Stages of mixture hardening

This process cannot be reduced to primitive evaporation of moisture; solidification is a stepwise chemical reaction. Water serves only as a stimulating factor due to which the components interact; this stage is called hydration. The mixture goes through three stages - setting, hardening, strength gain.

Grasping

After combining with water, the solution quite quickly loses its plasticity and fluidity, so everything related to stirring, pouring and initial processing must be completed in a short time. The work will be made easier by following several recommendations:

- premature setting will ruin the entire batch of material, and to avoid it, it is better to prepare the mixture directly on site. Transportation is possible only in a concrete mixer;

- to prevent premature drying, filling, compaction, and leveling are performed without interruption and at maximum speed;

- It is important to avoid layers of the mixture; cold bridges will subsequently appear in these areas.

It is important to avoid layers of the mixture.

The latter circumstance can cause the material to freeze at low temperatures.

Hardening

The mixture crystallizes and the mass gains strength. Here, how long it takes concrete to dry is influenced by an important factor - at what temperature all manipulations are carried out.

Strength gain

This stage lasts, on average, a month if the ambient temperature remains at least 20°C. It is also important that the air humidity is close to 70%.

How long does it take for a brick wall to dry?

Traditionally, people continue to prefer a brick house to any other. A brick wall finally dries out within a month, just like the brickwork in a heating furnace. Most builders wait 3-4 days to putty and lay wiring and get to work. In emergency cases, they plaster and putty immediately after installation, but the strength of the wall built in this way is reduced several times.

Apparently, Russian citizens do not trust any building material as much as brick. Despite the rapid development of the construction industry, including in terms of the emergence of new materials and technologies, brick houses are perceived as the most reliable and preferable.

Most people planning to build their own home intend to use brick. If we are talking about purchasing a finished house, then the majority also prefer to buy a cottage made of brick rather than from another material. Construction companies, of course, focus on the needs of the population, so in Ufa there are a lot of offers in the segment of brick houses. As an example, the company Image Stroy, which carries out the construction of individual brick houses.

If you decide to build yourself, then you probably already know that brickwork is a rather complex structure. When erecting brick walls, a lot of subtleties and nuances arise, each of which can affect the final properties of the entire house.

Polymerization of concrete

Concrete hardening is carried out due to hydration - a special chemical reaction that occurs between binder components and water. The process is intended to convert the base raw material (cement-sand mixture with crushed stone and sand) into calcium hydrosilicate. At the end of the hardening period, a monolithic base with increased strength properties is created.

- Brand of cement mixture.

- Proportions and ratio of components in the solution.

- Indicators of atmospheric humidity.

- Production technology.

- Ambient temperature.

- Thickness and density of concrete pouring.

- Compliance with the rules for caring for the solution during the hardening process.

- Grasping.

- Set of declared strength.

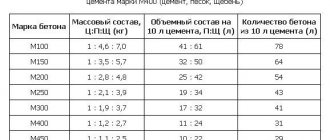

When determining how long concrete takes to dry, it is important to consider the brand of cement that was used when mixing the mixture. The M500 model is characterized by the greatest reliability, and the M100 has the minimum strength.

The hardening time of concrete is determined by the proportions of the components and the presence of various fillers in the composition. The more sand or gravel there is in the solution, the faster the excess liquid will come out of it. If you use a large amount of expanded clay and slag, the water will begin to evaporate more slowly.

To retain moisture in the mixture, it must be covered with a waterproofing film. It can be polyethylene or bitumen mastic. The purpose of such materials is to enhance hydration and protect the solution from rapid loss of liquid.

This effect is also achieved by periodically wetting the solution with water. It is applied by spraying or spraying.

Grasping

Setting of concrete is the first stage of its polymerization and takes no more than 1-2.5 hours. The exact interval is determined by the temperature conditions under which the work is performed:

- If the ambient temperature is 20°C, the chemical reaction will start 100-120 minutes after pouring the mixture into the formwork. Then the composition will dry for another hour.

- At a temperature of 1... 19°C, setting will occur in 3-5 hours.

- At zero temperature, the reaction begins 7-10 hours after mixing. In this case, the drying time will be 16-20 hours.

If there is a negative temperature at the construction site, the components of the mixture will no longer enter into the process of hydration with water, and the mixture will not be able to dry. It will remain inert until temperatures rise above 0°C. To get rid of this phenomenon, you can add special fillers to the concrete composition that accelerate hydration, or build insulated formwork.

If it is hot enough outside (above 30°C), the setting time of the concrete will be shortened, but the quality of the final product will be reduced. This is due to the rapid evaporation of moisture and deterioration of the strength properties of concrete products.

During hot periods, special fillers are added to the mixture, which increase the hardening time of concrete.

- Acid NTF.

- Sugar feed molasses.

- Sodium gluconate.

- Complex compositions.

- Other additives.

How long it takes concrete to dry and how long it takes to set depends on a lot of factors. Hydration refers to the process of converting raw materials into calcium hydrate, i.e. the cement base begins to mineralize and becomes monolithic.

Curing time

After setting, the concrete hardening process begins. It consists in the occurrence of a chemical reaction between cement granules and the liquid from the solution. The best hydration rates are observed at air humidity of 75% and at a temperature of 15...20°C.

We suggest you familiarize yourself with what impregnation to treat the inside of a bathhouse with

If the temperature remains below 10°C, special anti-frost components will need to be added to the composition. Otherwise, the concrete will not receive its design strength.

How long does it take for floor screed to dry: cement mortar and other types

How long does it take for floor screed to dry? This question worries everyone who is faced with this type of work when finishing a room, because a lot depends on the correct determination of the time period. If facing materials are laid too early, on a damp base, numerous problems can arise, and waiting too long can stop all subsequent work for a long time.

Separation of screeds by consistency

Drying time is influenced by many factors. First of all, this is the installation method and the consistency of the composition used. It is customary to distinguish three main types of screeds:

- Dry.

It is a mixture of components that cannot be diluted with water. It is because of this that this option is considered the fastest, because drying time is not required. The dry method involves the use of bulk materials such as expanded clay as a filler. - Wet.

