Our company offers the average market price for road curbs.

You can buy our road curb in Moscow, the Moscow region and in the regions neighboring the Moscow region, and if you need a highway curb, contact us - we will sell and deliver! If you need to know what the current price for such a stone is, go to the card of a specific brand - the current cost is always indicated there! A road curb is a concrete, vibro-pressed stone, very durable and heavy. Usually has a size of 1000x300x150 mm. and is used on highways. The weight of such a stone is usually 95-100 kg.

Our borders are always of consistently high quality because they are produced on modern equipment, by a professional team, in compliance with the requirements of GOST 6665-91! In general, curbs can be made using several methods, both with your own hands and with the help of a high-tech automated line. As a large manufacturer, we use the vibropress method. With this production method, the required strength characteristics and the required frost resistance are obtained.

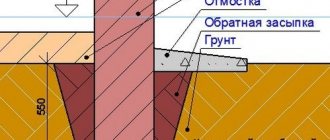

Installation or laying of a road curb is usually carried out on a prepared sand and crushed stone “cushion”, followed by fastening with concrete mortar.

Ask a Question

A commonly used definition of “ curb stone”

" implies the construction terms "

curb

" and "

edge stone

". The border is produced in accordance with the technical specifications of GOST 6665-91.

Curb stone is used in the manufacture of road surfaces as a material that separates the main elements of the road surface from each other. It protects the edge of the road surface from destructive influences and helps strengthen the main part of the road surface and extend its service life. In addition, it performs decorative functions and can also serve as a marking of the beginning and end of a certain road zone.

The advantages of this building material are strength and durability at a relatively low cost, as well as versatility: thanks to its aesthetic characteristics and the ability to choose colors, it can fit harmoniously and naturally into any design project.

The scope of application of curbs is quite wide: it is used on roads, in parks, squares, and suburban areas.

Depending on the application, borders are divided into the following types:

— For road construction. Used as strengthening and fencing of the roadway from the lawn, from the stopping area or from the sidewalk; for arranging driveways and parking lots, they can also serve as a drainage system - for the construction of guide water drains from the road. A type of road curbs are main curbs, which are used on highways and long-distance routes. Road curbs are characterized by an increased level of strength.

— For landscaping areas (so-called sidewalk or garden borders). They are used for artistic decoration of both the entire area and individual landscape elements (for example, fencing flower beds), for zoning the territory both in urban construction and on a garden plot. Since their main function is decorative, they have a fairly wide range of color variations.

The area of use of curb stone determines its performance characteristics, because it is constantly subjected to high intensive loads. Therefore, the main requirement for the manufacturing material is durability and resistance to mechanical loads.

Concrete class depending on tensile strength when bending; — concrete class depending on compressive strength; — strength and crack resistance; - water absorption; - frost resistance.

Side stones can be made from fine-grained or heavy concrete. The practical strength of concrete, depending on the rated indicators, should be determined in accordance with GOST 18105

. At the same time, for a curb length of 1.0 m made of fine-grained concrete, it is recommended to use vibrocompression technology. Curbs 3.0 and 6.0 m long are made of heavy concrete using reinforcement. The concrete composition is selected in accordance with the recommendations of GOST 27006 and established industry requirements and recommendations. Water-cement ratio - no more than 0.40. Concrete mixtures according to GOST 7473 are prepared using air-entraining additives.

XX 1. 2. 3. 4

Where XX is the designation of the type of stone; 1 - number indicating length (cm); 2 - number indicating height (cm); 3 - number indicating width (cm); 4 — radius of curvature (may be absent). In addition, the class of prestressed reinforcement can be indicated through a dash sign.

By type, side stones are divided into:

BR - straight privates; — BU — straight with widening; — BUP — straight with intermittent widening; - BV - entry; - BL - straight with tray; - BC - curvilinear.

The type, size and shape of the border determine its area of use.

If we talk about the cost of a curb stone, it depends on the technical characteristics and its purpose. Accordingly, sidewalk curbs are more economical with sufficient strength and durability, which makes their use universal.

| Dimensions (L x W x H in mm): 500x200x80 Weight (in kg): 20 |

| Dimensions (L x W x H in mm): 800x200x80 Weight (in kg): 26 |

| Dimensions (L x W x H in mm): 800x300x150 Weight (in kg): 85 |

| BR-100-20-8 Dimensions (L x W x H in mm): 1000x200x80 Weight (in kg): 40 |

| BR-100-30-15 Dimensions (L x W x H in mm): 1000x300x150 Weight (in kg): 100 |

| BR-100-30-18 Dimensions (L x W x H in mm): 1000x300x180 Weight (in kg): 120 |

| BR-100-45-15 Dimensions (L x W x H in mm): 1000x450x150 Weight (in kg): 145 |

)

–

heavy concrete stone intended

for separating the roadway of passages within city blocks and for separating green spaces. Curb stones are widely used to separate the carriageway of streets, roads and public transport stops from sidewalks. The use of such curbs effectively prevents the erosion of curbs, road surfaces, slopes and urban landscape design. The curb protects popular sidewalks made of concrete tiles from spreading. In private buildings, curbs have also found their use - with their help, durable paths, courtyards and high lawns are formed and maintained.

If the area for improvement has the correct geometry

–

no rounding or turning

–

Only an ordinary curb is installed. Otherwise, drive-in (BV) and curved (BC) stones are also used to create a full-fledged enclosing covering of any shape. Border stones are durable and crack-resistant; they should not erode or crumble. A popular element of urban infrastructure, the curb meets all strict quality requirements. The norms and standards for the production of ordinary straight stone are contained in

GOST 6665-91

.

By adding various pigments to the concrete mixture, the border can be produced in a wide range of colors, and can also imitate natural materials (granite, marble, natural stone). Thanks to modern technologies of vibration pressing and vibration casting, curbs are smooth, durable and evenly colored.

