A self-made vibrating table for paving slabs allows you to prepare at home the required amount of finishing material for finishing paths on the territory of a country house or country house.

The vibrating table for the production of paving slabs can be of various sizes and configurations.

Mortar for laying bricks. How to make a sauna stove from brick? Laying aerated concrete blocks with your own hands: step-by-step instructions. More details>>

Vibrating table device

Paving slabs are made from a concrete mixture that includes water, sand, Portland cement, fillers and additives. This mixture is prepared using a concrete mixer, after which the solution is poured into special molds.

A welding machine is needed to make a vibrating table.

The natural compaction of concrete in a mold with the removal of air bubbles from it is carried out very slowly, and this process is not controlled by humans. In order to speed up the compaction process and be able to control it, it is necessary to manufacture a special device - a vibrating table.

This device consists of a tabletop, which is movably mounted on a special frame using springs or suspensions. The table cover must be in a strictly horizontal position during operation. The mobility of this structural element is limited in the vertical and horizontal directions. To set it in motion, an electric motor is used, which is included in the design of the vibrating table.

To shake the table top, a massive eccentric is installed on the electric drive. During operation, the eccentric, rotating on the shaft, leads to a radial displacement of the center of gravity of the electric motor, which causes vibration of the latter. This vibration is transmitted from the electric drive to the table top, on which the electric motor is rigidly fixed. From the table, vibrational displacements are transmitted to the molds for casting the tiles and to the concrete in them.

General characteristics of a vibrating table for the production of paving slabs

It’s not only possible to make a homemade vibrating machine for producing tiles at home, but also necessary. For the tile itself you need cement, some sand, water and dye. A vibrating table is required to form and compact the raw materials in each slab blank. Naturally, you can purchase a ready-made table at a special hardware store, but the cost will be too high, even if you choose the minimum power of the product.

The price will depend on which:

- Equipment;

- Dimensions;

- Power;

- Manufacturer.

You can make a vibrating table for the production of paving slabs yourself

In general, it is quite possible to make a homemade table for forming slabs, and this will allow you to save a lot, and all the money invested will pay for itself more than once. Basically, large batches of paving slabs are not made at home, and therefore it is not worth spending money on huge vibration mechanisms.

The appearance of a homemade vibrating table is very simple; it is a metal structure, which in appearance resembles a very ordinary table. The tabletop is installed on a frame with a spring or glasses with a special gap. The motor is installed in the lower part, and it is due to it that the tabletop will undergo vibrations in order to ensure high-quality compaction of the cement mass placed in the slab molds.

Uniform distribution makes the slabs more durable, non-porous and wear-resistant. This increases their performance properties and service life.

Some believe that it is possible to make tiles without such a special table, but then you can immediately be prepared for low quality, medium density and too short a service life. It is the air bubbles inside the products that cause their early destruction.

Preparing tools and material for constructing a vibrating table with your own hands

Manufacturing equipment such as a vibrating table for paving slabs is not a technically difficult task.

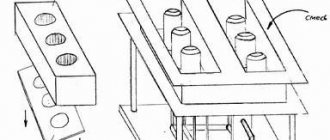

Diagram of a vibrating table and sifter.

Before starting work on the manufacture of a device, it is necessary to prepare a drawing of the device according to which it will be manufactured, as well as all materials and tools that may be required in the manufacture of this type of equipment.

To carry out work on the manufacture of such a device as a vibrating table for paving slabs with your own hands, you will need to prepare the following materials:

- 4 iron pipes and channel;

- metal sheet for making countertops;

- vibration drive, any electric motor with an operating voltage of 220 V with the required power;

- steel springs to create a movable support for the table top.

During the work you will need the following tools:

- welding machine;

- bolts for fastening the electric motor to the plane of the tabletop;

- drill;

- grinder for adjusting the dimensions of metal parts in accordance with a previously developed drawing.

After developing the drawing, preliminary preparation of metal blanks that are part of the structure of the vibrating table is carried out.

