Important characteristics of a building material are the weight and density of reinforced concrete. These parameters determine the performance qualities of the finished element or structure. A wide classification of reinforced concrete products according to these characteristics is proposed. The amount of weight and density is influenced by many factors, in particular the quantity and quality used in the initial mixture for manufacturing.

Types of reinforced concrete

The weight of 1 m3 of reinforced concrete may vary depending on which of the following types of mortar was used:

- Particularly heavy - limonite, magnesium and barite weighs more than 2.5 thousand kg per 1 m3;

Pouring heavy composition

- Heavy - crushed stone or gravel. The weight of 1m3 of reinforced concrete of this type is 1.8-2.5 thousand kg;

- Lightweight , with fillers such as expanded clay, perlite, wood concrete, etc. This class of mortars also includes foam concrete and aerated concrete. The weight of 1 cube of such a mixture is 500-1800 kg;

- Particularly light - 500 kg per cubic meter of building mass.

The photo shows light blocks

Note! These weight indicators indicate only the weight of the solution itself without including the weight of the reinforcement cage in the value.

This variation in mass indicators is due to the fact that different mixtures contain fillers of different densities, the weight of which has a fundamental influence on this value.

As an example, consider some density coefficients of reinforced concrete when using different types of aggregates:

- Expanded clay, depending on the type of sand, can have different masses per cube:

- 0.8-1 thousand kg when using perlite sand;

- 0.8 – 1.2 thousand kg when using quartz sand;

- 0.5-1.8 thousand kg when using expanded clay dust as a filler;

- Tuff will weigh 1.2 to 1.6 thousand kg per cubic meter;

- One cubic meter of foam silicate weighs from 0.3 to 1 thousand kg;

- The mass of a cube of shungizite ranges from 0.1 to 1.4 thousand kg;

- Pumice weighs from 0.8 to 1.6 kg per cubic meter.

Physical characteristics of concrete: mass, density, weight, volumetric and specific gravity

Modern regulatory documentation for concrete and other mortars and mixtures uses physical characteristics such as mass and density.

Mass is a scalar positive physical quantity that characterizes the inertial properties of a body. According to the international SI system, it is measured in kg.

Density is defined as the ratio of a body's mass to the volume it occupies. Measured in kg/m3.

Previously, the standards used other physical quantities - weight, volumetric gravity, specific gravity.

Weight is the force with which a body acts on a support in the field of gravity. The SI system uses the Newton (N) value to measure this characteristic. Although weight and mass are scientifically different concepts, their strict distinction is accepted only in science and technology, and in everyday life they are often used interchangeably.

Effect of reinforcement on mass

Rods of different diameters

The weight of m3 of reinforced concrete is a value equal to the sum of the mass fractions of concrete mortar and metal reinforcement frame. The weight of the steel will also have a major influence on the specific gravity of the reinforced concrete.

In order for a monolithic structure to have excellent strength indicators, various types of reinforcing rods are used.

Note! Reinforcement class AII I is the most commonly used in practice. The density of such steel is 7,850 kg per 1 cubic meter, which is several times higher than the specific gravity of any type of concrete solution.

Depending on the calculations used in the design and the required level of strength of the structure being constructed, different numbers of reinforcement rods with different cross-sectional diameters are used.

The steel content in a concrete raster is an indicator that should vary from 70 to 320 kg.

Note! When calculating the strength of a structure, one should take into account the volume of mortar that will displace the steel used to construct the frame. Thus, it will be necessary to subtract this displaced volume from the total volume and add steel. The resulting indicator will be the calculated volumetric density of the building material.

Weight of concrete in 1 m3 during dismantling

But in order for the improved characteristics of reinforced concrete to be evenly distributed, hardening is carried out according to certain schemes. As a rule, the rods are placed in the body in the form of a three-dimensional grid with a cell size of mm. The rods can be tied to each other with thinner steel wire, and then its presence can be neglected when calculating the density of reinforced concrete.

But in large structures, instead of wire rod, sections of the same reinforcement are used. In this case, additional elements will have to be taken into account. To determine it, you can take as a basis the proportions of the solution in units of mass.