An ordinary curb stone has a rectangular shape with a bevel on one side. A significant mass of ordinary curb stones from

40

kg is due to the fact that stone with a length of 3000 mm inclusive is reinforced. Reinforcement of the BR curb stone is made with rod reinforcement (stressed and non-stressed) and reinforcing wire. Also, an ordinary curb stone has mounting loops for ease of lifting, since this concrete product has a significant mass.

Strength and frost resistance

–

the most important performance characteristics for curbstones. Particular strength is imparted during the production process - vibrocompression. In order for the side stone to be frost-resistant, sand is specially added to the concrete, which gives the material both heaviness and strength. The grade of concrete for frost resistance for curbs depends on the area of their application and varies from F100 to F300.

Another important characteristic of borders is uniform color. So that the stones do not differ in shades and do not spoil the color composition of the entire border, during the manufacturing process they are evenly painted throughout their entire depth. The part of the monolithic curb buried in the ground is usually the same in height as the above-ground part.

Product marking

The symbol for the stone consists of alphanumeric groups separated by a dash. The type of stone, length, height and width of the BR stone in centimeters are indicated

As an example of side stone marking, consider

BR 300.30.15

(3000x300x150 mm), where:

BR

–

type of stone

–

airborne private;

Length, width and height in cm.

Markings of side stones are applied to the end face of at least 10% of the stones from the batch.

Product quality control

There should be no cracks in an ordinary curb stone, except for a small number of barely noticeable surface cracks no more than one tenth of a millimeter wide.

Deviations in the geometric parameters of the curb stone along the length can be no more

±6, width ±4, height ±5 mm. Deviations in the straightness of the BR are possible no more than 6 mm.

On

acceptance tests

indicators are tested:

concrete class for compressive strength;

transfer and tempering strength of concrete;

compliance of reinforcement products;

strength of welded joints;

accuracy of geometric parameters;

thickness of the protective layer of concrete to the reinforcement;

the presence and width of possible cracks;

categories of concrete surface;

grades for workability of concrete mixture,

volume of entrained air in concrete mixtures with air-entraining additives.

Party

ordinary curb stones

must be accompanied by a document from the manufacturer (technical passport),

which certifies the quality of BR side stones. IN

data sheet

indicate:

batch number of BR stones, symbol, total quantity in pieces;

BR test results;

grade of concrete in terms of strength and tempering strength of concrete;

concrete grade for frost resistance;

class of prestressed reinforcement;

GOST designation.

Transportation and storage

Curb stones are transported by various transport packaged in bags. It is important that the bags are secured with wire or other means to prevent damage to the stones. For the same reason, it is worth making sure that unloading does not occur in bulk or by dumping.

BR side stones are stored in stacks no higher than 2 meters, on wooden spacers, sorted by brand and size.

To reach the goal

–

that is, reliable separation of roadways from sidewalks and lawns using curb stones; it must be placed on a specially prepared base - crushed stone, concrete or sand. In this case, if installed correctly, the road entrance curb will fulfill its direct function and will last a long time.

This is a building element of a highway, sidewalk path, a kind of border of a pedestrian area, a parking pocket. It is the side stone

has become widespread on our streets.

The edge stone

has a discreet, natural beauty and gives the paths of squares and alleys a slight touch of nostalgia.

The curb stone

/border/ as a demarcation between different zones of heavy traffic, both in the city and on intercity highways, must be securely fixed.

This is now one of the indispensable parts of the road construction. It not only divides the roadway from the pedestrian one, but also serves as a stop when laying paving slabs or when paving. Border

fits harmoniously into the appearance of any object, giving it solidity and uniqueness.

As a special property, it is possible to reuse it.

By definition, a road curb

Side stone

is designed to protect the edge of the road surface from destruction, therefore increased demands are placed on its properties, in particular, strength and frost resistance.

In this regard, both road curbs

and sidewalk curbs are made from heavy concrete with increased density.

One of the main requirements for curbs is heavy weight and water resistance. A good curb the

roadway from destruction.

Border stone

/road and garden curbs/ are produced by semi-dry vibrocompression using vibrocompressing equipment. High-quality materials are used in production: granite chips, washed sand, M-500 cement, and anti-frost additives in the cold season.

Types and purpose of standard blocks

Such products not only delimit areas, but also give the design a complete look.

In addition to their aesthetic function, sidewalk curbs direct water flow towards storm drains, maintaining the integrity of the road surface. A sidewalk curb is one of the types of reinforced concrete products that are installed on sidewalk blind areas. It should be noted that there are 4 categories

products:

- Curb

. This is the most common type of stone used to delimit lawns, pedestrian areas and bicycle paths.

Vibrocast curbs

. Such products immediately attract attention with their unusual shape and colors. Products can be produced in the form of steps, waves or arcs. The usual gray color of concrete curbs is changed by the addition of dyes and plasticizers. Vibrolithium stones are commonly used as architectural decorations.

Lawn blocks

. This is a type of curb that usually borders lawns to prevent the topsoil from spreading.

road stone

. This variety can be considered a sidewalk curb at a stretch. They are used to preserve the integrity of the road surface, so the products have massive dimensions and reinforcement is required during manufacturing.

The technology for the production of sidewalk curbs involves the use of heavy concrete grade M 300

or

M 500

. This is a prerequisite for the structure to have a high margin of safety and resistance to dynamic compression.

Standard sizes according to GOST

Sidewalk curbs are manufactured in accordance with GOST

, therefore they have standard sizes, regardless of the manufacturer.

According to the state standard number 6665-91

, the products have the following dimensions:

Curb.

- Length - 500/1,000 mm.

Width - 45/50/80 mm.

Height - 200/210 mm.

Lawn block.

- Length - 500 mm.

Width - 70 mm.

Height - 211 mm.

Road block.

- Length - 1,000 mm.

Width - 300/450 mm.

Height - 150/180 mm.