Equipment manufacturing

Blanks for the vibrating table: 1) matrix development; 2,3,4) pallet blanks; 5,6,7) frame of the matrix from below (corner 25x25); void carrier fastening bar; 9) emptiness; 10) upper void plug; 11) lower void plug.

2,3,4) pallet blanks; 5,6,7) frame of the matrix from below (corner 25x25); void carrier fastening bar; 9) emptiness; 10) upper void plug; 11) lower void plug.

In order to make a vibrating table for paving slabs with your own hands, in addition to your hands, you will need:

- electric welding transformer (you can use any: AC, DC, semi-automatic, as long as the power allows you to weld metal 4 mm thick) with cables, clamps and a welding mask;

- welding electrodes Ø 3 mm or welding wire for semi-automatic machines Ø 0.8 mm;

- metal corner with shelf up to 60 mm for table top. The length of the corner is equal to the perimeter of the table cover and the length of the transverse or longitudinal jumpers in the case of using thin tin or plywood for the cover;

- tin with a thickness of more than 2 mm for the table top, plywood, OSB or chipboard based on the area of the lid;

- angles (channels) or pipes of any size and profile for the length of the frame, depending on the design of the latter. It is advisable to take a corner with a shelf from 30 mm, and pipes: round section - from 1 inch (2.54 cm), square - from 25x25 mm;

- four springs (can be from car engine valves, cut moped or car springs, shock absorbers, etc.);

- electric motor: single-phase 220 V or three-phase 380 V, power about 50 W with wires and starter;

- fastening bolts with nuts;

- angle grinder (“grinder”) with cutting and grinding wheels;

- hammer;

- roulette.

It is most convenient to make the frame (bed) of the vibrating table from a profiled pipe of square (rectangular) cross-section.

First you need to make a bed with your own hands. To do this, we prepare 4 straight sections of a channel, corner or pipe for the legs, the length of which is slightly (10 centimeters) shorter than the height of the planned table. In the same way, we take 4 segments with a length equal to the width of the bed and 4 segments with a length equal to the length of the bed itself.

Choosing the height of the table is a purely individual matter. For large volumes of paving slabs and blocks produced, when the vibrating table will operate for a long time, it is advisable that the worker does not bend over. The height of the table is therefore 90-100 cm, but you can make it low - from 40 cm. The length and width of the frame depends on the size of the lid and should be equal to its dimensions or slightly less.

Vibrating table manufacturing process

Vibrating table drawing.

The vibrating table design is straightforward and not complicated. First of all, you should pay attention to the manufacture of the base of the device. The base is constructed using a channel or metal corner measuring 50x50 mm. The ideal table dimensions are considered to be 700x700 mm, but these dimensions can be changed depending on the needs and needs of the owner. When designing a table, you should remember that the larger the table, the more powerful the motor required as a vibration drive.

Iron pipes welded to the base are used as supports for the table. In order to ensure maximum stability of the vibration device, metal plates should be welded onto the ends of the pipes or the base should be secured by digging the pipes into the ground. To increase stability, you can fill the buried pipes with a small amount of concrete. When metal plates are used as support, the table becomes portable. When the supports are dug into the ground, the table turns into a permanent installation. It is necessary to choose the height of the table in such a way that the engine does not touch the ground during operation and it is convenient to work with the table.

After making the table support, the next step in the design process is to make a movable table top. Springs are welded at the corners of the supporting structure, and when making a tabletop of a large area, the spring should also be welded in the center of the structure. It is best to use springs from a moped, cut in half, as a support for the tabletop.

After the springs are secured to the support structure, a metal sheet is placed over them. The thickness of the metal sheet used to make the tabletop must be at least 8 mm. An electric vibration drive is attached to the bottom plane of the sheet.

On top of the tabletop there is a mold for making tiles. If the tiles are small in size, then several forms can be placed on the surface of the countertop.

Device requirement

The hardening of concrete is always accompanied by slight vibrations, during which air bubbles are released. Thanks to this, the future product becomes durable and the structure of the concrete is compacted. To ensure this, a vibrating table is needed. It oscillates at a frequency of 3000 movements per minute.

