Calculation of concrete consumption

Concrete calculations are carried out on the basis of a finished design of the building being constructed, which takes into account climatic conditions, engineering surveys, as well as other technical nuances. Only design documentation will make it possible to determine the type of foundation and its geometry in order to ultimately build a reliable and durable structure that will last no less than the design period.

Concrete consumption is determined depending on the type of base and the features of its design: the amount of reinforcement in the reinforcing layers, the shape of the stiffeners, etc.

Calculation of the volume of concrete for a strip base

A strip foundation is the second most expensive concrete after a monolithic slab.

Calculation of the concrete that will be spent on a strip foundation is carried out in accordance with the design of the facility. For ease of calculations, you need to make a separate sketch on which to display the geometry of the base, and then calculate the required value.

Since the strip foundation in projection is a strip, it is recommended to divide it into rectangles in the sketch. If the tape has a complex shape with additional partitions inside the perimeter of the building, you need to select rectangles so that most of them have the same dimensions.

After dividing the tape into parts, you need to measure their dimensions and write down the number of matching fragments opposite each of them. Next, you should calculate the areas of the rectangles: multiply the length and width of each of them, respectively, and then multiply by the number of repeating parts. These values should be summed up to give the total area. The formula for calculation is as follows:

where an is the length of the nth rectangle;

bn – width of the nth rectangle.

To calculate how much mortar needs to be prepared for a strip foundation, you will need to multiply the total area by the height:

where H is the height of the tape.

The calculated value does not reflect the possible shrinkage of the strip foundation, especially if the strip is massive. Therefore, it is recommended to reserve approximately 2% of the obtained value in order to determine how much the total volume of the solution will be. The presence of reinforcement in this case can be neglected.

We recommend watching a video on how to calculate a strip base with your own hands.

Types

Next we will look at all the main types of foundations.

Tape

The calculation must be carried out taking into account the configuration of the foundation of the house. According to construction canons, it should be located under all walls: load-bearing and partitions, and form a single continuous structure. In cross-section, such a foundation is a rectangle, the sides of which are the width of the tape and its depth.

To make it clearer, let's give an example with numbers. For ease of calculation, we assume that the depth of the foundation is 1 m, its width is 0.5 m. Now it is necessary to calculate the cross-sectional area:

1 x 0.5=0.5 m²

To calculate the volume of the structure, you need to multiply the resulting area by the length of the structure. The last indicator is taken from the drawing that is included in the house design, or the lengths of the dug trenches are measured with a tape measure. The main thing is that in this case the total length of the foundations located under all the walls is required. For example, the total length is 200 m, which means that the following mathematical operations must be carried out:

200 x 0.5=100 m³

This is the concrete consumption in cubic meters for a strip foundation with the parameters we set. It is necessary to note that in some projects a more powerful foundation with an increased width is poured under load-bearing walls. Therefore, the calculation of concrete cubic capacity must be carried out separately for load-bearing walls, separately for partitions. And at the end, add both values.

Plate

A slab foundation is simply a slab with certain dimensions and pouring thickness.

Essentially, it is a cube, the volume of which is calculated by multiplying the sides of the figure. Therefore, you must first decide on the size of the sides.

For example, if the dimensions of the building being constructed are 6 and 9 m, then the area of the slab will be: 6 x 9 = 54 m². The volume of the structure will additionally depend on the thickness of the fill, for example, 0.3 m. This means the final result: 54 x 0.3 = 16.2 m³. This is the required amount of concrete for such a foundation.

If the slab structure is not an exact geometric figure, for example, as shown in the photo below, then it is necessary to divide the area into sections with exact figures. In this case, these are two rectangles: one main section, the second protrusion. The volume of the two sections must be calculated separately, and then the resulting values must be added. This will be the required volume of concrete solution.

Columnar

Calculating concrete for a columnar foundation is also simple, but there are some nuances here. The thing is that a columnar foundation is a small cross-section of support. In this case, the section itself may have a different configuration. It is either a rectangle or a circle. Depending on the selected section, the amount of concrete is calculated. The calculation is based on the cross-sectional area.

The area of a rectangle is the multiplication of the dimensions of its sides. That is, the area of the slab foundation and the section of the strip foundation were calculated in exactly the same way.