Vibro-cast curbs have similar dimensions, but do not have a clear geometry.

| Small border | Large border | Garden border (vibropress) | Road curb (vibropress) | |

| Dimensions, mm | 500*200*45 | 500*200*70 | 1000*200*80 | 1000x300x150 |

| Weight, kg | 8 | 12 | 25 | 100 |

| On a pallet, pcs. | 100 | 100 | 40 | 18 |

| Frost resistance | F200 | F200 | F200 | F200 |

| Cement brand | M500 | M500 | M500 | M500 |

This will be useful to you

To better understand tiles for sidewalks and paths, to confidently navigate their types, shapes and sizes

Cost of curb stones

| № | Color | Price in rubles from (for 1 piece) | |||

| 1000x200x80 | 1000x300x180 | 1000x300x150 | 500x200x70 | ||

| 1 | Grey | 130 | 320 | 230 | |

| 2 | Color | 130 | 400 | 320 | 70 |

Self-installation of sidewalk curbs

The sidewalk curb is easy to install, which is an undeniable advantage of this type of product. Even a novice builder can cope with this task; it is enough to follow the following order of work:

- The territory is marked taking into account the features of the landscape.

According to the markings made, pegs are driven in and the thread is pulled between them. This will be the level of the top of the curb.

Then a trench is formed along the entire length of the marked area. Depth is 1/3

from the top point of the stone, the width is

10 centimeters

greater than the size of the block.

The bottom of the trench is compacted to prevent soil subsidence.

Install the border at the level of the cord. The stones are leveled in height by placing mortar underneath.

The joints are also filled with mortar, the installed borders are left for 24 hours

so that the solution sets.

Then the free space of the trench is filled with soil, which must be thoroughly compacted. At the final stage, the sidewalk is installed.

Manufacturing technology

Typically, sidewalk curbs are made in a factory, but the production technology is quite simple, so you can make the blocks yourself. This option is ideal for owners of personal plots who want to diversify the landscape design of a country house.

The technological process begins with the manufacture of a mold for casting. It is immediately necessary to clarify that the form can be purchased ready-made - it is a monolithic structure, convenient for pouring and removing concrete mixture. However, you can make the mold yourself using sheets of plywood or metal.

The block size can be chosen arbitrarily, in accordance with individual preferences. However, the length of the stone should not exceed 2

- meters (otherwise the block may break).

Note that for ease of installation, one side of the block should have a slight bevel. This can be achieved by making an appropriate mold or cutting off the excess plume with a machine after the mixture has set.

- To prepare the mixture, it is necessary to prepare a cement-sand mixture (proportion 1:3

). The components are mixed until a homogeneous mass is obtained.

Then add crushed stone in a ratio of 3 parts

stone per

1 share

of dry mixture. Add water to the mixture and mix, avoiding the formation of lumps.

After this, the mixture is poured into the prepared mold, having previously lubricated the walls with used machine oil.

If you plan to make a reinforced curb, fill the form halfway, then install the reinforcement and add the rest of the concrete. The surface is leveled with a construction trowel.

To be able to remove the block, the filled mold must sit in a cool place for 3-4 days.

. After this, the block is removed and left to dry in the open air for another week. After this period, you can begin installation.

Plastic border - an affordable alternative to stone

This is an excellent solution for decorating personal plots. Such garden borders are usually cheaper than their concrete counterparts, and are much more convenient to install. However, ideal materials do not exist in nature, so plastic borders are also not without their drawbacks, but first things first.

Pros and cons of plastic on the garden path

Advantages:

- A wide range of. In addition to the usual ribbon models, you can find decorative elements on sale, imitation of natural stone, brick, wood and metal.

Practicality. If the plastic section is damaged, it can be easily replaced. You will have to tinker with concrete sidewalk curbs much longer.

Long service life. Plastic belongs to the category of durable materials.

Neutrality to any environment. Plastic products are resistant to sudden temperature changes, are not afraid of humidity, and do not fade in the sun.

Attractive appearance. Such borders are available in a variety of colors, which opens up almost limitless possibilities for decorating personal plots.

It should be noted that the plastic bends easily, which allows you to create winding paths.

Speaking of disadvantages

, the following nuances cause complaints:

- Fragile plastic is susceptible to mechanical damage.

The material burns well.

Questionable environmental safety.

Typical dimensions and installation

The width of plastic borders varies within 10-28

centimeters, thickness:

0.5-2

mm.

If we talk about installation features, plastic products are much more convenient than their concrete counterparts. The key difference is that there is no need for preliminary site preparation. A trench is dug along the path or flower bed, about 10 cm

. Pointed pegs, which are located at the base of plastic borders, are hammered here.

The sections are fastened together with locking joints. The curb is leveled, then the trench is filled with soil.

Watch the video: 30 examples of fencing for paths, flower beds and beds

Thanks to the different standard sizes, choosing a sidewalk curb for landscaping your garden area is not difficult. Those who want to save on purchases can make the blocks themselves, since the production technology does not look complicated.

In addition, you can decorate paths and lawns with plastic borders, which attract attention with their affordable price and ease of installation. In any case, sidewalk curbs will give the area an original and complete look.

Concrete and reinforced concrete side stones BR100.30.15 or curbs are construction products that are widely used in road construction for the construction of roads, highways and sidewalks. Side stones BR100.30.15 are intended for separating the carriageway of streets and roads from sidewalks, lawns, playgrounds, public transport stops, separate tram tracks, etc.

Side stones BR100.30.15, made of concrete reinforced with high-strength steel, are able to withstand any mechanical loads, including collisions with vehicles. Concrete has low permeability, so it can easily withstand the effects of any climatic precipitation, temperature changes, can be used in a humid environment and is not destroyed by the action of chemical compounds. The high strength of reinforced concrete allows side stones to prevent soil movement and strengthen the road surface and paving slabs. The use of high-strength curbs made of reinforced concrete side stones has a beneficial effect on the service life of road and sidewalk surfaces.

