Design Features

When designing a foundation made of screw piles, it is imperative to calculate their number. Engineers involved in the design of pile foundations recommend paying attention to the following subtleties:

- total weight of the structure;

- the actual weight of the structure, which includes the weight of the walls, various floors, roofing, roofing and finishing materials with which the internal and external walls and facade of the house will be processed;

- calculation of the payload of the structure on the piles, which can include the mass of furniture and people who will be in the room (you can use the SNiP calculation, according to which this value is 150 kilograms per square meter);

- load caused by precipitation (snow), which must be calculated based on data that can be provided by state statistical bodies or the hydrometeorological center for the region where the house will be built;

- safety factor, which under normal conditions is taken as 1.1;

- the ability of the soil to bear a load established based on its characteristics at the location where the foundation is installed;

- the depth at which the support will lie (with normal soil it is considered equal to 1.7 meters).

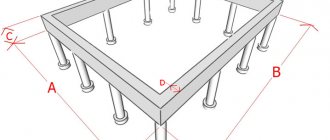

Schematic layout of a screw pile.

It is also necessary to pay attention to technical calculations based on standard screw piles for the foundation (the base immersion depth of 1.7 meters is taken as the basis):

- a screw pile with dimensions of 76 x 200 x 2500 mm has a calculated minimum load of 1000 kg;

- a pile measuring 89 x 250 x 2500 mm has a calculated minimum load of 2000 kg;

- a pile of 108 x 300 x 2500 mm has a minimum load of 2500 kg.

What is the maximum capacity of one pile

Once all the nuances of the process of calculating the load-bearing capacity for a screw support have become clear, you can understand the maximum possible load that one element can withstand. For these purposes, you must use the following information:

- The type of soil in this case will be empty sand, its maximum load-bearing capacity will be 15 kg/cm2.

- For support, you can use piles 219. The diameter of the petals of such a product will be 600 mm.

- For the reliability coefficient, it is worth taking a value of 1.75. In this case, we are talking about accurately determining the number of piles, no more than 5 pieces.

The video shows the load-bearing capacity of screw piles 108:

As a result, to determine the maximum load-bearing capacity of a screw pile, it is necessary to use the following algorithm:

- Determine the area of the petal support. In this case, it will be 2826 cm2.

- The non-optimized value of the reference capability can then be determined. To do this, it is worth multiplying the area of the petal support by the bearing capacity of the soil: 2826x15=42.4.

- To calculate the exact load-bearing capacity, it is necessary to divide the resulting value by the reliability factor: 42.4/1.75 = 24.23 tons.

What kind of concrete is needed for the foundation of a two-story house can be found in this article.

Based on the presented calculation, we can conclude that one support, with a petal radius of 30 cm and embedded in dense sand, can withstand a load of 24 tons. Due to the fact that screw bases are able to withstand such heavy loads, they are in such wide demand today.

You can learn how to pour a foundation for a house made of aerated concrete from the article.

Algorithm for calculating a screw pile foundation

After studying the factors that influence the correct calculation of the maximum load on a pile foundation, as well as the average technical indicators of screw piles of various diameters for the minimum withstand load, you can proceed to calculating the maximum permissible weight. After which it will be possible to calculate the required number of piles with the required diameter.

What data must be taken into account when calculating the maximum permissible load:

- The area of the house roof and various extensions.

- The amount of area of the attic space.

- The sum of the area of various house floors (this applies to houses that have several floors or have living space under the roof).

- The sum of the area of external house walls.

- The sum of the area of the interior load-bearing wall or walls.

- The perimeter of the foundation itself.

After calculating all the required areas and dimensions, you need to find out what material the above elements of the house will be made of. Then take a reference book in which you should find the approximate weight of a particular material that will be used in the construction of the structure and its individual elements. Next, using general mathematical operations, you need to calculate the total weight of each structure and walls.

An important point will be to determine the maximum snow load. To do this, you will need to contact the relevant service for information on the amount of snow falling per centimeter or square meter in the region where construction will take place. Then, having the roof area, calculate the load on the foundation at this point.

You should also take into account the soil characteristics of the land plot where construction will take place. The publication provides the main technical characteristics of the piles, which will be screwed into the ground to a depth of 1.7-2.5 meters without taking into account soil freezing. In this case, again, you can contact the relevant government agency, where you can obtain data on the depth of soil freezing in the region.

Calculation of the load weight of a screw pile

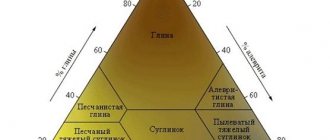

For the calculation, it is necessary to take into account the dimensions of the screw piles and the quality of the soil in which they will be installed. To perform a preliminary calculation, it is necessary to multiply the base area by the soil resistance and clarify the calculation of the pile foundation.

You can learn how to properly install galvanized screw piles by reading this article.

The photo shows the installation of screw piles:

For example, to calculate the capabilities of a screw pile 133 screwed into ordinary clay, it is necessary to carry out the following action plan:

- Calculate the area of the petal base. For pile 133, the diameter of the base of which is 30 cm, this parameter will be 706.5 cm2.

