If you want to carry out repairs yourself, it is important not just to study the sequence of certain works, you need to learn how to correctly calculate the amount of building material. In this article we will talk about how to calculate the consumption of tile adhesive per 1m2. The amount of adhesive composition is always determined in kilograms; it is important to determine how much is used per m2. The resulting figure is multiplied by the total number of meters. This formula allows you to get a general idea of upcoming expenses.

But it is quite difficult to unequivocally answer the question of what is the consumption of tile adhesive per 1 m2 of tiles. And that's why. In each specific case, a different type of tile is used, adhesive mixtures of different composition are purchased, and a different base is used each time. That is why it makes sense to talk separately about each factor that affects the consumption rate of tile adhesive.

Different types of glue

On sale today you can find three main types of adhesive composition for ceramic tiles:

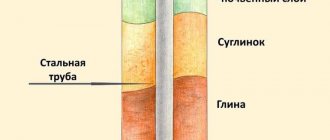

- Cement-based adhesives.

- Dispersion compositions.

- Epoxy mastics.

Cement-based adhesive is the most popular material. It is inexpensive and quite easy to work with. It is possible, if necessary, to adjust the position of the ceramic tiles during installation. The consumption of tile adhesive is also low. It ranges from one kilogram of dry mixture per 1 sq.m. up to 1.9 kg (per mm of installation thickness). It all depends on which manufacturer the composition was purchased from for cladding.

Dispersion compositions are ready-made liquid mixtures. They have high elasticity and strength. That is why they have low glue consumption per 1 m2. These types are used where high waterproofing requirements are not imposed on the tile facing.

Epoxy tile adhesive is a two-component composition. It is based on a resin and a catalyst. When they are mixed, a chemical reaction begins to occur, making it possible to obtain an adhesive composition with unique properties. It is not afraid of water or low temperatures; during hardening, such tile adhesive does not shrink, adheres quite firmly to the surface and does not crack over time. Only experienced tilers can work with such compositions, so they are not very popular among ordinary people.

It is quite difficult to calculate the consumption of tile adhesive per 1 m2 on a dispersion and epoxy basis independently using the above formula. As a rule, there are no general standards for calculating the amount of material that can be used to cover one square meter. Each manufacturer has its own. Therefore, before purchasing, you must carefully read the instructions published on the product packaging. Manufacturers always indicate parameters and numbers that can help solve the problem.

What affects glue consumption?

Since the issue of saving on construction and repair materials is very acute, you need to know that there are a number of factors that affect the consumption of tile adhesive. Taking these factors into account, you can significantly reduce consumption and, therefore, save money. So, glue consumption per 1 m2 of tile increases if:

Floor screed before installing tiles

The laying surface is not prepared or there are pronounced defects and irregularities on it.

Many people try to level the installation surface using so-called “thick-layer” tile adhesive, but this approach, as a rule, costs a pretty penny.

Therefore, uneven surfaces must be prepared before tiling work begins - “pull together” the floor, plaster and putty the walls, and only after that proceed with the installation of tiles.

The adhesive solution was prepared incorrectly. The technology for preparing tile adhesive involves adding a dry mixture to water in strict adherence to the recommended proportions, but “newbies” in the field of repairs often neglect the rules for preparing the solution and, as a result, encounter a lot of problems - glue that is too thin does not “hold” the tiles well, and glue that is too thick does not “hold” the tiles quickly. hardens and spreads poorly on the surface.

To reduce glue consumption when carrying out facing work, follow the manufacturers' recommendations regarding the proportions of the mixture and water, and also mix the solution thoroughly.

The tile size is too large. The larger it is, the more glue is consumed. To ensure that the tile fits tightly to the mounting surface, you should “adjust” the thickness of the tile adhesive.

So, for tiles measuring 10x10 centimeters, the recommended layer thickness is 1-2 millimeters, for samples measuring up to 30x30 centimeters - 2-3.5 millimeters, for tiles measuring up to 50x50 centimeters - 3.5-5 millimeters, slabs measuring more than 50x50 centimeters are laid on a “double” layer of glue - the first is applied to the base of the installation, the second - directly to the back side of the tile.

The tiles are laid in unfavorable conditions. The optimal conditions for indoor tiling work are considered to be a room temperature of 20 degrees Celsius with a relative air humidity of 60%.

If the room temperature is lower and the humidity is higher, the glue consumption per 1 m2 increases.

