Advantages of paving slabs

- low price of the product;

- availability of material, the ability to freely purchase it at a hardware store;

- installation of the coating can be carried out on various bases: sand, concrete, natural stone, asphalt, etc.

- laying paving slabs is easy to do with your own hands;

- paving slab coating is durable, reliable, resistant to temperature fluctuations, waterproof and frost-resistant;

- You can purchase material of different colors and shapes and make garden paths colored or patterned.

There are several ways to lay tiles outdoors: on a sand bed or on a concrete base.

Laying tiles on a sand bed

Laying on a cushion is carried out when the load on the path is small, otherwise use the second option.

To fix the tiles to the concrete base, glue is used.

To ensure that the track can be used for a long time, and its appearance does not deteriorate during use, it is necessary to choose the correct fixing composition.

Advantages and disadvantages of laying paving stones on a concrete base

The concrete base for laying paving stones has the following advantages:

- high strength and resistance to the application of significant loads and mechanical stress;

- durability;

- installing tiles on a concrete base minimizes the risk of shrinkage;

- ease of implementation, allowing you to lay paving slabs with your own hands;

- there is no need to use complex expensive technical devices;

- resistance of the base to chemical influences, water washout, temperature changes;

- on a solid concrete base, the process of leveling tiles in a single plane is much easier, resulting in a clear, straight shape and a perfectly flat surface

- absence of failures caused by poor-quality compaction of the base;

- environmental friendliness of paving with tiles.

Existing disadvantages:

- the technology for laying paving stones on a concrete base is more complicated than on sand and crushed stone pads;

- the need for reliable drainage systems. Having seeped through the seams in the coating, water will remain between the concrete base and the tiles and, when freezing temperatures set in, it can swell and even split the paving stones. To avoid this, paving stones are laid with certain slopes, point water inlets are laid in the concrete, and stormwater systems are installed;

- a concrete base for paving stones is more expensive than a simple base of crushed stone and sand;

- If the technological process is disrupted, coloring of the concrete base may occur after the end of the first winter.

Classification of adhesive for laying tiles

Which glue is best to choose for organizing garden paths?

Adhesives for laying materials vary in purpose and composition.

Classification depending on the operating conditions of the tiles

The industry produces the following types of adhesives:

- universal;

- reinforced;

- moisture resistant;

- heat resistant;

- for installing tiles on a non-concrete base;

- white;

- frost-resistant.

Universal adhesive is used when laying tiles in standard situations. However, it is not recommended for use in cases where the garden path is planned to be used in low temperature conditions. In addition, it is also not recommended to use it if there is an increased mechanical load on the coating. It is best suited for laying ceramic wall tiles.

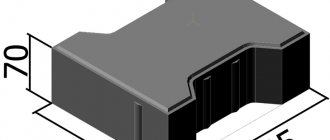

Calculation of paving slabs

Reinforced adhesive for paving slabs has higher adhesion rates, and therefore it is used for laying floor coverings. It is also not recommended to use it for organizing garden paths, since it is not designed for operation under conditions of sharp temperature fluctuations.

The moisture-resistant composition is usually used when lining swimming pools or artificial reservoirs. It perfectly resists the effects of water, and when fixing the tiles to such an adhesive, the lining will not peel off from the concrete base. However, it cannot be used for outdoor use.

Moisture-resistant adhesive composition

For lining surfaces that must operate at high temperatures, for example, for fireplaces, special compounds are used that belong to the heat-resistant class.

If you plan to cladding non-concrete surfaces, but, for example, wood or metal, special compounds are also used that are designed specifically to work with the selected type of surface.

If transparent tiles are being laid, a special white adhesive is used.

When organizing tiled garden paths, special frost-resistant compounds are used that do not lose their performance characteristics even when the temperature drops to -50°C. With their help, they lay not only garden paths, but also floor coverings in unheated rooms.

Frost-resistant adhesive for paving stones

This frost resistance is achieved by introducing special additives into the glue, which increase the adhesion of the composition to concrete and ceramic tiles, as well as the plasticity and resistance of the glue to low temperatures.

Frost resistance is characterized by the number of cycles of freezing and thawing of the adhesive layer. The label should also indicate the minimum temperature at which the tiles can be laid.

