The technology for manufacturing liquid granite requires compliance with certain rules. The first of them says that the production premises should consist of two rooms. The first is required for casting, while the second is required for polishing the resulting product. The production of liquid stone begins with degreasing the surface, removing dust and dirt.

Before coating, the base is washed with water and dried well. All damage and cracks must be repaired.

Making liquid stone with your own hands is quite simple. It is a modern finishing material, which is manufactured using technology that makes it possible to achieve an imitation of the resulting products with the appearance of natural stone. This name is explained by the fact that the finished product is the result of polymerization of a multicomponent liquid composition based on polyester resins. The resulting materials are used in various fields, such as finishing work, facade cladding, and the manufacture of plumbing fixtures.

At the next stage, a mixture of transparent gelcoat with granules is prepared. You need to use a 2 to 1 ratio.

Advantages and disadvantages of liquid stone countertops

A special feature of a composite material is its manufacturing process. Which involves the use of fillers, natural pigments and polymer resin. The popularity of acrylic stone is due to its strength and resistance to various chemicals.

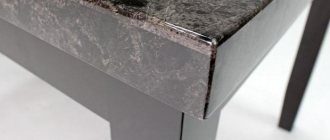

This countertop made of artificial stone will become a harmonious element of the interior.

It is easy to use, so if you wish, you can make a high-quality kitchen countertop yourself. The finished product has a number of advantages:

- homogeneity of structure, impermeability - bacteria do not penetrate through such a surface, dirt does not accumulate;

- imitation of natural rock;

- wide choice of color palette;

- safety, environmental friendliness;

- Possibility of grinding, self-removal of scratches.

Artificial stone can be called an eternal material.

The material is warm to the touch and adds aesthetics to the room. You can also note the long service life. It is easy to care for such a tabletop; just wipe the surface with a cloth. If you need to restore furniture with this coating, you only need polish and sandpaper.

Any product has its drawbacks.

The disadvantages are not significant, but they are:

- tendency to form abrasions, easily scratch the surface;

- absorption of chemical dyes;

- not high temperature resistance.

It is recommended to use this surface carefully and try not to knock or throw heavy objects onto the surface.

You can always choose the color of the artificial stone countertop.

In any case, if the tabletop is deformed, you can carry out the repair yourself, giving it its original, attractive appearance.

Equipment and materials

To create an IR on your own, you need special materials and technical equipment:

- Vibration stand . Processing artificial stone without it will not work;

- Models for making casting molds (not relevant if you are using a ready-made mold);

- Separation solution . It is necessary to cover the model when creating the mold and the mold itself before casting the product. Thanks to it, products and forms do not stick to each other;

- Casting molds . You can make them yourself or use ready-made ones;

- Casting mixtures (compounds) and resins for artificial stone;

- Set of pigments . Thanks to them, you can get a stone of any color;

- Sand cushion tray . It is necessary for independent silicone molds;

- Thermal gun . Necessary for final molding and welding of acrylic elements.

Types of liquid stone for countertops

Depending on the type of resin used in production, liquid stone comes in several varieties. Each has its own positive and negative sides.

At the same time, they are in demand on the market; more and more consumers are purchasing this particular material for the manufacture of countertops.

Acrylic

Thanks to the mineral filler, the material has a solid structure. Resins act as a binder. The presence of natural pigments gives the stone different colors. Therefore, you can often find a variety of shades and shapes.

Artificial (or acrylic) stone is a durable material.

Liquid stone for countertops can be monotonous, sandy in color, with marble stains, small veins, and translucent. Advantages:

- density, non-porous structure;

- does not stain, the stain that appears can be easily removed with a sponge;

- high wear resistance;

- allows you to implement the most original seamless designs;

- possibility of assembly from separate pieces;

- suitable for repair work;

- huge range of colors.

The glossy countertop looks attractive.

Products made from acrylic stone can be in glossy or matte finish. The big advantage is that the material does not fade over time, the color remains for several years.

Agglomerate

No less popular, available in the price segment. Suitable for complex finishing. Has high strength. This material is produced by combining individual particles of natural stone, polyester resins and additives.

Artificial stone is lighter than natural stone.

Pros:

- resistance to high temperatures;

- durability;

- non-toxic;

- easy to care for.

Despite its excellent characteristics, the material is suitable for creating simple geometric shapes.

A tabletop made of agglomerate becomes almost eternal.

Sheet artificial stone

Acrylic sheets are often large in size, making it possible to produce any structures of non-standard configurations. The canvases are connected to each other using acrylic glue, and there are completely no traces of butt seams. The sheets are easy to use and easy to install artificial stone.

A large palette of shades and textures of artificial stone can satisfy the wishes of any buyer.

Advantages:

- the ability to create any shape, looks like a monolith;

- when chips appear, they can be quickly sanded without compromising the quality of the surface;

- easy to clean;

- does not emit harmful substances and odors;

- UV resistant.

The price of an artificial stone countertop directly depends on the complexity of the design.

Due to its low porosity, it does not absorb moisture, and you can place hot items on the surface. Even after a long period of use, the appearance of the finish remains the same. The material retains expressiveness, maintaining the richness of colors.

Stone cladding: positive and negative sides

Stone is a beautiful and extremely durable material. Making steps from natural stone is a solution that is not affordable for everyone, so many people use artificial analogues. They are in no way inferior in beauty and are endowed with undeniable advantages:

- A staircase made of natural stone will never creak or create other extraneous noise.

- The material is considered environmentally friendly and has a 100% fire resistance level.

- Cladding stairs with stone will never lose its original appearance and its inherent performance characteristics.

- Stone steps for stairs are characterized by high strength, the highest degree of reliability and wear resistance.

