cord;

- sandpaper.

Concrete balusters can be a wonderful addition to the interior of any home. They can provide the desired aesthetic appearance and the required quality, while they can be made with your own hands. Modern additives to concrete mixtures make it possible to imitate natural stones, which significantly increases the competitive ability of such elements.

What will you need for work?

Balusters.

Before starting installation work, prepare the elements for assembling the structure:

Currently reading: Methods of drilling concrete

Balusters are vertical posts that hold handrails. Handrails are a component of the railing that is held by hand. Bollards (rotary and end) are vertical posts that are stronger than balusters and are attached at the beginning and at the end of the staircase railing.

The choice of construction arsenal depends on the material for the stair railings. So for metal railings you will need:

welding machine; grinder; tape measure; building level; hammer drill; screwdriver; electric drill; cord.

For wooden fencing structures use:

hammer; chisel; chisel; wood saw; jigsaw; screwdriver; screwdriver; building level.

Before installing wooden railings, their surface must be polished.

Return to contents