Such adhesives allow installation even at negative ambient temperatures.

Attention! In order for the garden path to be used for a long time, it is necessary to use special glue and special frost-resistant tiles.

How to lay paving slabs on concrete?

Dear colleague!!

I didn’t study at a vocational school! University Thank God behind us! I've been laying tiles for eight seasons now - from early spring until the white flies. I haven’t blushed for my work yet! And if it’s a new building material, then I give up!! No comments as they say! Gluing 60 on a curbed concrete area is the height of luxury! Plus, you completely forgot about the fact that over time one dick will begin to tear the concrete, and with it the glued tiles. And it’s on the sand (the tiles will simply reflect the movements of the concrete and that’s all). In extreme cases, rearranging a few squares is not a problem. But if it is glued, it’s already hemorrhoids! What is shown on yours with a blind area is the right decision in this particular case - to lay it on glue. Moreover, there is no curb on part of the blind area - however, there are savings. The only thing wrong is the brand of glue. I can't digest Yunisa! I prefer Knaufs. But that's my personal opinion. Best regards, colleague! “RodStone - Adhesive” is a specialized mixture - a white adhesive solution, based on high-strength white cement, white quartz sand and European polymer additives for laying and fixing paving stones and natural stone slabs (with a relief back side) on horizontal surfaces, for outdoor work. Recommended for light to medium transport loads.

Adhesive for paving stones RodStone-Adhesive

Application area:

“RodStone - Adhesive” is a specialized mixture - a white adhesive solution, based on high-strength white cement, white quartz sand and European polymer additives for laying and fixing paving stones and natural stone slabs (with a relief back side) on horizontal surfaces, for outdoor work. Recommended for light to medium transport loads.

Surface requirements:

The reverse side of the tile or natural stone must be clean: free from dust, dirt, oils, etc. Highly absorbent materials must be thoroughly moistened.

Mode of application:

The mixture is poured into a container with clean water (at the rate of 5-5.5 liters of water per 25 kg) and mixed mechanically until a homogeneous mass is obtained (about 2-3 minutes). The solution is kept for 2-3 minutes, after which it is mixed again for 2 minutes. The prepared portion of the solution is used for its intended purpose within 180 minutes (after adding the mixture to the water). If the solution loses mobility, it is permissible to re-mix without adding water or any other components. The solution is applied to the back surface of the tiles (paving stones) with a smooth spatula in a thin layer (2÷5 mm.). The tiles or paving stones are carefully laid on the base and pressed evenly into it. Before the mortar hardens, the joints between the tiles should be cleaned. Wash off any solution that gets on the front side of the tiles with clean water. Grout the joints after the tile masonry has completely dried (48 hours) using a special mixture for grouting joints.

Mixture consumption:

1.3-1.4 kg/m2 with a layer of 1 mm, on average 5-6 kg/m2.

Packaging and storage:

25 kg - kraft paper bags. Shelf life - 12 months from the date of manufacture indicated on the packaging, in undamaged original packaging, avoiding moisture and sudden temperature changes in covered dry warehouses (air humidity no more than 60%) rooms.

Security measures:

Do not let the dry mixture get into your eyes. In case of contact, rinse the affected area thoroughly with running water and consult a doctor if necessary. Wear goggles and protective clothing when working.

Specifications:

Color White Amount of mixing water per 1 kg 0.2-0.22 l. Compressive strength at 28 days, no less than 10 MPa Frost resistance, no less (cycles) F100 Filler grain size 0-0.6 mm Open time, no less than 10-15 minutes Pot life, no less than 3 hours Density of the solution, no less than 1, 6 t/m3 Layer thickness 1-10 cm. Application temperature +5..+30 Consumption, with a layer of 1 mm 1.3-1.4 kg/m2 Packaging: kraft paper bags 25 kg

Classification by composition

For exterior work, adhesives based on cement or polymer are used.

The most popular of them is a composition using a cement-sand mixture.

Cement based tile adhesive

Its composition is approximately 90% cement and sand, and another 10% are plasticizers. The number of additives may vary. Sold dry in 25 kg bags. Most often, liquid glass and hydrophobic additives are added to cement compositions to increase frost resistance. The introduction of plasticizers reduces the amount of water used to prepare the solution.