Another important advantage of reinforced concrete, from which side stones BR100.30.15 are made, is the ease of installation and repair. They are installed directly into the ground (sidewalk curbs) or onto a concrete foundation (road and highway curbs). Installation consists of preparing a trench into which stones will be immersed, which is then compacted with sand, crushed stone or filled with monolithic concrete. The width of the trench should be slightly larger than the width of the curbs. Then the side stones BR100.30.15 are installed in the trench, so that the buried part of the curb is equal in height to its above-ground part. A strengthening solution, usually consisting of sand, cement and water, is poured into the gaps left on each side due to the larger width of the trench. And if it becomes necessary to repair the curb in any area, the damaged element is simply replaced with a new one.

Reinforced concrete side stones BR100.30.15 are a rectangular slab, the upper part of which is beveled on one side. The top, bottom and vertical edges of the stones must be mutually perpendicular. It is also allowed to produce side stones BR100.30.15 with a technological slope of the non-facial vertical edges up to 5%, rounding of the front edges with a radius of up to 5 mm and non-facial ones with a radius of up to 15 mm or chamfers up to 10 mm wide.

Side stones BR100.30.15 are manufactured in accordance with the requirements of GOST 6665-91 “Concrete and reinforced concrete side stones. Technical specifications" from fine-grained and heavy concrete. The concrete class for compressive strength is accepted to be no less than B22.5. The frost resistance class of concrete is assigned depending on the design temperature of the outside air during the coldest five-day period in the construction area: at a design temperature of the outside air above -5°C, the frost resistance class of concrete is assumed to be F100, at temperatures from -5°C to -15°C inclusive - F150, from -15°С to -45°С inclusive – F200, at temperatures below -45°С – F300. The water absorption of concrete side stones should not exceed (as a percentage of the mass): 6% for stones made of fine-grained concrete and 5% for stones made of heavy concrete.

Reinforced concrete side stones BR100.30.15 are reinforced with welded mesh and volumetric frames made of prestressed or non-prestressed steel. Hot-rolled steel bars of periodic profiles of classes A-IV and A-V or thermomechanically and thermally strengthened steel of periodic profiles of classes At-IV and At-V are used as prestressing reinforcement. Hot-rolled steel rods of classes A-I and A-III and ordinary periodic wire of class BP-I are used as non-prestressing reinforcement. Mounting loops are made of steel rod hot-rolled smooth reinforcement of class A-I.

Side stones BR100.30.15 are very important products, on which the safety of pedestrians and vehicles largely depends. Therefore, quite serious requirements are placed on the quality of manufacture of these products.

Side stones BR100.30.15 must maintain sufficient strength throughout the entire service life of the products. In this case, the value of the standardized tempering strength of fine-grained concrete should be 90% of the concrete class for compressive strength and the concrete class for tensile strength in bending at any time of the year. The value of the normalized tempering strength of heavy concrete should be 90% of the concrete class for compressive strength and the concrete class for tensile strength during bending in the cold season and 70% in the warm period. The transfer of compression forces to the concrete (releasing the tension of the reinforcement) is carried out only after the concrete reaches the standardized transfer strength. The actual strength of concrete must correspond to that required by GOST 18105, depending on the standardized strength and indicators of the actual uniformity of concrete strength.

Side stones BR100.30.15 must be manufactured in compliance with all dimensions specified in the project. The values of actual deviations from the linear size of the stones should not exceed 6-10 mm in the length of the products, 4 mm in the width of the upper edge, 6 mm in the width of the base and 4-5 mm in the height of the products. The deviation from the straightness of the profile of the upper surface along the entire length should not be higher than 6-15 mm, depending on the length of the stone. The deviation from perpendicularity of the end and adjacent faces should be within 4-5 mm.

Side stones BR100.30.15 do not allow reinforcement to be exposed. Cracks on the surface of stones are strictly not allowed, with the exception of surface cracks with a width of no more than 0.1 mm and a length of up to 50 mm, in an amount of no more than 5 pieces. per 1 m2 of surface. In this case, the maximum crack opening width when testing for strength and crack resistance should not exceed 0.2 mm.

Reinforced concrete side stones BR100.30.15 are stored in the finished products warehouse, sorted by grade in stacks or bags up to 2 meters high. Stones in stacks are placed on wooden pads with a thickness of at least 30 mm, located vertically one below the other at a distance of 0.2 lengths of the stone from the end, or on pads made of other materials that ensure the safety of the stones. The bottom row of stones should be laid on transverse pads with a width of at least 80 mm.

Modern landscaping can include a variety of elements. For example, concrete side stones according to State Standard 6665 91 are very effective.

They are intended for the following:

- separation of roadways and streets from sites, sidewalks, and public transport stops;

- segregation of tram tracks;

- for separating various territories, squares, sidewalks and pedestrian paths from lawns.

Service life of curbs made of different materials

The service life of curbs depends on the material of manufacture and operating conditions. The most durable are curbs made of natural granite. The service life of a concrete curb stone directly depends on:

- on the quality of materials used in the manufacture of side stones;

- depending on the area of application and operating conditions.

For the manufacture of concrete and reinforced concrete side stones, fine-grained or heavy concrete is used. For curbs made of fine-grained concrete, it is recommended to use vibrocompression technology. Main curbs 3 and 6 meters long are made of heavy concrete using reinforcement technology. GOST regulates the technical characteristics of curbs according to the following parameters:

- concrete class for compressive strength;

- class of concrete for tensile strength.

The lifespan of curbs is influenced by many factors, including environmental influences. Indicators of strength, frost resistance, crack resistance, water absorption, and resistance to temperature changes are taken into account. The service life of curb stones separating the pedestrian area from the roadway is significantly less than the service life of garden borders with higher strength and durability. On average, the service life of curbs is 5-20 years. Plastic products have the shortest service life, which, depending on the conditions of use, can be 3-5 years. The question of how long it takes to change curbs is often asked by owners of country houses, summer cottages, parking lots, etc. Replacement of curbs is carried out during repair and restoration work after the expiration of their service life or after damage to the curb stones for various reasons, the main ones being:

- settlement of pavement or curbs;

- installation of borders of a different shape;

- increasing the height of curbs due to an increase in the thickness of the coating.