All vibrating tables can be divided into two types:

- Industrial with hydraulics;

- For home use, creating vibrations using an eccentric mounted on an electric motor.

It is the latter that we will consider.

Important! Since it is impossible to know the number of vibrations, the vibrating table must have an amplitude adjustment function.

But first things first.

To make a vibration table with your own hands you will need:

- Metal sheet with a thickness of at least 3 mm;

- Springs;

- Channel and corner;

- Pipes;

- Electric drill;

- Welding machine;

- Bulgarian;

- Spanners;

- Metal legs;

Features of attaching the vibration drive to the tabletop

To create vibration, an electric motor is fixedly fixed to the tabletop. Very often, ready-made vibrators IV-98 or IV-99 are used for this purpose with the eccentrics set to minimum.

When using these types of vibrators, the vibration created is quite strong, so the table cover should be made quite massive. To add massiveness, the tabletop should be weighted by attaching massive metal corners to it (in addition to the corners, concrete ballasts can be used for weighting).

As a drive for a homemade table, it is best to use ordinary household electric motors, on which a specially made homemade eccentric is mounted instead of a pulley.

A homemade eccentric is a bushing with a screw for fixing; in addition, a bolt is attached to the bushing at the threaded end. The attached bolt must be able to move laterally. This allows you to adjust the vibration strength. To create a vibration effect, you can unbalance the original electric drive pulley. To unbalance, you need to cut off part of the pulley or make holes on one side of the pulley.

The motor on the fixture can be mounted in 3 different positions. When the drive is mounted in a horizontal position, vibration occurs in the vertical direction; when the motor is mounted in a vertical position, vibration occurs in the horizontal direction. If it is necessary to perform vibration movements in 2 directions, the motor should be fixed in relation to the tabletop at an angle of 45°.

What is a vibrating table?

We can say for sure that without such irreplaceable equipment as a vibrating table, it would be impossible to produce such simple and necessary little things in our lives as paving slabs, statues, curbstones, various shaped elements, blocks, window sills, decorative fences and much more. From the above, it becomes clear that vibrating tables are special equipment designed for the production of various concrete elements using the vibration casting method.

The entire design of this unit consists of a movable vibrating table with an unbalance attached to it in the form of a special motor. The vibrator creates vibrations that set the vibrating table in motion. All components of the structure are made of high-strength steel. This reliability allows the vibrating table to withstand strong vibrations during the production of concrete and decorative products.

As a rule, in addition to a conventional vibrating table, work requires stripping and forming devices, as well as special molds for casting, which can be made of steel, polyurethane or plastic.

The undeniable advantages of this equipment include the possibility of using it both for the production of massive products and for the production of miniature elements. Vibrating tables allow you to process the mixture equally well in molds of any size. This is achieved due to the uniform distribution of vibrations over the entire surface of the table.

Rice. 1 — Electric vibrating table

Requirements for the operation of the vibrating table

During operation of the device, the range of vibrations should not be too large, and in order to produce high-quality tiles, the vibrating table must have vibration of the same intensity over the entire plane of the tabletop. Uniform vibration allows the material from which the tiles are made to be evenly compacted. The building material must be loaded accurately to ensure uniform tile thickness when the material is compacted. A small self-made vibrating table should have a height of at least 80 and no more than 90 cm. The size of the tabletop is selected in such a way that it is convenient to work on its surface.

The frame of such a table should be made of corners, and the legs should have fastenings for installation on anchors. If there are no fastenings to the anchors, the table may sway during operation, which will affect the quality of the manufactured product.

When assembling the table, it is recommended to use locknuts and cotter pins to ensure the quality of threaded connections (during equipment operation, vibration weakens bolted connections).

Choosing a motor for a vibrating machine for paving slabs

As already noted, the installation of a vibrating table begins exclusively with the preparation of drawings. They are needed to select the height and width, visualize the future structure and draw up a plan of materials and tools.