Plasticizer for frost-resistant adhesives

Advantages

- low price;

- the possibility of mixing the adhesive composition in certain portions;

- elasticity allows you to create an adhesive layer that is plastic under temperature fluctuations, which avoids cracks;

- the water resistance of the mixture prevents moisture from penetrating into the adhesive layer, so that when freezing, water will not destroy the fixing layer;

- high strength of the fixing layer;

- has excellent adhesion to ceramics and concrete bases;

- able to withstand more than 100 freeze-thaw cycles;

- Can glue both wall and floor tiles;

- it is used to lay tiles, porcelain tiles, natural stone, etc.

Installation of paving stones with adhesive composition

Flaws

- It is necessary to independently prepare the composition of the required consistency before starting work.

Adhesive for clinker and porcelain tiles

These materials are used for outdoor work. Ceramics can be used for installation in conditions of high humidity and temperature changes. Frost-resistant clinker adhesive must withstand temperatures down to -50 degrees. But in this case it is better not to use porous tiles, as they will absorb water.

Also on the topic: How long does it take for tile adhesive to dry: when can you grout?

And when the air temperature drops to 0 degrees, the water will turn into ice, the porous material will collapse, and the glue will come off. Even frost resistance will not help in this case. Clinker tiles have a special structure; they have pores, but moisture is removed from them. Accordingly, the product does not crack at sub-zero temperatures. Porcelain tile loses in this regard .

Clinker and porcelain tiles have a minimal level of water absorption, so there is no need to worry about moisture accumulating inside the slabs. However, this advantage turns into a disadvantage when it comes to the adhesion of ceramic slabs to the base. Good adhesion is ensured due to the fact that the glue penetrates deep into the pores of the ceramic.

Frost-resistant adhesive for paving stones must provide good adhesion and also be resistant to negative temperatures. Other requirements for the product: elasticity, resistance to temperature changes.

In order for the coating to last a long time, the tiler must follow the technological process and carry out work in strict sequence. Porcelain tiles and clinker tiles absorb little moisture, so they must be laid with force. The thickness of the applied adhesive layer should depend on the characteristics of the facing material. The remaining product must be removed with a spatula, but if you leave a small amount, you can strengthen the primer.

The tiles are also laid on a mortar containing cement and sand. If the facing material is used in winter, be sure to choose frost-resistant glue. In this case, it is necessary to take into account the characteristics of the climate. Sometimes it is necessary to use ordinary glue that is not frost-resistant.

It should be noted that frost-resistant glue provides excellent adhesion. To reliably fix the facing material, before applying the glue, you need to sprinkle the surface of the material with a small amount of cement (the procedure is called “Ironization”).

It prevents the formation of moisture inside the tile and protects the surface from contamination. To enhance adhesion, PVA glue can be applied to the underside of the ceramic instead of cement.

Cladding work is not difficult to carry out, the main thing is to have the appropriate knowledge and skills. The master must follow a clear sequence of work and, if necessary, press down the tiles.

Glue characteristics

For most frost-resistant compositions, the main characteristics are:

- frost resistance > 100 cycles;

- solution lifetime – 0.5-3 hours;

- adhesion – about 1.4 MPa;

- tile adjustment time – 10-15 minutes;

- operating temperature – from -50 to +50°С.

In addition, good glue allows you to install the garden path covering at a minimum temperature of -10°C and above.

To reliably glue the tiles to the surface, when installing the garden path covering, it is enough for the adhesive layer to be approximately 15mm thick.

Laying tiles on a concrete blind area

Blind areas around buildings are usually made up to 1 m wide. First, the condition of the blind area is examined, after which the following operations are performed:

- the concrete is cleaned of dirt, existing cracks in it are cut out;

- the entire surface of the old concrete is filled with a 2 cm layer of cement mortar;

- the boundaries of future paving are marked with driving in pegs;

- The location of the curb along the edge of the site is planned; the top of the curb should be located taking into account the slope away from the building of 2 cm for each linear line. m. and below the top for paving stones by 3 cm. Then a mark is marked on the base equal to the sum of the height of the tile and the thickness of the preparation for it, to which a strong cord is attached, the second end is tied to pegs at the planned height of the top of the curb;

- according to the arranged markings, a trench is developed for the curbs, then an earthen trough is developed between the edge of the blind area and the curbs;

- Then the work is carried out in the order described above when installing a concrete base and paving with paving slabs.