Features of manufacturing and installation

- The instructions emphasize that the use of such elements makes it possible to strengthen slopes and roadsides, as well as prevent their erosion by groundwater, rain and melt water.

- Concrete side stone is capable of performing not only important practical tasks. It can also have decorative functions. For example, if you combine stones of different colors, this will make it possible to decorate the transport arteries of the city.

Product manufacturing

The instructions emphasize that the use of such elements makes it possible to strengthen slopes and roadsides, as well as prevent their erosion by groundwater, rain and melt water.

Road curbs are made from various stone-like materials, the most common are:

- concrete;

- reinforced concrete;

- natural stone;

- granite.

Note! It is important that the material of the products is strong enough and massive. So, to separate the road surface, it is optimal to use side concrete stones of grade 400. In this case, the curb will be durable, reliable, resistant to mechanical stress and extreme weather conditions.

Curb reinforced concrete stones can be produced by two methods.

- At the moment, products produced using semi-dry vibration pressing technology are popular

. Such designs are most suitable for urban conditions. They have a high level of reliability, density and strength. In addition, their price is low when compared with granite analogues. - The method of formwork concrete casting is less reliable

. This technology is older and the quality of borders obtained with its help leaves much to be desired. After 3/4 years of service they begin to deteriorate.

Manufacturers produce the following types of borders:

- main lines;

- garden;

- pavements;

- road.

Regardless of their purpose, all products must, according to the standard, be made only from high-quality quartz sand, cement, crushed stone and modifying additives.

Installation technologies

Regardless of their purpose, all products must, according to the standard, be made only from high-quality quartz sand, cement, crushed stone and modifying additives.

Side stone can be installed using different methods.

The standards highlight two of them.

- Border. In this case, the elements are installed flush, in other words, they do not form steps. (See also article.)

- Curb. By installing the stones in this way, a separating edge is created. For example, concrete side lawn stones according to State Standard No. 52289/2004 must have a side surface and an upper part with markings applied to it. The standards for do-it-yourself installation of the described elements on the roadway are especially strictly regulated.

Thus, “safety islands” on roads should be marked with markings or side stones. The latter are installed near pedestrian crossings if the intensity of vehicle movement along this section of the road is at least 40 kilometers per hour. In this case, the height of the part of the “safety island” raised above ground level should be strictly 10 centimeters.

GOST R No. 52767/2007, which was adopted in 2007, defines the following.

- "Guiding Islands" The height of the curb of these road elements must be determined using a level (according to the requirements of State Standard No. 9392), as well as a measuring ruler (according to State Standard No. 427).

Note! The height level of the fence should be determined by measuring the gap between the road surface and the bottom of the level placed horizontally on top of the side stone. The height of the fence in any place should not be more than 10 centimeters.

- "Safety Islands" The height of their curbs is measured in the same way as in the previous paragraph. In this case, its indicator at any point of the fence should be 10 centimeters (± 1 cm).

When installing edging stones, a situation often arises when they need to be cut.

For example, when installing the final sections of fences.

- The optimal method is to cut reinforced concrete with diamond wheels. In this case, you can use both stationary or portable stone-cutting machines, and hand tools, for example, a large grinder.

- In addition, it may be necessary to drill the element. For this purpose, diamond drilling of holes in concrete is used.

Ramps and lowered curbs for disabled people

Library

SP 59.13330.2016 - 5.1.5 at intersections of pedestrian and transport paths with a height difference of more than 0.015 m, pedestrian paths are equipped with ramps on both sides of the roadway or artificial unevenness along the entire width of the roadway. At the crossing of the roadway, curb ramps with a width of at least 1.5 m must be installed, which should not protrude onto the roadway .

When moving around the city, the main obstacle for wheelchair users is curb stones. They do not allow you to drive from the road surface onto the sidewalk without assistance and freely cross intersections. To overcome these obstacles, ramps or lowered curbs are built.

The height of side stones (curbs) along the edges of pedestrian paths in areas along lawns and green areas should be at least 0.05 m .

The height difference of side stones along maintained lawns and green areas adjacent to pedestrian traffic routes should not exceed 0.025 m .

Height differences are considered obstacles on pedestrian paths with a height of more than 2.5 cm:

Overcoming a curb stone up to 1.5 cm , as a rule, is not difficult for a disabled person in a wheelchair.

Height differences of 1.5 to 2.5 cm are acceptable, but may cause difficulties for some disabled people. Since to overcome a difference of more than 2.5 cm in a wheelchair, outside help may be required .

At all places where pedestrian paths intersect with the roadway of streets and roads, the height of sidewalk stones must be at least 5 cm .

To overcome these obstacles, ramps or lowered curbs are built.

SP 59.13330.2016 - 5.1.8 in places where the heights of the surfaces of pedestrian paths change, they are made with a smooth decrease with a slope of no more than 1:20 (5%) or equipped with ramps.

The minimum width of the lowered curb, based on the dimensions of the wheelchair, must be at least 90 cm. The lowered curb must be painted with bright yellow (or white) paint.

The ramp is a “mini ramp.” Sidewalk exits should have a slope of no more than 1:10, like a ramp. Width – at least 90 cm .

SP 35-101. Exit ramps should not protrude into the roadway .

The ramp must be located entirely on the sidewalk.

When constructing ramps, their longitudinal slope should be no more than 1:20 (5%) , near the building - no more than 1:12 (8%), and in places characterized by cramped conditions - no more than 1:10 for no more than 1 .0 m .

The height difference between the bottom edge of the ramp and the roadway should not exceed 0.015 m .

If the ramp is located perpendicular to the sidewalk, then there must be a level passage without a side slope for the passage of people and safe passage in a wheelchair. On this flat part of the sidewalk, a disabled person in a wheelchair will be able to safely turn around and slide onto the roadway.