Differences between calculated and actual densities

Prefabricated structures

In practice, the value of the structure density turns out to be slightly lower than calculated in the design documentation. The reason for such circumstances is the presence of a small number of voids in the monolith.

Pouring concrete structures on a construction site or pouring prefabricated structures in production conditions are processes directly related to the formation of voids of various sizes in the thickness of the mortar.

The appearance of air in a monolith is an inevitable process, but its amount can be reduced by using the method of compacting the solution after pouring the building mass into the mold or formwork. But even after compaction, a certain amount of air will still remain in the thickness of the solution.

Note! The volume of air in the solution should not exceed 1% of the total mass. This volume does not significantly affect the strength of the structure.

The instructions for making reinforced concrete products with your own hands stipulate the need to reduce the number of cavities in the concrete mass. Thus, the strength and durability of the finished product can be significantly increased.

What does the density and weight of reinforced concrete depend on and how are they calculated?

Important characteristics of a building material are the weight and density of reinforced concrete. These parameters determine the performance qualities of the finished element or structure. A wide classification of reinforced concrete products according to these characteristics is proposed. The amount of weight and density is influenced by many factors, in particular the quantity and quality used in the initial mixture for manufacturing.

Calculation of the mass of a reinforced concrete structure

To calculate the specific gravity of a structure made of reinforced concrete, the weight coefficients of the metal and concrete solution are simply summed up. The result of this summation is divided by the volume of the resulting structure. The use of such a simplified calculation eliminates complex mathematical calculations in which inexperienced builders can make serious mistakes.

Components of concrete

Example

Let's consider calculating weight using heavy concrete as an example. This solution uses fillers, which are crushed stone and gravel. They have a fairly large mass, so such concrete weighs from 1.8 to 2.5 tons per cubic meter.

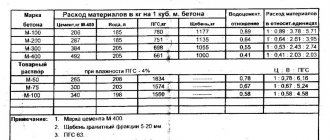

The composition of this raster in mass fractions will be as follows:

- Water - no more than 0.2 tons;

- Sand – no more than 0.75 tons;

- Crushed stone - no more than 1.3 tons;

- Cement – no more than 0.45 tones.

If we sum up the mass of all these fillers, the weight will be 2 tons 700 kg. This value is correct, because during the drying process the water will evaporate, and the mass will be equal to 2.5 tons.

The heaviest types of solutions weigh more than 2.5 tons due to the fact that they contain magnetites, scrap, barites and hematites. Such solutions are used to create armored caps in areas of radioactive contamination.

How do they calculate?

The density of concrete products can be obtained by taking known mass volumes of the solution as a guide. In this case, data on water is excluded, so it is corrected from the finished product. As an option, average values of material density by concrete grade are used. The characteristics of steel reinforcement and reinforcement scheme are also taken into account. For example, the specific gravity of reinforced concrete in a strip foundation, made with M300 concrete and reinforced with 16 mm rods with a density of 7850 kg/m3, is calculated as follows:

- Determination of the volume occupied by reinforcement in a cubic meter of material using the formula: π·r2·L = 3.14·(0.008)2·16 = 0.003 m3. As a result, concrete accounts for 0.997 m3.

- Calculation of the mass of reinforcement: 0.003 × 7850 = 23.6 kg.

- Determination of the mass of concrete: 0.997 × 2400 = 2392.8 kg.

- Obtaining the density of concrete products: 23.6 + 2392.8 = 2416 kg/m3.

To calculate how much a reinforced concrete structure weighs, you need to add up the mass fractions of the mortar and metal components. From the resulting value, subtract the volume of concrete displaced by the reinforcement. It is important to take into account that the heaviest types of concrete will weigh more than the calculated weight, since there are impurities that affect the final indicator. If determination of indicators is needed when dismantling and demolishing a structure made of reinforced concrete products, then you need to measure the height, width and length of the structure being destroyed. In this case, reinforced concrete blocks will have a volumetric weight taken to be 2500 kg/m3. This indicator is multiplied with measurement data to obtain waste tonnage.