When performing the work yourself, the cost of paving is reduced by at least 2 times. Additionally, you can read technical literature or consult with specialists about how to properly lay paving slabs; this will help avoid damage to expensive materials and ensure the durability of the coating.

Video with installation steps.

Interesting: “How to cut ceramic tiles”, “Density of building sand”, “How to lay tiles”.

Choosing glue for laying paving stones

- The adhesive class should be 2, since class 1 compounds are intended for fixing tiles with glue indoors.

- The number of freezing-thawing cycles must be at least 100.

- The glue must match the type of surfaces being glued.

- The selected composition must have a certificate

Garden path made of frost-resistant tiles

How to choose the right adhesive for paving slabs

Gray concrete paths in a suburban area look dull and uninteresting.

To remedy the situation, it is best to lay paving stones on the old base, which today are made in a variety of shapes and colors.

The advantage of such a path renovation is that you don’t have to remove the old slab; you just need to purchase high-quality adhesive for paving slabs and lay the new coating yourself.

In construction stores, such adhesive bases are presented in a wide range. These can be various mixtures suitable for interior and exterior use. To choose the best glue, you need to know the requirements for “street” mixtures.

Features of choosing adhesive for paving slabs

When choosing an adhesive solution, it is necessary to take into account a number of indicators.

Glue base

If you are choosing adhesive for outdoor tiles, then you need to choose a mixture based on one of two bases:

- Cement (marking C1 and C2). Adhesives of this type are sold dry (in bags of 25 kg) and consist of a ground mixture of sand, cement and plasticizers.

- Polymer (marking D1 and D2). These are water-soluble ground resins that are optimal for difficult surfaces.

Typically, polymer adhesive bases are sold ready-made, so they do not have to be mixed or diluted with water. In all other respects, they are no different from analogues supplied in dry form.

Regardless of whether you choose dry or ready-made glue, you need to pay attention to the frost resistance characteristics of the glue. This indicator is indicated in the number of defrosting and freezing cycles.

Frost resistance

When choosing an adhesive, many people confuse frost resistance with the minimum permissible temperature at which the fastening component can be applied. But, if you buy a composition that can be used even at the North Pole, then its strength and other characteristics will not differ from those of a solution for above-zero temperatures.

Usually, to increase the level of frost resistance, liquid glass and hydrophobic additives are added to cement compositions. If the composition contains many plasticizing additives, then less water is used when mixing such a solution, as a result of which the number of freezing and thawing cycles increases.

The frost resistance of paving slab adhesive must be at least 100 cycles.

Glue type

The adhesive packaging must list the combinations of substrates for which the adhesive is most suitable. If you glue a polymer product onto an adhesive base for ceramics, the strength of such a connection will be almost 5 times worse.

Elasticity after hardening

The composition must have high elasticity after hardening (denoted as S1 or S2), since the tile will experience stress when walking or driving on it. If the glue does not “extinguish” such pressure, the coating will quickly deform.

Adhesion

Adhesion is the ability to “slip” and break off. If the degree of adhesion is low, then the paths made from such tiles will also quickly deform.

There is a special classification of tile adhesive components according to DIN EN 12004, which you should familiarize yourself with before purchasing adhesive.

Glue class

There are two classes of tile adhesive:

- Class 1 is only suitable for lightweight ceramic products that are installed inside heated rooms;

- Class 2 (reinforced compounds) is used for large-sized slabs laid outdoors.

It is also worth paying attention to the manufacturer of the mixture.

Adhesive brands for paving slabs

Among the most popular and reliable adhesive compositions it is worth highlighting:

- Ceresit CM This base is suitable for fastening all existing types of mineral slabs to concrete and cement bases. The cost of the dry mixture is 750-800 rubles per 25 kg.