Contrasting coloring helps people with visual impairments to navigate and at the same time indicates to people with musculoskeletal disabilities (walking on crutches, in wheelchairs) places of possible entry and exit onto the sidewalk.

It should be noted that in world practice, as a rule, the curb is lowered not to 2.5 cm, but to zero , in order to eliminate all obstacles in the paths of people. But it was determined that in Russian conditions this creates difficulties for landscaping services - when a cleaning machine goes, all the garbage ends up on the sidewalk.

Fencing, curb with a guiding function along the sidewalk

SP 35-101. Use of fencing, parapets, borders (including greenery) to identify safe routes of movement on the site .

4.15. It is recommended, if no other coloring is required, to highlight: in yellow – limiting edges, crossing paths, the first and last steps of the stairs .

The difference in height, curb or fence along the sidewalk is determined by a cane and protects the blind person from entering the roadway.

For building areas where there is no heavy traffic, it is allowed to combine the roadway and pedestrian parts.

In this case, the best option is a tactile strip with guiding reefs to the main entrance.

The absence of guiding elements cannot be the reason for the inaccessibility of the territory for the blind. A visually impaired person can use other landmarks to move around, including a sound beacon, or use the help of an accompanying person.

When determining the degree of accessibility of a territory, guiding elements are not taken into account at this stage.

If there are no borders along the lawns, it is necessary to recommend the installation of a border or decorative fence or tactile strip.

| Back | Table of contents | Further |

Size and quality standards

Concrete and reinforced concrete side stones are designated based on the requirements of State Standard No. 23009/78.

- The first of them indicates the type of product, its height, length and width in centimeters, as well as for curved borders and the radius of curvature in meters.

- The second group voices the class of prestressing reinforcement used.

For an example of designations, let’s take side concrete stones of grade 300.

- BR/100.30.15. Stone type - BR (road straight). Its length is 100 mm, height 30 cm, width 15 cm.

- BK/100.30.18.8. Curb type - BC (road radius). Its length is 100 cm, height 30 cm, width 18 cm, radius of curvature 8 meters.

- BR/600.30.18-AIV. Stone type - BR (main straight).

Its length is 600 cm, height 30 cm, width 18 cm. Category AIV fittings are used.

Types of borders

Depending on the purpose, there are different types of borders: for example, for decorating a flower bed or fencing a highway. Accordingly, the length of the curb stone according to GOST, the dimensions of the curb stone according to GOST also differ. The operational features of a curb stone are denoted by the letters “BR”, the numbers after it mean the following: the first number is length, the second is height and the third is width. Thus, GOST regulates the following types of edge stone:

- GOST for highway curb stones - BR100.45.18. Such a curb is used for road construction, to fence the edge of the road to prevent cars from running off. This type of border copes well with intense loads.

- GOST for curb stones for sidewalks - BR100.20.8 is used in combination with paving slabs; these sizes are sufficient to perform decorative, fencing and strengthening functions.

- GOST for road curbs - BR100.22.15 (used to fence roads, but the size of the curb allows a car to move off it) and BR100.30.15 (separates roads and sidewalks).

The small sizes of border stones according to GOST are intended for the design of flower beds and fountains. Such curbs are made using the vibration casting method.

Conclusion

Check out the video in this article. It contains a lot of interesting information.

Read about how cutting reinforced concrete with diamond wheels and diamond drilling of holes in concrete occurs in other articles on our information portal.

Curb stone is a product that separates the pedestrian, bicycle or roadway from the lawn and other landscape elements. Its functions are dividing, completing the design of the landscape, and aesthetic. With a high-quality curbstone, the edge remains neat and beautiful for a long time.

Asphalt, paving slabs (read about the types of paving slabs), lawns that are not decorated with a stone border gradually crumble, spread to the sides, and their contours lose clarity. Requirements for border elements:

- Frost resistance

- Moisture resistance

- Strength to maintain the geometric integrity of the site edge.

The best material for making curb stones is concrete, which contains cement, sand, and crushed stone.

According to purpose, the main types are:

- Sidewalk

- Road.

Asphalt, paving slabs (read about the types of paving slabs), lawns that are not decorated with a stone border gradually crumble, spread to the sides, and their contours lose clarity.

The elements separating the lawn, pedestrian zone from the roadway are subject to significant mechanical loads, and therefore have large dimensions in comparison with those used exclusively in the pedestrian zone. Road stone protects the area bordering the highway.

With the help of sidewalk curbs, gardens, parks, lawns are decorated, and bicycle paths are demarcated. Its purpose is to preserve clear boundaries of all elements of the urban landscape: flower beds, paths.

It can have either a straight or curved, arched shape for designing curved sections of the road and safety islands.

Marking:

- BR - ordinary curb stone.

- BU - ordinary curb stone with widening. This element looks like a chamfered block.

- BUP - curb stone with intermittent widening. With its use, elements of the urban landscape are landscaped - stops, driveways, flower beds.

- BL - straight with tray. This element has a flat bottom gutter to drain rainwater; used in areas where rain erosion is possible and frequent snow loads occur. It is used as a drainage channel along the roadway, on sidewalks, stops and parking lots.

- BV - entrance curb stone. It is used to lower the height of the curb at the intersection of the sidewalk with the roadway; it is used to design entrances to the courtyard and intra-block territory.

- BC - curvilinear. It is installed in places where it is rounded, has a rounded shape, and has bevels in the upper part.

Curb height according to GOST

The height of the curb according to GOST is one of the important factors in the design of road and sidewalk surfaces. The installation of curbs is carried out to strengthen the road itself, to separate pedestrian zones and, above all, to visually define the roadway for persons driving vehicles.

Construction, reconstruction and compliance with construction standards are carried out by road services, which belong to the Administration of the locality in which the work was carried out. Based on numerous complaints and appeals, appropriate changes to the legislation of the Russian Federation were adopted.