It consists of a cement solution with the addition of sand and other components. It is diluted with plenty of water and acquires a liquid consistency. The minimum period of time for such flooring to dry is 12–14 days. Traditional concrete and cement-sand mortars with a large amount of moisture in the composition are types of wet screed - Semi-dry.

It is an intermediate link between the above types. It contains a minimum amount of water, the volume of which is calculated from the needs of cement. It takes 6–7 days for such a screed to dry. The semi-dry method of arranging a monolith requires the use of special technical means, but the quality at the finish is worth the expense - The fastest drying screed is considered to be gypsum screed; it dries in 6–8 days.

- The question of how long it takes for a cement screed to dry cannot be answered unambiguously. Cement mixtures come in different consistencies, so the time period varies greatly.

- Sand concrete differs from cement-based mortar in having a lower water content, which helps reduce the time for complete drying by several days.

Naturally, the process depends on numerous nuances, so a comprehensive assessment of all indicators should be carried out.

Types of screed material

Indeed, the materials used to create the rough base have a great influence. The following options exist:

On a note! The choice of decorative facing material is of great importance. For example, for a laminate without a backing, the optimal moisture content of the base should not exceed 5%. But if you use a non-hygroscopic pad, then there is no need to wait for final drying; installation begins in 4-5 days.

Installing the finishing coating on a damp screed leads to disastrous results. Parameters affecting drying time

When determining the drying time of the screed, it is necessary to consider:

Naturally, high temperatures contribute to the rapid evaporation of water, but forced acceleration of drying using heaters is a threat to the quality of the flooring. Radical accelerated methods of drying screed in most cases lead to damage to the flooring

Thus, numerous parameters have a direct influence on the drying time.

Cement mixtures

Cement mortar is considered the most traditional for creating a rough coating. But it is wet mixtures that take the most time, because they contain a large amount of water.

It must be taken into account that many people mistakenly evaluate the drying process by the appearance of the applied coating. Indeed, the initial setting occurs from above, but it is inside that the main moisture is retained, so great attention should be paid to the thickness of the flooring.

With a thickness of up to 50 mm, complete drying occurs only after 3–4 weeks. But this does not mean that further work is postponed for such a long time.

An increase in thickness of 0.5 mm adds 3 to 5 days to the time. Filling is often done in several layers, this significantly increases the drying time. So, a coating filled with two layers of 25 mm each will take about 9 weeks. If we compare with semi-dry mixtures, then the indicated time is reduced by 2–2.5 times.

The final strength gain of cement mixtures depends not only on time, but also on air temperature

Important! It is impossible to reduce the amount of water in the cement mixture, otherwise the composition will not acquire its characteristics.

The final result is greatly influenced by the microclimate of a particular room. This parameter is very important for wet cement-based screed. The optimal temperature throughout the drying process should be 22–25 degrees; a lower value will increase the required time. Air humidity should be within 65%.

Due to the fact that these indicators are not always possible to control, the surface is covered with plastic film, which also prevents the appearance of cracks.

Modern quick-drying mixtures

Indeed, such materials contribute to faster hardening of the coating; for cement mortars this takes much longer.

The drying speed is affected by special additives included in such mixtures:

- the accelerator allows you to reduce the amount of liquid that needs to be added to the solution;

- the converter performs the function of drainage, quickly removes water from the inner layer;

- The thinner increases the plasticity of the solution.

Special quick-drying mixtures for leveling floors are an order of magnitude better than traditional concrete, but they are much more expensive.

But even quick-drying mixtures require mandatory testing before laying the decorative coating. There are special devices for this procedure, but there is no point in purchasing them for one-time use, so you can use a simple method. Place an ordinary napkin on the surface, which appears to be dry enough, press it with a small weight and cover it with a layer of polyethylene. This is done at night; if the next morning the napkin is wet, then you need to wait additional time.

Source

xn——-63dzc0djjcep6ac8s.xn--p1ai

Impact factors

To help the cement dry out and avoid various troubles, there are several factors that should be observed:

- protect concrete from direct exposure to sunlight;

- if cement suddenly loses moisture, cracks may form; to avoid this, concrete must be moistened periodically;

- in the event of an unexpected cold snap, the poured concrete needs to be heated, this can be done using special heaters, steam, electricity, etc.;

- special salt-free and salt preparations, sold in construction stores, affect the drying time of cement - they significantly reduce it;

- More expensive brands of concrete harden faster than cheaper ones.

Sometimes it happens that the drying process needs to be slowed down, if, for example, it has already been prepared, but has not been delivered to the construction site. In this case, special surfactants are used.

The amount of surfactant that can be used directly depends on the initial proportions of the concrete components. Now you know how long it takes cement to dry and how you can influence this process. This information will help you accurately calculate the total construction time.

In this aspect, seasonality, the composition of the solution, the presence of auxiliary additives, and the level of strength of the material are important.

If pouring is done outdoors and the air temperature does not exceed 5°C, the concrete will take 2 times longer to gain strength than at 20°C. If the thermometer drops below zero, the mixture will thicken due to the freezing of water, but will not be able to achieve the desired level of integrity. Also, the hardening time depends on the proportions in which water, gravel or crushed stone filler, cement, and sand were used.

Climatic, technological and protective additives can be introduced into the solution. The first include chemical components that help the mass obtain sufficient hardness in too hot or cold conditions. Protective additives enhance the material’s resistance to aggressive environmental influences; sea salt is a prime example.

Technological additives are used in cases where it is planned to subject the mixture to long-term transportation: under such conditions, a significant slowdown in the thickening process of the solution is expected. They are also relevant if it is necessary to speed up construction work and achieve faster drying without loss of quality and load-bearing capacity.

Factors related to the strength of concrete certainly affect the speed of formation of structures made from it:

- cement and water used in certain proportions affect the rate of chemical reaction. If there is too much liquid, pores will appear profusely, which will negatively affect the quality of the product;

- The larger the filler present in the mass, the stronger it becomes when dried.