Concrete grade

The characteristic that determines the strength of a concrete product is called grade. It shows how much load concrete can withstand after complete hardening without collapsing. It is designated by the letter M and a number that indicates the permissible load per square centimeter. For example, M200 concrete can withstand 200 kg/cm2.

Heavy concrete is a cement mixture in which the main filler is crushed stone or gravel.

In the case of preparing lightweight concrete, where expanded clay or other similar filler is used, the design grade will not correspond. Therefore, you can use a simple calculation when preparing a concrete mixture for constructing a foundation, pouring monolithic floors, floors and paths in your garden.

Complete misunderstanding

How much cement is needed per 1 cubic meter of concrete for a foundation? How many liters are in one cubic meter? 1m3=1000 liters or 1 liter = 0.001m3. How much cement, sand, crushed stone is in a cube of concrete? — A concrete mixture traditionally consists of three components mixed with water - cement, sand and filler.

And their weight differences vary significantly. Conventional concrete mixed from the components - cement, sand, water and filler (gravel or crushed stone) will vary in weight from 1800 kg to 2500 kg, and it will depend on the volumetric weight of the filler. Filler (gravel or crushed stone) - 1200-1300 kilograms.

More sand and cement will be consumed if the filler is larger and less if it is smaller. Different brands of concrete weigh differently. There cannot be a definite answer here, since there are several types of concrete, the difference is in the brand of cement, filler, and additives.

1 m³ = 1000 dm³ = 1,000,000 cm³ = 1,000,000,000 mm³ = 1,000 liters ≈ 35.3 cubic feet ≈ 1.31 cubic yards ≈ 6.29 barrels. To heat a cubic meter of water from +1 to +100 degrees Celsius at standard atmospheric pressure requires about 100,000,000 calories (100,000 kCal = 100 MCal) or 116.299 kilowatt-hours.

In fact, during the year of its activities, the LLP removed 15,166 m3 (cubic meters) of solid waste (garbage). In any case, during the trial of the case (if you intend to appeal this act), you could demand a calculation formula and a legal basis for these calculations.

It is important for me to know whether there are GOSTs in force in the Republic of Kazakhstan on these issues. The weight of a cubic meter of solid waste depends on its density. There is such a draft state standard “METHODOLOGY FOR DETERMINING THE MORPHOLOGICAL COMPOSITION OF MUNICIPAL SOLID WASTE”. Is it possible to clearly answer this question and why are different units of measurement of the same building material used?

Only an experienced builder can clearly calculate the ratio of the initial components, therefore, if you are not sure of the proportions, it is advisable to contact a specialist for help. If we are talking about crushed stone packaged in bags (regular or colored), the unit of measurement will be kilograms.

And vice versa: the weight of a cubic meter of small crushed stone or granite screenings will be at least a hundred kilograms more. So, for example, a cubic meter of limestone crushed stone weighs about 1300 kg, gravel - 1600 kg. However, this knowledge is not enough to begin certain construction.

In addition, liters in our country have not become a generally accepted “production” and trade unit for measuring volume. One cubic meter, or in its abbreviated version - one cube, turned out to be a fairly convenient and popular unit of volume for practical use.

How much does a cubic meter of crushed stone weigh?

After all, their costs, prices, rates, consumption rates, tariffs, supply contracts are almost always tied to cubic meters (cubes), and much less often to liters. Site visitors, when asking how much 1 cube weighs, often indicate specific units of mass in which they would like to know the answer to the question. Density and specific gravity in physics are usually measured not in kg/m3 or tons/m3, but in grams per cubic centimeter: g/cm3. Debris density and specific gravity are given in Table 1 as additional information.

Amount of cement in 1 cube of concrete

Let's start with the fact that all units of measurement currently used in physics, and in everyday life, are the result of centuries-old experimental decisions. As a result, in order not to get confused in all the pounds, miles, inches, it was decided to come to common measurement values.

Through simple reflection we come to the conclusion that 1 liter of water weighs 1 kilogram. It should be noted that in the vast majority of countries these metrics are accepted as the main ones, sooner or later, but accepted.

Cubic Meter - means a unit of volume of dry Gas equal to one (1) cubic meter at a temperature of plus twenty degrees Celsius (20 C) and a pressure of one absolute atmosphere. How many cubic meters of acetylene and water are required to obtain 45 tons of 98% acetaldehyde using the Kucherov reaction.