As for the design parameters, for ease of use, you should choose a height of about 90 cm, a length of 180 cm, and a width of 70-180 cm.

Naturally, the width of the tabletop will determine how many materials can be placed on it, and this will affect the power of the purchased engine. It is important at the construction stage to decide what type of table the table will be, in particular, portable or stationary.

For a vibrating table, an engine model IV-98 would be an excellent option.

Those who make their own tables and various installations like a circular saw prefer to use:

- Available means;

- Parts from old vehicles;

- Only proven spare parts that will definitely work after assembly.

For a vibrating table, an engine model IV-98 would be an excellent option. The most important thing is that the motor is simple and can be removed from an old washing machine. In this case, power is not a very important indicator and the optimal value is sufficient. The main criterion by which an engine is selected is an eccentric, or, in other words, a device that provides vibration. Engine models IV-98 and IV-99 can be an excellent analogue of a household engine.

Features of use

Before starting work, make sure that you have all the necessary equipment for vibratory casting: a concrete mixer, casting molds and a vibrating table. The described unit is supplied already configured, so no additional debugging or adjustments are required. Once the equipment is connected to a grounded electrical outlet, you are ready to start working.

After the concrete solution is prepared, it must be poured into special forms that are installed on a vibrating table. The duration of vibration depends on the type of element being manufactured, its mass and dimensions. This indicator is determined by the technical specifications for the product. Do not exceed this figure, since longer vibration can lead to deterioration in processing results. It is important to know that the operation of the vibrating table is short-term. The duration of continuous vibration is no more than 2 minutes.

During operation, it is important to monitor the vibrator motor. It shouldn't overheat. You should also be careful when handling concrete, since water or solution that gets on switches, the motor housing, or other conductive parts can disrupt the operation of the device.

Upon completion of work with vibration equipment, it is necessary to clean the surfaces from contamination.

The principle of operation of the vibrating table can be understood from the proposed video: https://www.youtube.com/watch?v=SjCYxK8avwk

Components of a vibrating table

A standard vibrating table consists of the following elements:

- movable desktop;

- engine with unbalance (it can be designed for a voltage of 380 or 220 V);

- control Panel;

- Some tables may come with a transformer.

The working surface is the most important part of this unit. It is usually made from steel sheets firmly attached to a vibrating device. The thickness of the steel sheet depends on the scope of use of this equipment. For example, for the production of concrete blocks and other heavy products, a working surface with a thickness of at least 6 mm will be required.

An unbalanced motor or vibrator drives all equipment. It is this that is the source of mechanical vibrations in the device. Vibrators of the IV-98 or 99 type are usually used.

Rice. 2 — Hydraulic vibrating table

Selecting a vibrating table

To obtain high-quality products, it is very important when choosing a vibrating table to pay attention to the amplitude and frequency of vibrations of the working surface. It is important that the vibrations are distributed evenly throughout the table. The direction of vibration should only be horizontal. It is better to choose vibrating tables with a vibration amplitude in the range of 0.10-0.15 mm and a vibration frequency of 100-200 Hz.

When choosing a unit, no less attention should be paid to the thickness of the steel elements from which the table is made. As a rule, the mass of high-quality vibrating tables should exceed 200 kg. Otherwise, there is a suspicion that the manufacturer has saved on quality components.

If you want to purchase an electric vibrating table, pay attention to the characteristics of its electric drive. It must be adapted to operate from a specific network. We recommend giving preference to equipment with a motor powered by a three-phase 380 V network. Such units are the most durable and reliable.

Types of vibrating tables

Vibrating tables are generally classified by motor type.

The table below most fully describes the common types of this equipment, their features and scope of application. Types of vibrating tables

| Vibrating table type | Characteristics | Application area |

| Hydraulic vibrating table | Has an increasing amplitude of vibration, a design feature is a springless system | Used for the manufacture of heavy elements weighing no more than half a ton |

| Electric vibrating table | The table is equipped with a movable tabletop with springs, a dynamic vibrator and a transformer | Used in various manufacturing plants |