How long concrete dries depends on the coolness of the filler.

Over time and as it dries, the strength characteristics of the product increase; a stop in this progress is caused by a drop in temperature below zero.

To find out how long concrete takes to dry, it is necessary to take into account a number of conditions that affect the rate of concrete hardening.

Seasonality

The key factors that determine how long concrete hardens are the environment and the period of the year when construction work is carried out. This group includes indicators of outdoor temperature and air humidity.

If in summer the composition can harden in a few days, then in the cold period hardening will take more than a month. The specifics of strength gain under favorable concrete hardening conditions are as follows:

- 1-3 days - no more than 30% brand strength.

- 7-14 — 60-80%.

- 28 — 100%.

If you want to make the foundation mortar quick-hardening, you need to add special additives to its composition.

Tamping

Tamping has an even greater influence on the drying time of concrete. The better this procedure is carried out, the better the reaction of water with astringent components will be. In the industrial production of concrete solutions, vibration equipment is used, but at home you can get by with bayoneting.

A dense screed does not tolerate cutting and drilling after compaction, so for such work it is necessary to use diamond drills. A simple tip will quickly fail.

Compound

How long the concrete hardening process can take depends on its composition. So, if it contains a large amount of porous additives, such as slag and expanded clay, water will linger in the solution for a long time. If the mixture contains sand or gravel, the liquid will come out faster.

We suggest you familiarize yourself with How to attach a cable duct to a concrete wall

To reduce the intensity of moisture evaporation and increase the strength characteristics of the composition, it is diluted with additional components. It can be bentonite or a soap composition. The introduction of such additives increases the overall cost of the work, but prevents the problem of early drying out of the solution.

How to choose quality clay

Fireclay clay called “Kaolin” and ready-made mixtures are sold in construction stores. There are good reviews about both Russian and foreign manufacturers of this heat-resistant material. The best is considered to be fireclay produced at Western European enterprises.

When choosing materials, pay attention to the year of production and its quality. A high-quality mixture and clay do not contain particles exceeding the fraction size indicated on the packaging.

The mixture for preparing the solution should not contain crushed stone or sand larger than 2.5 mm.

The letter “U” on the package indicates that the fireclay is made from recycled, recycled material. The letter “Ш” means that the material has not been recycled, it is better suited for laying the firebox.

Construction materials are stored in specially equipped warehouses. If fireclay is stored in a dry room, in sealed bags, at a temperature from plus 40 to minus 40 degrees, then the shelf life of mixtures and clays is unlimited. Long-term storage (more than three years) in conditions of high humidity will lead to deterioration of the properties of the material due to moisture saturation.

Caring for concrete after pouring

Any concrete mixture requires proper care after pouring. First of all, it is necessary to provide suitable conditions for a normal chemical reaction between water and binder components. If the basic rules are followed, the solution becomes strong and solid. The specifics of care directly depend on the time of year when the installation was performed.

Experts do not recommend carrying out construction work in the heat, so it is better to start it in the morning or evening, after sunset. If pouring is done during the day, it is necessary to provide good protection from ultraviolet radiation by covering the layer with roofing felt, slate sheets or other covering material.

Aftercare is to protect the surface from erosion and holes. When performing independent mixing, it is necessary to adhere to the requirements of SNiP and not allow long pauses between activities. In summer, the mixtures dry quite quickly, so any downtime is contraindicated.

In hot weather, the mixture must be regularly moistened with water and adhere to technological standards that prevent the evaporation of the liquid.

If the outside temperature is more than 15°C, water must be added to the composition every 10-12 hours. In windy weather - after 2-3 hours.

There are no special difficulties in caring for the poured base. The main thing is to maintain optimal humidity and temperature during the setting and hardening stage of the mixture.

The order of work when finishing a house is to do the screed, then putty.

Finishing is the final stage in the construction of a new home, as well as a key element of the work during renovation. In the case of construction, this is the moment when the interior begins to take its final forms. At the same time, the order of work when finishing a house does not depend on the weather. This stage determines the final result; compliance with all the rules is crucial, so correctly following the sequence of work when finishing the house is extremely important. Finishing work begins after all installations have been completed.

After what to install windows?

Installing windows is the final stage of building a house. When the walls and roof are ready, the moment comes when installing plastic windows can be considered one of the final touches before finishing. This is the final stage. When the windows are already installed, we can move on to finishing the house.

After what to do the screed?

We begin finishing the house by implementing screeds in all rooms. Within a few days after the spill, you can begin to walk on the floors, but before you can lay the floor covering on them, it will take about six weeks for the screed to dry properly. This is especially important when laying a wooden floor, such as parquet, which requires appropriate humidity and adherence to the order of work.

After what to do putty and plaster?

After completing the screed, you can start plastering the ceilings and walls. Plastering will also require drying time, after which you can putty, lay tiles, and paint the walls. The drying time for plaster depends on its type and thickness and ranges from two to four weeks.

Drying temperature for screed and plaster

During the period when the floors in the house are drying after screeding and plastering, special attention should be paid to proper temperature and ventilation. Drying plaster in sub-zero temperatures will prolong the time required for drying and in extreme cases can negatively affect the strength and structure of the plaster. Too high a temperature causes it to dry out extremely quickly, causing the plaster to crack due to rapid shrinkage. At what temperature does plaster dry optimally? It is worth trying to maintain the temperature in the range from 10 to 20 ° C.

If we plaster walls in winter in a heated building using radiators, then maintaining the required temperature does not present any problems. At the same time, drying with electric and diesel heaters requires much more attention and more control. At this stage, you should also ensure proper ventilation by leaving the windows on the ventilation setting. Ventilation must be carried out regularly. This will allow moisture that is released during drying of the plaster to be removed to the street.

After what to install the doors?

If you plan to install doors, you should do this only after the plaster has completely dried. Depending on the drying speed, you need to wait a week or two so that moisture from the walls does not cause dampness and swelling of the wooden frames. You should wait until the plaster is completely dry before installing the interior doors. When installing doors, we must ensure that their installation height corresponds to the final floor level in the room with floor covering.