Approximately 1.2 kilograms of air. This year, my wife and I decided to move to Vologda permanently. Good afternoon. I have a dacha in the village and I already want to do new plaster there, but before I do it, I would like to read a little about it.

How to fit everything you need in the bathroom? How many bags will be needed?) This is a question for the builder. The cement content in one cubic meter and the practicality of concrete consumption depend on the correct choice of the binder component of the mortar.

Triple switch with socket, Buy triple switch, Triple pass-through switch (6) How much cement is there in a cube of concrete? 14) Walls in the kitchen. What's better? (15) Wire cross-section and load (16) Do-it-yourself installation of plastic windows, Brick mass (weight), How to fit everything you need in the bathroom?

When calculating cement per cube of concrete, the weight of the dry composition is taken as the basis. The question of how many kilograms are in a cube of concrete is more relevant when preparing cost estimates and determining the type of transportation. How much cement is in a cube of concrete is a very individual calculation and requires the most serious approach. In one cubic meter of this type the mass is no more than 500 kg. There is a not entirely correct opinion that the greater the specific or volumetric weight of concrete, the higher its strength.

Effect of water quantity

An excessive amount of water in a concrete mixture does not improve the plasticity of concrete, as some people mistakenly believe, but rather worsens its quality. Excess water disrupts the homogeneity of the material, reduces strength and increases final shrinkage. To increase plasticity, it is recommended to add plasticizers, which are aimed at changing the quality of building materials. In private construction, various detergents are used as effective plasticizers.

Will a calculator help you save money?

The final cost depends on the brand of concrete. The higher the grade, the more cement is required to prepare the concrete mixture. Thus, a cube of concrete grade M100 costs approximately 2,000 rubles, and M300 - 3,500. Therefore, determining the exact number of components for preparing concrete is of great financial importance and affects the overall cost of construction.

The correct selection of the proportions of the components of the concrete mixture affects the physical, mechanical and technological characteristics of concrete products and structures.

Unjustifiably inflated expenses lead to unexpected financial costs. Therefore, we invite you to use a simple and convenient online calculator on our website. It will help you quickly, easily and accurately calculate the required costs for preparing a concrete mixture.

Extra heavy concrete: production and applications

Particularly heavy concrete, having a cubic meter weight of more than 2500 kg/m 3, is a specific material that is not used in ordinary civil engineering. They are in demand for the construction of facilities associated with exposure to radioactive radiation.

To increase the density of the material, magnetites, red and brown iron ore, and barites are used as fillers. In the production of especially heavy concrete mixtures, the following are in demand: cast iron shot, scrap, and crumbs.

Table of the relationship between concrete strength classes and the weight of one cube

Types of concrete by density

Strength classes

How much does a cube of concrete weigh, kg

Heavy and fine-grained concrete mixtures: types and characteristics

Technical conditions for heavy and fine-grained concrete, the weight of 1 m 3 of which is 2000-2500 kg, are determined by GOST 26633-2015. Heavy concrete mixtures are the most common materials used in construction.

They are used to create load-bearing structures - foundations, walls, ceilings.

Heavy mixtures include:

- binder - usually Portland cement grades M400 or M500;

- coarse aggregate - dense, the most common options are granite, gravel, limestone crushed stone;

- fine aggregate - quarry or river sand, purified from harmful impurities;

- pure water;

- additives that improve certain characteristics of a plastic concrete mixture or product after hardening.

The composition of fine-grained concrete includes: binder, dense fine aggregate, water and additives (if necessary). Fine-grained mixtures are used for the manufacture of thin-walled structures, paving slabs, and landscape design items.