- Such structures are very easy to maintain.

- The stone on the steps does not need any additional processing or decoration.

- The peculiarity of stone stairs is also that they have a positive effect on the energy of the house.

In this video you will learn how to lay out a stone staircase: There are also disadvantages to this type of finishing:

- High level of heat absorption.

- High cost of materials, especially natural ones.

- The large weight of stone structures is also considered a disadvantage that is worth paying attention to. This must be taken into account when calculating the strength and load of the foundation.

All natural stones do not emit heat; they only absorb heat. This must be taken into account when choosing and installing stone steps. This shortcoming can be mitigated by laying a carpet or rug on top.

What tools are needed for manufacturing

Having decided to make the tabletop yourself, you should follow all the steps step by step. But first you need to prepare the tool:

- electric drill, jigsaw;

- milling cutter and grinding device;

- heat gun;

- screwdriver;

- sandpaper.

You must have the necessary tools for the job.

There are no specific recommendations for choosing a tool for working with artificial stone. However, in order to achieve high-quality processing and durability of the product, it is necessary to use an electric tool designed for intense loads. The cutting discs must be made of tungsten carbide.

Cement-acrylic floors

Self-leveling floors with a cement-acrylic base are successfully used in production workshops of the food industry, having proven their suitability with high performance properties. Seamless, highly durable, resistant to disinfectant solutions, cement-acrylic flooring retains its integrity for many years.

Recently, self-leveling floors using artificial stone have become popular. They are used in the bathroom, kitchen, etc. The basis for self-leveling floors can be ceramics, concrete, metal, asphalt, wood and many other materials. Acrylic floors often serve as a leveling layer for laying floors made of other materials, such as ceramic tiles.

Acrylic stone, the floor and numerous products from which you see in real life, can be purchased on the AMIGO STONE website. Stone samples in our catalog are presented in a large assortment. Stone processing masters and designers offering services will help with advice, and, if desired, will carry out any work professionally. With us you will not have any problems finding the right material at the best price.

The process of making artificial stone countertops

After preparing the tools and material, you can begin to work.

Choose artificial stone for the countertop.

Step by step execution:

- Two blanks are made, five millimeters larger than the desired option. They need to be glued together and the edges processed;

- then you need to cut holes for the hob and sink;

- The next step is to mount the mold on the work surface and install the required plumbing. Using plasticine, you need to cover up the places where the cracks have formed;

- Now you can pour liquid stone, strictly following the instructions.

Important! It is necessary to work with the composition carefully and quickly, as it can harden quickly.

If necessary, the height of the tabletop can be made to any size.

Also, before spraying the material, it is better to place fiberglass cloth over the workpiece. This will give greater strength to the structure. Next, the surface needs to be sanded and the edges need to be routed with a milling cutter. It is imperative to check visually how level the structure is installed. If distortions are noticeable, the surface should be leveled.

You can make your own countertop.

The process described above gives an understanding of how to make a countertop from artificial stone with your own hands. There is nothing complicated about this, the main thing is desire and step-by-step implementation.

Preparing the stone

The simplest design has a rectangular shape and is easier to work with. The first step is to prepare the surface, strips for finishing the edges, and you will also need a wall edge. When planning a future product with smooth curves, first the acrylic sheet is heated to one hundred and sixty degrees using a hair dryer.

First make a sketch of the tabletop.

It makes it possible to bend the stone to the desired configuration. A circular saw or cutting equipment is suitable for cutting artificial stone.

Manufacturing technology

Determining the desired dimensions and external design is the first thing to do before making a countertop. Then, in the kitchen, the space near the sink is measured, followed by drawing a sketch on paper. It is not recommended to make wall sides too high; five to seven centimeters will be enough. Using a router, you need to cut out spaces for the hob and sink. Then all edges are carefully processed with sandpaper.

Have your countertop fabricated by a professional.

Next, you need to cut strips of plywood, about eight centimeters long. They are used as a frame. You also need to make a frame; the treated stone surface will be glued into it. The ends are covered with decorative tape.

Repair of artificial stone countertops

The material is aesthetically attractive, looks original, but requires careful handling. Even careful use of the countertop sometimes leads to various damage appearing on it over time.

You can repair your stone countertop yourself.

As already mentioned, artificial stone is easy to repair or restore. This will require a minimum of time and no special skills are required.

Crack repair

If cracks or chips are noticeable on the surface, first degrease the deformed areas. Then you will need a two-component glue, which is used to fill the crack itself.

Stone countertops are quite durable.

After waiting for it to harden, you should grind it, then carefully polish the tabletop by hand. In this way, it is possible to restore the beauty and original appearance.

Scratches

The appearance of stains and shallow scratches on the surface does not look aesthetically pleasing. Therefore, it is better not to delay in eliminating this problem. You will need a piece of sandpaper with which you can quickly sand the countertop.

It is recommended to first use coarse-grained material, then go through with fine-grained material. Some experts advise additional polishing of the stone using a drill with a felt attachment. The result is a smooth, even surface without scratches.

Blisters and spots

In addition to any chips, the surface may sometimes swell. In this case, a router will help out, with which you need to cut out the problem area. Then you will need a liquid stone for the patch; it must be poured into the place where part of the swelling was cut out. After hardening, polishing and grinding are also performed.

A real decoration of the kitchen will be a countertop made of artificial liquid stone, made by yourself. This product will last for many years, delighting you with its original appearance. At the same time, working on such a surface is a pleasure. It is easy to care for this product, just wipe with a sponge.

Take care of the countertop to avoid blisters and scratches.

If cracks or scratches appear, the material allows you to restore the coating yourself using a two-component adhesive. Also, regular sanding and polishing will help restore the original appearance.