Types of spatulas

The wrong tool has been selected for the job. It would seem that it doesn’t matter at all what kind of spatula you use to “throw” the mortar onto the surface, but a professional tiler would not exchange “his” spatula for anything, because it is the one that allows you to determine exactly how much glue is needed to glue one tile.

To work with small tiles, choose a “six” spatula; for larger tiles, use a “eight” spatula.

As a rule, it is precisely because of the incorrectly selected tool that the calculation of the consumption of the adhesive composition turns out to be completely incorrect!

Thus, in order to save glue consumption when laying tiles, you must first prepare the installation base, create optimal working conditions, properly prepare the adhesive solution and choose medium-sized tiles (if you like large samples, select the appropriate “reinforced” types of glue, they “grip” better to the surface and hold large slabs more firmly with low mortar consumption) and select a spatula that matches the size of the tile.

Tiles of different sizes

The size of the tile also affects the amount of adhesive used. There is one general rule that must be taken into account when purchasing an adhesive composition: the thicker and larger the tile, the thicker the layer of mortar will have to be made. Here are the approximate consumption rates for the materials described.

For 10x10 tiles, the thickness of the adhesive layer should be 2 mm. Such facing material is usually laid on walls.

For modules 20x30 cm, the layer of solution will have to be increased and brought to 4 mm.

For material laid on the floor (50x50 cm), the thickness of the solution can reach up to 4.5 mm.

Note! The figures given are, of course, approximate. Therefore, in addition to the indicated parameter, in this case it is necessary to take into account other circumstances. Let's designate them too.

Spatula shape

Few people know that when purchasing an adhesive solution, it is necessary to pay attention in the list of technical data sheets of the product not to the layer of the composition, but to the length of the teeth of the tool used. Each manufacturer specifies this parameter in the instructions supplied with the product. A spatula with a tooth height of 8 mm is suitable for installing 30x30 cm tiles. For 50x50 cm modules, manufacturers indicate the use of a spatula with a tooth height of 12 mm.

Why is this particular indicator taken into account? Because even a professional tiler cannot determine by eye how thick the adhesive composition is distributed on the tile. Only a notched trowel allows you to evenly redistribute the composition and make a normal, even layer. The most common variations in design are the described tools with tooth lengths of 6 and 8 mm, 10 and 12 mm. Manufacturers produce tile adhesive and indicate exactly the dimensions of the trowel teeth in its technical data sheet. Using this tool, it is easy to apply a controlled layer of adhesive to the tiles.

However, you don’t need to think that a spatula with a 6 mm tooth will help form a layer of mortar 6 mm thick. This figure will indicate the height of the ridges that the described tool will leave behind. When the tiles are facing, the modules are lightly pressed against the surface with a certain force, the pressure force helps to redistribute the solution over the entire surface of the tile. An experienced tiler knows that the amount of mortar can be calculated by multiplying 0.5 by the height of the trowel tooth. The resulting figure will indicate the thickness of the adhesive composition.

Types of tiles

The structure of the tile also affects the amount of adhesive used. For example, handmade tiles always have a non-uniform back side. Its structure is always porous. During installation, such a base absorbs the maximum amount of water from the glue. Factory glazed tiles cannot boast of such water absorption. And porcelain stoneware, due to its high-density structure, does not absorb water from the solution at all. Wall tiles are laid in a thin layer, floor tiles with a thick layer of glue. The consumption of glue when laying on plasterboard is less than the consumption of the composition when laying on a cement base. This must be taken into account.

Today you can find special compositions for each type of facing product. But there are also universal samples on sale. Their use involves applying a layer of glue both to the surface being treated and to the reverse side of the material. This method of laying is used when the cladding has a large specific gravity (assembled from natural stone, for example).

When calculating the consumption of the adhesive composition, it is important to take into account the quality of the back side of the facing material. If it is smooth, the consumption rate is standard. The back surface of clinker tiles is uneven, so glue is applied to the surface to be treated, and the back side of the module is also pre-leveled with it. In this case, the consumption of the described material increases by about one and a half times.

Sometimes the design requirements of a room require the use of modules of different thicknesses to form the cladding. In this case, the difference in the thickness of the tiles is compensated by increasing the adhesive layer. And this is also an additional expense. You need to be prepared for this in advance.

Types of adhesives

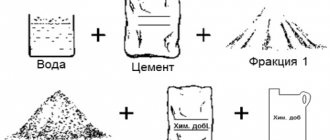

Popular tile adhesive mortar is represented by the following compositions:

- cement;

- on epoxy resin;

- dispersive.