- Taking into account the specified soil type, it is worth choosing the right soil. For clay it will be 6 kg/cm2.

- The two obtained values must be multiplied, and the result will be 4.2 tons. This is the weight that screw pile 133 can withstand. It can be installed in a clay bud to a depth of 2-2.5 m.

You can find out which brand of cement is suitable for pouring the foundation from this article.

The video shows the load-bearing capacity of screw piles:

You can learn how to make a solution for the foundation from this article.

Useful tips for calculating the load on a screw foundation

First of all, you should pay attention to the information contained in various reference books on the technical characteristics of certain materials. If something remains unclear to a person when calculating the weight of a house element, then one should not think at random that, in case of an error, the foundation will still hold up. It must be remembered that a foundation made of screw piles, despite its reliability and versatility, does not tolerate miscalculations.

In order to correctly calculate the future load on a pile foundation, you need to operate with accurate data. To do this, you need to be patient and, if possible, be surrounded by reference books. If you don’t have time for this, then it’s better to turn to specialists who will do it according to all standards.

Description of products and nuances of their installation

Screw piles are steel pipes that have a pointed end and screw blades for screwing into the ground. The absence of any seams on the piles explains their high strength and low susceptibility to corrosion. The walls of the pipe can have different thicknesses - usually this figure is in the range from 4 to 7 mm. The construction market offers the consumer piles of any length, the minimum is 1 m.

The purpose of the screw tip is not limited to the installation function; the blades prevent the product from being pushed out by the ground. The non-screwed version of piles requires concreting, while products with threaded threads do not need to be fixed in the soil structure. This allows you to reduce the cost of foundation construction.

The dimensions of the foundation and the scale of the project are the factors that determine the choice of technology for installing screw piles:

- manually;

- using hydraulic special equipment.

Work on screwing in piles

The installation method does not affect the load-bearing capacity of the products. In any scenario, the pipes are screwed into the ground like a screw. But to increase the strength of the future foundation, the installation of screw products requires compliance with a number of rules:

1) in soil that is frozen or has inclusions of hard rocks, it is first necessary to make a well with a drilling rig. This leader hole will facilitate construction and will not damage the load-bearing capacity of the future foundation;

2) on swampy and frequently flooded soils, it is very important to carry out a number of anti-corrosion measures. First, the inside of the pipe body is filled with concrete mortar, then the steel surface is treated from the outside with any hydrophobic composition;

3) an important task is to increase the strength characteristics of 2-meter piles; they are strengthened from the inside with reinforcement.

The bearing capacity of piles is calculated for ideal installation conditions. Even small deviations from the installation technology are deviations in the strength of the finished structure. It is important to correctly assess the structure of the soil and outline the exact sequence of work operations.

Feasibility study of foundation construction

To determine the real amount of money for constructing the foundation of a house on screw piles, all costs are reduced to a single total. Prices for materials and prices for work are taken on average across the country.

- The cost of a pile 108x2500 is 2.8 tr. Total amount - 30 pcs x 2.8 = 84 tr.

- The price of a pile 89x2500 is 2.2 thousand rubles. The total amount is 6 x 2.2 = 13.2 tr.

- Manual installation of all aircraft with trimming to a horizontal level is equal to 36 x 1.8 = 64.8 tr.

- Delivery of piles to the construction site – 1.5 thousand rubles.

- The cost of channel No. 20 with welding installation is 120 linear meters. x 1.05 = 126 tr.

- Delivery of channel – 4 tr.

The total cost will be 293.5 tr.

For comparison, installing a strip foundation for such a house will cost approximately 900 rubles. That is, a pile foundation on screw supports will bring savings of 300 - 400 rubles.

Methods for installing screw piles

Small supports (up to 2 m) are installed manually. Piles with a diameter of 108 mm or more, a length of 2.5 m or more are mounted using a mechanized method.

Installing a screw pile manually

Manual installation of screw supports

- Aircraft up to 2.5 m long are often installed manually. This is done as follows:

- First, the pile field is marked. Pegs and cord mark the installation locations of the supports.

- Using a hand drill, make a funnel 30–40 cm deep. This will set the vertical direction of the aircraft’s immersion into the ground.

- If there are no mounting holes in the upper part of the barrel, then cut them yourself. This can be done with a gas torch or an acetylene torch.

- The support is lowered into the hole. The ends of the levers are inserted into the mounting holes (these can be sections of water pipe).

- 3 people are involved in the work. Two workers rotate the barrel using levers. The third worker controls the vertical of the aircraft.

- Using a level, marks are made on the shafts of the supports, fixing the design height of the ground part of the piles.

- Using an angle machine, excess parts of the support trunks are cut off.

- Depending on the grillage design, the supporting parts of the aircraft heads are formed.

- Install the grillage.

The piles are installed at a distance from each other no more than 3 m. If the distance is 4 m, then an additional stand is installed in the middle.

Installation of a 3 m screw pile using a mechanized installation

Mechanized installation of screw supports

The power unit for rotating the aircraft is installed on the feed boom of any mobile lifting mechanism. There are specialized mobile installations for aircraft.

The speed of formation of the foundation base using a mechanized installation significantly reduces the construction time of the facility.