- The area of a circle is a formula that contains a constant value - the Archimedean number (π), equal to 3.14, and the diameter of the circle. Here is the formula: S=πD²/4. For example, if the diameter of a support column for a house is 0.2 m, then its area will be equal to: (3.14 x 0.2) : 4 = 0.157 m².

- But before calculating the amount of concrete for the foundation for one support post, its pouring depth is necessary. For example, let it be 0.8 m. This means that the volume of the support will be like this:

0.157 x 0.8=0.126 m³.

Now you need to multiply the result obtained by the number of foundation columns that will be poured under the walls of the building. For example, let's take 20 pillars. Therefore, the final result will be equal to: 20 x 0.126 = 2.5 m³.

As you can see, calculating how many cubes of concrete are needed to pour the foundation is not so difficult. The main thing is to know the formulas for the volume of geometric shapes. There is one more point that needs to be paid attention to. This is a reinforcing frame that is laid into the body of the foundation structure. It is made from metal reinforcement in the form of a mesh or cages. When calculating the volume of concrete solution for pouring the foundation, the frame is not taken into account due to its small volume.

Calculation of concrete consumption for a slab base

Calculating a slab foundation is much simpler than a strip or column foundation. This is due to the fact that its design is a rectangular parallelepiped, the volume of which must be calculated by multiplying its dimensions:

where a is the length of the base of the parallelepiped;

b – base width;

H is the height of the parallelepiped.

However, for large areas, it is additionally necessary to strengthen the foundation with stiffeners, which will also require concrete. Therefore, in accordance with the project drawings, it will be necessary to additionally calculate the consumption of the concrete mixture using formula (3), only with the substitution of the corresponding values. These values need to be added to the V plate and get the calculated amount of solution. In a real situation, a reserve of approximately 5% should be included, which will be used for shrinkage of the structure as it gains strength.

Watch the video on how not to make mistakes when calculating the amount of mortar for pouring the base.

Since the ratio of length and width in a slab foundation is several times greater than its height, quite a lot of reinforcement is used in the structure to increase its rigidity and reliability. This means that in order to save money, you need to take into account the volume of reinforcement being installed. The formula for calculating it is as follows:

where i is the number of reinforcing bars;

R – reinforcement radius;

L is the length of the rods.

The volume of mortar for a slab foundation will be determined by the following formula:

Concrete table.

The introduction of unsifted sand with impurities, stale cement or dirty crushed stone worsens the structure of the material and negatively affects the process of strength gain. Despite the increase in the mobility of concrete when diluted with water, it is strictly not recommended to violate the proportion indicated for it. The same applies to ready-to-purchase solutions. The scope of application of various brands is determined by the operating conditions and the loads experienced, in particular, one of the following options is selected:. M - used in road construction, curbs and in preparing the base of a building for pouring main structures.

Go to new. The contractor refuses to provide a concrete composition selection map citing commercial secrets.

Not suitable for concreting critical and loaded areas. M - brand of lightweight concrete for auxiliary purposes. The scope of application includes screeding floors, constructing garden and pedestrian paths, curbs, foundations for light buildings, and pouring monolithic slabs.

M is a strengthened grade of concrete, optimally suited for retaining walls, floor screeds, foundation structures, blind areas, garden areas and paths.

M is a heavy variety, in demand in private construction. It is used when pouring foundations, flights of stairs, bases for fences and outbuildings, and tiled floors with low loads.

It doesn’t matter for what purpose you need the concrete mixture. If you decide to prepare it yourself, then without calculating the composition you will not be able to achieve the required strength indicators. This is due to the fact that work is not always carried out in ideal conditions, and the mixture is very sensitive to changes in temperature and humidity. You also need to take into account that ready-made concrete can only be used within hours after adding water to the dry mixture. All this time it must be stirred to avoid setting.

Concrete M can be used in industry, but only for low-rise buildings. M is the initial grade for the foundations of multi-storey buildings.

This concrete is characterized by high strength and water resistance and is suitable both for the construction of hollow-core slabs and beams, and for concreting monolithic structures. It is from this that bowls of public swimming pools, airfield roads, columns, supports, grillages and other loaded concrete products are poured. M - extra-heavy quick-setting grade. Announcements for help. Selection of concrete composition Type of work:.