The most profitable is considered to be a tile composition with a cement component. Its use makes it possible to efficiently lay elements on curved bases, and if they are even slightly damaged, they can be replaced without any problems. The most popular tile adhesive with a cement component is the brands Unix, Ceresit, Hercules, EK.

The advantages of dispersion agents include low glue consumption per square meter, good elasticity, and strength. This solution is sold ready-made, which is quite convenient for installation. Inconveniences include its poor surface waterproofing properties.

Regarding epoxy resin mixtures, they have a good degree of water resistance along with elasticity and strength. However, they are difficult to prepare, and besides, they are quite expensive. Common brands of epoxy mixtures include Litokol, Lugato, Ceresit.

Influence of element parameters

The impressive dimensions of the elements correspond to their heavier weight. Consequently, the thickness of the adhesive layer is increased. So, elements whose dimensions are 10 by 10 may require a cement tile layer of about a couple of millimeters. Whereas for elements 20 by 30 - about 3 mm, and for elements 30 by 30 and further - around 5 mm.

It is very difficult to measure the thickness of the adhesive mixture. Even when the adhesive layer looks smooth, in fact it can be an illusion. The size of the spatula teeth is a more accurate determinant that should be relied upon. So, for elements 30 by 30, a spatula is used, the height of the teeth of which is 8 mm. When applying glue, the spatula is held at a right angle to the wall, and here the adhesive thickness is calculated much more correctly.

Optimal adhesive distribution involves first applying it with a standard spatula, and then passing it with a serrated tool. For this reason, the consumption of the adhesive mixture for ceramic tiles is determined by the size of the spatula (which is usually indicated by the manufacturer). So, for example, when applying Ceresit CM12, the glue consumption rate is 4.2 kg per square meter, when using a spatula with 10 mm teeth, and elements - 30 by 30 mm.

Variety of tiles

Different types of products absorb different amounts of glue. For porcelain stoneware this indicator is at the lowest level. Glazed surface tiles may require slightly more mixture. But for the porous structure, handmade samples and cotto tiles, the largest amount of glue is needed.

A slightly increased volume of the mixture is applied to a not entirely smooth surface of the tiles, which will also lead to an increase in the consumption of the composition.

Influence of substrate type

The ideal surface for laying elements should be a flat, smooth base without visible cracks. In such a situation, the tile adhesive solution is consumed in a minimal amount. And it is needed only for adhesion of elements to the base.

If curvatures or cracks are noted on the base, they are leveled out by applying thicker glue. Elements that have differences on the back side (for example, clinker) will also need such alignment.

The heterogeneity of the structure greatly affects the installation. The higher the porosity, the more glue will be absorbed. And therefore, additional costs are required to securely fix the elements.

For example, concrete bases absorb less adhesive mixture than a cemented base. To minimize the volume of tile adhesive per square meter. It is worth choosing a product recommended by the manufacturer exclusively for this type of foundation. As an example, we can cite the composition of the group of the company EK, which satisfies the needs of multiple customers.

- EK-1000 WIDE - excellent for leveling surfaces;

- EK-3000 - is intended for application on relatively flat and plastered floors and walls; in addition, the composition can be used as a grout for joints and small sinkholes in the base plane. The composition is also allowed to glue stone tiles with low moisture permeability;

- EK-5000 AQUA is necessary for surfaces in rooms with high humidity conditions; the adhesive has high-quality characteristics that make it possible to achieve a reduction in the rate of consumption of the composition over the entire area.

Influence of weather conditions

The normal temperature regime, which must be maintained when laying tiles, can vary between 18-25 o. However, the critical values go beyond this range and are 5o, 38o. A higher temperature inside the room will result in greater glue consumption. Because moisture will evaporate faster. For outdoor work, you will need a special frost-resistant adhesive composition.

The influence of the tiler's qualifications

The volume of mixture used is also determined by the technique of its application. More glue consumption can be expected when holding the spatula at an angle of 65 degrees, rather than 45 degrees (here the deviation will be from 20 to 30%). The shape of the instrument is also important. Work will be more economical with a V-shaped spatula. The work is slightly less economical with a U-shaped spatula. The maximum consumption of the mixture occurs when using a spatula, the teeth of which represent a square. And, naturally, a master with qualifications and experience skillfully controls the consumption of the mixture, but a beginner is not yet able to do this. Therefore, at the very beginning of developing experience in the field of tile work, you should purchase a mixture for gluing with a reserve.