Information on the standards established for curbs and the rules for their installation can be obtained in the normative act GOST 6665-91.

This document talks about all types of borders and their areas of application. In paragraphs 4.2.4. and 4.2.5. It is noted that the height of the curb according to GOST at any point cannot exceed 10 centimeters. In order for you to measure the height of the curb according to GOST, you will need a special measuring ruler or a special level. For accurate measurements, it is best to seek the services of a specialist who will provide more accurate data.

By “Curb height according to GOST” you need to understand the distance that is between the road surface and the bottom edge of the level. The level must be installed horizontally on the top edge of the stone.

Consequences of violations of curb construction standards

The consequences of violations of established parameters for the construction of road and sidewalk curbs can be different. This may include damage caused to the driver of a vehicle who damaged his car as a result of parking, or to people of retirement age who, due to their age and health, cannot overcome a high curb. This design also plays an important role in the lives of mothers of children with strollers or cyclists. Persons forced to leave the sidewalk by getting off or sliding onto the road automatically create an emergency situation. It is in order to avoid such situations that ramps are built from the sidewalk.

Where to contact?

If you have suffered some damage or suffered due to violated standards for the construction of curbs, you need to file a complaint with the municipal governing body. If the damage occurred by hitting a curb, depending on the situation, you may need to call the traffic police. If you have a CASCO insurance policy, you can contact the insurance company to call an accident commissioner.

In both cases, an inspection will be carried out and a corresponding report will be drawn up. Next, with the received documents, having drawn up a complaint with claims, you should contact the Administration at the scene of the incident. If you receive an unsatisfactory answer, you should legally go to court with a statement of claim to receive compensation, based on Art. 1064 of the Civil Code of the Russian Federation, also providing documents corresponding to the infliction of harm. The participation of an independent examination will also be required, without the results of which your application may not be accepted. Or it will affect the duration of the process. As a result, actions will be carried out on the specified section of the road to check its compliance with GOST parameters. If a violation is detected, the organization responsible for it will be obliged to correct the consequences caused by improper performance of work. You will be compensated for the damages you have incurred and the curb will be restored to a legal standard through reconstruction.

The legislation of the Russian Federation regularly introduces amendments and changes in order to improve a particular area of application of a particular law. But the vigilance of citizens also plays an important role, who, having noticed certain violations, must report them to the relevant authorities. Only thanks to this, the current situation as a result of any inconsistencies can be corrected.

In this article you learned about what the height of the curb should be according to GOST. If you have any questions or problems that require the participation of lawyers, then you can seek help from the specialists of the Sherlock information and legal portal. Just leave a request on our website and our lawyers will call you back.

Editor: Igor Reshetov

Border stone for a personal plot and cottage

Country and backyard landscapes are also designed using borders. Its functions are the same as in the city limits - protection and definition of boundaries. No massive road or main stone is used on the territory of the summer cottage.

It is not cheap, and its weight and dimensions make it difficult to install it yourself without the use of heavy equipment.

Country and backyard landscapes are also designed using borders. Its functions are the same as in the city limits - protection and definition of boundaries.

Paths, flower beds, and garden beds are separated by a thin sidewalk border. When using paving slabs, borders of a suitable design and color are ordered simultaneously with its elements.

Dimensions and specifications

- BR100.30.15 - separates the sidewalk from the roadway. Its marking contains the main characteristics: BR - curb stone; 100 - length 1 meter; height and width, respectively, 30 and 15 centimeters. The weight of one element depends on the materials used in production; it is 95-150 kg.

- BR100.22.15 - a low road curb is also in demand when designing roads. From the markings it is clear that with a length of 1 meter, a width of 15 centimeters, it has a height of 22 centimeters.

- BR100.45.18 - high main curb. This type is used in the design of highways, city highways and highways. It protects the pavement and extends the life of the roadway. Able to withstand significant mechanical loads. Dimensions: length - 1 meter, width - 18 centimeters, height - 45 centimeters. The mass of one element is 180 kg.

- BR100.20.8 - garden sidewalk border. Compact product with a small chamfer. The weight of one stone is about 40 kg, length - 1 meter, width - 8 centimeters, height - 20 centimeters.

Being an element that ensures safety and aesthetics on the roadway, curb stone is manufactured in accordance with GOST.

The photo shows an example of the original use of garden border stones

GOST 6665-91 applies to products made of concrete and reinforced concrete (curb stones). This document regulates the shape and dimensions of the product, the grade of concrete used for production, and material consumption indicators.

- BR100.30.15 - separates the roadway and intra-block passages from the sidewalk.

- BR100.30.18 - separates the roadway from sidewalks, lawns, stop areas and tram tracks.

- BR300.45.18 - designed to separate roads from sidewalks, ramps with an embankment no more than 2 m high.

- BR300.60.20 - separates the roadway from sidewalks in tunnels and on ramps with an embankment more than 2 m high.

- BR100.20.8 - separates sidewalks from lawns.

- BU300.30.29 - separates the roadway of intra-block driveways from lawns and sidewalks.

- BU300.30.32 - separates the roadway from lawns and sidewalks.

- BL300.32.68 - used for installing safety strips.

- BV100.30.18 - for registration of entrances it is used together with ordinary stone of the appropriate size.

- BK100.30.18.5-BK100.30.18.15 - used when designing curved sections.

Properties to be controlled: crack resistance, compressive strength, bending tensile strength, frost resistance, water absorption, geometric correctness.

Making curb stones

The properties of curb stones are determined by the correct ratio of recommended materials and compliance with production technology.

The properties of curb stones are determined by the correct ratio of recommended materials and compliance with production technology.

Materials: concrete mixture with additives that ensure plasticity, aggregates - crushed stone, gravel, blast furnace slag. To save cement, it is permissible to add slag, ash, or ash and slag mixture to the concrete mixture.

Using vibration allows you to remove air from the mixture and distribute all components evenly.

