The word “anchor” in translation means anchor, and this word perfectly reflects the functions of anchor bolts, which for brevity are simply called anchor. Like an anchor holding a ship, anchor bolts secure massive objects to the floor, walls, and ceiling. It is important that the material to which the fastening is made is hard and dense - this is mainly real concrete. Foam concrete and its other porous varieties, as well as hollow blocks, are not suitable for anchoring. Chemical anchors are used for fastening into porous materials. As a rule, anchors are indispensable when renovating and building houses. The use of anchors is envisaged in the design of residential buildings, as well as in ready-made residential building projects.

The word “anchor” in translation means anchor, and this word perfectly reflects the functions of anchor bolts, which for brevity are simply called anchor. Like an anchor holding a ship, anchor bolts secure massive objects to the floor, walls, and ceiling. It is important that the material to which the fastening is made is hard and dense - this is mainly real concrete. Foam concrete and its other porous varieties, as well as hollow blocks, are not suitable for anchoring. Chemical anchors are used for fastening into porous materials. As a rule, anchors are indispensable when renovating and building houses. The use of anchors is envisaged in the design of residential buildings, as well as in ready-made residential building projects.

Technical features of wall installation

Anchor fasteners are installed in durable surfaces. For example, concrete, brick or stone, which is highly hard. To ensure a strong fastening, you need to focus on bolts with fixing nuts. However, in some cases this is unacceptable due to the protrusion of the pin. Protrusions even of a few millimeters can create inconvenience when installing in a wall.

The range of anchors from popular manufacturers on the market offers a list of fasteners with stud sizes from 18 to 400 millimeters. The required indicator is calculated based on the assigned tasks.

Consequently, the size of the sleeve also differs - from 6.5 to 20 millimeters. On long parts, the bushings can withstand maximum loads. The maximum permissible loads of each part are specified in the technical documentation. When selecting the appropriate mounting hardware, it is important to consider the thickness of the platform on which you intend to install the item. The length of the anchor does not determine its reliability. There are also risks of through holes, which affects the surface properties.

Ground anchor installation

The technical term "anchor" translated from German means anchor. The first mention of ground anchors appeared 30 years ago, when the famous American company Foresight Products LLC received an order to secure floating oil production platforms. To solve this problem, engineers developed a system of special anchors that reliably hold the massive hull of the platform on the ocean floor. The result was so successful that the idea of an anchor was transferred from the ocean to land, as a result of which the ground anchor appeared.

A ground anchor is a fastener fixed in a solid load-bearing foundation (soil), which ensures the transfer of tensile forces from the fastened structural elements directly to a solid soil foundation.

Components of a ground anchor:

- Header. In the anchor design, this part performs the function of transferring the load forces of the structure being secured or another element directly to the anchor rod - the anchor rod.

- Anchor rod. The main technical purpose of the element is the intermediate transfer of pulling forces from the head to the root part of the anchor.

- The root part is the embedment left in the ground.

More detailed information about other earth anchor devices is contained in the technical document of departmental standards VSN 506-88 “Design and installation of earth anchors”.

Fastening with anchor bolts

The future fate of the fastener depends on the correct installation. The key point is that it is important to correctly calculate the load that the anchor bolt can withstand. There are a number of rules that are important to consider when working with fastening systems:

- To drill a hole you will need a drill for the concrete or stone you will be working with. Focus on the length and diameter of the anchor bolt.

- The hole cannot be drilled if the bushing diameter does not match. To enlarge it, you can use a drill of the same diameter.

- If you start to drill out the mounting hole, this will cause the bushing to become unfixed. As a result, it simply will not be able to perform its functions. The work will not bring results.

- After drilling, you need to remove excess debris from the formed hole. Crumbs clog it, which can lead to an obstacle in installation. As an option, you can use a construction vacuum cleaner.

- After the bolt penetrates the hole in the wall, you should not immediately approach installation. There is an easy way to test the strength of this system. Tighten the bolt fully using a wrench. When the bushing becomes convex, this indicates its working position. After testing, you can proceed to the final installation stage.

- Install the item and tighten it with nuts. This is a proven mount that guarantees the reliability of the work performed on the wall.