- KNAUF – FLIESEN PLUS. A reliable composition with good adhesive properties suitable for both natural and artificial stone. Costs about 400 rubles per package.

- FOUND GRANIPLIKS AC14. Suitable for products made of natural stone, porcelain stoneware and ceramic tiles.

Healthy! It is not recommended to buy universal adhesives, since the strength of the adhesive joint in this case will be much lower.

You can also make the adhesive solution yourself. To do this, it is necessary to add a plasticizer to a regular cement mortar in the proportion indicated on the package with the additive. Ceresit CC 83 is considered the best of these plasticizers.

After choosing the adhesive, all that remains is to lay the tiles on the old concrete surface.

Laying tiles with glue

To install tiles with adhesive yourself, follow these steps:

- Clear the concrete surface of debris.

- Prepare the formwork.

- Dilute the glue in the proportion indicated on the packaging (if you add a plasticizer to the solution, then the volume of water must be reduced, but only strictly in the proportion indicated in the instructions for the additive).

- Apply glue to the concrete base (not all at once, but as you go, since the adhesive composition dries quite quickly) using a trowel.

- Lay the slabs, first immersing each of them in the adhesive solution by 2-3 mm.

- Wait for the solution to dry completely (the duration depends on the composition).

In custody

When buying glue, ask the seller for certificates of compliance with international and Russian standards. If they don’t provide you with these, then most likely you have a low-quality product that will not be able to withstand “street life” and operational loads.

Source: https://zamesbetona.ru/podgotovka/klej-dlja-plitki-trotuarnoj.html

Preparation of the adhesive composition

To prepare the working solution you will need the following tools:

- mixer or drill with attachment;

- container for mixing glue and water;

- Master OK.

Stage 1. Measure out a certain amount of mixture and the required amount of water.

Stage 2. Pour water into a container and add the dry mixture to the water.

Stage 3. Mix the components using a mixer or drill with an attachment at low speed.

Stage 4. Wait 5-10 minutes - this is necessary for the components of the mixture to react. Then mix the solution again. The mixture should fall from the spatula, but not freely.

Stage 5. Wash the kneading tool in water, as the solution sets quite quickly.

Stage 6. If there are lumps, the mixture must be stirred again.

Attention! You cannot add water to the prepared solution.

Recommended glue

Among all types of adhesives for laying tiles and natural stone, cement-based mixtures have the best properties.

All varieties of Glins, Eunice, Litakol, Forward are recommended. "Unis 2000" is a special new generation adhesive for all types of tiles, mosaics and natural stone. It has the best abilities registered in accordance with GOST-31357. Used for gluing to floors and walls. Withstands a weight of no more than 400 grams per square centimeter. Recommended for finishing work with high humidity. Perfectly suitable for both internal and external work.

Characteristics:

- Maximum layer thickness

- about 15 mm

- Amount of water per 1 kilogram of glue (dry mixture)

- 200 -260 ml.

- Work temperature

- from +5 to +30°С

- Viability of solution

- three hours

- Consumption when working with a notched (size 6X6) spatula

- 3.5 kg/m2

- Time of first walk

- in 24 hours

- Tile adjustment time

- about 10 minutes

- Adhesion strength

- 5 kg/cm2

- Weight held

- 400 g/cm2

- Packaging options

- 25 and 5 kg

- Frost resistance

- 35 cycles

Unis 2000 adhesive is characterized by high adhesive strength and therefore will be easier to work with. Thanks to this, tiles can be installed using the top-down method. The glue is made from environmentally friendly materials (sand, cement and special chemical additives) - perfect for you and the health of your loved ones. If during operation it accidentally comes into contact with the skin or eyes, it should be rinsed with the required amount of water.

Recommended for use on concrete, cement, brick, gypsum substrates and asphalt. First, clean the surfaces from falling elements and treat them with a specialized primer, spruce must be done several times until completely impregnated.

For direct work, the mixture is prepared by mixing with clean water in the proportion of 200-300 milliliters of water per kilogram of dry glue. The main thing is to use the prepared solution within 180 minutes. There is no need to wet the tile with water.

New technologies come into everyday life every day. This makes construction easier and homes more comfortable.

It's always easier with Unis 2000 glue.