Calculation of the volume of concrete for a columnar foundation

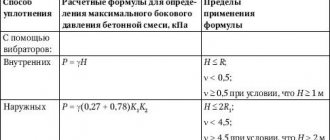

To determine how much mortar will be spent on laying a columnar foundation, it is necessary to calculate the volume of the pillars and make a reserve for shrinkage of up to 2%. If the pillars have a rectangular or square cross-section, then their volume is calculated using formula (3) with the substitution of the corresponding values.

For foundation pillars with a round cross-section, the calculation is carried out using the following formula:

where D is the diameter of the pile;

i – number of piles;

H – pile height.

To calculate grillages, formula (3) can be used.

Calculation of the number of components of a concrete mixture

When laying a columnar foundation, there is no need to prepare the entire volume of concrete at one time, as, for example, for a strip or slab foundation. Therefore, there is a need to calculate the components for mixing the solution yourself.

For these purposes, use the data from Table 1 and Table 2. The first table will allow you to determine the consumption of cement and select its brand, depending on the requirements for the resulting concrete. Table 2 determines the approximate consumption of cement powder per 1 m3 of finished mortar, and Table 3 determines how much sand and crushed stone is required.

Watch the video on how to calculate the required proportions of materials for the solution.

In practice, the calculation of the volume of concrete for the foundation rarely coincides with the required one. There are many reasons for this, ranging from technical to climatic. Therefore, all components must be purchased with a reserve.

Table 1. The ratio of water to cement in the prepared mortar

Table 2. Cement consumption per 1 m3 of solution

Table 3. Determination of sand and water consumption depending on the size of crushed stone

Calculation of laboratory composition of concrete

The laboratory composition of concrete is calculated using the absolute volume method. According to this method, the consumption of all four components of the concrete mixture should be such that the sum of their absolute volumes is 1000 l (this does not take into account the small volume of entrained air):

(5.8)

where C, V, P, Ш

– respectively, the consumption of cement, water, sand and crushed stone, kg;

ρц, ρп, ρш

– respectively, the true density of cement, sand and crushed stone

Material costs are determined in the following order:

1) The cement-water ratio from formula (5.5), reflecting the basic law of concrete strength (if C/V is less than 2.5):

(5.9)

If C/V > 2.5, which is typical for high-strength concrete, then formula (5.7) is used for calculation, from which it follows:

(5.10)

If additional requirements for frost resistance and water resistance are imposed on concrete, then the obtained C/V values are compared with the standardized ones and the larger of them is accepted for further calculations.

2) The approximate water consumption (B) is taken according to table 5.11 depending on the required workability of the concrete mixture, the type and size of the aggregate.

Table 5.11

Approximate water consumption per 1 m3 of concrete mixture

on dense aggregates

| Concrete mix grade based on workability | Water consumption (l/m3) at aggregate size (mm) |

| gravel | crushed stone |

| SZh1 | |

| Zh4 | |

| Zh3 | |

| Zh2 | |

| Zh1 | |

| P1 | |

| P2 | |

| P3 | |

| P4 | |

| P5 |

Notes: 1. Water consumption is given for mixtures based on cement with a normal dough density of 27% and sand with a particle size modulus Mkr = 2.

2. When the normal density of cement paste changes by every percentage point downward, the percentage of water should be reduced by 3-5 l/m3, and increased by the same amount if it is upward.

3. If the sand fineness modulus changes downward by 0.5 of its value, the water flow should be increased by 3-5 l/m3, and if Mkr changes upward, it should be reduced by the same amount.

3) Cement consumption is determined taking into account the found C/V

and

B

:

(5.11)

The resulting value of cement consumption must be checked with the regulatory requirements of GOST 26633 for the minimum cement consumption, which is assigned depending on the nature of the structure’s reinforcement, operating conditions and type of cement. So, for example, when using non-additive Portland cement, the minimum consumption is: for unreinforced structures - 150 kg/m3, for reinforced with non-prestressing reinforcement, exposed to atmospheric influences - 200 kg/m3, for structures with prestressed reinforcement, exposed to atmospheric influences - 240 kg/m3 . If, as a result of the calculation using formula (5.11), the result is a value less than that required by the standards, then the standard minimum value of cement consumption should be accepted.