After installing the door, you should check that it is installed correctly and securely. When everything is in order, you can remove the doors so that they do not interfere with the installation of floors and are not stained with paint from painting the walls.

After what to install window sills?

At this time you can also do the installation of window sills. Installation of wooden window sills should be carried out after the plaster has dried to avoid swelling of the window sill due to the absorption of moisture from the plaster.

After what to lay the floor and lay laminate?

After completing the work associated with plastering and screeding the floor, it is time to lay the floors. If we are laying a wooden floor, then we need to check the humidity of the screed using a special apparatus or an electronic hygrometer. Wood is a very demanding material when it comes to moisture. This happens because it absorbs moisture well, which can lead to deformation of boards and parquet and the formation of cracks.

It is good practice to place parquet or planks in the room for two to three weeks before flooring work begins. This will equalize the moisture content of the wood with the humidity of the environment in which the floor will be laid, which will have a positive effect on the final result. This procedure will increase the time required to complete the work, but keep in mind that wood is a very demanding, but at the same time rewarding material.

Similarly, you should wait until the floor and walls are completely dry for other floor work, and then lay the laminate. Correctly and carefully performed parquet work and other floor installation work will allow you to enjoy and admire the look of the beautiful flooring for a long time.

Painting the walls, then painting the ceiling

The next step is to paint the walls for the first time, after which you can paint the ceiling. To do this, you must protect door frames, windows and floors using duct tape and film. For wood floors, the first painting can be done before the floor is laid. Another coat of paint will only be applied after the floor has been sanded, varnished and polished. This procedure is necessary, since laying parquet is quite a dusty job, which is accompanied by a lot of dust. After painting the walls for the first time, you can also install skirting boards and possibly finish the plinths with tiles.

After what can I lay tiles and ceramic tiles?

There will be much fewer worries than with parquet with ceramic tiles. The properties of ceramic floor tiles make it possible to lay them on a screed even after two weeks from the date of its installation. The same period applies to laying tiles on a plaster wall. In the case of wooden panels, it is better to wait a little longer, about two to three weeks from completion of the plastering work. Panels placed on a floor that is too wet can swell and prevent moisture from passing through, which can lead to mold and mildew.

Related article: How to attach a shelf to a drywall wall

Repainting walls

The second coat of paint is applied to the walls after completion of the work associated with laying and finishing the floors and door assemblies. If you want to cover the walls with wallpaper, then at this stage you can also start gluing the wallpaper. Before starting work, you need to thoroughly clean and vacuum the room to avoid the accumulation of dust on the fresh paint, and then glue the wallpaper or paint the finished walls. The third layer is applied after the second has dried. Now all that remains is to install sockets and switches.

Kitchen finishing, when to lay tiles on kitchen walls

In the case of kitchen decoration, there are two small things to remember that will help you work easily:

- First of all, furniture assembly can begin after the walls have been painted for the first time, so that any abrasions and dirt on the walls, which are essential for installing kitchen furniture, can be covered with two coats of paint.

- If we plan to decorate the wall with ceramic tiles, then it is worth gluing it before installing the countertop and all the furniture. A gap of one centimeter should be left between the planned level of the kitchen countertop and the bottom edge of the tile. After fixing the countertop, it will be masked with a kitchen plinth, which also serves as a seal.

Do not rush during finishing work. Walls and floors must be properly dried after plastering and screeding. Otherwise, proper execution of other finishing layers will be impossible.

The drywall will begin to bend, the plaster and paint may stain, moisture and mold will develop under the floor, and each plank of the hardwood floor will begin to take on a life of its own. Similar effects can appear when we start finishing work too early after concreting the walls and ceilings. This is the most common mistake made by inexperienced and impatient homeowners, resulting in mold and moisture appearing in their new home at the very beginning of its use.

How long does it take for cement to dry, and in what order should the work be carried out?

Cement is the most basic and common material for construction, used as a binder for the preparation of concrete. All artificial stone materials are made on the basis of cement mortar containing fillers such as crushed stone, gravel, sand, as well as water and other components.

Pouring something with concrete is a complex process consisting of a number of actions, the order of which must in no case be disturbed. This process includes both the production of a solution from pre-selected ingredients and the implementation of maintenance actions in relation to the finished object, when the hardening of the material has already begun.

According to the generally accepted theory, if the cement mixture is mixed in accordance with the rules and proportions, placed in a formwork form, it begins to slowly harden, while increasing its strength indicators. But immediately after hardening, the object does not have sufficient strength to allow construction to continue. Any significant load can easily crack and destroy it.

During the hardening of the cement mixture, its components form very strong compounds. It begins very quickly, gradually slows down, and then can continue for a long time, sometimes taking years.

But to continue construction work, a one-month holding period is quite sufficient. In some cases, when it is better to play it safe once again, this period is increased to three months.

The timing depends on where the work is performed - outdoors or in heated conditions. Experts cite the most typical cases as averages.

On the street

Examples of operations performed in warm weather:

- foundation for a compact fence. The formwork is left for no longer than a week; after its removal, a fence can be erected;

- when figuring out how long it takes for a concrete foundation to dry, you should take into account the brand of cement - M200 and M300 gain strength within 24-30 days;

- M400 used in industrial sectors is maintained for at least 84-96 days.

During large-scale construction, specialists monitor the condition of the mixture using special measuring instruments.

In room

If you create an optimal temperature background and ensure that there are no fluctuations in humidity, concrete acquires the desired performance properties within 23-30 days.

Indoors, concrete dries and acquires the desired properties within 23-30 days

Using fireclay clay

If the furnace does not heat up to more than 1000°C degrees, then a solution of fireclay clay can be used for its construction. In situations where this indicator inside the firebox significantly exceeds the normal limits, the combustion chamber must be lined with bricks that are resistant to high temperatures.

Laying the furnace

For these works, you should also prepare the furnace mortar using one of the following methods:

- In a specialized hardware store, purchase clay for laying stoves, which contains kaolin, and then make the batch yourself according to the instructions.