The dosed components enter the concrete mixer. The finished mixture is sent to forming equipment (vibropress, vibrating table with molds), where it is molded and compacted. The next stage is drying. At some enterprises, it is replaced by steaming in chambers with high humidity and temperature, which reduces production time.

Special molds allow small batches to be produced on a vibrating table.

Different types of borders serve for the separation, aesthetic, geometrically correct and safe design of streets, roads, garden paths (it is written about the production of garden paths), personal plots.

This is a building element of a highway, sidewalk path, a kind of border of a pedestrian area, a parking pocket. It is the side stone

has become widespread on our streets.

The edge stone

has a discreet, natural beauty and gives the paths of squares and alleys a slight touch of nostalgia.

The curb stone

/border/ as a demarcation between different zones of heavy traffic, both in the city and on intercity highways, must be securely fixed.

This is now one of the indispensable parts of the road construction. It not only divides the roadway from the pedestrian one, but also serves as a stop when laying paving slabs or when paving. Border

fits harmoniously into the appearance of any object, giving it solidity and uniqueness.

As a special property, it is possible to reuse it.

By definition, a road curb

Side stone

is designed to protect the edge of the road surface from destruction, therefore increased demands are placed on its properties, in particular, strength and frost resistance.

In this regard, both road curbs

and sidewalk curbs are made from heavy concrete with increased density.

One of the main requirements for curbs is heavy weight and water resistance. A good curb the

roadway from destruction.

Border stone

/road and garden curbs/ are produced by semi-dry vibrocompression using vibrocompressing equipment. High-quality materials are used in production: granite chips, washed sand, M-500 cement, and anti-frost additives in the cold season.

Block B-5, Side curb stone

| Block B-5 Series 3.503.1-66, Side curb stone GOST 6665-91 | ||||

| Name | Dimensions (LxWxH, mm) | volume, m3 | Weight, t | Price for 1 unit. with VAT, rub. |

| BR 100.20.8 | 1000x80x200 | 0,015 | 0,036 | 140 |

| BR 100.30.15 | 1000x150x300 | 0,041 | 0,1 | 245 |

| BR 100.30.18 | 1000x180x300 | 0,05 | 0,12 | 295 |

| Block B-5 (BR 100.45.18) | 1000x180x450 | 0,071 | 0,175 | 560 |

Curb stone is designed to separate the carriageway of streets and roads from lawns, sidewalks, public transport stops, various sites, to separate pedestrian sidewalks from lawns, as well as to strengthen the edges of the road pavement.

Installing curbstones reduces the risk of the roadside and slopes being washed away by rain. An important element when installing curb stones is preparing the base, the best material for which is M200 concrete. As a rule, curb stones are installed simultaneously with the construction of the pavement base. The main requirement when installing curb stones is compliance with straightness in plan and profile. It is necessary to take a very responsible approach to the installation of curbstones, because its destruction will inevitably entail the destruction of the road surface itself, slopes, and sidewalks. That is why the installation of side stone (this is what curb stone is often called) should be carried out by organizations that have the appropriate knowledge and professional skills. First, the subgrade is prepared, leveled and compacted, then a base of sand (sand cushion) is prepared, then metal or wooden formwork is installed on both sides, a concrete base is prepared and side stone . After this, concrete is poured into the formwork. The final steps are caulking and grouting. The installation of the side stone is carried out using a cord stretched between metal pins at a height that corresponds to the mark of the upper edge of the side stones. The upper part of the side stone should rise above the edge of the covering by about 15-20 cm. As a rule, the border is installed manually, but with the use of special devices.

Side stones are made from fine-grained concrete by dry vibration pressing, which gives them increased characteristics of frost resistance, water resistance, moisture resistance, and abrasion. Curb stone is resistant to many external influences, almost any weather conditions, and road chemicals.

Side stone is divided into several main groups: road curb , highway curb , garden curb or curb . The garden border (curb) is marked BR 100.20.8 , as a rule, it is used on pedestrian areas, courtyard areas, and in private suburban construction. Garden border BR 100.20.8 is called a curb due to the fact that when installed it usually rises above the paving level. The road curb is marked BR 100.30.15. In percentage terms, BR 100.30.15 is the most popular type of curb stone. The main curb, in turn, is divided into two subcategories: the main curb BR 100.30.18 and the main curb BR 100.45.18 The first type BR 100.30.18 differs from the road curb in its larger size in width and is often used on various sections of highways and cities, and the main curb BR 100.45.18, also manufactured by vibrocompression, is an analogue of Block B-5 Series 3.503.1-66, because completely copies its external dimensions. Block B-5 is the main type of side stone used in the construction of federal roads. The difference between Block B-5 and the main curb BR 100.45.18 is the presence of mounting loops.

Border stone

The production of road curbs complies with the requirements of GOST 6665-91.

GOST 6665-91

Characteristics: — Weight (m), kg — Length (L), mm — Width (B), mm — Height (H), mm

The marking of a curb stone includes an alphabetic and numerical designation of the type of product, for example:

BR 100-30-15 - designation (marking) of the foundation block, where:

BR - curb stone

100-30-15 - length 100 cm, width 15 cm, height 30 cm.

GOST for curb stones

GOST for sidewalk curbs describes in detail the technical characteristics of the product. It would take a long time to list all the characteristics; if you are interested, you can study GOST itself. Section 6665-91 lists the following options:

- Low temperature resistance;

- Moisture absorption;

- Strength of concrete for expansion and compression.

During the construction process, it is extremely important that the height of the curb stone according to GOST corresponds to its intended purpose. For example, the height of the curb according to GOST for highways is 450 mm. It is extremely important to choose products that comply with GOST, as this is a guarantee of quality and compliance with technical standards. Prices vary from manufacturer to manufacturer, but a high price is not an indicator of high quality.

Border stone is used to improve and separate sidewalks from roads, flower beds from paths, bicycle areas from pedestrian ones. Depending on the purpose, there are various curb stones, and accordingly GOST.