Substrate quality

Typically, strict requirements are imposed on the cladding base. It should be smooth, clean, without changes in height. But in practice, unevenness cannot be completely eliminated.

- If the unevenness of the plane is no more than 3 mm, you can lay the tiles with a minimum adhesive thickness (5 mm). In this case, the described composition will only ensure adhesion of the facing material to the surface. The above formulas for calculating the amount of material consumed are just right for this type of installation.

- If the surface of the base is complex and uneven, it is necessary to use compounds that will simultaneously ensure adhesion of the cladding and the base, as well as level the surface. This leveling method can be used if the height difference does not exceed 3 cm. Naturally, in this situation, the glue consumption increases significantly.

Leveling adhesives are excellent for installing clinker tiles and other similar materials whose back side is profiled and has an uneven surface. If such material is placed on ordinary thin-layer glue, the consequences will be disastrous. The clinker will fall pretty quickly.

Summarizing what has been said, we can draw an intermediate conclusion: before purchasing glue, you need to know exactly what surface the tiles will be placed on. If it is flat and smooth with a minimal difference in heights, thin-layer compounds are suitable for cladding. Their consumption is calculated using a standard formula. In other cases, it is necessary to use compounds that will simultaneously provide adhesion and leveling of the base. In this case, the consumption of adhesive material increases by one and a half times.

Note! Glue consumption doubles if the base has a porous structure and if façade tiles are laid vertically. As a rule, it weighs more than regular wall tiles, so to glue it it is necessary to apply glue both to the base of the wall and to the façade tile itself.

Consumption rates

The consultant will tell the buyer how much tile adhesive is needed. But the seller does not take into account the type, size of the material, type of surface, or skill of the installer. Before purchasing, you need to calculate the cost per square and multiply by the area of the masonry. The main indicator is the adhesive consumption per 1 m2 for tiles, and it differs for different brands.

Ceresit

Products differ in composition, scope, technical characteristics and service life. Polish brand adhesives are in high demand because the compositions have good adhesion and are suitable for any type of surface. Consumption of Ceresit glue per 1 m2, according to the manufacturer’s technical documentation https://www.megastroika.biz/index/normy_raskhoda_kleja_pri_ukladke_plitki/0-208:

- Cement composition for ceramic tiles of various formats CM9 STANDARD, with a tile adhesive consumption rate of 2-4.2 kg/m2.

- The adhesive consumption per 1 m2 for porcelain tiles, when using Ceresit CM11 Plus, is 1.7-4.2 kg.

- Large fragments of tiles and porcelain stoneware can be glued using Ceresit CM12, the cost of which varies from 4.2 to 6 kg.

- A high-quality cement-based mixture Ceresit CM14 Extra qualitatively connects surfaces with a recommended consumption of 2.7-6 kg.

- To calculate the costs of Ceresit CM 16 tile adhesive, we start from the parameters of 2-4.2 kg per square of masonry.

- The superelastic composition Ceresit CM17 is consumed at a rate of 1.5-4.1, depending on the format of the fragments 10-40 cm.

- Consumption per 1 m2 of mosaic and marble, when using Ceresit SM 115, varies from 2.5 to 4.4 kg.

- Facade tiles, porcelain stoneware and marble cladding should be economically laid with Ceresit CM117 glue, the cost of which will be 1.8-4.7 kg.

Polish brand adhesives are in high demand because the compositions have good adhesion, are suitable for any type of surface, and are used for interior and exterior work. High adhesive properties ensure reliable fixation of tiles on difficult substrates, in rooms with high humidity, as well as when cladding facades, terraces, and street steps.

Eunice

A recognizable brand, under whose brand the manufacturer has been producing adhesive mixtures for more than 20 years. The main product line consists of cement adhesives for tiles of various formats and structures. Adhesive substances have a self-leveling effect and help smooth out imperfections on uneven substrates. The technical documentation provides approximate consumption rates of tile adhesive per 1 m2 for porcelain tiles, mosaics, and tiles:

- Universal glue Yunis 2000 - consumption per 1 m2 is 1.16-3.5 kg, with a layer thickness of 1-6 mm.

- The consumption of Yunis Plus tile adhesive is the same as that of Yunis 2000 - 1.16-3.50, intended for tiles, mosaics and porcelain tiles.