Anchor bolt mounting options

There are three main methods for installing fasteners:

- mechanical impact on a part in order to modify it;

- the use of special fillers with fixing properties;

- vibrocaulking.

There are several types of fastening:

- Wedge: an open sleeve is located on the cone. The nut is installed together with the washer, which provides better fixation. The rod comes into contact with the metal bushing, and during the screwing process the bushing becomes wedged.

- Sleeve: the length of the sleeve is equal to the rod. During installation, the diameter of the bushing expands. This results in a fixed fit to the walls of the two parts of the hole. This option is suitable for working with porous and heterogeneous surfaces.

- Driven: fastened using percussion tools.

- Expanding: an expansion spring is used for a tight fit. The bushing changes shape, due to which the system can withstand heavy loads and perform the assigned tasks.

- Special: manufactured to solve special problems.

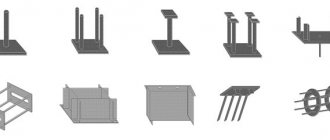

Types of anchor bolts

- With a nut. The budget version of the fastening system guarantees the reliability of the connection. The structure of such a bolt consists of a screw, a steel tube and a nut. During installation, the bolt moves along the length of the rod. As a result, its tip becomes thicker. Bolts with a nut are suitable when working with concrete structures, brick, and natural stone. Anchor bolts of this type are found in a diameter range from 6 to 28 millimeters. The length of such a product can reach 3 centimeters.

- Wedges. This is an improved version of the anchor bolt with nut. The main difference is the bushing at the end. The other part contains a nut and washer. To avoid damage due to corrosion, the bolts are galvanized. The products themselves are made from carbon and stainless steel. They differ from each other in diameter (from 6 to 12 mm), permissible thickness of the product that you plan to mount (up to 2 cm), surface thickness during installation (up to 53 mm), and strength. A standard set of tools will be sufficient for installation. The fastening method is no different from conventional anchors. Wedge bolts can withstand heavy loads. Due to the high internal tension, the tearing force increases, which makes it possible to mount heavy objects into walls.

- Hexagonal. Designed to work with surfaces of increased hardness. They are in demand in the construction and repair sectors. The hex head, which distinguishes them from other types, rotates along the threads of the spacer bolt. Due to this, an expanded bushing is obtained. The products are made of galvanized steel, which protects against corrosion.

- Drums. Suitable for mounting massive objects when aesthetics do not play a special role. Used when working with building structures, plumbing fixtures and other heavy parts. The base on which you plan to install the anchor must be sufficiently dense. The bolts differ from each other in length (up to 5 cm), diameter (up to 2 cm), and the magnitude of the pulling force. The key rule is that the surface thickness must be at least 10 cm. The wall installation process includes several stages. First you need to make a hole in the surface. It should be longer than the bolt itself. Then we clear the hole from dust. We hammer in the bushing, which, when exposed to impact tools, adjusts to the desired diameter. Screw in the bolt. Keep the anchor bolt perpendicular to the surface at all times.

- Four-segment. Designed for large items. Due to the special design, it is possible to guarantee increased reliability of the fastening system. Used in durable homogeneous rocks and porous walls. The structure of the bushing has four segments. One pair is fastened with a ring, the second with a spring. There is a spacer element. The bolt moves along the length of the anchor when screwed in. Reliable fixation is ensured along the entire length of the fastening element.

- Screw. Reinforcing bars are used for production. They are fixed in the hole using special fillers. The kit includes a rod, washer and nut.

Sizes and prices

The marking of an anchor certified in Russia according to GOST has 3 digits:

- External diameter.

- Inner diameter.

- Total length.

Standard sizes vary within:

- 0.8 – 2.0 cm in diameter;;

- 4.5-12 cm in length;

Bolts are sold packaged in 10, 15, 25, 50 and 100 pcs. packaged.

Prices depend on the size, manufacturer, material of manufacture, purpose of the bolts and other factors.

A minimum size bolt of 8×45 mm will cost on average 2-3 rubles. per piece, then the price naturally increases and reaches 60-65 rubles. per unit of goods. As a rule, manufacturers indicate the price per 1000 pieces and per package of a certain packaging.