4) To determine the consumption of coarse and fine aggregates, two conditions are specified:

a) the sum of the absolute volumes of all components in a compacted state is equal to 1000 l (1 m3), which is expressed by equation (5.8);

b) the cement-sand mortar should fill all the voids with coarse aggregate, taking into account some spreading of the grains by this mortar. The amount of expansion is set by the coefficient of expansion of grains of coarse aggregate (crushed stone or gravel), which shows how much the volume of the solution exceeds the volume of voids. An excess of the mortar part is necessary to obtain a workable concrete mixture and good (complete) binding of the aggregate grains into a single durable monolith. This condition can be written as the equation:

(5.12)

where Vp.sch.

– voidness of coarse aggregate;

ρts

and

ρп

– true density of cement and sand, respectively;

– bulk density of coarse aggregate;

α

– coefficient of separation of coarse aggregate grains.

Coefficient value α

for rigid concrete mixtures it is taken to be 1.05-1.15.

In mobile concrete mixtures, the value of the grain expansion coefficient varies over a wider range: α

= 1.25 – 1.55.

the the α

value, since to increase the plasticity of the mixture, the grains of coarse aggregate must be more distant from each other.

α can be used

from the volume of cement paste

Vc.t.

(Fig. 5.9).

The volume of cement paste is calculated by the formula

(5.13)

By solving the system of two equations (5.8) and (5.12), you can calculate the required amount of crushed stone (gravel) per 1 m3 of concrete:

(5.14)

where , ρш

– bulk and true density of crushed stone (gravel), respectively, kg/m3.

Calculation of consumption of fine aggregate (sand P

) per 1 m3 of concrete is fulfilled according to the formula

(5.15)

For ordinary heavy concrete, the calculated density of the concrete mixture in the compacted state, defined as Pb.s. = C + V + P + Shch

, (5.16)

is in the range of 2350-2450 kg/m3.

The calculated composition of concrete is specified in test batches. First, a batch of concrete mixture is prepared to check workability. Due to the peculiarities of the properties of the cement used and local aggregates, it is possible that the value of the cone settlement or the rigidity of the concrete mixture may differ from that accepted in the calculation. If the mixture turns out to be more mobile, then a small amount of sand and coarse aggregate is added, approximately 5-10% each, until the required workability is achieved. If the mixture turns out to be less mobile, then add a small amount of water (5-10%) and increase the cement consumption by the same amount in order to maintain the calculated cement-water ratio. Test batches are repeated until the required workability indicators are obtained.

In both cases, the composition is recalculated based on the actual density of the concrete mixture obtained using the compaction method adopted in production conditions.

Control samples are made from a concrete mixture adjusted for workability, which, after hardening under normal conditions for 28 days, is tested for compressive strength. If the strength of the control samples differs from the specified value by more than ±15%, then the cement composition is adjusted up or down, control samples are made and tested again. The result of an experimental verification of the calculated composition of concrete is a new, refined composition that takes into account the properties of specific materials.

In industrial settings, wet aggregates are often used to prepare concrete mixtures. Additional water contained in aggregates leads to the need to adjust the compositions. As a result of recalculating the consumption of materials, taking into account the actual moisture content of the aggregates, the production (working) composition of concrete is obtained.

First, the amount of water introduced by the aggregates is calculated using the formula

ΔВп = ПWп,

(5.17)

ΔVsh = ShchWsh,

(5.18)

where Wп, Wш

– moisture content of sand and coarse aggregate, %;

ΔВп

and

ΔVsh

– the amount of water contained in sand and crushed stone, respectively, kg/m3.

Then the water flow is set taking into account the moisture content of the aggregates:

Bw = B

– (

ΔVp

+

ΔVsh).

(5.19)

In order to maintain the calculated amount of aggregates in the mixture, it is necessary to increase their consumption by the amount of water they contain. In the production composition, the consumption of sand and crushed stone, taking into account humidity, will be:

П′ = П + ΔВп. (5.20)

Shch′ = Shch + ΔVshch. (5.21)

Cement consumption when recalculated in the production composition remains unchanged.

The volume of a concrete mixture is always less than the total volume of its components in bulk. This is explained by the fact that during the mixing process, smaller grains fill the voids in the larger ones, and the cement paste fills the voids in the smallest grains. To estimate the volume of the resulting mixture, the yield coefficient of the concrete mixture β

:

(5.22)

where is the bulk density of cement, sand, crushed stone, kg/m3.