- Yunis XXI is a new generation universal product, area of use - tiles, mosaics, stone, consumption 1.16-3.5.

- The same cost rate for Yunis Granite tile adhesive and the waterproof mixture Swimming Pool - consumption is 1-3.1 kg.

- When using high-tech mixtures UNIS FIX and UNIS Hi Tech for mosaic and tile compositions, 1.16-3.5 kg are spent.

Hercules

Reliable compositions that are suitable for laying tiles, tile cladding, porcelain tiles of various formats are domestically produced Hercules brand adhesive products. Universal-purpose cement-polymer-based substances have good heat resistance, moisture resistance and high adhesion. Table 1, compiled according to the manufacturer’s instructions, will help you calculate the required amount of Hercules glue:

Table 1. Consumption of Hercules tile adhesive, kg/m2

| Marking | Purpose | Base | Layer thickness, mm | Consumption, kg per square |

| Base | Tile, mosaic, ceramics | Concrete, brick | 3 | 4,5 |

| Aqua-Stop | Ceramics | Wet areas, water tanks | 1 | 5-8 |

| Strong | Large format tiles | For interior and exterior use | 1 | 5-8 |

| GM-35, 45, 55 | All types of cladding | Any surfaces | 1 | 1,53 |

The company produces adhesives labeled GM-195, GM-125, GM-215, GM-125. The consumption of Hercules glue of the listed types per 1 m2 of tile is 1.33-1.81 kg, with a layer thickness of 1 mm. Special additives improve the individual characteristics of mixtures, so you need to choose a composition according to its intended purpose - frost-resistant, heat-resistant, waterproof.

Knauf

Knauf powder mixtures have good adhesion to concrete. Cement adhesives are used for finishing street structures and cladding rooms. Knauf tile adhesive is economical in consumption. The manufacturer's line includes four compositions:

- Fliesen - 2.2-2.9.

- Fliesen Plus - 1.7-3.7.

- Flex – 2.2-2.9.

- Marble – 2.3-2.9.

The values are given in kg/m2 under the conditions that the tiles with a smooth surface are laid on a level base and the installation is carried out with a 6 mm notched trowel. For relief fragments, you need a spatula with large teeth, which increases the consumption rate of adhesive for Knauf brand tiles.

Plitonite

Dry mix of the Plitonit brand is represented by a wide selection of products; the manufacturer’s line includes adhesive substances for ceramics, mosaics, and marble. The consumption of Plitonit adhesives per 1 m2 is given in Table 2.

Table 2. Plitonit glue - consumption rates

| Brand | Application | Consumption |

| A | Ceramics | 1,8-4,5 |

| IN | Mosaic | 1,7-5,1 |

| In the pros | Ceramics, porcelain tiles, mosaic | 1,7-5,1 |

| With easy | Tiles, marble | 1-3,1 |

| Wb | All types of finishes | 1,8-5,3 |

| To the super floor | Floor finishing | 2,9-7,3 |

| Super fireplace | Tiles for fireplaces and stoves | 1,4-4,5 |

| Aqua Barrier | Mosaic for water tanks | 1,3-3,5 |

Among the advantages of Plitonit compositions, it should be noted a wide selection of adhesives that are characterized by increased adhesion. The mixtures do not allow moisture to pass through and are suitable for cladding complex substrates.

Lux

The glue consumption of the Belarusian manufacturer is not specified in detail; the technical specifications define an average parameter of 2-4 kg per 1 m2 for ceramics, clinker, and other finishing materials. Properties of Lux mixtures are resistance to negative temperatures, environmental friendliness, no slipping on vertical surfaces. It is allowed to apply an adhesive layer with a thickness of 2-10 mm.

Prospectors

Cement, sand and mineral components are the basis of high-quality adhesives from the Starateli brand. The product line includes Standard, Lux, Premium, Plus and Bystry adhesives. For all substances, the consumption per m2 of floor tiles and installation of wall cladding is indicated, in the range of 3-5 kg. The prepared solutions can be used for laying mosaics and tiles.

To make an adhesive composition, just mix a kilogram of dry mixture with water (200-300 ml). You can mix the solution with a drill with an attachment at low speed. 10 minutes after laying the finishing material, you can “correct” the fragments to obtain an ideal plane.