- Get fireclay sand and then mix it as described below.

If the second option is chosen, then they go to a place where you can easily get fireclay sand or buy it in a store, and you will also need white or gray clay that is resistant to high temperatures.

All components are taken in the following ratio:

- One part heat-resistant clay.

- One part regular clay.

- Four parts of fireclay.

Subsequently, the preparation of the material occurs in the same way as ordinary clay would be prepared. It is only very important to monitor the fat content of the solution so that the structure does not crack in the future. Knowing clearly how to prepare fireclay mortar for laying a furnace, you can be sure that the erected structure will be strong.

Strengthening stages

Hardening of concrete until it reaches grade strength takes about 28 days, but it is possible to determine exactly how long the material hardens only at the construction site.

- The first is the setting of the mixture, when all its components are combined into one whole.

- The second involves a set of strength properties and hardening.

To clarify how long it takes for concrete to set, you can first focus on the generally accepted value of 1 day from the moment of pouring. The exact time depends on temperature conditions. If it is warm enough outside (above 20°C), the process will take no more than 5 hours.

We suggest you find out how long it takes split birch firewood to dry

The mixture begins to set within 2-3 hours from the moment the components are mixed. In autumn this can last more than a day. At the same time, construction work continues in cold weather.

During the first stage, the mixture remains in a mobile state, so the user can make changes to the shape of the future structure. To reduce viscosity, the thixotropy mechanism is used.

The next step is to harden the mixture. Brand strength characteristics appear after four weeks, but finishing properties are achieved after a couple of years. The curing time of concrete depends on temperature and humidity conditions.

The first 5-6 days from the moment of pouring are characterized by the maximum intensity of hardening, so during this period the material already has 30% strength. After 90-10 days, the indicator will be 20% higher than the brand value.

During the first week, concrete must be exposed to temperature, moisture, heat and waterproofing.

Particular attention should be paid to maintaining optimal humidity. At a temperature of 25...30°C, concrete is loaded within 7 days from the moment of pouring.

The intensity of strength gain also depends on the grade of concrete. The lower the grade of concrete, the higher the strength characteristics will be. Compositions under the M15-M150 brands are characterized by a critical strength of up to 50%.

Structures made from M200-300 grade materials have a value of 40% of the grade. At the same time, the safe indicator allowed by standards is 50%, and construction work can begin only after receiving marks of 72% of the specified values.

To assess the strength properties of a concrete mixture, you can use two methods:

- Destructive. Involves crushing a cube using a press.

- Non-destructive. In this case, the properties of the material are determined without destructive effects.

The second technology is more in demand and is based on the use of elastic rebound devices, ultrasonic equipment or impact devices.

With the help of modern portable devices, you can quickly and accurately determine the degree of strength.

- Electronic. They are highly accurate and capable of storing up to 5 thousand measurements per diagnostic.

- Mechanical. They are used to determine the strength properties of concrete of different classes.

- Ultrasonic. Designed to assess transfer and tempering strength during solidification. The propagation speed of ultrasound exceeds 4500 m/s.

How long does clay mixture take to harden?

When constructing a furnace, it is imperative to use refractory material for both internal and facing work. Among the advantages of chamotte mortar are:

- High level of environmental friendliness.

- Excellent steam permeability.

- Resistant to high temperatures and temperature changes.

- Long service life.

However, the masonry mixture is not famous for its advantages alone. It also has certain disadvantages. First of all, it is necessary to address the issue of price. Even if you prepare the solution yourself, its cost will be very high, when drawing an analogy with other materials in this group.

The mixture contains phenolic resin. This element has a high level of toxicity, and accordingly, environmental pollution occurs during production. And the work itself at the enterprise does not benefit anyone, since a lot of harmful dust is generated during the entire work process.

Factory produced mixture

As for efficiency, it is not as high as we would like. For example, if you need to lay only 25 bricks, then you will need to purchase about 20 kg of clay mass, but to lay one cubic meter of structure you will need as much as 100 kg of material.

The time for complete drying of fireclay paste in air is 72 hours, inside the brickwork this time increases, it depends on the thickness of the masonry, temperature and humidity of the surrounding air. Petrification of fireclay mortar occurs at 800 degrees Celsius.

Important! Fireclay masonry does not like sudden changes in temperature.

The furnace is heated for the first time three days after construction is completed. Use thin, quickly burning logs. The dampers and vents are fully opened during the first fire. Then the stove is dried for a week, burning small portions of wood daily.

Fireclay masonry dries faster than masonry made from ordinary clay-sand mortar and ceramic bricks, but only the firebox is usually made of fireclay. Therefore, the timing of the start of operation of a furnace with fireclay masonry will be the same as the timing of use of a furnace built on clay and lime mortar. In summer, a new stove is heated to maximum after 10-14 days, in winter - after a month.

Does formwork affect the hardening of concrete?

To illustrate how long it takes for concrete to dry in formwork, it is worth giving the minimum time for keeping the solution in the panels at an average daily temperature of 10°C:

- 5 days for monolithic foundations and vertical structures with reinforcement and porous filler;

- 14 days for compact openings and most horizontal slabs;

- 28 days for staircase structures exceeding 6 m in length.

These terms are relevant for concrete based on Portland cement M500; when using a lower quality base, the characteristics of the brand strength will change. If the work takes place in colder conditions, the hardening time is extended by 2-3 days. This amendment also applies to sudden changes in humidity and temperature.

The specified periods determine only the possibility of removing the formwork, but not the transition to the next stage of construction. Next, the concrete must gain at least 20% strength, during the process it will release moisture. During this period, you can inspect the surface and eliminate defects, but you cannot lay roll waterproofing or load the structure.

The procedure for preparing cement and its hardening time

Today, cement is the most popular and most traditional way of producing various grades of concrete. The correct combination with various fillers (sand, gravel, crushed stone), additives and water allows you to obtain products that are varied in their intended purpose. However, the actual process of obtaining a concrete product is quite complex and labor-intensive, including a whole sequence of work performed in several stages. This includes the selection of components for the mixture, the manufacturing and mixing process, as well as direct care of the result already obtained after it begins to harden.