Installing anchor bolts in a wall: key points

For reliable fastening, it is important to adhere to the rules of installation in the wall. There are several basic recommendations that will ensure a strong connection:

- It is necessary to select the correct drill bit to create the hole. All anchor bolts are standardized, so the drill is selected in accordance with the markings.

- Be sure to clean the hole from the resulting concrete or brick edge.

- During installation, the bolt must fit freely into the hole. If this is difficult, the diameter of the hole is incorrectly calculated.

- The nut must be tightened gradually and without sudden movements. This way it will be possible to ensure a tight fit of the anchor bolt to the wall of the sleeve.

- When choosing a bolt, a number of parameters are taken into account: dimensions, maximum permissible loads, bending value, material.

How to install an anchor bolt in concrete?

When working with anchor bolts, as with other fastening systems, it is important to take correct measurements. There are a number of features with concrete surfaces:

- When installing, it is important to consider not only the quality of the bolt itself, but also the quality of the concrete. Also taken into account are such criteria as the features of the design itself and the type of anchor.

- If you need to install the structure on a base with finishing, the hole must be longer. This is important due to the lower strength of finishing materials than concrete itself.

- The diameter of the drill should be approximately half a centimeter smaller than the intended hole.

- The instructions for the bolts indicate the permissible number of turns until they are fully secured.

Scope of application and principle of operation

They are used everywhere for structures with heavy weight, moving fragments and breaking forces.

They are used for fastening floor slabs, partitions, and stairs. They allow you to reduce the installation time and increase the reliability of various equipment, such as air conditioners, water heating boilers, etc. Shelves, hangers, wall cabinets, suspended ceilings, etc. are also mounted on anchors.

Anchors are suitable for various types of concrete, brick, and natural stone.

The chemical anchor provides a reliable connection due to the high adhesion (adhesion) of the materials of the bolt itself and the surface using synthetic resins. We can use it not only in dense monolithic structures, but also in those with a significant number of pores and voids inside.

Mechanical anchors in one way or another create widening inside the hole, due to which they stay tightly inside them.

Combined and very effective options are often used, combining both chemical and mechanical fastening methods.

How to install an anchor bolt with a nut?

The anchor bolt with nut is fixed by opening the spacer sleeve. The nut is designed to allow the bolt to fit into the sleeve, and it will open the tabs for a strong fit.

Step-by-step instructions for installing an anchor bolt into a wall:

- make a loophole;

- remove generated debris;

- hammer in a bolt with a nut;

- tighten the nut firmly.

When the installation of the anchor bolt is completed, the nut must be tightened correctly. After this, you can proceed to installation of the structure. This type of fastener is most suitable for installing objects on solid foundations. The anchor bolt is made from high-quality steel with zinc coating. Due to this, the fasteners can withstand heavy loads. For porous surfaces, there is a double-spacer fastener. Its design is distinguished by the presence of two bushings that open when screwed in.

Installation of anchor bolts: what are their advantages

Such fasteners are considered reliable when installing massive structures. High-quality fastening, which can be guaranteed with anchors, cannot be achieved with other types of fasteners.

Advantages of using it for concrete:

- increased resistance to various loads - dynamic or static;

- resistance to deformation under the influence of external factors;

- do not corrode;

- simple and quick installation in concrete or other type of surface;

- variety in length, type of fastener, diameter, load-bearing capacity, material and other indicators;

Anchor bolts have no obvious disadvantages. The only thing is that it is important to follow the rules of selection and installation. Only with an accurate calculation of the depth of the hole and the choice of drill can one count on the strength of the connection.

Kinds

According to installation technology there can be

- Chemical , i.e. have a capsule with substances that is crushed when the anchor is installed, turning it into a single monolithic whole with the surrounding material.

- Mechanical , i.e. whose action is based on the forces and laws of physics.

The group of mechanical anchors is large and includes the following types:

- Mortgage – inserted after pouring the concrete mixture and firmly fixed during its hardening.

- Driven - mounted by driving into a hole with a sleeve pre-installed there.

- Wedge - during installation it acquires a wedge-shaped expansion.

- One-/two-distance – has, respectively, one or two movable couplings.

- Frame - its design has a countersunk head.

Bolts can be either straight or curved. For ease of installation of equipment or individual interior elements, for example, chandeliers, anchors with hooks or rings at the end are used.