EC

The main difference between the construction mixture is that EK adhesives need to be distributed over the surface in a thin layer. The products can be used for installing finishing tiles indoors and outdoors. To calculate the mixture consumption, you don’t need a calculator - the average rate per 1 m2 is:

- 2.8 kg when laying mosaics and facing fireplaces, as well as using universal compositions EK 3000 Universal, EK 3000 Universal Eco.

- On average, 2.7 kg of the finished mixture is used for laying EK 4000 Titan, EK FAST FIX, EK 5000 Aqua - waterproof compositions with improved characteristics.

- 3.3-3.4 kg of glue will be required for thermal insulation and insulation of facades with mixtures marked EK 1000 WIDE, EK 2000 KERAMIK, EK 2000 KERAMIK ECO, specially designed for ceramics.

When working on vertical surfaces with EK grade compounds, zero slipping of the tiles is noted. The substances have good resistance to temperature changes and moisture. The longest service life is guaranteed when laying with EK glue in dry rooms.

Bolars, Vetonit, Kreps

Table 3 provides a comparison of three popular brands of glue to clearly demonstrate the average consumption of compounds per square of cladding.

Table 3 Adhesive consumption rates

| Vetonit | Kreps | Bolars | |||

| Optima | 1,29 | Plus | 2-4 | Base | 3-3,5 |

| Easy fix | Aqua | Standard | |||

| Granite fixed | Base | Elastite | |||

| Pro plus | 1,35 | Standard | Plus | 2,7-3,2 | |

| Ultra fix | 1,29 | Super | Granite | 2,7-3,2 | |

| Ultra fix winter | 3-3,5 | Just glue | Aqua-plus | 2,5-3 | |

| Marble | 1,29 | Reinforced | 2-3 | Elite | 2,5-2,8 |

| Absolute | 3-3,5 | Express | Express | 3 | |

| weber.vetonit RF | White reinforced | ||||

Manufacturers' mixtures have pronounced adhesive properties and easily adhere to different surfaces. The basis of adhesives is predominantly cement with various additives.

External factors

External factors can also affect the consumption of adhesive composition. Much depends on the temperature climate, installation technique and experience of the master. There are ideal temperature parameters at which the cladding can be installed. This is +18, +24 degrees. When the temperature rises by five degrees, the percentage of liquid evaporation from the adhesive composition increases, and hence its consumption. At temperatures from +4 and below, the materials described begin to deteriorate; in this case, it is quite difficult to predict how the glue will behave. The amount of glue used also increases when installing in windy weather. If the external cladding is being installed in such weather, be prepared for the consumption of the described material to double.

The experience of the master must also be taken into account when calculating the required amount of glue. Different angles of the spatula provide different consumption of the adhesion compound. The difference could be 25 percent. And this is a significant number. Consumption is greater at a spatula angle of 60 degrees; at an angle of 45 degrees, the figure decreases significantly. Anyone who is just mastering the skills of laying tile material rejects a certain amount of adhesive mortar. Therefore, in this case, you need to buy glue with a reserve.

In addition, the shape of the spatula is of great importance. A little less glue is used if a v-shaped spatula is selected for the job; a u-shaped spatula increases the amount.

Generalization on the topic

So how to calculate the amount of glue? The easiest way is to decide on the manufacturer’s brand and go to its official website. As a rule, you can always find a calculator that will accurately help you calculate the amount of material being described. Everything is entered into the calculator: the size of the tile, the area of the surface to be treated, and the brand of glue, so the calculation result is quite reliable. If the surface being treated is not perfectly flat, or if you have little experience in laying tiles, the resulting figure should be multiplied by 1.5.

If it was not possible to determine the brand of glue, when calculating the amount of composition, you need to use the calculation scheme described above in the article. On average, it takes 1.3 kg of composition to lay one square meter of cladding. This figure must be multiplied by the expected thickness of the adhesive layer. Such calculations are approximate, all adhesives are different, but average indicators help to navigate and purchase materials with a reserve.

Tile adhesive consumption per square meter: how not to make mistakes in calculations?

When laying tiles yourself, you need to purchase enough adhesive solution to cover the entire area of the facing surface. To determine the exact amount of mortar, use the formula: tile adhesive consumption per 1 m2 of tile, multiplied by the surface area.

Typically, this formula is used by construction crews when cladding large objects. It is also suitable for independent calculation, but to simplify this procedure there are special online services - tile adhesive consumption per 1 m2 calculator. Such resources help determine the consumption of tile adhesive; they take into account both the area of the room and the characteristics of the manufacturers of the substance.