A correctly (theoretically) prepared composition from a technological point of view, without creating special setting conditions, placed in formwork, gradually begins to harden, gradually increasing its own strength. However, as a result, such material, after hardening, does not have the necessary characteristics allowing it to be used as the basis for future construction. During the process of hardening of the mixture, cement grains are gradually transformed into special strong compounds called potassium hydrosilicate. This transformation is similar to the result of an avalanche, increasing its speed over time, sometimes this process can take years.

In order for the setting process to occur in parallel with the increase in strength characteristics, it is necessary to create special conditions. For example, during frost, when the water that actively appears during the hydration process simply freezes, setting may not begin at all, or may end at the initial level, creating an even more shaky material structure. The time it takes for cement to set depends on the purpose of the work being carried out, that is, there may be a division into internal finishing and external external work. The rules and regulations that exist today stipulate strict limits on permissible temperature, humidity level, pressure, etc.

At first, this is approximately 20-25 days; to obtain the required level of strength, concrete requires special care - shelter from direct sunlight (protection from excessive drying) and periodic moistening of the material. Concrete blocks and materials are best stored indoors and handled exclusively using industrial forklifts to avoid damage to the product. Moisturizing effects are achieved using special fabrics and films that protect the material from excessively rapid loss of moisture. It is acceptable to use wet straw or sawdust with periodic moistening during the first time immediately after laying.

www.colorchem.ru

Ways to speed up the drying process

Two methods are practiced to reduce the hardening time of the mixture - the introduction of special additives and autoclave processing. The latter is difficult to implement at home: the filling is placed in a special chamber in which a humid environment is created. Hot steam is supplied under high pressure, and within 24 hours the concrete reaches strength characteristics equal to a year’s curing.

In addition to the example above, an effective way is to use expensive additives that are introduced in the last minutes of stirring. Modifying additives correct the physical and mechanical properties of the mass, which shortens the period of strength development.

Certain variations cannot be used when forming reinforced concrete products, as they can have a strong corrosive effect. All chemical reagents are introduced with strict adherence to proportions, as they can impair the plasticity of the mixture.

Acceleration of the setting of the solution is ensured with the help of specialized formwork, equipped with electrical heating, creating conditions under which evaporation is minimized. A heat gun can be installed in the room; it is easier to control humidity here; the surface of the structure is regularly moistened and covered with film.

Methods for checking the quality of the resulting substance

After the droplets of condensation have disappeared, you need to carry out quality control of the dried oven. For this purpose, firewood is laid that will be used every day. The total mass of burnt firewood will be 20 kg. It is advisable to adjust the draft so that combustion efficiency is maximum.

Over the course of several hours, the masonry in the firebox area is inspected very carefully. Ideally, no cracks should occur. But in some situations, the appearance of small cracks is considered normal. Small formations that look like cobwebs do not need to be sealed. The oven is ready for use.

The preparation was successful.

Dry mixtures are made from fireclay clay for preparing plaster and masonry mortars and creating fireproof bricks.

Furnace laying

When building a stove or fireplace, many stove makers try to use heat-resistant bricks made from a clay-fireclay mixture. When choosing it, you should pay attention to the labeling; the letter “Ш” should be indicated on the packaging. Since such a brick is much more expensive, only the firebox is built from it, and the rest of the stove is laid out from ordinary red brick.

Fireclay bricks must also be laid on refractory clay, which has the same expansion coefficients as bricks. For 100 bricks you will need approximately three buckets of mortar.

The consistency of well-prepared clay paste resembles sour cream. The plasticity of the finished mixture is checked in one or more ways.

- The solution is taken with a trowel or spatula and tilted at an angle of 45 degrees. A normal solution does not flow from the trowel, does not fall from it in lumps, but remains on the working surface of the tool.

- The solution is applied to the brick in an even layer (5 mm) and dried. If the composition is “lean” (contains excess sand), then after drying the paste crumbles off the brick with light mechanical stress. After drying, the greasy solution will become covered with cracks; it contains a lot of clay and little sand. Normal paste hardens in an even layer without cracks. It does not crumble, does not crumble, does not crack.

Photo 1. Method for checking the quality of the mortar: on the first brick the dried mixture crumbles, on the third it cracks, the best consistency is on the second.

- The plasticity of the finished mixture is checked with a flagellum. A “sausage” with a diameter of 1.5-2 cm and a length of up to 20-22 cm is rolled out of the solution. The flagellum is slowly stretched and wrapped around a cylindrical object. A less flexible strand of thin clay will immediately break. A flagellum made from a fatty mixture will stretch strongly and stick to the surface. A bundle of a solution of normal composition will break when stretched when its diameter decreases by approximately 20%.

If the solution is too thick (the consistency is thicker than sour cream), add water to it and stir thoroughly.

If the solution is liquid (drains from the spatula), all the ingredients (clay, sand) are added to it in the previously selected proportions and also mixed.

The mixture, without adhesive additives and cement, retains its qualities after drying. It needs to be filled with water and soaked. If the paste is completely dry, soaking will last several days.

If the solution contains chemical additives, cement and adhesives, then the dried solution cannot be soaked (like, for example, mortar). The manufacturer indicates this information on the packaging.

Different clays differ in their plasticity. There are:

- “fat” clays with high plasticity;

- material of medium ductility;

- “lean” clays with a low level of plasticity.

I determine the level of plasticity using a simple method. The clay is poured with water to turn it into a dough-like mass suitable for molding. The material is used to make cylinders seven centimeters long and 30 mm in diameter, the ends are pinched with fingers and slowly torn apart. Plasticity is judged by the shapes that the cylinder takes at the point of rupture, by its elongation. A plastic material is characterized by the formation of a long and thin neck, and if the clay is thin, the neck will be thick and short.

The level of plasticity is determined in another way. Flagella about twenty centimeters long and 1.5–2 mm in diameter are rolled out of the working material and bent into semicircles or pretzels. If cracks appear on the materials at this time, the clay is thin. Cracks that form during bending indicate that the clay is of medium plasticity, and fatty clay can be identified by the complete absence of cracks in the samples.