Coefficient β

It is also used to assess the quality of compaction of concrete mixtures and calculate the productivity of concrete mixers. The average yield coefficient for heavy concrete is 0.67, for light concrete – 0.75.

Basics of concrete technology

Concrete production includes the following main technological processes:

— preparation of concrete mixture;

— transportation of concrete mixture;

— laying and compacting the concrete mixture;

- concrete hardening.

The preparation of the concrete mixture is carried out by sequentially performing technological operations of dosing and mixing.

The dosing of concrete mixture components must ensure accurate weighing, which ensures that the actual composition corresponds to the specified one. According to the requirements of GOST 7473, the dosing accuracy for cement, water and additives should be no higher than ±1%, for aggregates ±2%. All materials are dosed by weight, except for porous aggregates, which are dosed by volume, adjusted by weight. For dosing, automatic dispensers are used, providing not only the required weighing accuracy, but also a short operation time.

Mixing should ensure the homogeneity of the concrete mixture due to the uniform distribution of the components throughout the entire volume of the mixture.

Mixing of dosed components is carried out in concrete mixers of various designs. Mixing of components occurs due to repeated mixing of particles and individual volumes of concrete mixture. During the mixing process, internal forces are overcome: friction, adhesion, gravity and shear resistance of the mixture. The magnitude of these forces depends on the composition of the concrete mixture and the properties of the starting materials. Fluid mixtures with a high content of water and cement mix much more easily than rigid mixtures with low cement consumption, in which the internal bonds are stronger. Coarse-grain mixtures mix more easily than fine-grain mixtures; Mixtures with light aggregate are more difficult to mix than mixtures with dense aggregate. These features of concrete mixtures are taken into account when choosing a mixer and mixing mode.

Based on the principle of mixing, concrete mixers are divided into gravitational and forced action ; according to the operating mode - cyclic (periodic action) and continuous action. In gravity mixers, mixing occurs in a rotating drum with a horizontal or inclined axis of rotation. The components of the concrete mixture are loaded into a concrete mixer; portions of the material, when rotated, are raised by trough-shaped blades to the uppermost position, from where they freely fall and are introduced into the concrete mixture at the bottom of the drum. So, as a result of repeated rise and fall, mixing occurs.

Stationary gravity mixers of periodic action have a loading capacity of 750, 1200, 1500, 2400 and 3000 liters, and a drum rotation speed of 13-20 rpm. The general view of the mixer is shown in Fig. 5.10.

The mixing duration, depending on the volume of the concrete mixer and the workability grade of the concrete mixture, is determined experimentally or according to the data in Table. 5.12.

Table 5.12 - Recommended duration of mixing concrete mixtures with dense aggregates in stationary mixers

| Mixer loading capacity, l | Duration of mixing, s, not less | |

| In gravity mixers for workability grade | In forced-action mixers for mixtures of all grades according to workability | |

| G1, P1 | P2 | P3-P5 |

| 750 or less | ||

| St. 750 to 1500 | ||

| St. 1500 |

Continuous mixers are used for large volumes of production of concrete mixtures of a constant composition, for example, for road construction.

for mixing rigid concrete mixtures, since they cannot ensure the homogeneity of the mixture even with increasing mixing duration.

In these cases, forced-action concrete mixers are used.

Inside the body of such mixers there are special mixing devices (blades, paddles, etc.) installed, which are attached to rotating vertical or horizontal shafts. These devices force the components of the concrete mixture to mix.

Based on their operating principle, cyclic mixers are divided into:

- counterflow with a rotating body (Fig. 5.11, a);

- rotary with a fixed body (Fig. 5.11, b).

A general view of the rotary mixer is shown in Fig. 5.12.

The loading capacity of cyclic mixers is 500, 750, 1500 l, the rotation speed of the working body is 15...40 rpm.

Single-shaft mixers are used only for mixing the components of fine-grained concrete; twin-shaft mixers are used for preparing ordinary concrete mixtures with coarse aggregate.

For continuous preparation of mixtures, twin-shaft paddle mixers with horizontally located shafts are usually used. The shafts rotate in different directions, and the blades not only mix all the components of the mixture, but also gradually move the mixture from the loading opening to the unloading opening.