Mass of garbage

4.10. FERr(TERr) does not take into account the costs of loading and removing construction waste and materials unsuitable for further use obtained during dismantling of structural elements of buildings and structures and engineering and technological equipment. These costs should be determined based on the current tariffs for the transportation of goods for construction, the mass of waste in tons and the distance of its transportation from the construction site to the landfill site, with costs reflected in local estimates. The volumetric mass of construction waste should be taken as averaged according to the following standards: - when dismantling concrete structures - 2400 kg/m3; — when dismantling reinforced concrete structures — 2500 kg/m3; - when dismantling structures made of brick, stone, beating plaster and facing tiles - 1800 kg/m3; — when dismantling wooden and frame-fill structures — 600 kg/m3;

When performing other disassembly work (except for work on dismantling metal structures and engineering and technological equipment) - 1200 kg/m3.

Note: - volumetric masses of construction waste from dismantling building structures are given based on their accounting in the dense body of structures;

The mass of dismantled metal structures and engineering and technological equipment is taken according to design data.

smetdlysmet.ru

Calculation of concrete composition

It often happens that when laying a foundation for a commercial building, building a fence or path, concrete work is required. It is not rational to turn to professionals to solve such a relatively small task, and special knowledge is needed to calculate the exact amount of material required.

A simple and convenient online calculator will help you independently calculate the correct composition of concrete to obtain the required grade.

At the same time, the quality of the concrete will be as close as possible to the exact fulfillment of the requirements of State Standards 27006-86 and 7473-94, which define the requirements for the composition and preparation of concrete mixtures based on Portland cement.

Components for mixing concrete.

You just need to indicate the volume and brand of concrete you need (provided that you use PC400 cement). The calculator will instantly perform the calculation, and you will know the exact weight and volume ratios of the components included in the solution.

Concrete Density Information

The density of reinforced concrete and concrete must be known to builders. If the first meaning was described in detail above, then the second is worth talking about. The main performance indicator for concrete is its response to homogeneity and compression, as well as strength. The listed characteristics are regulated by density, which is a physical indicator determined by dividing mass by volume.

In construction, it is customary to use the average value of this parameter, because it is influenced by various factors, including:

- quality and size of filler;

- type of filler;

- water composition;

- sand granularity.

Calculation of costs for services

To determine the level of financial costs, in addition to the volume of waste, it is necessary to find out what special equipment will be needed to remove construction debris. If the waste is light but takes up a large area, you will need a container. This category of materials includes wood, timber, logs. For rubbish consisting of soil, concrete and brick fragments, a closed bunker is required, designed for transporting heavy loads.

To calculate the size of a container or bunker, the use of which would be advisable, the following algorithm is used: the volume of garbage is divided by the size of the container (8, 20, 27, 30, 32). If the total figure exceeds 4, you should choose a larger container for significant savings.

Scope of application of concrete of different grades

M100 and M150

The material of the M100 and M150 grades is not very durable. It is used as a basis for laying paving slabs on pedestrian paths, when casting curb stones, for the installation of blind areas, drainage drains, drainage systems and in other cases when a stone monolith is required that is not intended to work under load.

M200 and M250

Concrete grade M200 is most often used for pouring concrete floors, reinforced screeds, small entrance stairs and landings. It can be used as a material for constructing foundations for buildings and structures made of light wall materials. However, the construction of such a foundation is only possible on solid, non-heaving soils with deep groundwater. It is also widely used as a reinforced concrete base when laying paving slabs in private construction.

M300 and M350

This is the best concrete for foundation construction in the construction of private houses, construction of supporting walls, stairs, platforms and fences. In industrial production, most reinforced concrete products are made from concrete grades M300 and M350, such as beams, lintels, floor slabs, foundation blocks, well rings and others.

What is the best way to determine the volume of one batch?

After calculating the total volume of the required concrete mixture, it is necessary to determine the number of batches and the volume of each of them. In this case, the concrete mixer will operate in optimal mode, there will be no excess concrete left, and the number of batches will be as minimal as possible.

Using a calculator, it is not difficult to determine the total amount of materials needed to complete the work, and then divide this value by approximately 2/3 of the volume of the mixer. But keep in mind that the prepared mixture begins to set within a couple of hours, and the entire solution prepared by this time will need to be laid.

If the preparation of the concrete mixture is done manually, then a correction factor for the grade of concrete must be entered into the calculations. This must be done due to the low quality of mixing and possible partial residue of components at the edges. When mixing manually, the grade of concrete will be lower by 5-15%.