Material composition

Any concrete solution consists of a mixture of sand, cement and water. Depending on the type of solution, various fillers are added to the main components:

- Crushed stone, gravel.

- Expanded clay.

- Slag.

- Polystyrene.

- Wood chips or sawdust.

The hardening time of the mass depends on the type of binder from which the concrete is made. How long the mixture dries is determined by laboratory tests, then the period obtained as a result of the test is used in practice during the construction of facilities.

What determines drying time?

When starting a renovation, you need to calculate not only the amount of materials, but also the time to complete the work. This approach will ensure a truly high-quality result and your efforts will not be in vain. The longest stage in floor repair is the maturation of the screed, and there are certain factors that can either shorten or increase this period.

What determines drying time?

The drying of the cement screed is affected by:

- humidity and temperature conditions of the room in which the work is performed;

- thickness and number of layers of cement mortar;

- the presence of fillers in the screed;

- quality of base waterproofing.

Beginning craftsmen often confuse the setting time of the mixture and the drying time. Yes, after a day you can safely walk on the floor without leaving marks, and after a week the surface seems quite durable. But in the pores of the cement layer there remains a lot of water that needs to escape. Since waterproofing is laid under the screed, water can only escape to the surface of the base, therefore, if the coating is laid too early, it will become damp and deformed. And even a week or two after filling there is still a lot of moisture inside.

Flooring laid on a damp screed may become deformed.

The standard drying time for cement screed is indicated within 28 days, but for this, each of the above factors must meet the standard.

Air humidity

Recommended indoor humidity should be between 40 - 60%

The recommended indoor humidity is 60-70%; if this indicator is lower, the water will evaporate too quickly and cracks will form on the surface. At high humidity, the drying time of the solution will significantly increase. If the humidity is less than 60%, you can regulate the process of water evaporation using plastic film, covering the work surface after the solution has set.

Temperature

The optimal temperature for drying any screed is considered to be +20-25 °C. At a higher value, the top layer begins to crack; at a low value, it takes longer to dry. Please note that both the room temperature and humidity must remain stable throughout the drying period, so be sure to exclude any air currents, direct sunlight, or heating the room with heating devices.

If the screed is being carried out in a new building where there is no heating yet, the solution must be poured at least 1.5 months before the onset of cold weather. Freezing of an unripened screed leads to its destruction throughout its entire thickness. You can use special plasticizer additives that give the solution frost resistance, but this will increase repair costs.

Plasticizer for all types of concrete

Thickness and number of layers

Subject to temperature conditions, a 10 mm thick layer of cement mortar dries completely in 7 days. The standard thickness of the cement screed is 40 mm, which means it will take 28 days to dry. But if the layer thickness exceeds 40 mm, for each additional centimeter you need to add not 7, but 10-15 days. That is, a screed with a thickness of 60-80 mm will dry for about 2-3 months.

Floor screed: diagram

If a thick screed is required to level the base, you can reduce the drying time by pouring the solution in several layers. For example, first the screed is poured so as to cover the deep recesses on the base, and after this layer has dried, another one is poured, which will cover the protruding areas and form a zero level.

Fillers for screed

Fiber fiber mixture

When special fillers are added to the cement mortar, the drying time of the screed is noticeably reduced. Expanded clay, expanded polystyrene granules, basalt and fiber fibers are used as fillers. This method is called semi-dry screed, since the amount of water in the solution is almost halved. A semi-dry screed takes 4-7 days to dry, although you must wait at least 3 weeks to lay parquet and parquet boards.

Quality of base waterproofing

There must be a layer of waterproofing under the rough screed, especially if the building is located in a low area, is often flooded, or there is a damp basement below. Without waterproofing protection, concrete and cement-sand screeds easily absorb moisture, and accordingly, the drying time takes a long time. Ordinary polyethylene is not enough in these cases; moreover, cement contains substances that corrode the film in 3-4 years. For reliable and high-quality waterproofing, it is necessary to use roofing felt, special vapor-waterproofing films or coating materials.

Before laying waterproofing, the base must be cleaned and its integrity checked. Roll materials are laid overlapping, and the edges are fixed to the walls at a height of 15-20 cm. The seams between the strips are sealed using bitumen mastic. When using coating materials, they are applied in a continuous dense layer to the base, including the lower sections of the walls. Typically two coats are applied, allowing the first to dry completely before applying the second.

Waterproofing a concrete floor with mastic

Thermophysical properties of waterproofing materials

| Type of material | Density, kg/m3 | Vapor permeability, Mg/(m*h*Pa) | Thermal conductivity, W/(m*S) |

| Bitumen | 1400 | 0,008 | 0,27 |

| Polyurethane mastic | 1400 | 0,00023 | 0,25 |

| Ruberoid | 600 | 0,001 | 0,17 |

| Polyethylene | 1500 | 0,00002 | 0,30 |

Cement hydration (setting and hardening)

Setting and hardening of cement

Everyone knows that when interacting with water, cement becomes hard and transforms into cement stone. But not everyone thinks about the essence of this process: how it hardens, for what reason, what serves as a catalyst and how the duration of hardening can be varied. And today, it is thanks to the study and understanding of all hydration processes that scientists create new and improved additives for concrete or mortar. Their special composition affects the processes that occur during the hardening of the cement mixture.

Today, in the production of concrete, people have an excellent opportunity to use these additives to their advantage. In this way, you can significantly reduce and get rid of unnecessary cement costs, improve the quality characteristics of the product as a whole (water resistance, frost resistance, ductility, strength, etc.), as well as carry out concreting in winter without specialized equipment. Such changes are real, and they are possible thanks to special additives for concrete or mortar. A complete list of our range of additives for concrete and mortars can be found in the section of our website: plastificator.com.ua/products/additives-for-mortars-and-concrete/

The concrete hardening process can be divided into two stages:

- Setting is a fairly short stage that lasts in the first 24 hours of the mixture’s life. It is important to note that setting time largely depends on air temperature. For example, if the ambient temperature is +20C, then the cement begins to set approximately 2 hours after mixing the cement mortar. Setting ends after 3 hours. Thus, the cement setting process lasts only 1 hour. However, if the ambient temperature is close to 0C, then the process can last from 15 to 20 hours. At 0C, setting only begins 6–10 hours after mixing the concrete. The speed of setting can also be influenced by specialized additives: setting accelerator and retarder.

It should be remembered that during the entire setting period the cement mortar remains mobile, that is, it can still be influenced. This is where the concept of thixotropy comes into play. That is, while you are acting on cement that has not completely hardened, the setting procedure is extended. It is on this principle that all mixers work, constantly “stirring” cement mixtures while maintaining their basic qualities.

- Hardening is the next process that occurs immediately after the cement sets. In fact, concrete hardening occurs gradually and can take years. The described period of 28 days is indicated only so that a certain brand of concrete is guaranteed to have a certain brand of concrete for a particular period of time. It is worth keeping in mind that the cement hardening schedule in the first few days is dynamic and non-linear. Why this happens and what causes cement to harden describes the hydration process in detail.

Mineralogical composition, cement hydration

It would be unnecessary to describe here all the stages of obtaining Portland cement, so let’s move straight to the composition of cement. Let us consider specifically the composition of cement and all its main components that participate in the reaction with water during the hardening of the cement mortar. So, let's get started. Any Portland cement is based on four minerals, which are obtained as a result of all stages of cement production:

- C2S dicalcium silicate;

- C3S tricalcium silicate;

- C3A tricalcium aluminate

- C4AF tetracalcium aluminoferite.

Moreover, each of the minerals has its own characteristics and its own specific effect at different stages of cement setting. Some of them immediately react with water, others - some time later. We propose to consider the reaction of each mineral in more detail:

C2S dicalcium silicate 2CaO x Si02

This mineral begins to act only a month after the cement hardens. Until this time, he simply seems to be in rest mode and waits for his turn. However, this “downtime” period can be significantly reduced by using special cement additives. The main advantage of this mineral is that its effect lasts for many years, strengthening the cement mixture.

C3S tricalcium silicate 3CaO x SiO2

This mineral is involved in increasing the strength of cement throughout time. We can say with confidence that this is the main link of our mixture, however, in the first day of the solution’s life, this silicate has a more significant opponent - SZA, which will be described below. Cement hydration is an exothermic process. That is, the chemical reactions that occur during solidification are accompanied by the release of heat. It is thanks to C3S that the solution “heats up” when mixed. Heating stops until the setting period itself, after which there is an intense release of heat throughout the entire setting stage, and only then can we observe a gradual decrease in temperature.

Tricalcium silicate performs its main and most significant work only in the first 28–30 days after pouring the cement mortar. This is the same guarantee period of brand strength that we talked about at the beginning. After this month, its effect on the strength of cement decreases significantly.

C3A tricalcium aluminate 3CaO x Al2O3

This is probably the most active of all the above components. Its vigorous activity begins with the beginning of the setting period. It is thanks to this aluminate that the strength of the mixture increases over the first few days. Subsequently, its influence on hardening and strength gain is insignificant, however, needless to say, it has no equal in speed.

C4AF tetracalcium aluminoferite 4CaO x Al2O3 x Fe2O3

About this component, you might think that it is generally superfluous in the cement mixture. However, do not underestimate him. Even if its influence on strength gain and hardening is minimal, not a single cement can do without this component. A slight effect on the strength of the composition can be seen already at the final stages of hardening.

All of the above components enter into a chemical reaction with water, thereby ensuring the growth, bonding and precipitation of crystals of hydration compounds. In fact, the hydration process can easily be called a crystallization process. It will be just as correct and more clear.

Many years of development by scientists and scientific experiments carried out in numerous testing laboratories and research institutes have given us the opportunity to predict and regulate the process of cement hydration. Today, you can easily influence the process of the beginning and end of setting, control the mobility of the mixture, significantly increase the characteristics of concrete: corrosion resistance, frost resistance, water resistance, and so on. We owe all this to specially developed additives in mortars and concrete.

plastificator.com.ua

Drying gypsum-based mixtures

Gypsum mixtures dry much faster. The complete drying time for a 10 mm thick layer is only 42 hours, after which laminate or other floor covering is laid. You can install the tiles even earlier, just 3-4 hours after the screed is formed, when the gypsum-based solution has already set, but has not yet dried.

For gypsum screeds with a thickness of more than 40 mm, the same rule applies as for cement screeds: to determine their drying time, 90 hours must be added to 42 hours for every additional 10 mm of mortar. For example, a layer 50 mm thick will take at least 132 hours to dry, which is equivalent to five and a half days. After this period, laminate or other material can be installed on the floor surface.

How to dry it properly

To obtain a high-quality surface, it is important not only to prepare the solution correctly and pour it taking into account all the requirements, but also to ensure drying conditions.

In the room with fresh screed, a constant temperature of 20–25 o C and air humidity in the range of 60–70% must be maintained for the entire period of its hardening. The windows of the room are covered with paper or curtains to prevent direct sunlight from reaching the floor. There should be no drafts in the room. If all these conditions are met, the floor surface will dry evenly and the complete hardening time will be equal to what the manufacturer indicates.

If the air temperature in the room is lower than optimal, then the time for complete drying increases, and the same will happen with increasing air humidity. It is important to provide conditions for natural chemical processes to occur between the components of the screed and not to artificially accelerate this process. Experts do not recommend increasing the drying time by increasing the temperature in the room, as this can subsequently lead to cracking and peeling of pieces of the screed.

If the screed is poured in the cold season, make sure that the room temperature is not below +5C. Freezing of an uncured floor surface is unacceptable.

Cracking of the screed is a consequence of improper installation and drying technology

In the first 10 days after installation, it is recommended to cover the floor with film and periodically spray it with water. This ensures the floor dries evenly. You can use forced surface drying no earlier than after 3 weeks, but even then you should not raise the temperature in the room above +26 o C.